ABSTRACT

Since becoming highly functional, complex and flexible, the machining system of CFRP(Carbon Fiber Reinforced Plastic) has recently become highly functional, complex and flexible, its has its controllers are changing into open and distributed structures. These, and need controlling to be controlled to maintain good quality of for a quality of machined parts. In particularSpecifically, an open controller is required urgently needed to apply the optimal processing program for each material and development of embedded SW, which enables after-production of CFRP, CFRP-metal stack material, waterjet processing, inspection, and modification. As theThe characteristics of CFRP materials may create processing defects such as stratified material stripping and un-cut., a A process monitoring module that can minimize or prevent the defects this technology needs to should be applied to hence reducinge tool wear causedthrough by high hardness carbon fiber. Since CFRP is mostly made from additive forming, there are many drilling processes, that require precision measurement techniques and process signal monitoring technology, exist. Tsince the cutting force load and various signals generated during processing are weaker than those during metal processing. An open controller for process control and monitoring of a CFRP processing system was therefore developed. The system will then It is going to develop open controller SW structural design and open platform, multi-channel signal processing algorithm and sensor system, process specific functions (CFRP process control, boundary detection, etc.) and mount drilling tool parent monitoring algorithm on open platform.

-

KEYWORDS: Open controller, Multi-channel kernel control, CFRP machining system, Multi-sensor monitoring system

-

KEYWORDS: 개방형 제어기, 다계통 커널 제어, 탄소섬유 복합재 가공 시스템, 다중센서 모니터링 시스템

1. 서론

최근 가공시스템은 고기능 복합화 및 유연화 추세이므로 제어기는 개방형, 분산형 구조로 변화하고 있고, CFRP (Carbon Fiber Reinforced Plastic)가공시스템은 품질 관리가 중요하므로 공정 관리, 모니터링 시스템 등과의 연동이 가능한 개방형 제어기를 필요로 하게 되었다.

1,2 특히, CFRP, CFRP-Metal Stack 소재의 절삭 가공, 워터젯 가공, 검사 및 수정 등의 후가공이 가능한 임베디드 SW 개발과 소재별 최적 가공 프로그램을 적용하기 위해서 개방형 제어기가 절실히 요구된다.

CFRP의 재료 특성상 드릴링 가공 시 적층된 소재의 박리, 미절삭 등의 가공결함이 발생하므로, 이를 최소화하거나, 방지할 수 있는 공정 모니터링을 적용할 수 있어야 하고, 고경도의 탄소섬유에 의한 공구 마모를 줄이기 위하여 가공공정 모니터링 모듈을 탑재하여 소재에 특화된 공정제어기술을 이용한 가공공정 최적화 기술 개발이 필요하다.

CFRP는 대부분 적층 성형으로 만들어지므로 드릴링 공정이 많은데, 이때 절삭력 부하와 가공 중 발생하는 다양한 신호들이 메탈 가공시 보다 미약하여 정밀한 측정기술과 이를 융합하는 공정 신호모니터링 기술이 필요하다.

이스라엘의 OMATIV사는 CNC 공작기계의 가공공정에 적응제어(ACM, Adaptive Control Monitor)와 진동제어(VCM, Vibration Control Monitor) 기술을 적용함으로써 가공 공정 시간 단축 및 공작기계, 부품 손상의 방지, 공구의 진동모니터링이 가능한 시스템을 공급 중이며, 국내에서 상용시스템은 전무한 실정이다.

3

본고에는 CFRP 부품 가공시스템용 공정제어와 모니터링 기술을 개발하고, 이를 담아서 가공시스템에 장착할 수 있는 개방형 제어기 개발에 관련 기술을 서술한다. 기존 CFRP 소재의 가공장비의 제어기는 다음과 같은 문제점이 있다.

1. 기존 제어기의 폐쇄적 구조로 인해 CFRP 특성을 고려한 가공 특화 기술의 적용이 어렵거나, 제한적이다. 필요에 따라서 용이하게 전용기능을 탑재할 수 있는 개방형 플랫폼 구조의 제어기가 필요하다.

2. CFRP 가공 품질관리를 위한 공정 모니터링 시스템이 거의 없으며, 전통적인 금속가공의 것을 적용하면 CFRP 공정 자체의 특정을 반영하지 못하므로, CFRP 가공공정 특성에 맞은 다중센서 시스템 모니터링 시스템이 요구된다.

4

3. 모니터링 시스템에 특정 고가의 센서시스템을 제한적으로 사용할 수 있으나, 실제 양산에 적용하기에는 한계가 있으므로, 공정 특화 신호처리 알고리즘을 개발하여 경제적인 센서 시스템이 요구된다.

이에, CFRP 가공 시스템용 공정제어 및 모니터링용 개방형 제어기를 개발하고자 하였다. 개방형 제어기 SW 구조설계 및 개방형 플랫폼 개발, 다중 다채널 신호 처리 알고리즘과 센서시스템 개발, 공정 특화기능(CFRP 공정제어, 경계면 검출 등)을 개발하고, 드릴링 공구 모 모니터링 알고리즘을 개방형 플랫폼에 탑재하고자 한다.

2. 개방형 제어기 기술

2.1 표준 산업용 디지털 서보통신 기술

가공 장비의 제어기가 공정 모니터링을 하기 위해서는 외부에 부가 장착한 센서나 측정시스템 뿐만 아니라, 장비가 직접 구동하는 이송계나 IO 접점, 그리고 센서 값의 디지털 데이터를 직접 취득할 수 있어야 한다. 이를 위하여 공정 모니터링용 개방형 제어기는 기본적으로 디지털 서보통신 대응형 제어기로 구성되어야 하고, 기존 아날로그 인터페이스 방식이 아닌 디지털 인터페이스 방식을 채택하고, 실시간 서보 제어를 위하여 오픈 프로토콜인 EtherCAT 통신을 채용한 네트워크 기반의 개방형 제어기를 구현하였다.

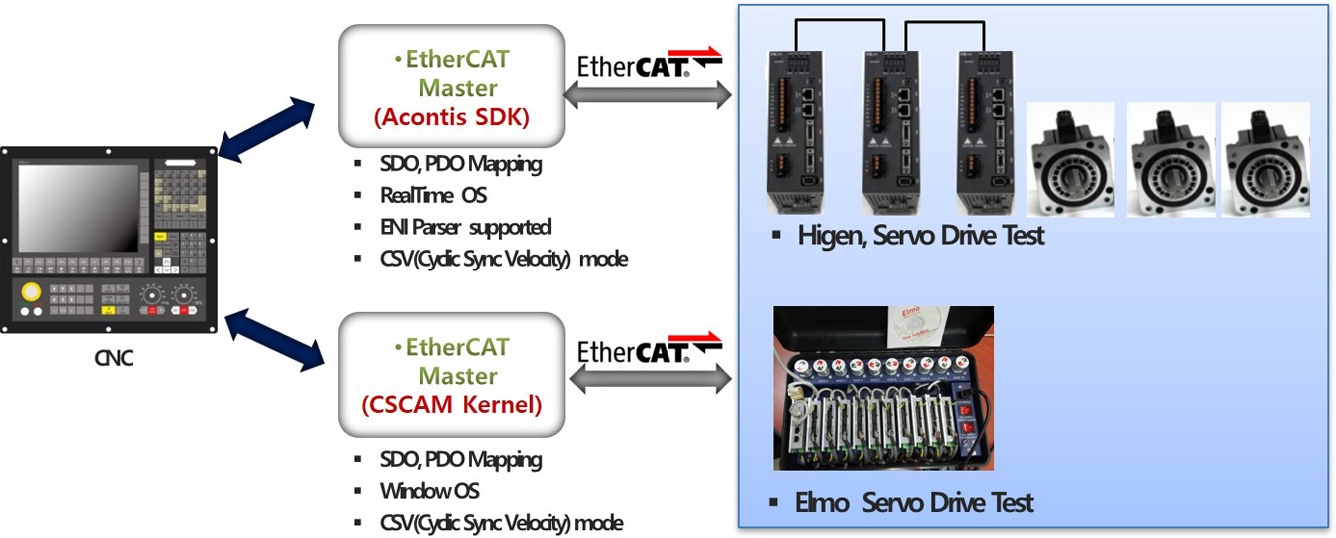

2.1.1 EtherCAT 마스터 제어기

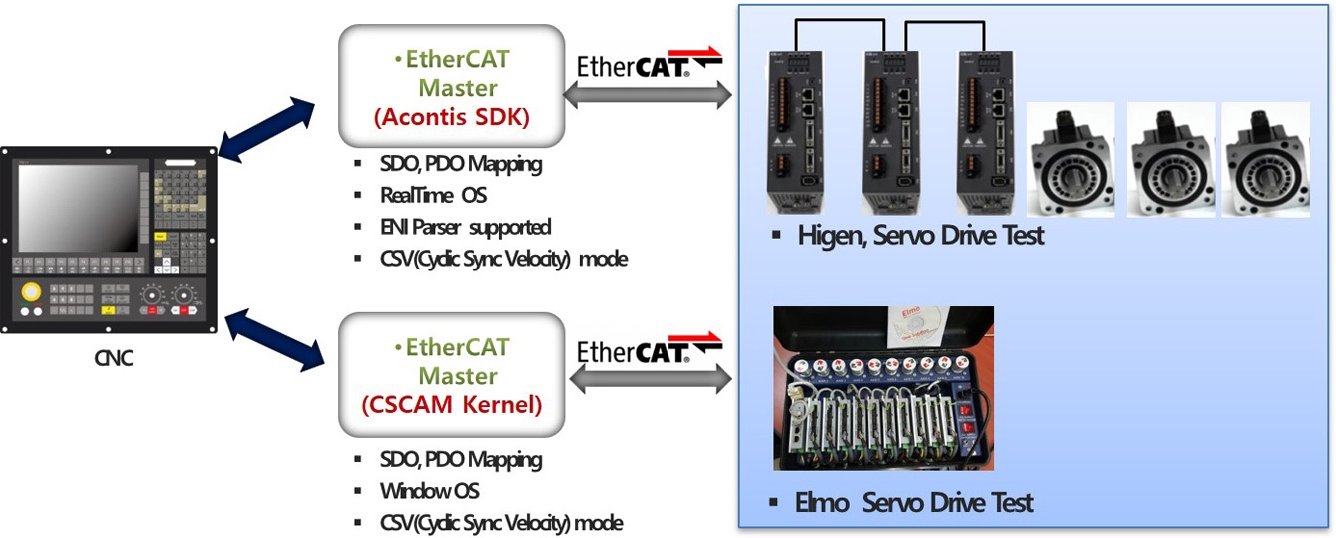

서보 드라이브, 스핀들 인버터, 입출력(I/O) 터미널이 모두 디지털 인터페이스로 연결된다. 표준 EtherCAT 기반의 마스터 스택(Acontis SDK)을 활용하여 실시간 OS (RTX) 기반으로 EtherCAT 마스터를 구현하였으며, CSV (Cyclic Sync Velocity), CSP (Cyclic Sync Position) 모드로 동작을 구현하였다.

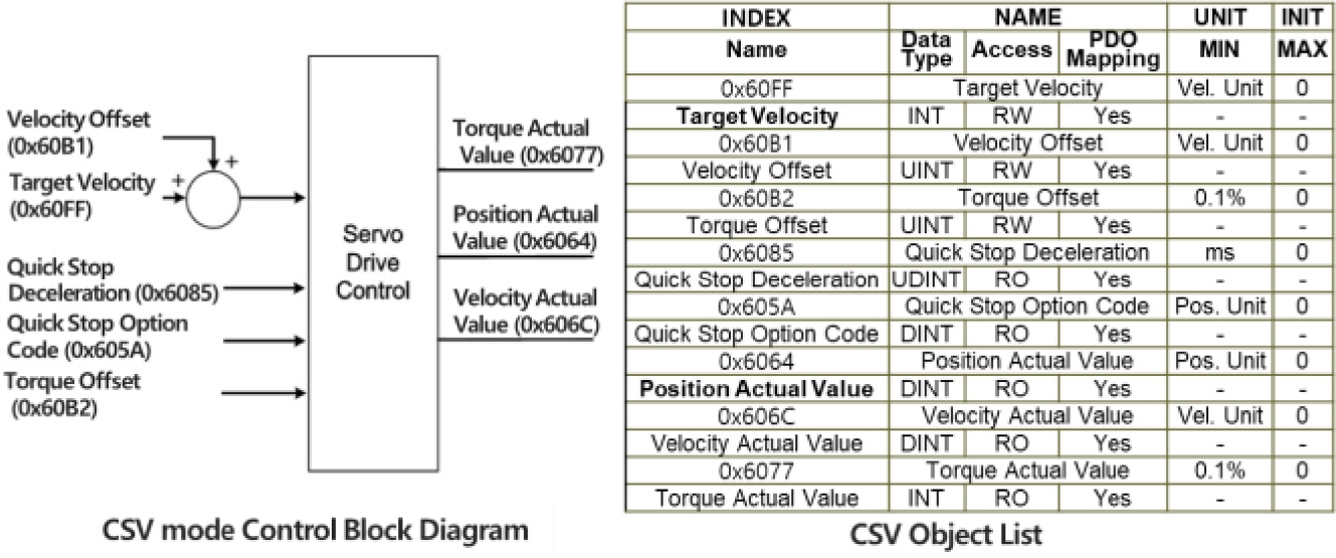

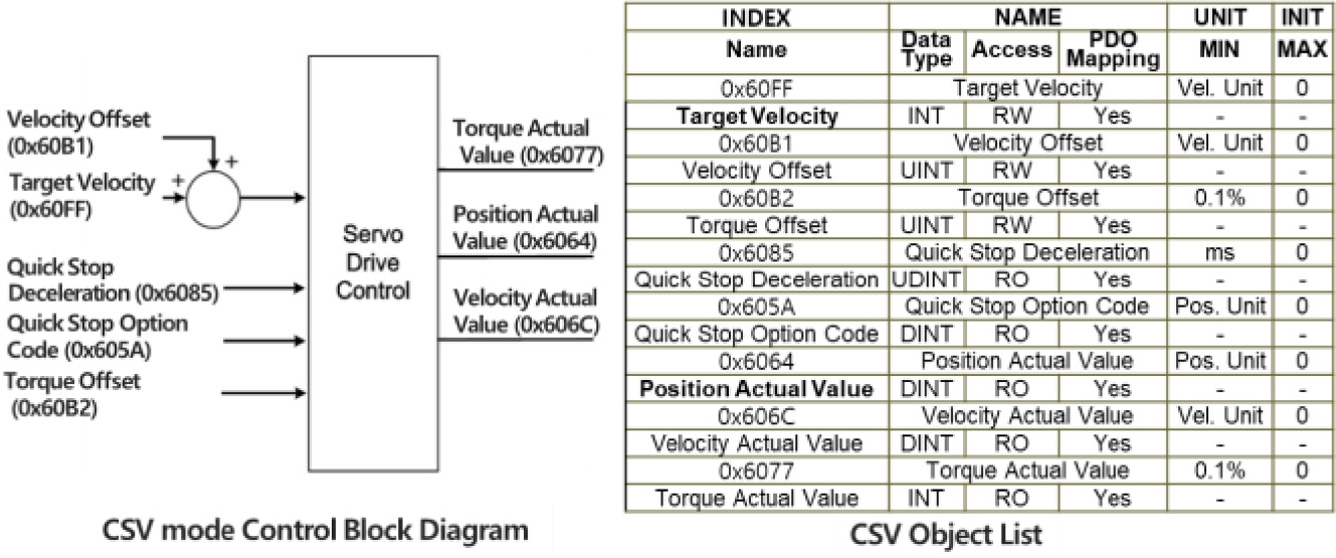

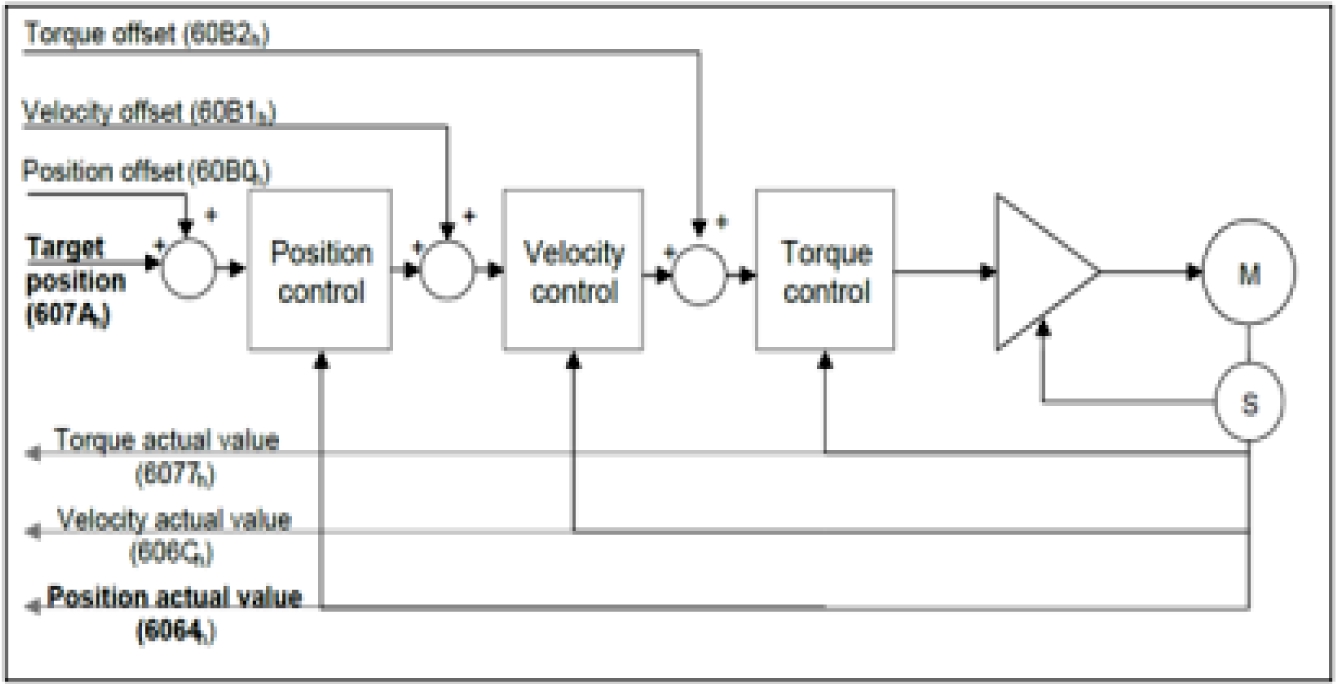

Fig. 1은 CSV (Cyclic Sync. Velocity) 모드의 제어 블럭과 Object 리스트를 나타내었다. CSP는 위치가 중요한 응용에 쓰이는 제어 모드이고, CSV는 속도가 중요한 응용에 사용된다. 가공기에는 CSV 모드 제어를 사용한다.

Fig. 1Object lists of CSV

실시간 통신 중에 있을 수 있는 통신 프레임 데이터의 손실의 발생유무를 체크하는 통신 신뢰성 점검을 수행하였다. Acontis 마스터 스택을 활용한 EtherCAT을 구현하고, 런타임 비용이 없는 자체 EtherCAT 마스터 커널을 개발하였고, Windows Embedded XP OS 상에서

Fig. 2에서처럼 연결하여 구동 시험하였다.

Fig. 2Operating test of EtherCAT master

EtherCAT 마스터 제어기는 슬레이브 기기 제조사가 제공하는 XML 파일 형태로 된 ESI (EtherCAT Slave Information) 파일로부터 현재 마스터에 장착된 슬레이브 노드를 재구성하는 ENI (EtherCAT Network Information) 파일을 만들고, 한번 설정된 구성은 새로이 정의되기 전까지 유지된다.

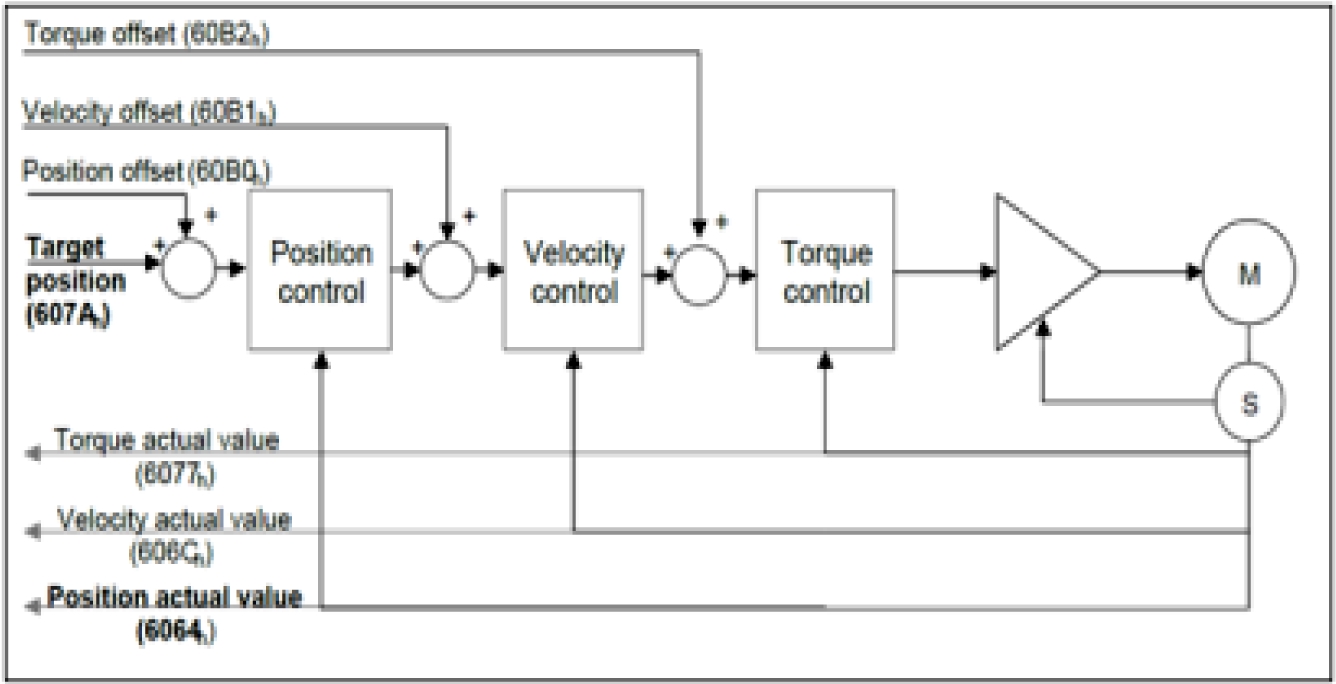

Fig. 3은 CSV 모드제어 블럭을 표준 프로코콜의 내용으로 도식화한 것이다.

Fig. 3Control block for CSV mode

2.1.2 EtherCAT 통신 이중화 및 결함 극복기술

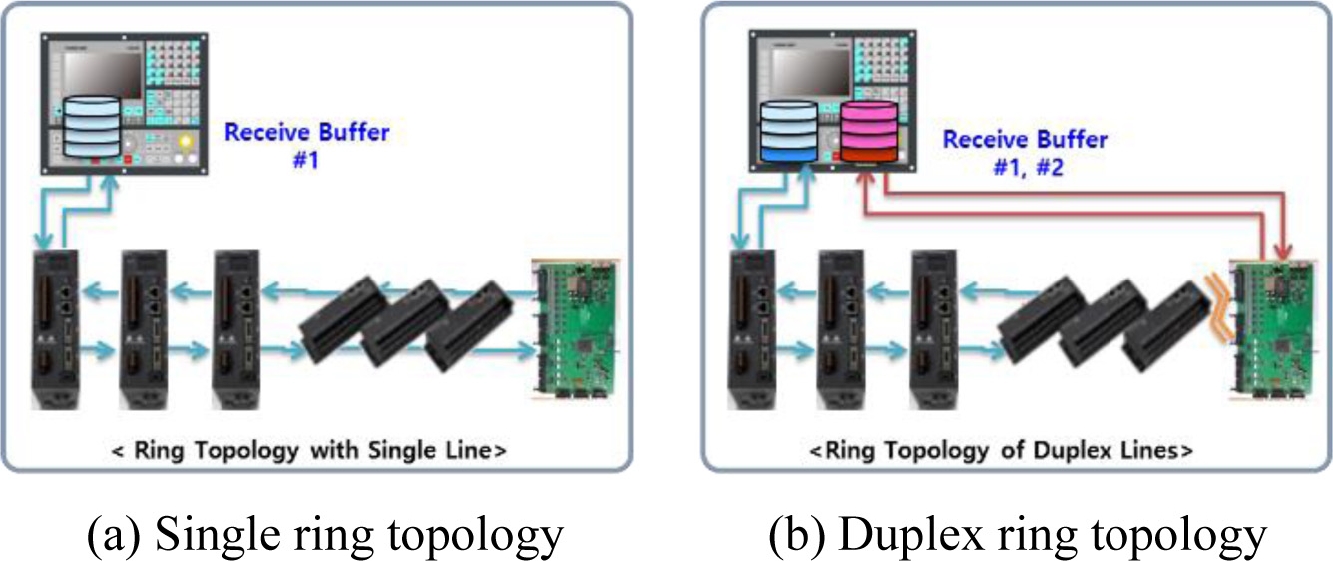

산업용 서보통신은 통신속도가 급속히 향상되어 기존 아날로그 배선을 대체할 정도의 경제성을 확보하였고, 배선의 편리성과 비용절감의 잇점까지 누릴 수 있어 1 ms 이내의 정주기의 실시간 처리해야하는 응용에까지 채용되었다. 이에 통신 결함극복과 자동장애 복구기능 등 통신 신뢰성을 확보할 수 있는 성능의 확보가 무엇보다 중요해졌다. CNC 제어기에서는 EtherCAT 슬레이브 노드인 다수의 서보 모터와 IO 접점을 실시간으로 처리해야 하며, 예기치 못한 통신 단절에 대한 대책이 있어야 한다. 즉, EtherCAT 통신 이중화를 활용한 통신 결함 극복(Fault Tolerant)이 기본적으로 요구된다.

EtherCAT 통신 이중화는 EtherCAT 표준이 지원하는 항목이기는 하지만, 개개의 개발 사이트에서 비용 상승과 기술적인 어려움으로 채용은 일반적으로 적용되지 않고 있었다.

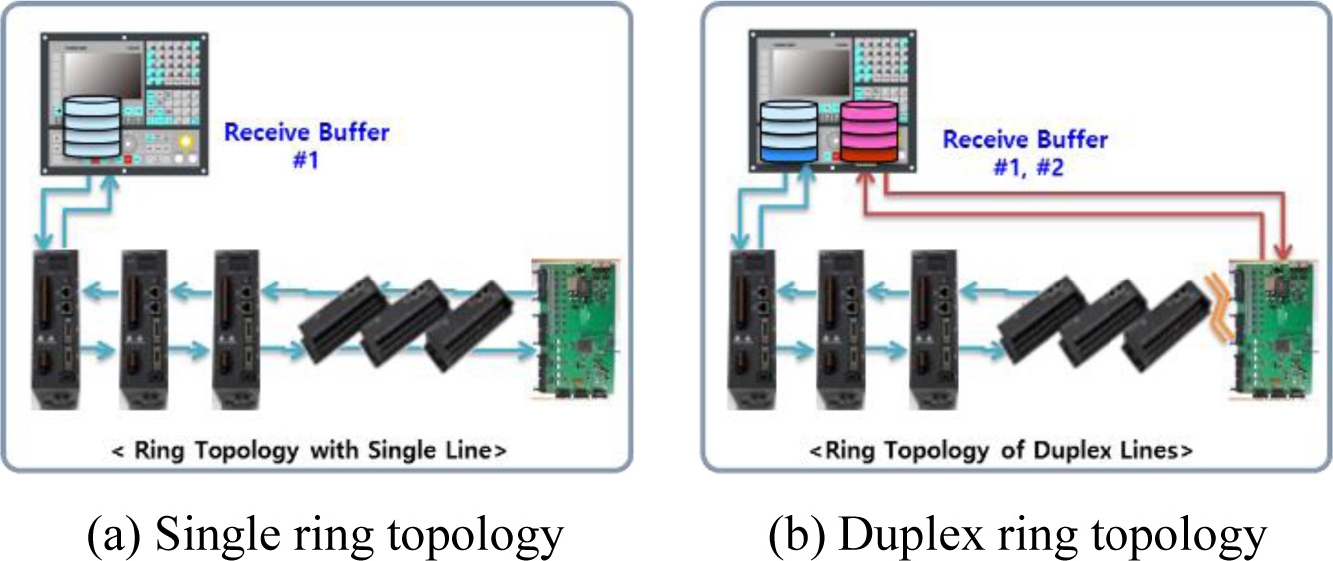

Figs. 4(a)처럼 단일 라인의 EtherCAT 마스터의 경우, 슬레이브 노드 중 하나가 단절되었을 때 통신 알람을 띄우고 정지하지만,

4(b)처럼 이중라인을 채용한 EtherCAT 마스터는 이중으로 통신 데이터를 수신 버퍼에 쌓아 두기 때문에, 둘을 조합하여 모드 슬레이브 노드의 통신 패킷을 만들어낼 수 있다. 이를 위하여 2개의 EtherCAT 지원랜 포트가 장착되어 있어야 한다.

Fig. 4Ring topology of EtherCAT for fault tolerant

EtherCAT 마스터 CPU 보드는 EtherCAT 용 랜 포트 2개에 모두 케이블을 이중으로 연결하고, 이를 통해 ISR (Interrupt Service Routine) 쓰레드를 구동하여 2개의 데이터 리시버 버퍼를 채우고, 전체 노드로부터 받은 데이터를 조합하여 통신 단절을 극복한다. 이때, 통신 전환지연(Switching Delay)은 15 us 이하이다.

2.1.3 내부 디지털 데이터 신호 활용

일반적으로 스핀들 인버터와 MPG 장치는 EtherCAT 표준 슬레이브 기기를 구하기 힘들다. 그리하여 씨에스캠이 보유한 DIO72/46 모듈을 EtherCAT 표준화하여 장착하였다.

Table 1은 표준 EtherCAT Slave EDIO72/46의 PDO map 할당을 나타내었다. 스핀들 인버터는 Spindle 출력(Voltage 0 - 10 V), Spindle 엔코더 피드백 값, Spindle 알람 입력을 할당하였고, MPG는 3개까지 연결 가능하고 각각 입력 Pulse를 카운트하고, MPG 축선택과 배율 선택 입력 항목이 할당되었다.

Table 1PDO map assign for EtherCAT slave EDIO72/46

Table 1

|

No. |

Object address |

Object name |

Device |

|

1 |

0x1F02 |

Spindle Voltage |

Spindle |

|

0x1F06 |

Spindle Output |

|

3 |

0x1F08 |

Output16 1st |

|

4 |

0x1F0A |

Output16 2nd |

|

5 |

0x1F0C |

Output16 3rd |

|

6 |

0x1FA2 |

Spindle Encoder Pulse |

|

7 |

0x1FA6 |

Spindle Input |

|

7 |

0x1FA6 |

Spindle Input |

|

8 |

0x1FA8 |

MPG1 Pulse |

MPG |

|

9 |

0x1FAC |

MPG2 Pulse |

|

10 |

0x1FB0 |

MPG3 Pulse |

|

11 |

0x1FB4 |

Input16 1st |

|

12 |

0x1FB6 |

Input16 2nd |

|

13 |

0x1FB8 |

Input16 3rd |

|

14 |

0x1FBA |

Input16 4th |

|

15 |

0x1FBC |

Input16 5th |

|

16 |

0x1FBE |

Encoder Disconnect |

2.2 개방형 HMI 기술

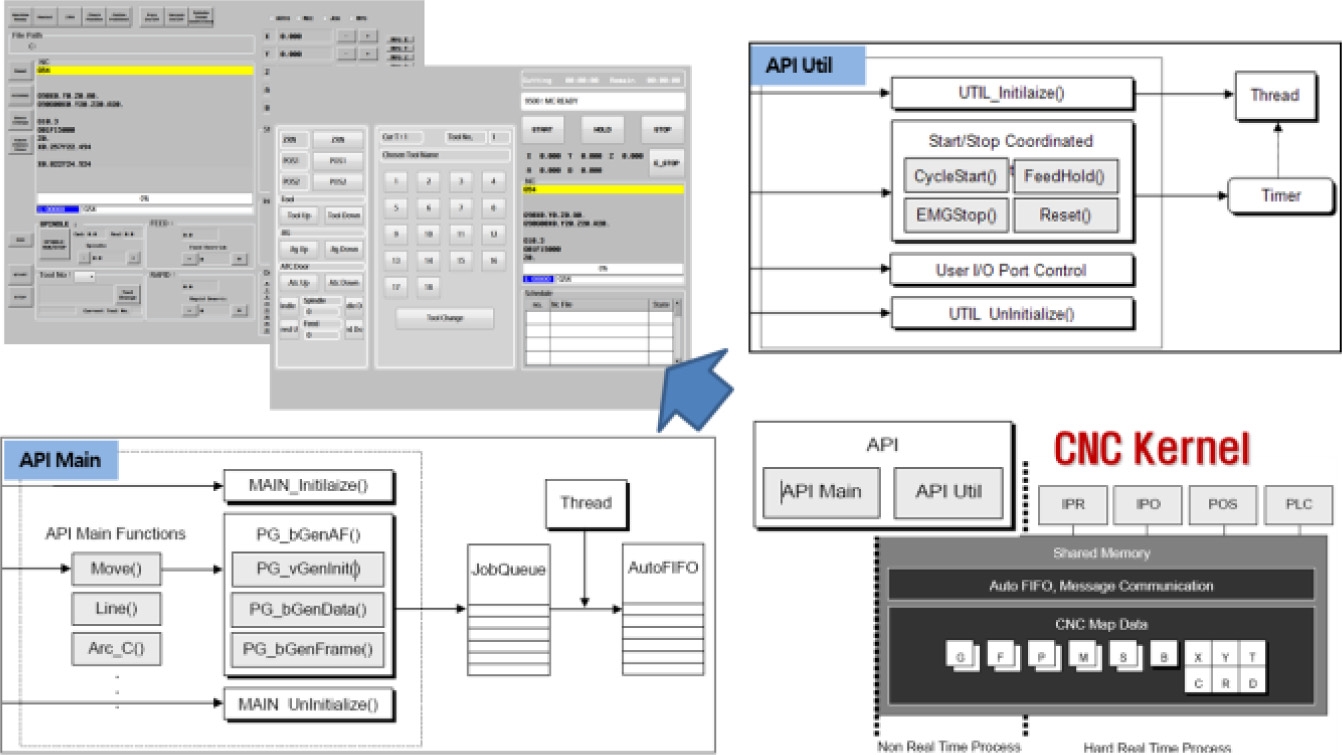

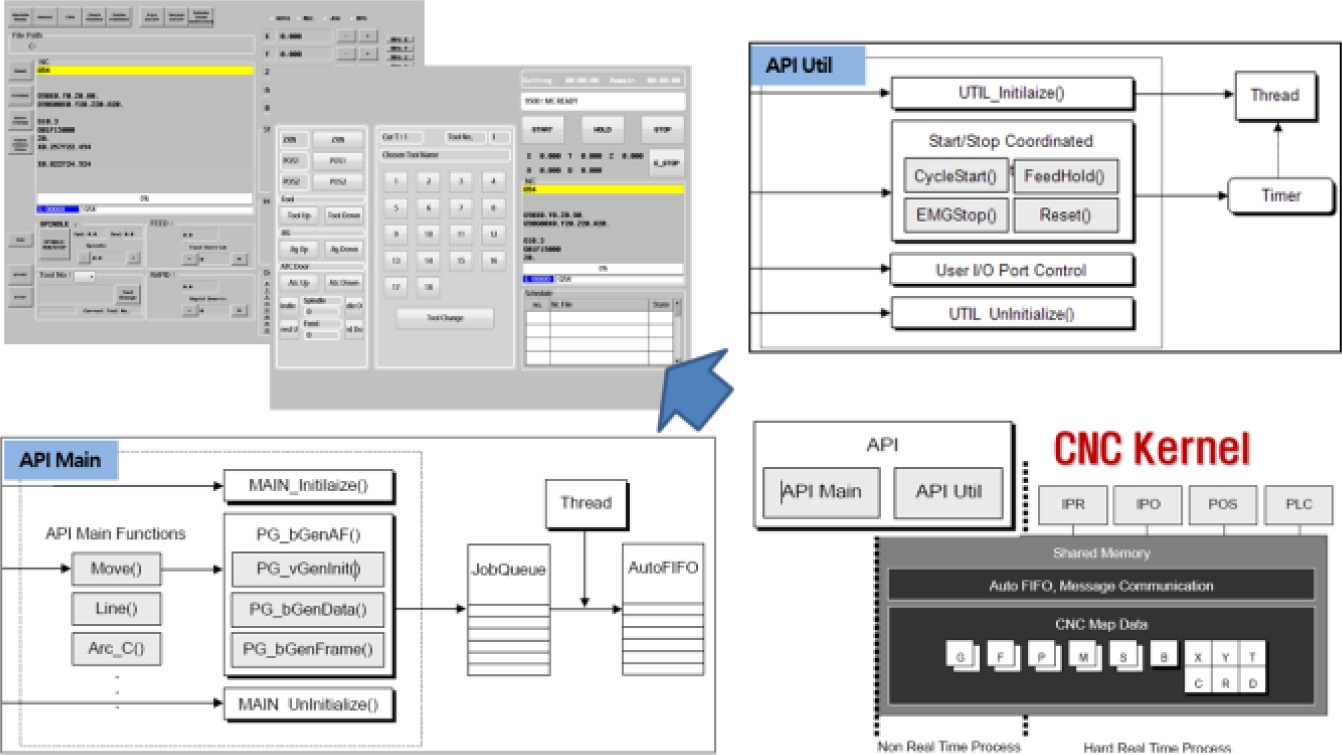

2.2.1 개방형 기능 모듈 개발용 API 함수

CFRP 가공중 실시간 모니터링 기능을 탑재할 수 있는 라이브러리와 API(응용 프로그램 인터페이스) 함수를 제공한다. API 라이브러리는 빌트인(Built-In) API와 원격(Remote) API, 2가지 형태로 개발하였고, 지원하는 기능은 동일하지만, 센서 모니터링 같이 CNC 시스템 내에서 실시간으로 동작하는 기능을 추가할 때는 빌트인 API를 사용하고, 경로 최적화나, 간이 CAM SW처럼 리소스를 많이 요구하는 기능의 경우 별도의 PC에서 통신으로 데이터를 주고 받을 수 있도록 하는 원격 API가 기존 제어기 구동에 영향을 주지 않고, 구현할 수 있어서 구별하여 활용할 수 있다.

제어기 내부 메모리를 직접 접속할 수 있는 방식이 빌트인 API이고, 별도의 PC에서 통신으로 데이터를 주고받을 수 있도록 하는 것이 원격 API이며, K-Com과 U-Com 통신 모듈이 포함되어 있다.

API 함수는 API 메인과 API 유틸로 나뉘며, API 메인은 CNC 커널의 파라미터 설정, 모션 지령, 상태 모니터링, 작업물 설정 등 커널 기능을 담당하고, API 유틸은 실제로 액션을 취하는 신호들, NC 데이터 실행(Start)과 정지(Feed Hold), 그리고 초기화(Reset)를 수행하는 기능을 담당한다.

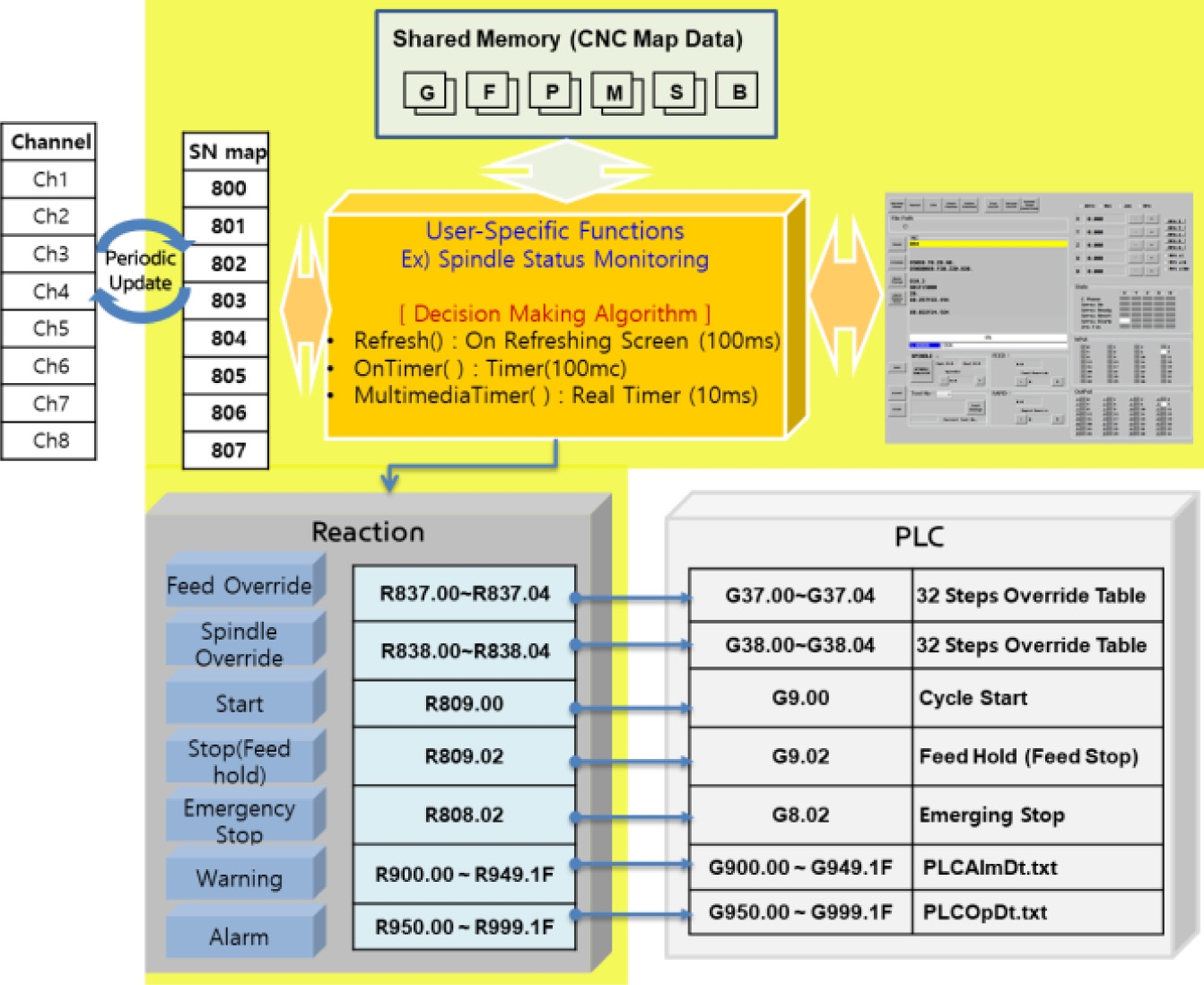

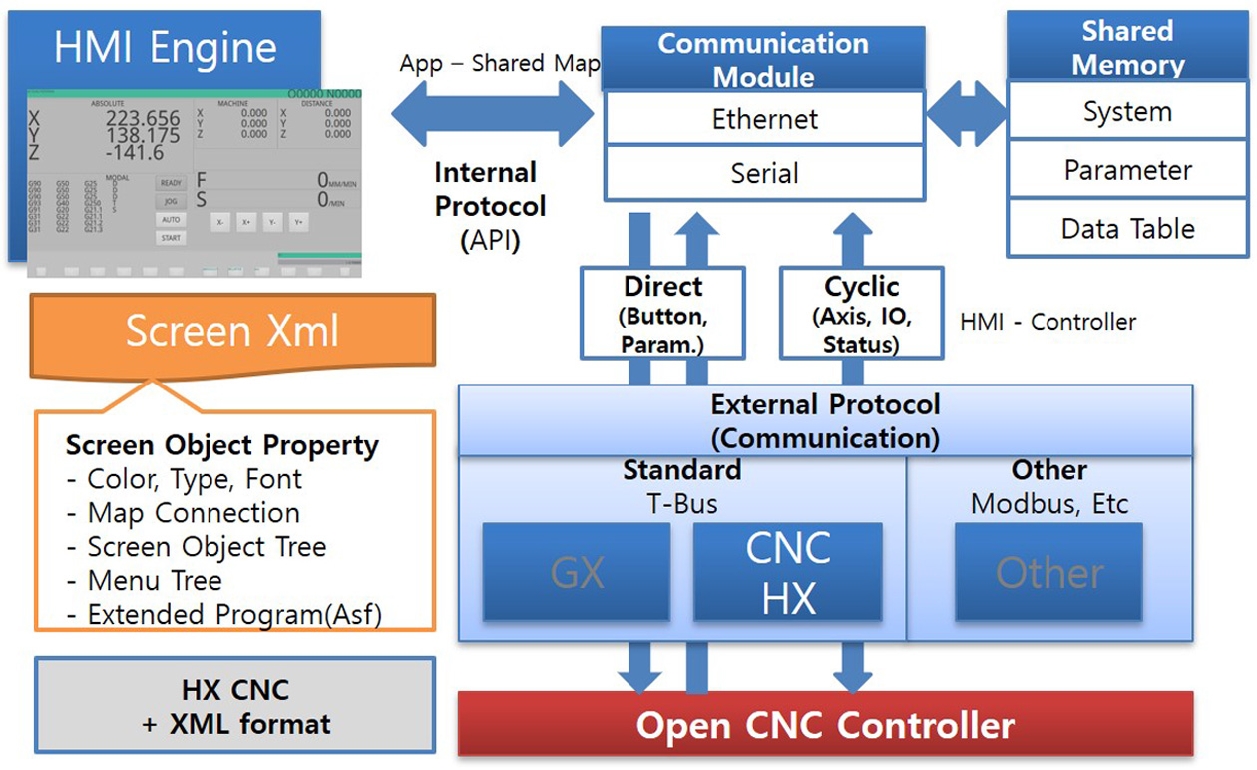

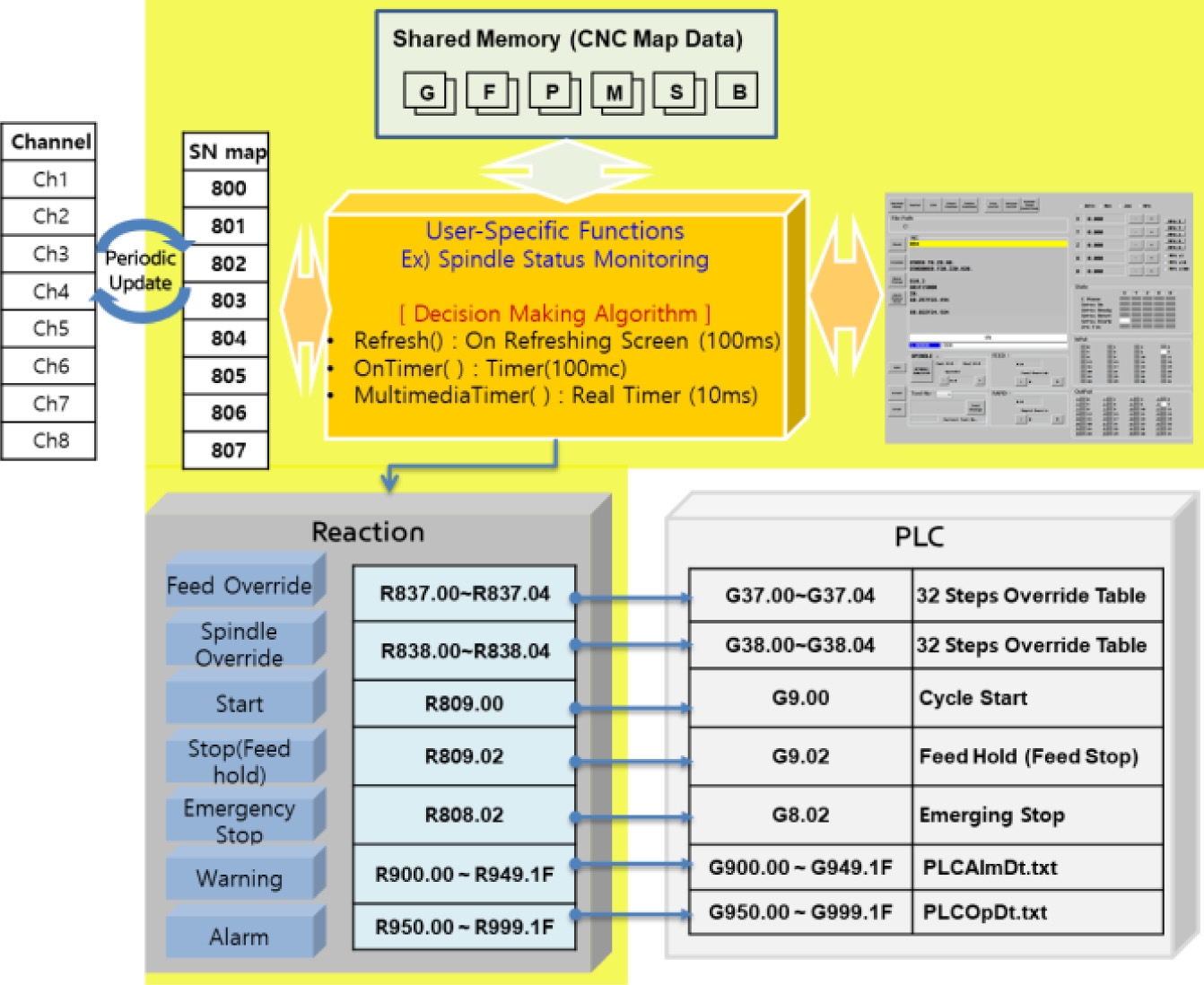

Fig. 5는 제어기 API 함수가 CNC 커널의 공유메모리에 접속하여 제작하려는 사용자 기능을 API 메인과 유틸을 활용하여 제작하는 구조도를 보여주며, 커널의 공유 메모리에 접근하여 원하는 기능과 화면을 만들어 넣을 수 있다.

Fig. 5Block diagram for API functions

기본적으로,

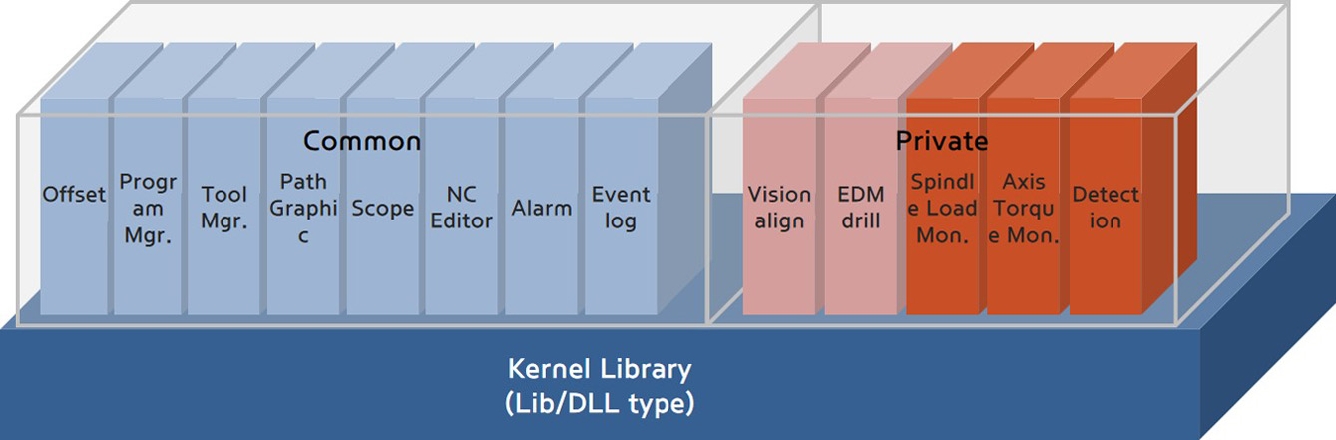

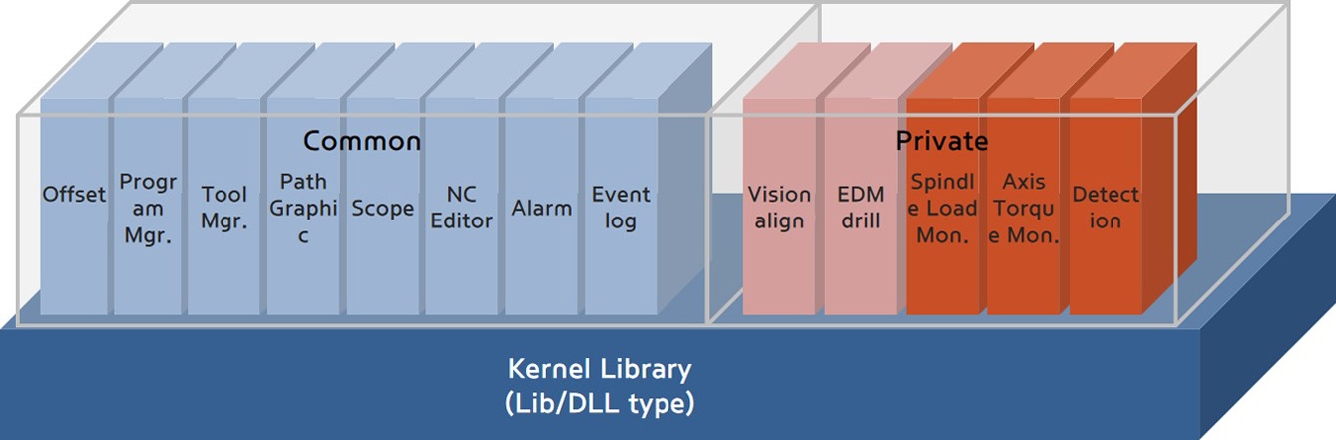

Fig. 6처럼 CNC의 기본 기능들도 동일한 구조로 탑재되어 있으며, 기종별로 특별한 기능이 요구될 경우, 기본 DLL을 공유하고, 추가의 DLL을 API 규약에 의하여 개발할 수 있도록 개방형 구조를 확장하였다. 윈도우 기반으로 인터페이스 방식을 표준화하였고, 링크하여 컴파일 하는 과정없이 플러그 앤 플레이 방식으로 SW 모듈을 연결할 수 있으며, SW의 기능을 제품의 옵션으로 처리할 수 있다.

Fig. 6Built-in API concept supporting plug-and-paly

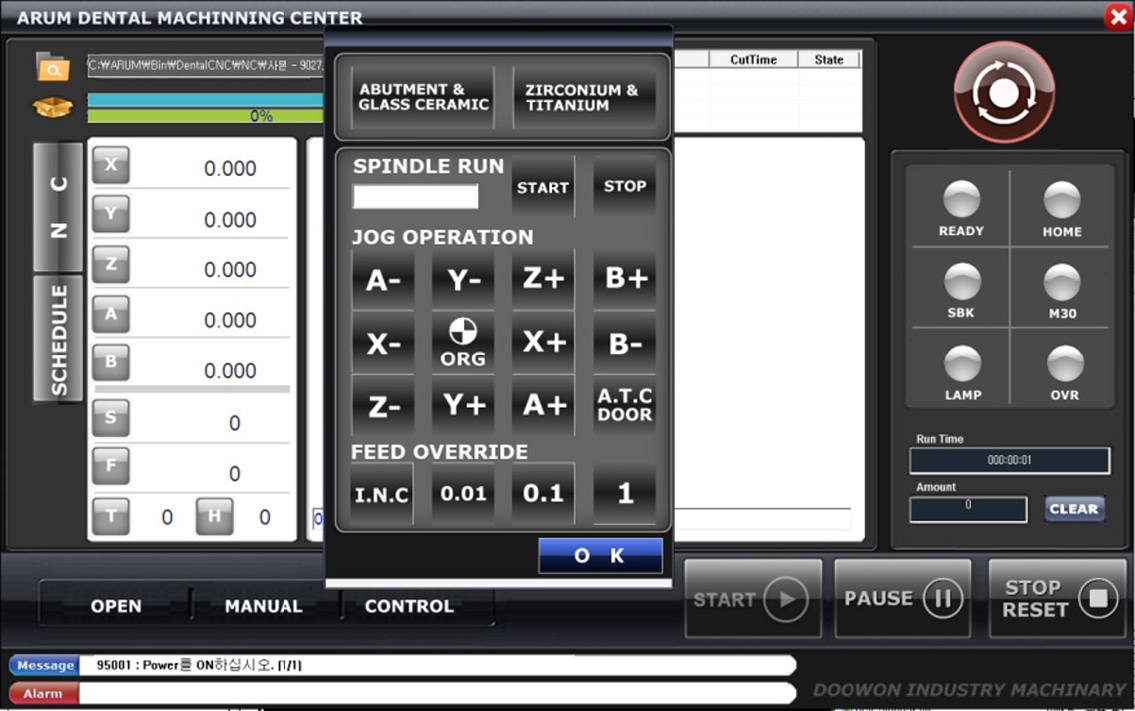

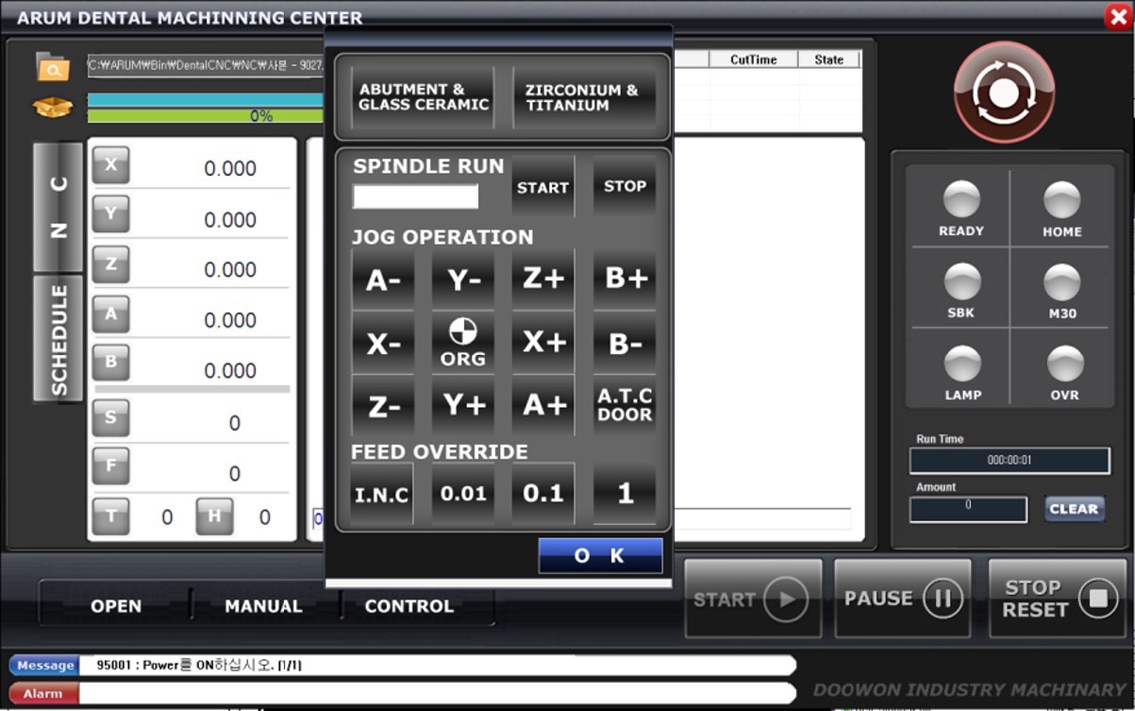

Fig. 7은 빌트인 타입 API를 활용하여 치아가공기의 화면을 구성한 예이다. 기존 CNC 화면의 기능을 첨삭하여 새로운 화면과 기능을 조합하였다.

Fig. 7Control screen made with Built-in API (Dental machining system)

원격 타입 API를 이용하여 별도의 PC에서 CNC를 구동할 수 있는 화면을 만들고, 통신으로 사용자 필요기능을 추가할 수 있다. U-Com 모듈을 활용하여 이더넷으로 접속하여 CNC 본체의 K-Com의 서비스를 받을 수 있다. 별도의 PC에서 원격 타입 API를 활용하여 CNC 상태정보 같은 주기성 데이터를 100 ms 주기로 표시하였고, 파라미터 설정이나 시작 버튼 같은 비주기성 데이터는 발생 즉시 수행하도록 하였고, 통신 프로토콜은 T-Bus라는 자체 프로토콜을 사용하였다.

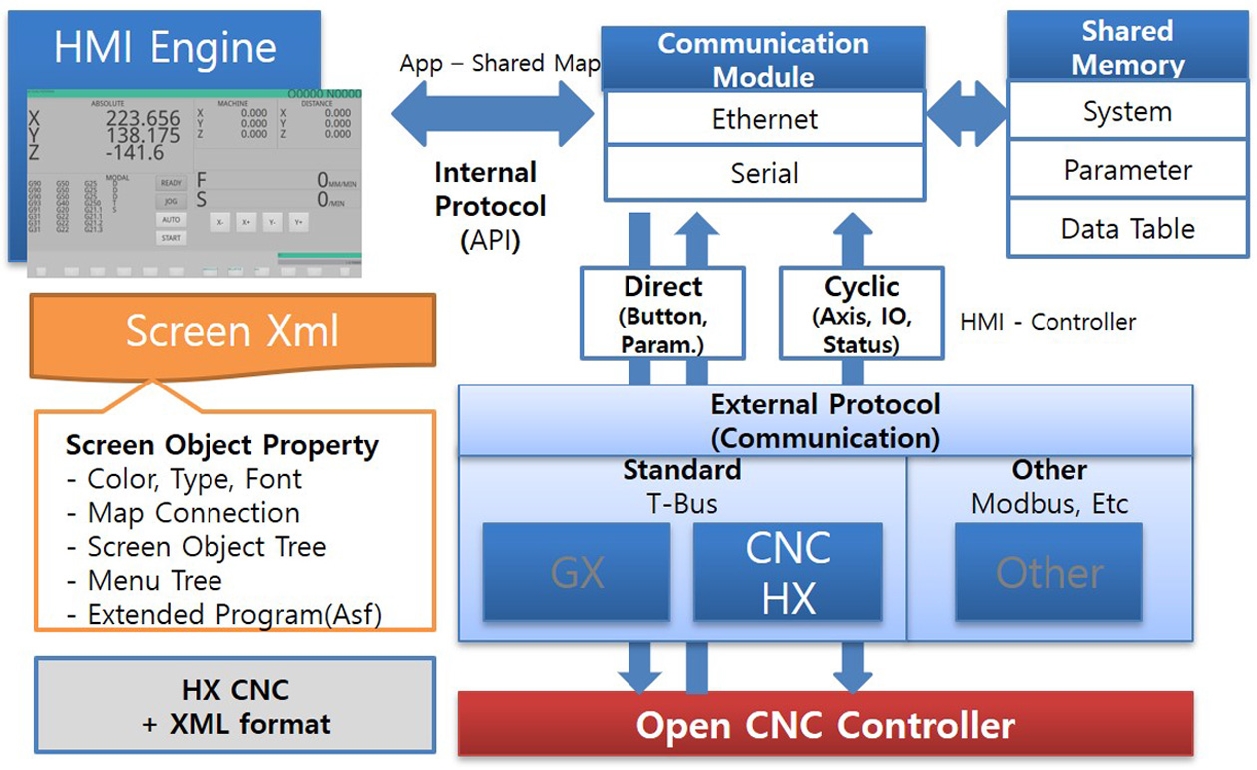

2.2.2 개방형 HMI 저작 도구 기술

개방형 기능에 대응할 수 있는 제어기 플랫폼 CNC 화면 개발을 위해, 손쉽게 화면을 제작할 수 있는 HMI 저작도구가 필요하다.

Fig. 8은 개방형 제어기의 HMI 데이터 흐름도를 나타내었으며, 제어기 화면을 Display 해주는 엔진으로의 데이터 전송은 내부에 정의된 프로토콜을 활용하여 API 함수로 표준화하였고, 화면 편집은 XML 포맷의 화면정의 파일을 사용한다.

Fig. 8HMI editor and engine for open controller

2.3 복합 가공 시스템을 위한 다계통 제어기 기술

2.3.1 다계통 제어기 커널 구현

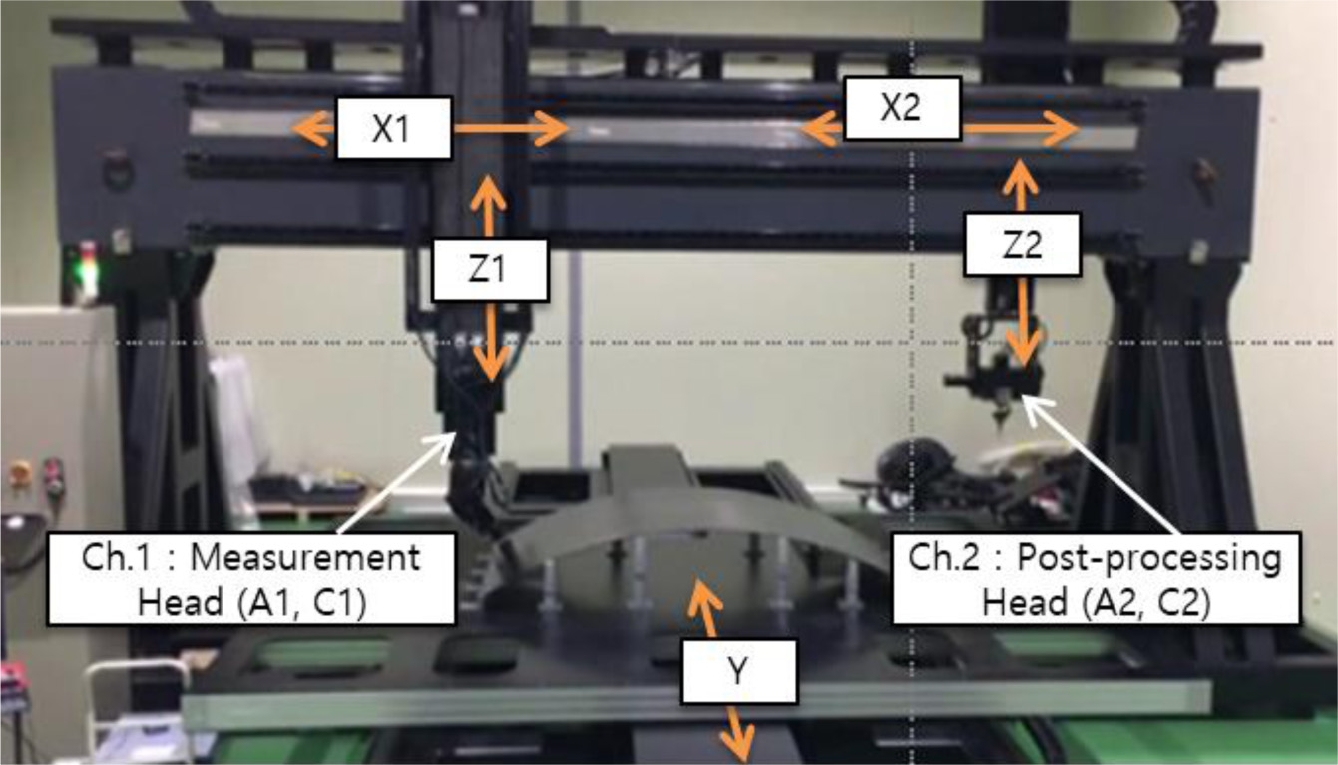

CFRP 가공장비는 자동차 차체나 항공기 동체 같은 대형 일체형 구조물로 사용되는 사례가 점점 증가하고 있어 가공장비가 대형화되고 있고, 복합 가공공정을 위해 소재를 이동 설치하기보다 한번 고정된 상태에서 모든 가공을 완료하는 것이 최종 가공품질과 생산성 면에서 유리하므로 일괄 가공할 수 있도록 장비가 복합화되는 추세이다. 본고에서는 워터젯 절단과 5축 드릴링을 동시에 할 수 있는 복합가공장비와 가공부 측정과 초음파 드릴링 후처리 공정을 동시에 할 수 있는 측정 및 후처리 복합장비를 대상으로 하고 있어서, 탑재되어 운용하는 개방형 제어기도 이를 처리할 수 있어야한다. 따라서, 2개 이상의 가공헤드를 각각 또는 독립적으로 제어할 수 있는 계통제어 기능과 대형장비가 주로 채택하고 있는 갠트리 타입의 구조물에 대한 정밀 동기제어 기능을 개발하였다.

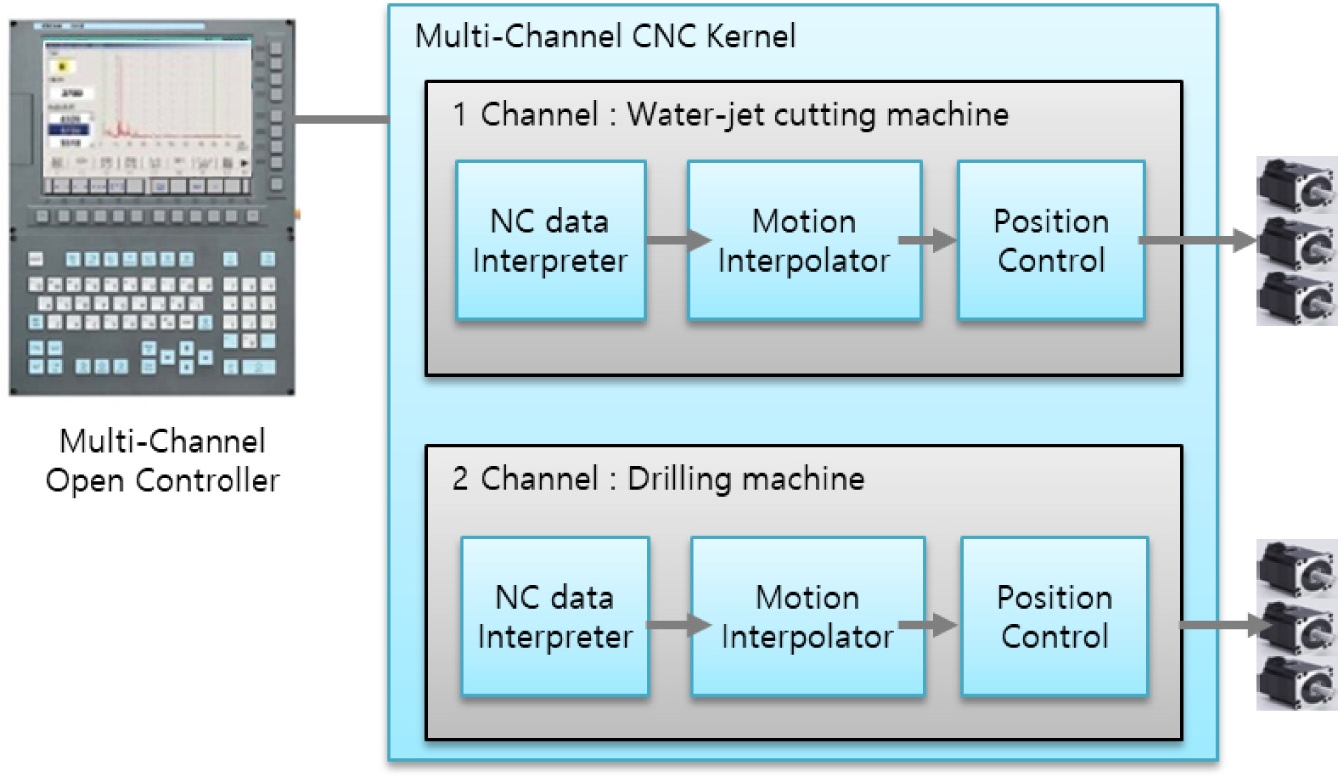

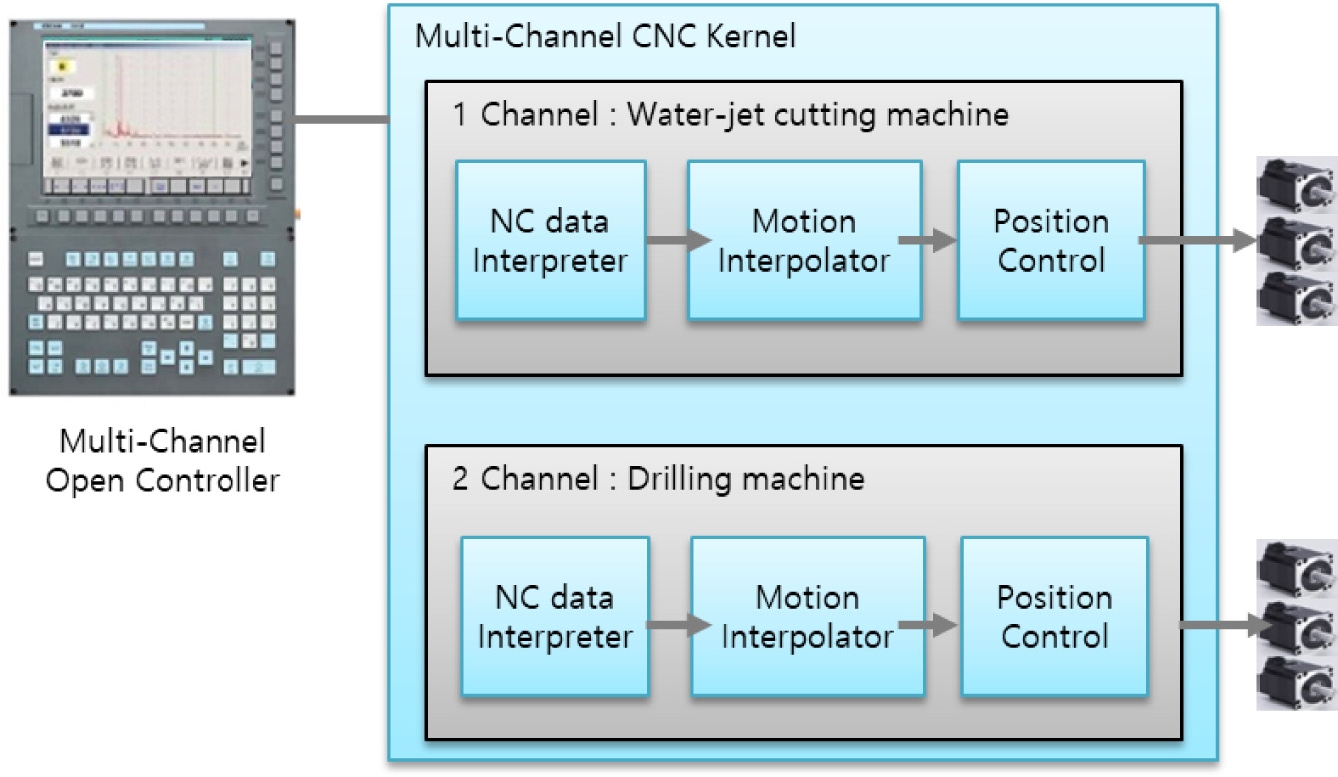

Fig. 9는 CFRP 복합가공장비와 측정/후처리 가공장비를 대상으로 2채널 다계통 개방형 제어기의 구성을 나타낸 것이다. 다계통 제어기는 하나의 HMI 화면에 여러 개의 NC 데이터를 동시에 처리할 수 있는 구조를 가져야 하며, 복합기에 적용할 수 있는 CNC이다.

Fig. 9Configuration of multi-channel controller

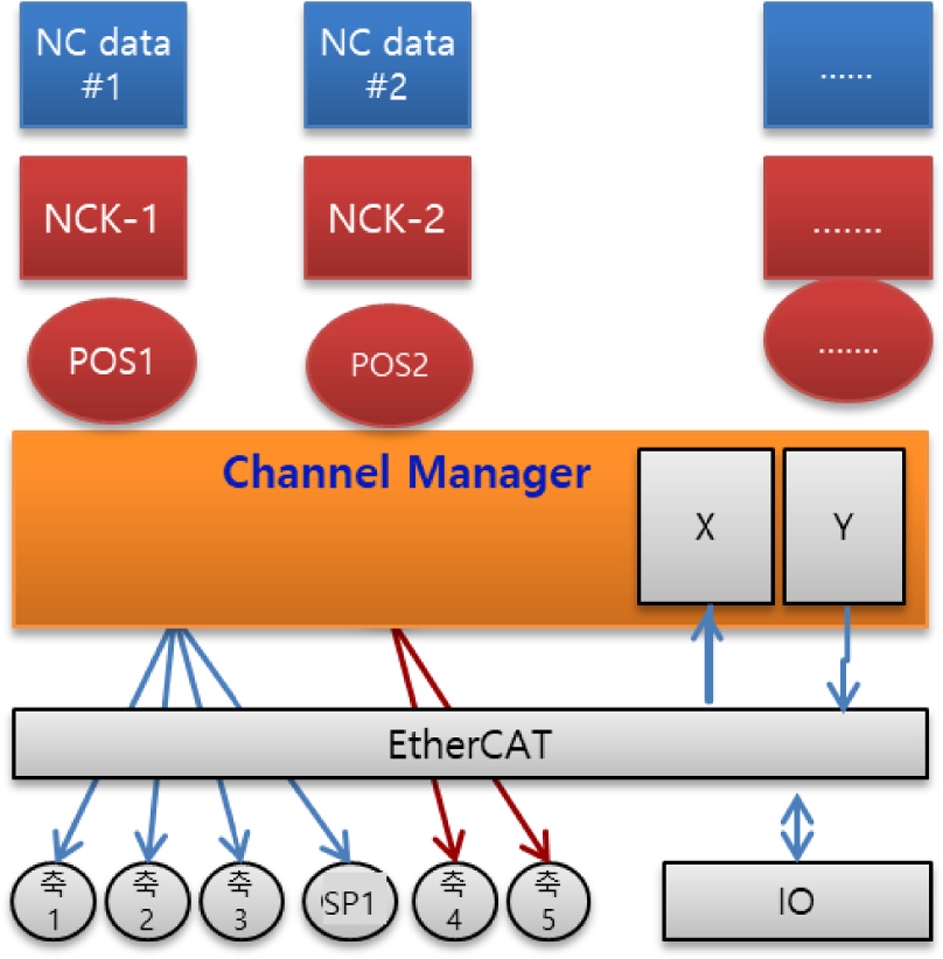

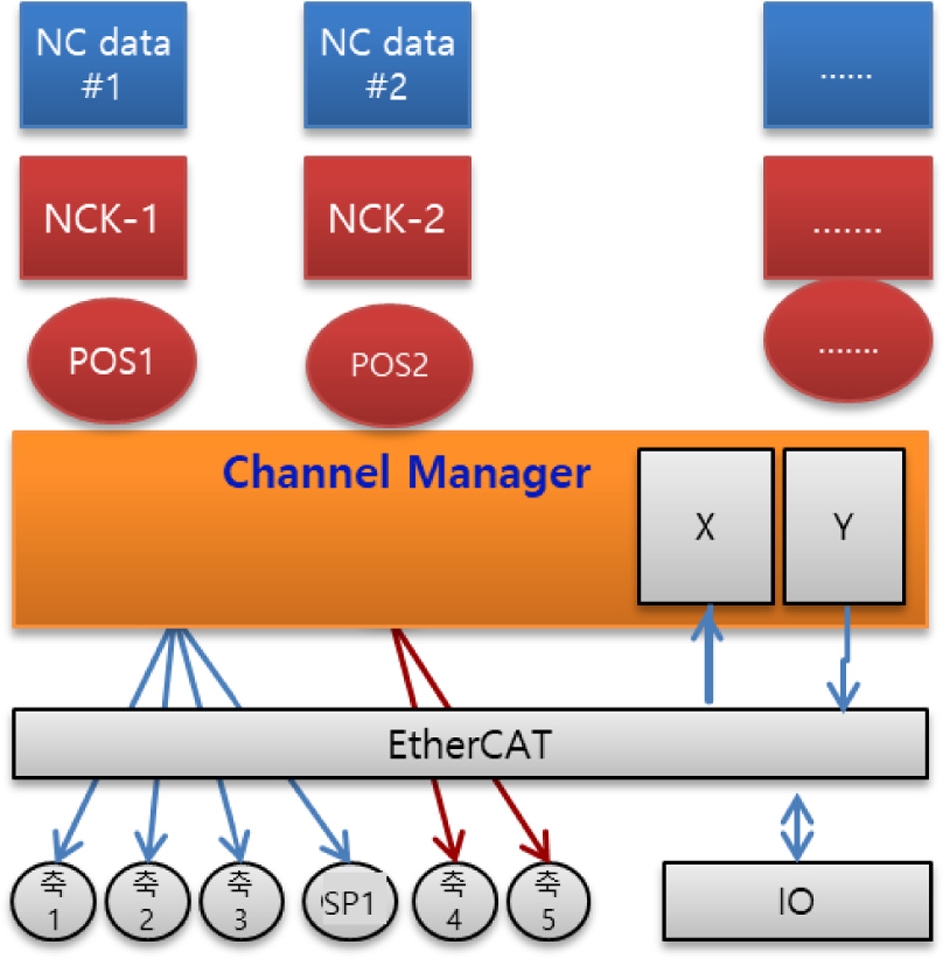

Fig. 10은 다계통 제어기의 커널 구조도이며, 각 계통 은 독립 NC 데이터와 축 구성을 가지고 독립적으로 보간 모션을 수행한다. 실제 물리적인 구동부, 이송축, 주축, IO 모듈은 개발된 계통 매니저를 통하여 할당되고 구동된다. 또한, 각자의 계통 사이에 동시에 선후 순서가 있어서, 동시에 시작해야할 필요가 있을 때, 계통간 동기 M 코드를 사용할 수 있도록 하였다.

Fig. 10Kernel of multi-channel controller

복합장비의 가공공정 순서를 정하거나, 동시에 움직일 필요가 있을 때 사용하며, 계통 간에 가공 시작 시점을 맞추기 위해서 필요하며, M Code로 제어되며 자동운전 중에 어떤 계통에서 대기용 M 코드가 지령되면 다른 계통에서 동일한 종류의 M 코드가 지령되는 것을 기다렸다가 다음 블럭을 실행하게 된다.

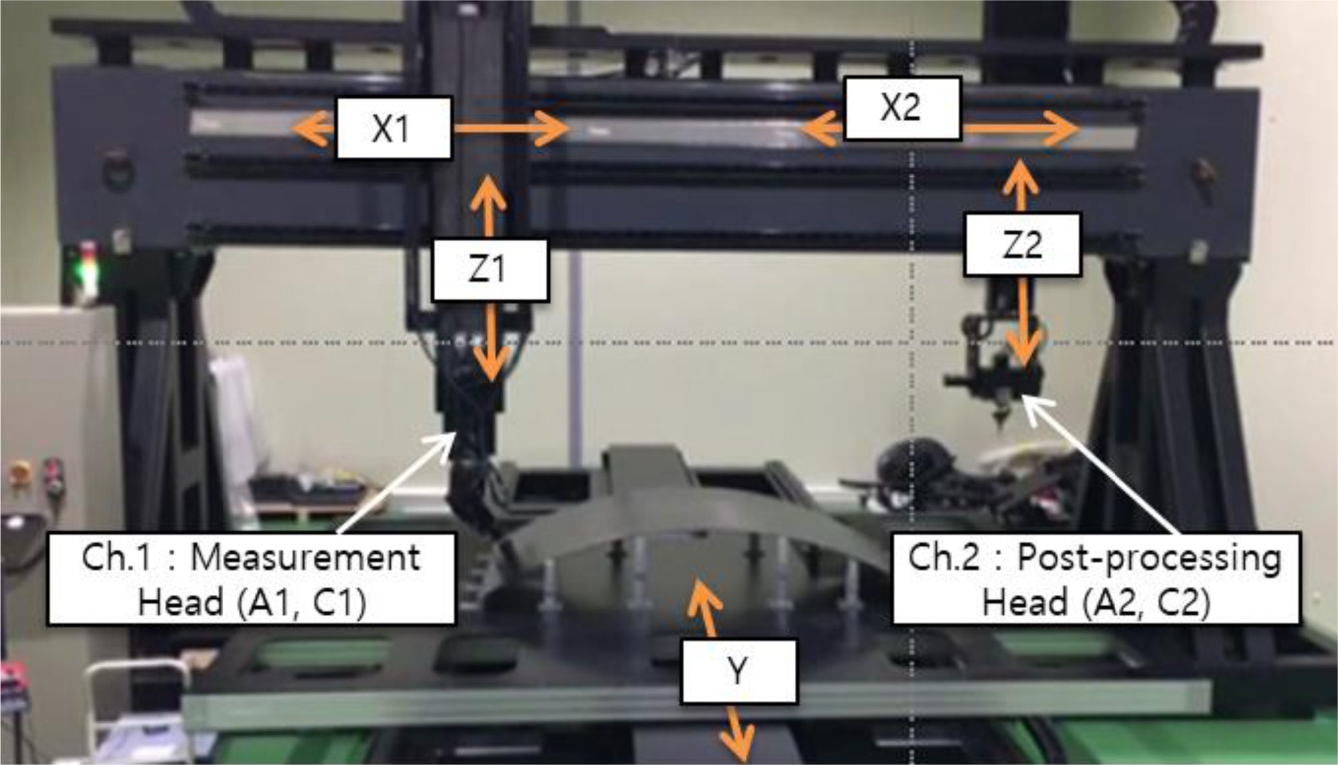

Fig. 11은 다계통 제어기가 탑재된 측정 및 후가공 복합 장비이다. 최대 6계통이고, 2계통 단위로 확장가능 하도록 계통 매니저가 개발되었으며, 측정 및 후가공 복합장비는 2계통으로 설정되었으며, 각 계통 5축 제어를 하며, Y축을 공유하도록 설정되었다. 1계통은 측정 헤드가 장착되어 드릴 가공된 개개의 드릴품질을 측정하여, 그 양불량을 판별하고, 그 위치를 기억한 뒤, 2계통의 후처리 초음파가공 헤드로 후처리가 필요한 드릴두멍 위치에 후 가공을 하여 드릴 품질을 전수 검사하여, 고품질 CFRP 부품을 얻고자 하였다.

Fig. 11Complex machine with multi-channel controller

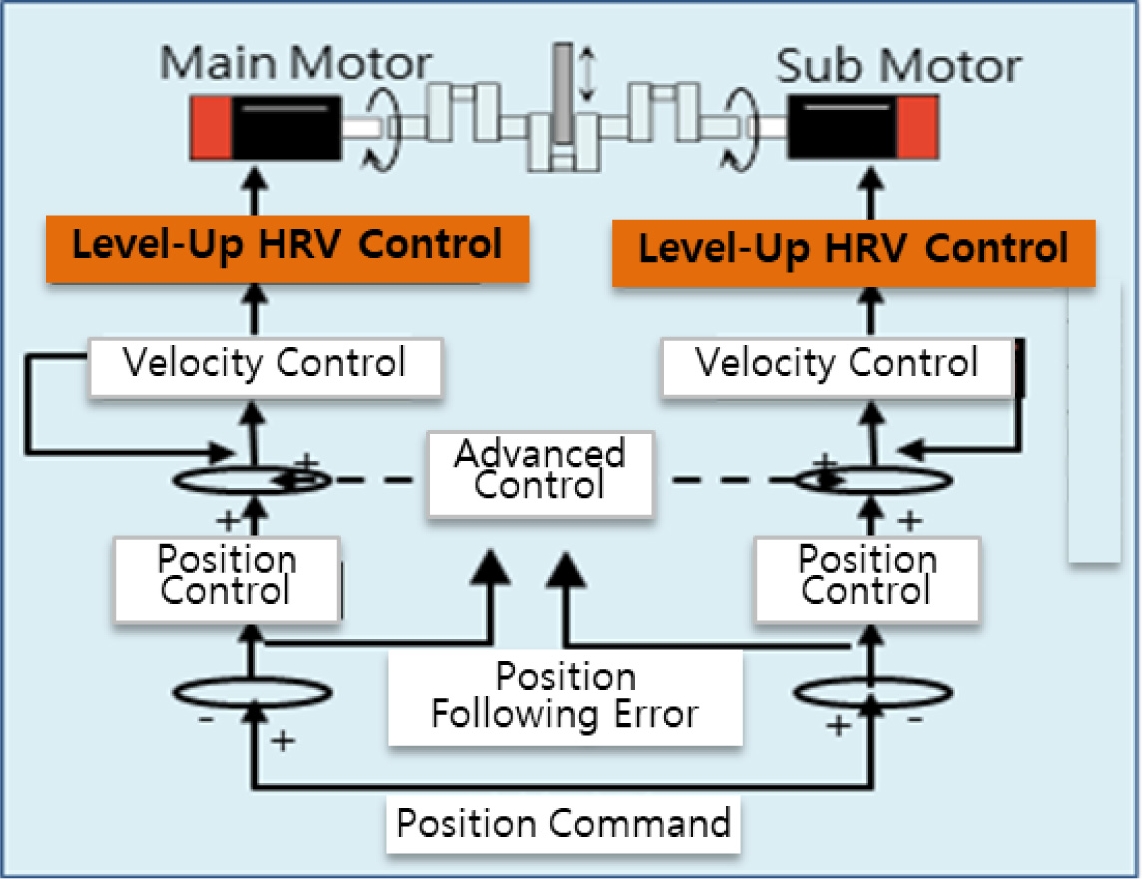

2.3.2 갠트리 동기제어

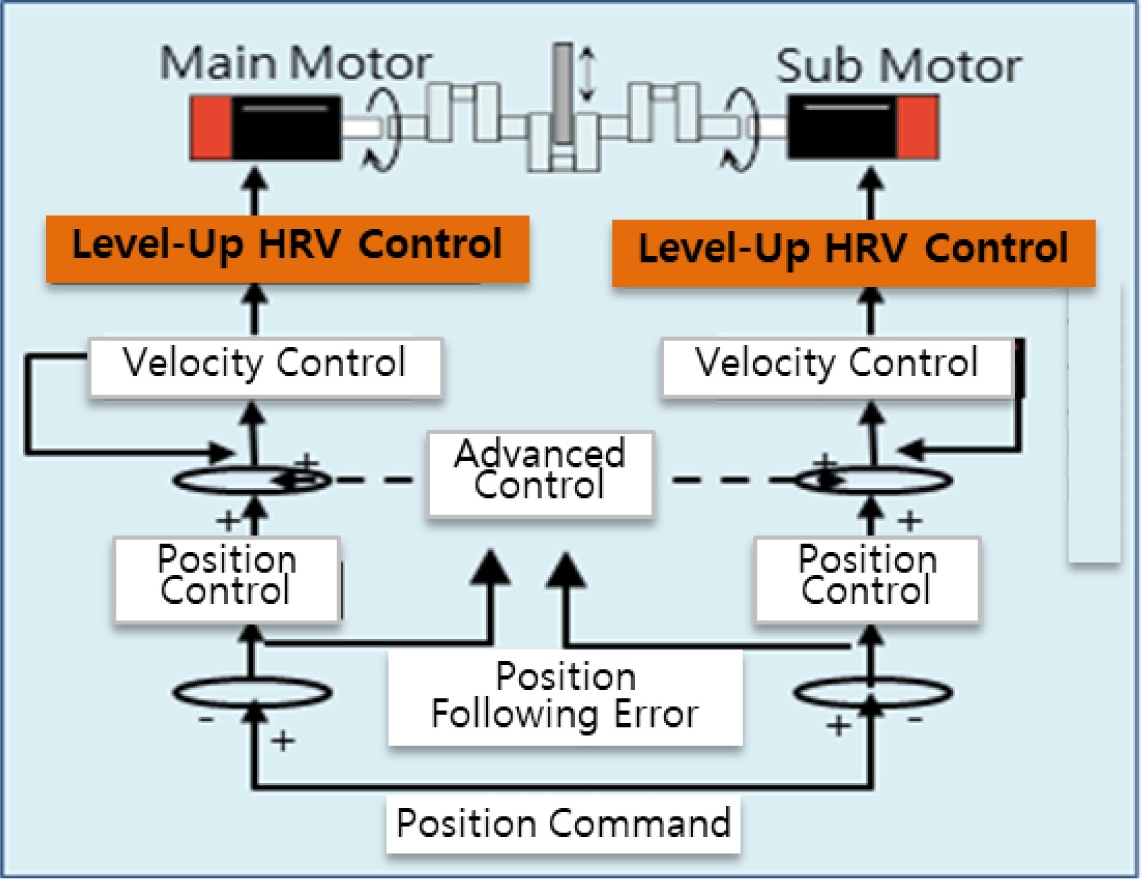

Fig. 12는 대형 갠트리 복합장비의 갠트리 축을 정밀 동기 제어하기 위한 FANUC의 텐덤 동기제어 개념도이다.

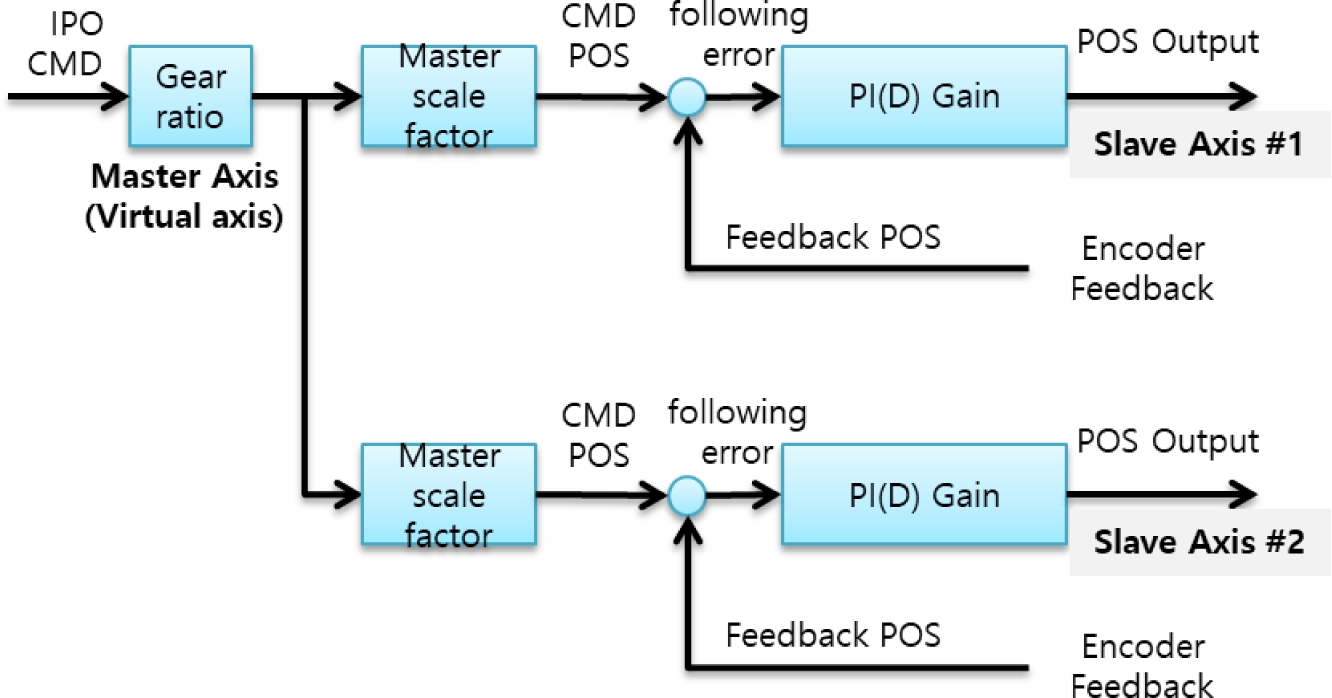

5 갠트리 축처럼 기구적으로 서로 구속이 되어있어 동기 운동이 되지 않으면 진동 소음이 발생할 뿐만 아니라, 가공물의 가공오차가 발생하므로 동기기법을 적용하여야 한다. 마스터/슬레이브 방식과 가상축 방식이 있는데 본고 에서는 가상축 동기제어 기법을 개발하였다.

Fig. 12Tandem synchronous control of FANUC

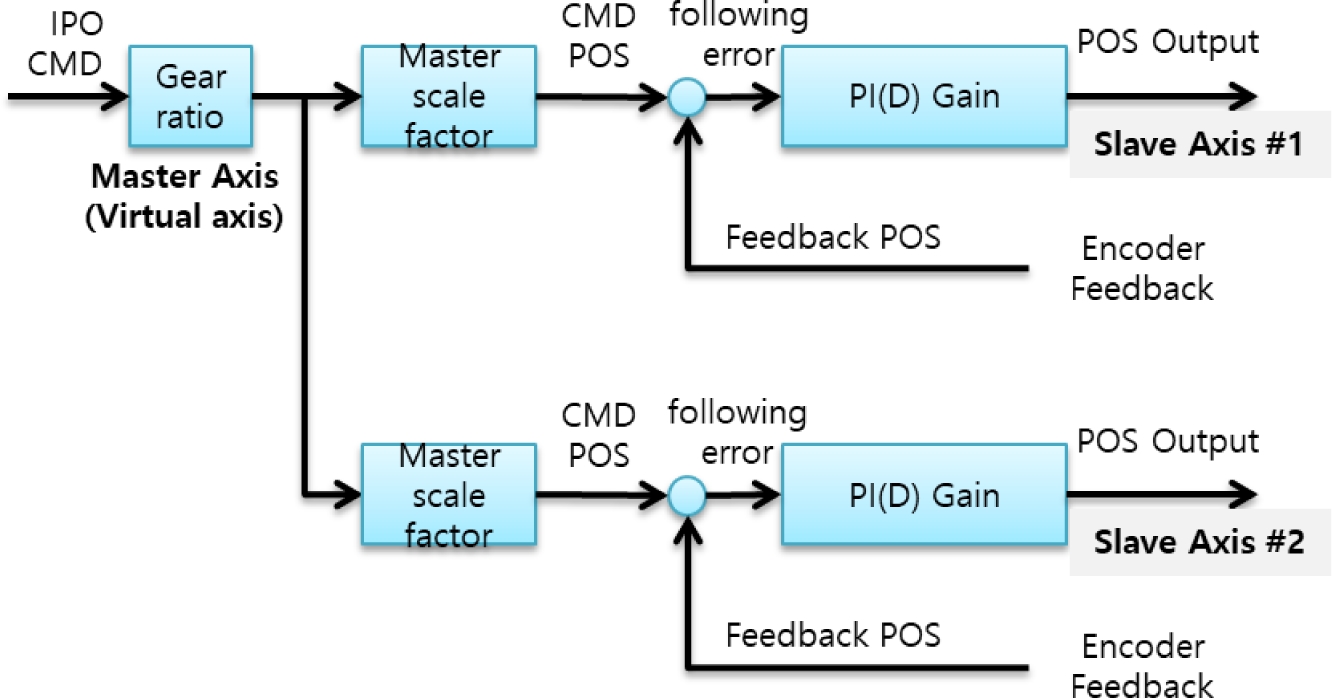

Fig. 13은 대형 갠트리 복합장비의 캔트리 축을 정밀 동기 제어하기 위한 가상축 동기제어 선도이다. 실제 축이 아닌 가상의 축을 설정하고, 실제 동기가 되어야 할 2개이상의 축은 이 가상축의 지령을 추종하는 방식으로 Virtual Command Following 방식이라고 한다. 갠트리 동기 축 제어뿐만 아니라, MPG (Manual Pulse Generation)를 구동할 때에도 이 방식을 사용한다. 기존 마스터/슬레이브 방식은 항상 슬레이브에 지연에 의한 오차가 남아있어 정밀 동기제어에는 적합하지 않다. 가상 축이 마스터가 되고, 실제축이 슬레이브가 되어 마스터 지령을 추종하므로 지연이 발생하여도 동일한 지연이어서, 결과적으로 정밀 동기제어가 가능하다.

Fig. 13Virtual command following method for gantry synchronous control

3. CFRP 가공 공정 모니터링 기술

CFRP 재료 특성상 드릴링 가공 시 적층된 소재의 박리, 미절삭 등의 가공결함이 발생하므로, 이를 최소화하거나, 방지할 수 있는 공정 모니터링을 적용할 수 있는 시스템이 요구된다. 또한, 고경도의 탄소섬유에 의한 공구 마모를 줄이기 위하여 가공공정 모니터링 모듈을 탑재하여 소재에 특화된 공정제어 기술을 이용한 가공공정 최적화 기술을 탑재할 수 있어야 한다.

CFRP는 대부분 적층 성형으로 만들어지므로 드릴링 공정이 타 소재보다 많을 수밖에 없고, 이때 절삭력 부하가 크지 않아서, 가공 중 발생하는 다양한 공정 신호들이 메탈 가공시 보다 미약하여 정밀한 측정기술과 이를 융합하는 다중 신호모니터링 기술이 필요하다. 결국, 탄소섬유복합 소재의 가공시스템은 현장 생산라인에 적용되기 위해서 소재특성에 따른 공정기술, CFRP 전용가공기, 그리고, 공정특화 기능을 탑재한 개방형 제어기 기술을 융합한 패키지화가 필요하다.

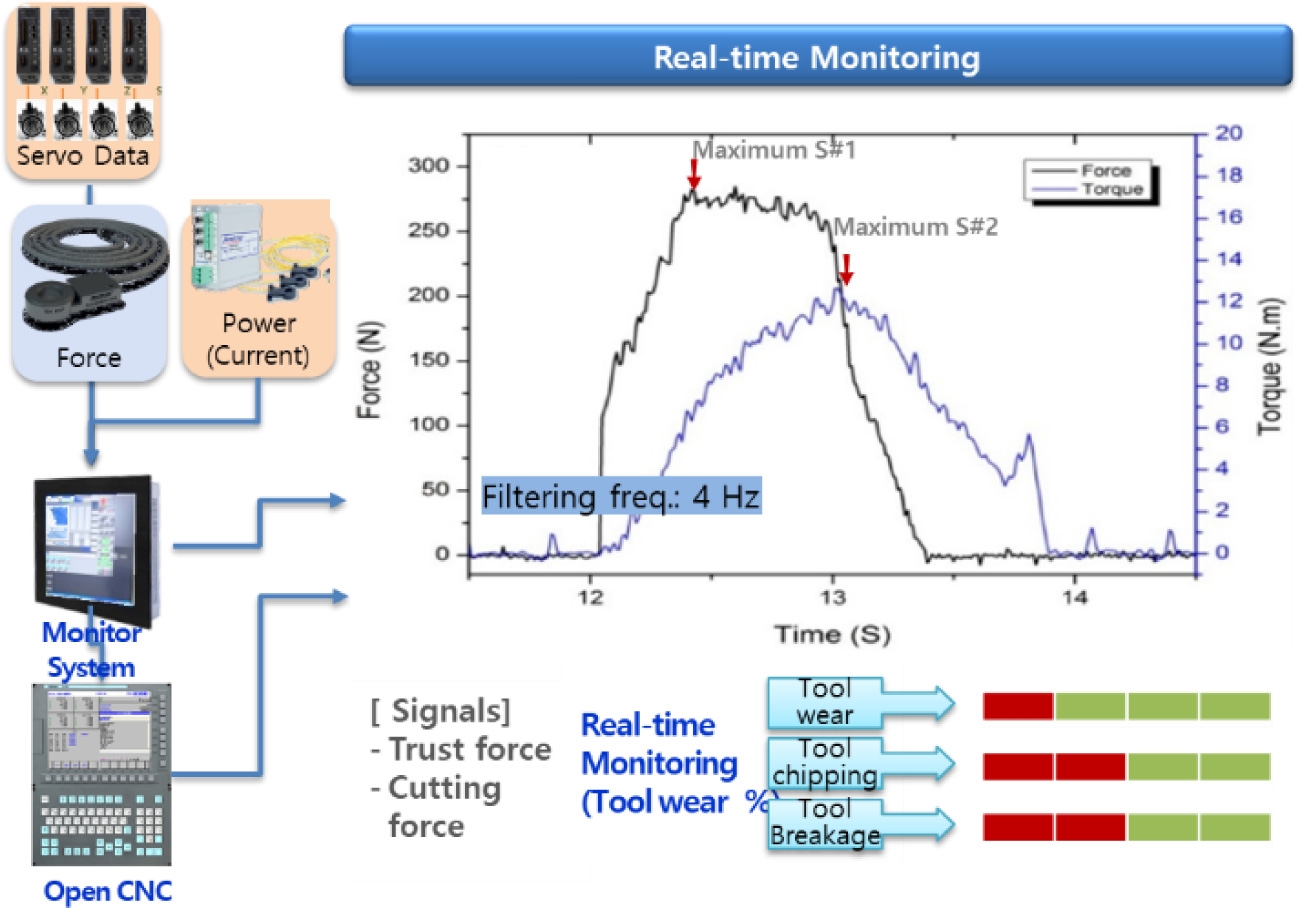

우선, CFRP 가공중 실시간 모니터링 및 이상감지 기능을 탑재할 수 있는 개방형 기능 모듈 라이브러리와 API(응용 프로그램 인터페이스) 기능을 개발하여 제공하고, 센서 모니터링의 2가지 방법으로 외부 센서 시스템을 사용하는 방법과 EtherCAT 통신을 통해 획득할 수 있는 내부 신호를 사용하는 방법을 제공하고, 실제 모니터링 예제를 구현하고자 한다.

3.1 다중센서 모니터링 시스템 연결

개방형 기능 모듈 라이브러리와 API를 활용하여 실제 CFRP 가공 중 실시간으로 모니터링하는 2가지 방법으로 외부센서 시스템을 사용하는 방법과 EtherCAT 통신을 통해 획득할 수 있는 내부신호를 사용하는 방법을 제공하고, 실제 모니터링 예제를 구현하고자 하였다. 먼저, 모니터링 대상이 되는 시스템의 특성을 파악하고, 가장 민감하고 효과적인 신호를 선택한 뒤, 필요하면 2개 이상 다중신호를 조합하여 이상감지와 판단하는데 활용할 것이다.

CFRP 가공 공정 모니터링 상황에서의 가공 조건들이 매우 다양하여, 모든 조건을 커버하는 모니터링 방법을 찾는 것은 너무 방대한 테스트를 요하므로, 현재까지 테스트 결과 자료로부터 찾을 수 있는(Detectable) 신호 취득 방법부터 탑재하기로 하였다. CFRP 판재 가공시 가공 조건과 주요품질 항목은 다음과 같다.

1. CFRP의 소재: 목적에 따라서 성분과 제조방법 다르고, 각각 가공성에도 차이가 남(적층 방식 UD/MD/Woven, Injection/Press Molding, 탄소섬유품질 T300/T700/T1000, 일반/내열/난연 에폭시 등)

2. 가공 공구: 재질_WC/PCD/TiAlN, 코팅 유무, 날수, 직경, 헬릭스 앵글 등

3. 가공 조건: 절삭유, 고압 송풍기(Air Blower)

4. 주요 품질 항목(드릴링/라우팅): 입/출구 박리(Delamin Ation) Factor, 벽면 결함(Fiber Pullout, Matrix Burnout, Ra), 공구 마모 (프랭크면 마모, 에지 라운딩)

선 가공 실험으로 찾을 수 있는 모니터링 항목(DetecTable Point)은 아래에 나열하였다.

1. 스핀들 진동신호: 드릴링시 절삭력 파형(공구 동력계로 측정)은 최대 100 N 이내이고, 주파수 분석결과 고주파(3 - 5 kHz) 성분에 피크가 있음이 확인되었으므로 CFRP 가공에서 진동신호의 FFT(3 - 5 kHz) 프로파일을 표시하는 기능 필요함을 확인하였다. 스핀들 진동은 가공공정 모니터링 뿐만 아니라, 스핀들 상태 모티터링 용도로도 활용 가능하다.

2. 소재 온도(또는 가공부위): CFRP의 레진인 에폭시의 녹는점이 약 150 - 300 °C이므로 소재 온도(또는 가공 부위)의 측정이 필요하다.

3. 전류 신호(이송축/스핀들): 드릴링시 Z축의 전류는 절삭 추력을 대표할 수 있고, 스핀들의 전류는 절삭부하를 대표할 수 있으므로 모니터링 대상이 된다.

4. 소재의 진동신호: 3 - 10 T의 CFRP 판재 드릴링시 소재에 진동 발생하여, 드릴 진입시와 드릴링시 진동을 방지하기 위하여 진입 이송속도를 공구 제조사 추천속도보다 느리게 설정하여 가공하고 있음을 알아냈고, 소재 진동을 측정하여 최적의 이송속도로 드릴링하는 방법이 필요하다.

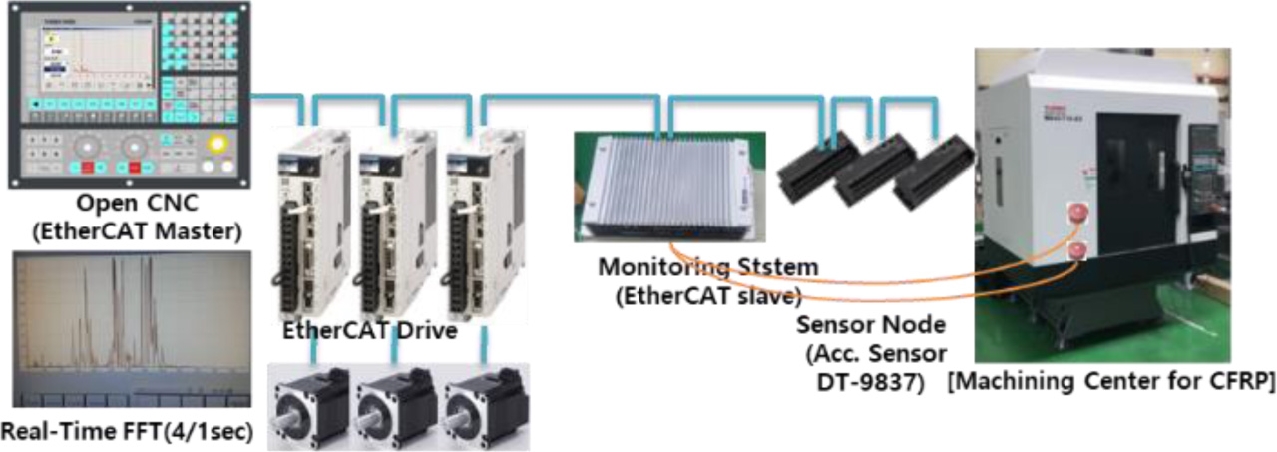

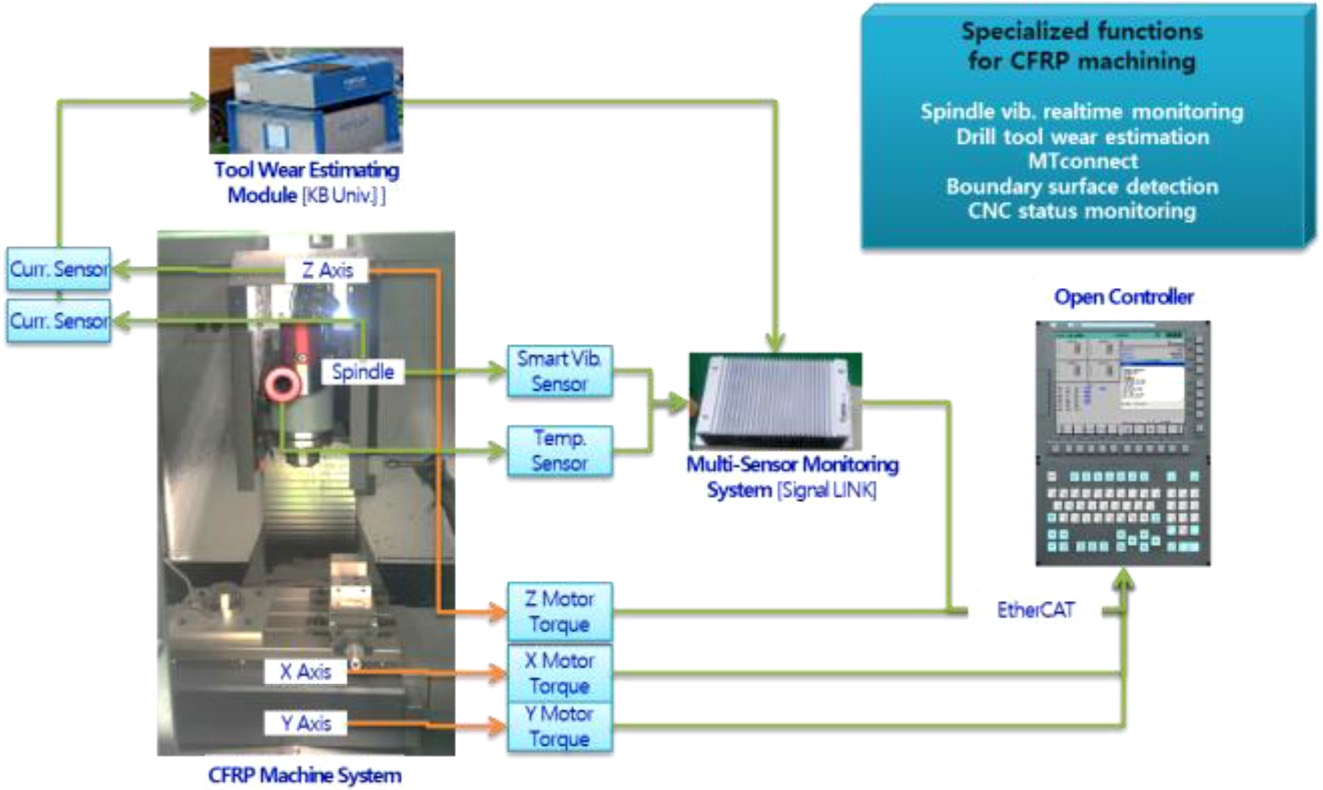

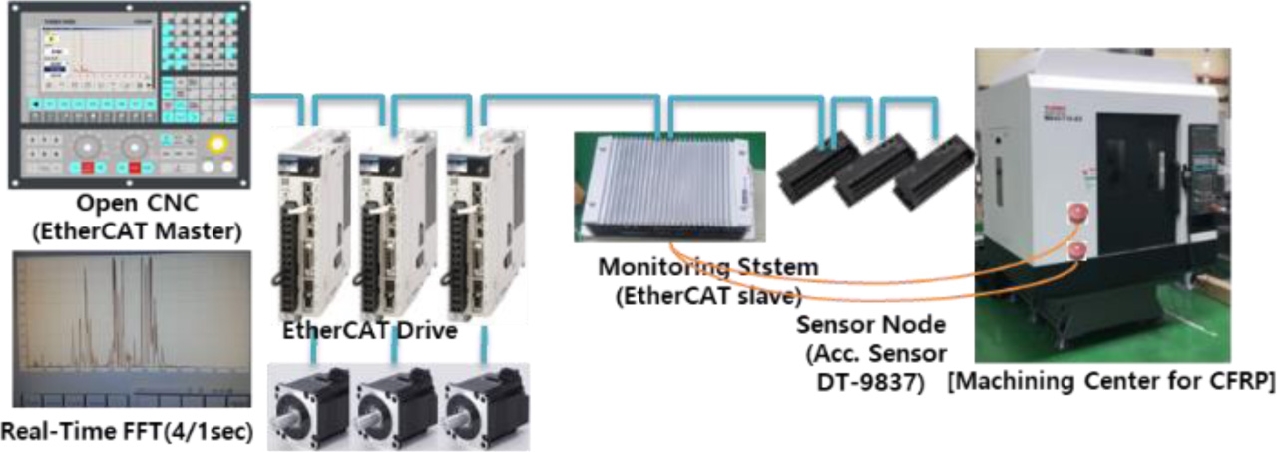

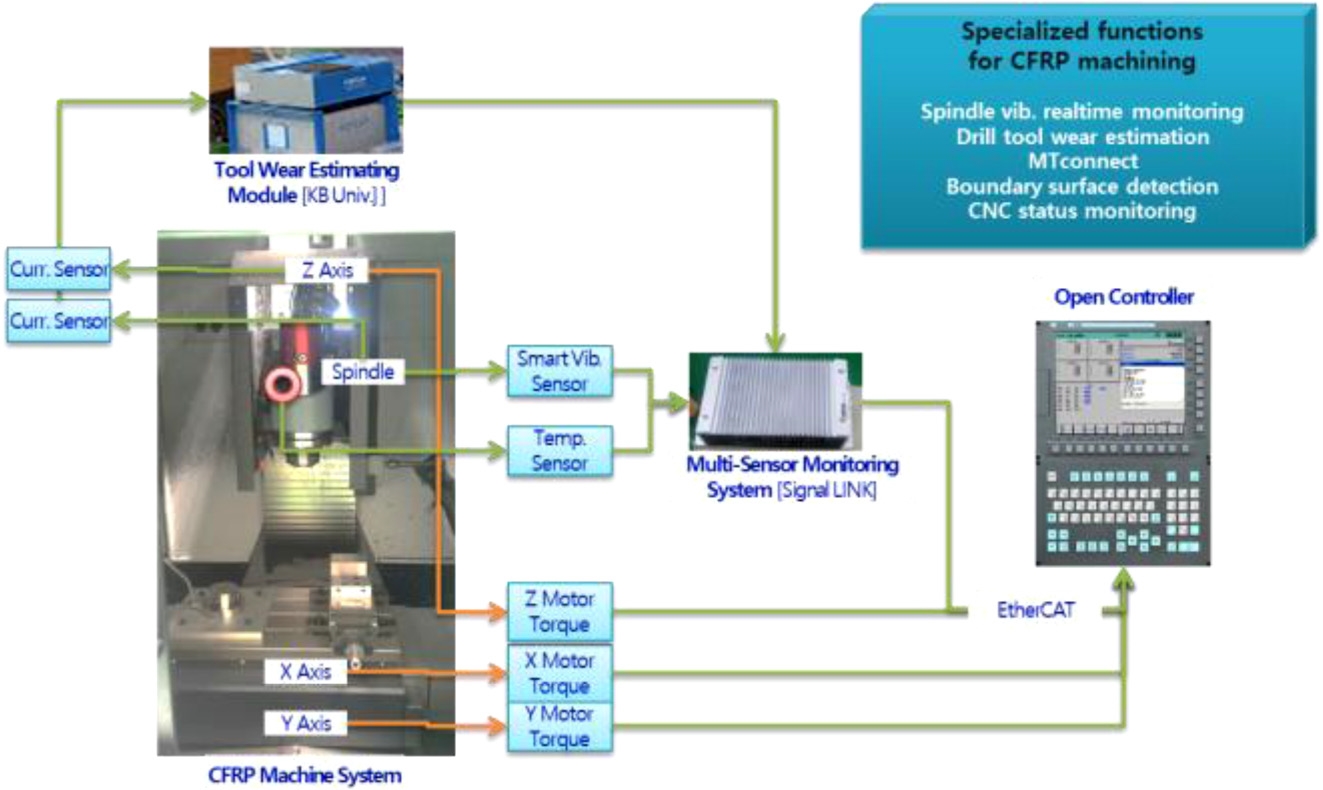

Fig. 14는 모니터링 시스템 연결한 연결도이며, 개방형 제어기에 표준 인터페이스인 EtherCAT 통신으로 다중센서 모니터링 시스템과 연결할 수 있는 기능을 구현하였다. 가공장비에 장착될 외부센서는 모니터링 시스템을 통하여 디지털 데이터로 변환되어 개방형 제어기로 전달되며, 제어기는 통신주기와 동일한 주기로 데이터를 받아낼 수 있다. 센서의 업데이트 주기는 50 - 150 ms이며, FFT 프로파일의 경우 데이터 개수가 많아서 평균 1초에 250 ms 주기로 전달된다. 수집된 센서 값은 CNC 내부 레지스터에 저장되어 그 파형을 볼 수 있고, API 프로그램에서 활용할 수 있도록 하였다.

Fig. 14Monitoring system for CFRP machine with open controller

Table 2는 다중센서의 모니터링 데이터를 수집하는 구성 예를 보여준다. 하나의 센서에서 시간 도메인과 주파수 도메인에서의 피크값이나 RMS 값을 선택적으로 받을 수 있고, FFT의 경우 특정 밴드를 설정하여 각 밴드에서의 피크값이나 RMS 값을 받을 수 있도록 하였다. 이러한 센서 데이터의 전달 통로는 8개로 구현하였고, FFT 프로파일은 별도의 통로를 제공하였다.

Table 2Data acquisition assignment for sensor monitoring

Table 2

|

Point |

Sensor |

Measure |

Unit |

Ch. |

Map |

|

Spindle |

Vib. sensor |

RMS |

m/s2

|

Ch1 |

SV[1100] |

|

FFT band1 |

m/s2

|

Ch2 |

SV[1101] |

|

FFT band1 |

m/s2

|

Ch3 |

SV[1102] |

|

Temp. |

|

°C |

Ch4 |

SV[1103] |

|

Z axis |

Curr. |

Thrust force |

N |

Ch5 |

SV[1104] |

|

X axis |

Vib. |

RMS |

|

Ch6 |

SV[1105] |

|

Vib. |

FFT band |

|

|

Y axis |

Vib. |

RMS |

|

|

Vib. |

FFT band |

|

|

Work Table |

Vib. |

RMS |

|

|

Vib. |

FFT band |

|

|

Sensitive spot |

Vib.

(10kHz) |

FFT profile

(df = 8Hz) |

|

Ch7 |

Every

250 ms |

3.2 내부 디지털 데이터 신호 활용

EtherCAT을 지원하는 표준 EtherCAT 서보 드라이브를 장착하면, 서보 드라이브의 전류(토크, 부하)정보를 표준 EtherCAT 통신으로 실시간으로 읽어 들여 상태 파라미터에 저장하고, API 함수가 이 저장된 실시간 부하정보를 활용하여 CFRP 공정제어에 활용하도록 정보를 제공하고, 속도와 위치는 CNC에서 제공하므로 가공 공정에서 부하에 관련된 정보는 모두 활용할 수 있다. 따라서, 내부 신호를 활용할 수 있도록 관련 API 함수를 지원하였다.

EtherCAT 표준인 CSV 프로파일 모드에서의 서보 모터의 토크 신호를 피드백 받을 수 있고, 모터에 인가되는 전류를 토크값으로 환산하여 받을 수 있고, 정격부하의 % 값으로 받을 수도 있다. 부하 토크는 최대 32축을 받아올 수 있으며, 서보 드라이브와 연결된 개방형 제어기에서 각축의 부하 토크를 매 통신 주기(또는 위치제어 주기) 마다 받아와서

Table 3의 이송 축 모터부하(내부 신호)의 CNC 저장 레지스터에 저장하도록 기능을 제공한다. 1 ms로 상태변수 SV[1250] - SV[1281]에 1 - 32축의 정격부하의 %값을 기록한다.

Table 3Register map assignment for the load of feeding axis

Table 3

|

Axis |

Torque value [Unit 0.1%] |

Map |

|

1 axis. |

10.5 |

SV[1250] |

|

2 axis |

13.1 |

SV[1251] |

|

3 axis |

38.5 |

SV[1252] |

|

: |

- |

: |

|

32 axis |

- |

SV[1281] |

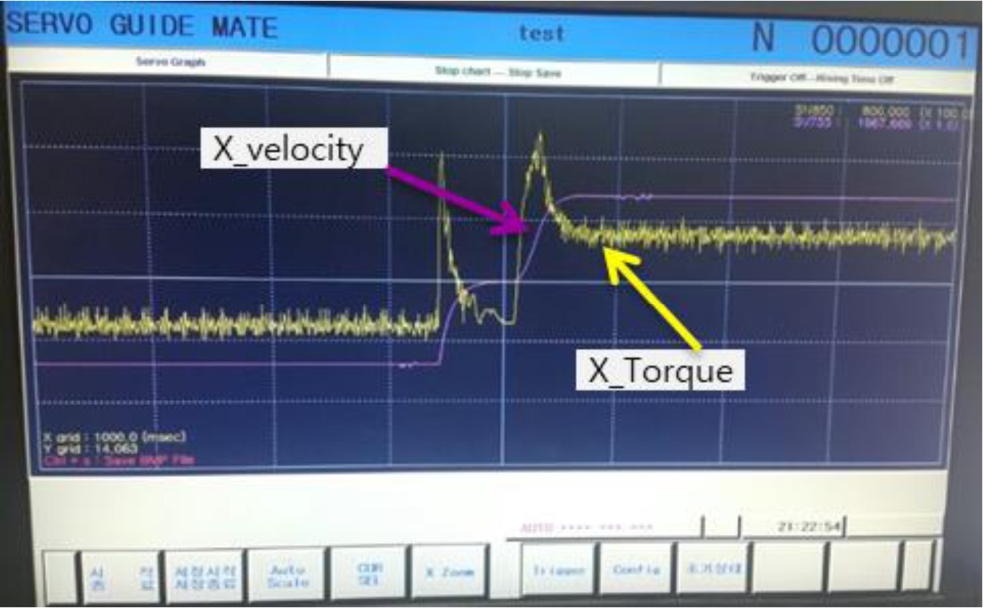

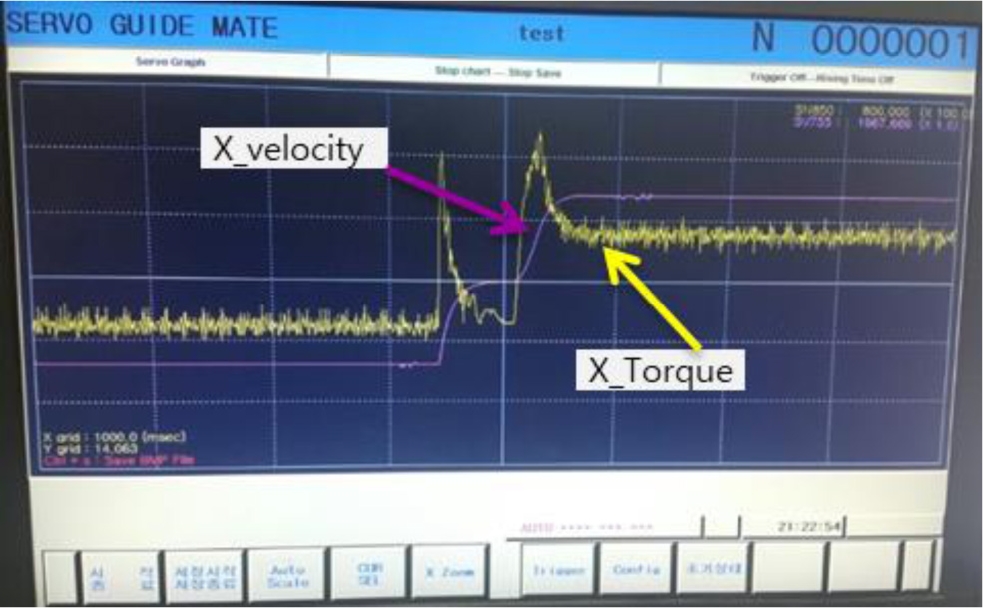

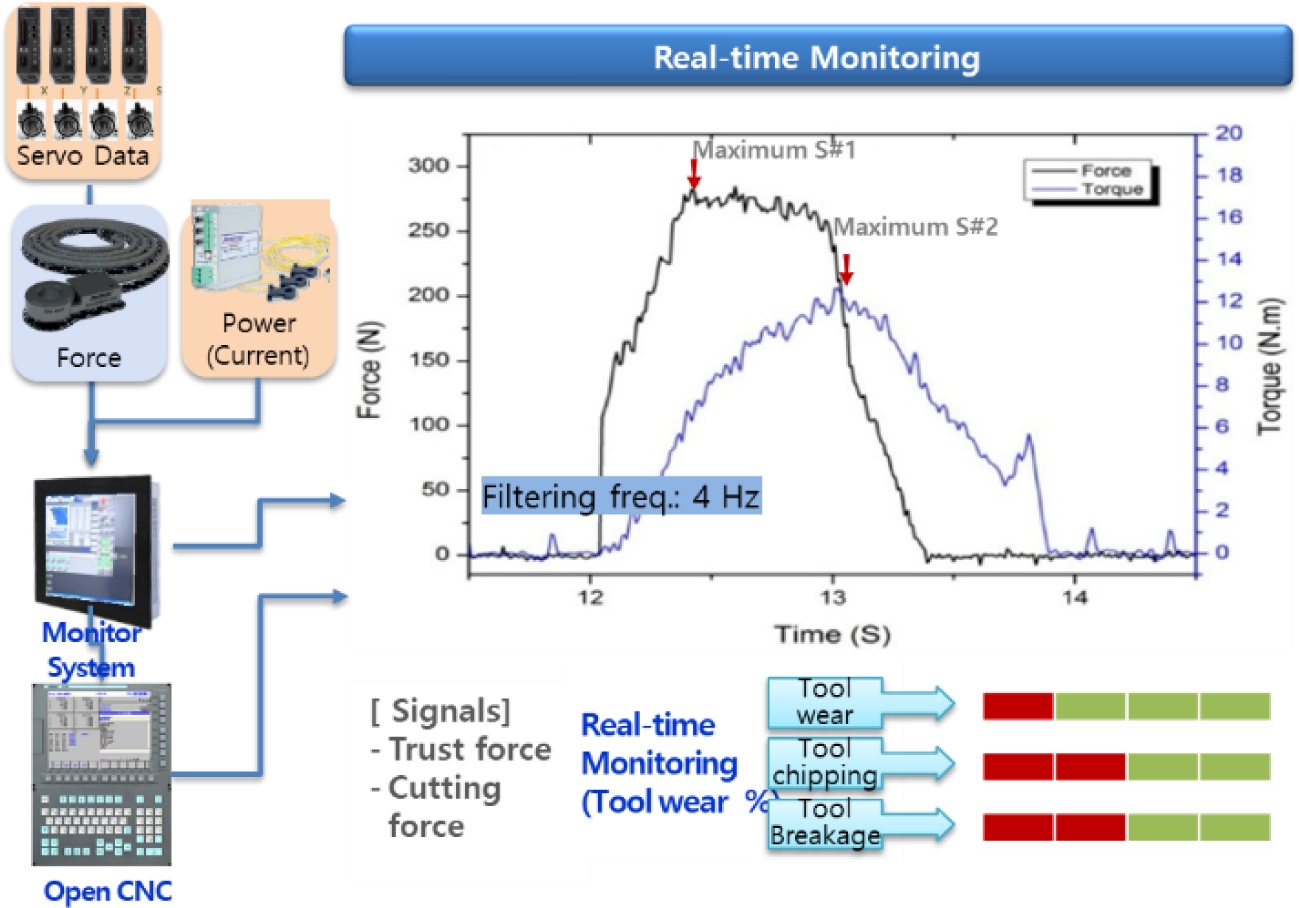

Fig. 15는 이송 축 서보 드라이브의 토크 신호를 모니터링한 것이며, 이송 속도와 동시에 파형보기에서 본 결과이다. 가속과 감속시에 전류 피크가 있음을 볼 수 있다. 샘플링 주기는 보간 주기 2 ms와 같으며, 표시단위는 [정격 토크*0.1 %]이고, 축 이송의 가 감속시에 부하 토크의 피크가 있고, 등속구간에서는 낮은 토크를 유지한다. 등속구간서 가공이 일어나면 부하 토크는 증가한다.

Fig. 15Torque monitoring for the load of feeding axis

Fig. 16은 개발된 API를 활용하여 CFRP 가공 공정의 센서 모니터링을 통해 사용자 특화 기능 모듈을 작성하는 가이드 라인이며, 측정된 신호는 CNC의 상태변수에 실시간 저장되고, API는 이 신호와 가공상태를 조합하여 결정된 결과는 PLC 접점을 통해 이송속도 오버라이드, 스핀들 오버라이드, 정지, 긴급 정지, 경고, 그리고 알람 출력 등의 액션으로 공정을 제어할 수 있다.

Fig. 16Reaction plan for monitoring on machining CFRP

3.3 스핀들 진동신호의 실시간 FFT

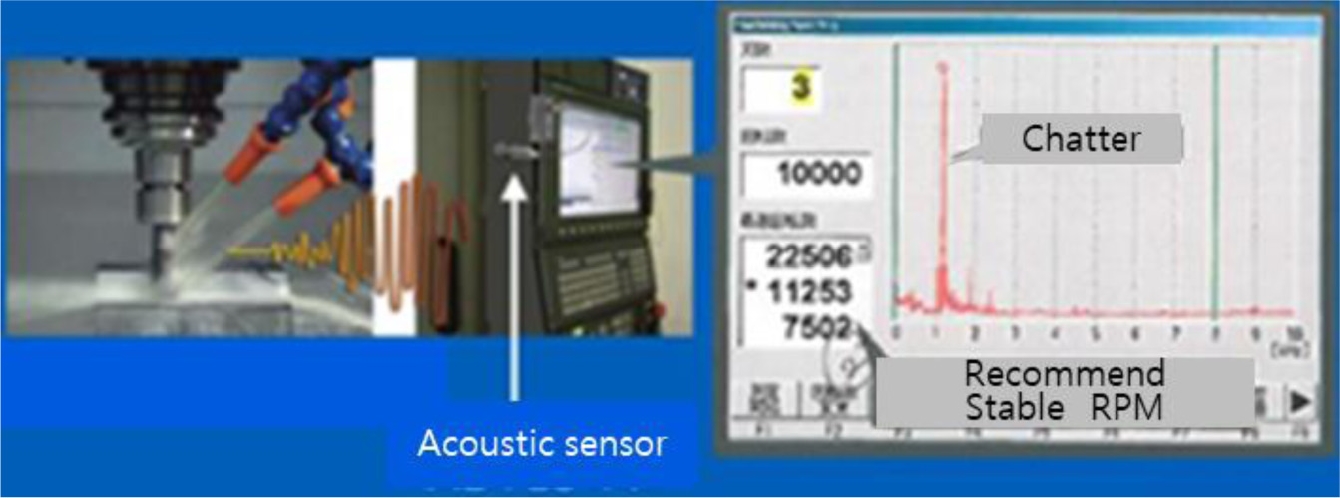

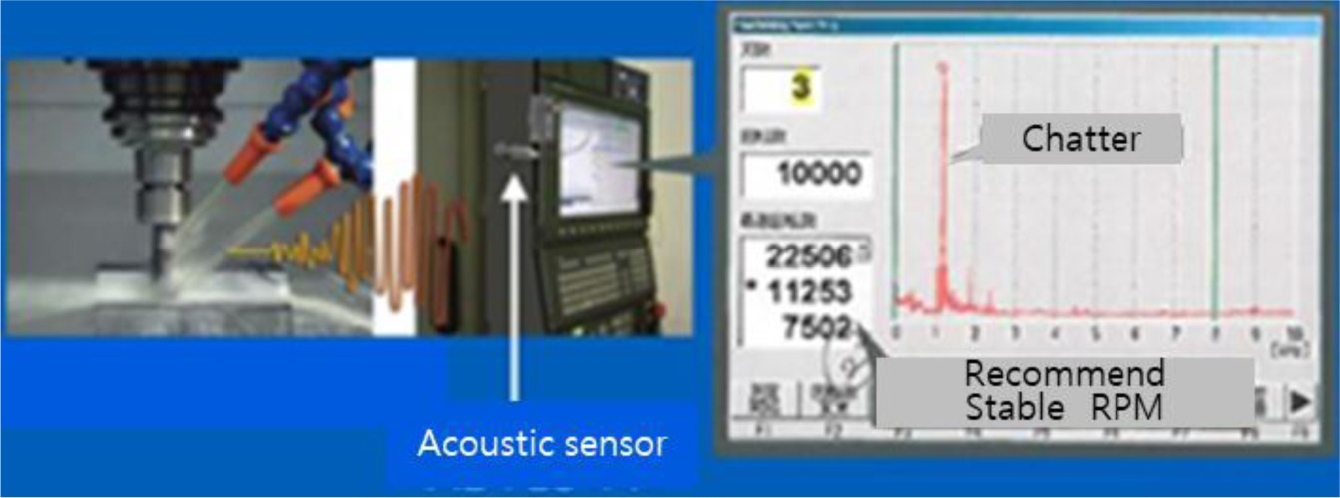

CFRP 드릴링시 절삭력 파형(공구동력계로 측정)은 최대 100 N 이내로 아주 작아서 이상 상황을 판단하기 용이하지 않고, 주파수 분석결과 3 - 5 kHz 대역의 고주파성분 피크가 있음이 확인되었다. 드릴날이 개개의 파이버를 절단할 때 나오는 충격파가 감지되는 것으로 추정된다. 따라서, CFRP 가공공정에서 특화된 모니터링 신호로 실시간 FFT 프로파일을 선정하고, 모니터링할 수 있는 기능을 탑재하였다. 센서의 샘플링 주파수는 12.8 kHz를 사용하고, FFT 프로파일 표시 대역은 6.4 kHz까지 된다. 8 Hz 간격으로 표시한다 해도 1회 표시하기 위하여 800개의 데이터가 필요하게된다. EtherCAT 통신주기마다 80개의 데이터를 100회 전달하여 하나의 FFT 프로파일을 구성하도록 하였다. 1회 연산 완료시 인덱스 값을 +1 증가시킴으로써 제어기는 인덱스가 바뀐 경우 데이터를 연결하여 하나의 FFT 프로파일로 표시한다. 가공시스템에서 FFT 프로파일을 보여주는 예는 오쿠마사(일)의 Machining-Navi에 탑재되어, 가공 상태를 감시하고, 스핀들 회전수를 추천하기까지 한다. 센서는 마이크로폰을 사용하며, 채터를 모니터링 하는 용도로 사용된다. CFRP 가공에서는 채터가 나타나는 경우가 극히 드물기 때문에 채터보다는 공구 마모에 의한 가공모드의 변화를 감지하기 위한 용도가 될 것이다.

Fig. 17은 Machining-Navi의 최적의 스핀들 RPM 추천 기능을 보여준다.

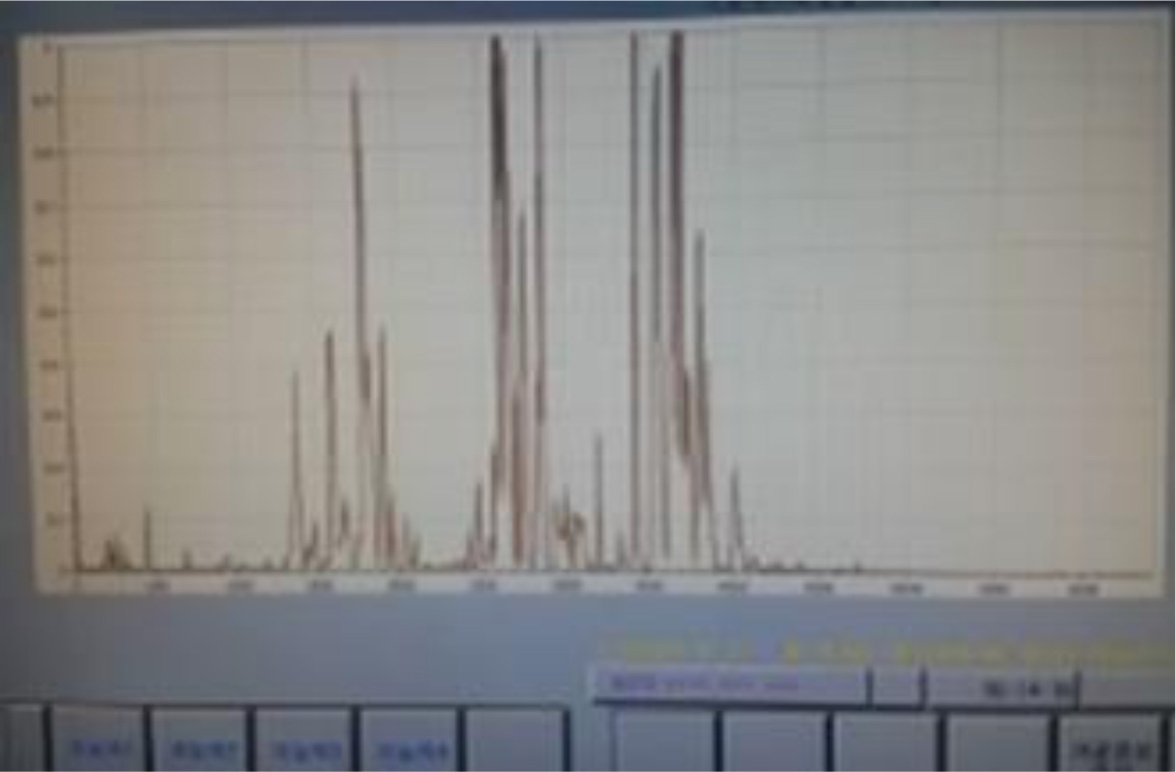

Fig. 17Recommend spindle RPM with Machining-Navi

Fig. 18은 개방형 제어기에서 스핀들 진동 센서의 실시간 FFT프로파일 표시한 것과 CFRP 드릴링시 고주파 영역의 피크값이 나타나는 양상을 보여준다. CFRP 가공 중 진동신호의 실시간 FFT프로파일을 1초에 4회 표시하고, 최상위 10개의 피크값과 그때의 주파수 대역을 표시하여 API 프로그램에서 활용할 수 있도록 하였다. CFRP 가공시 정상가공 프로파일의 결과와 매번 비교하여 이상진동 모드가 감지되면 제어기에 미리 정의된 조치를 취하도록 하는 것이 목적이다. 진동 모드의 분석은 진동을 가진하는 소스인 스핀들 회전, 공구 날수, 베어링 개수 등으로 부터 파악할 수 있다.

Fig. 18Real-time FFT profile of vibration sensor on spindle

3.4 CFRP 드릴링 공정 모니터링

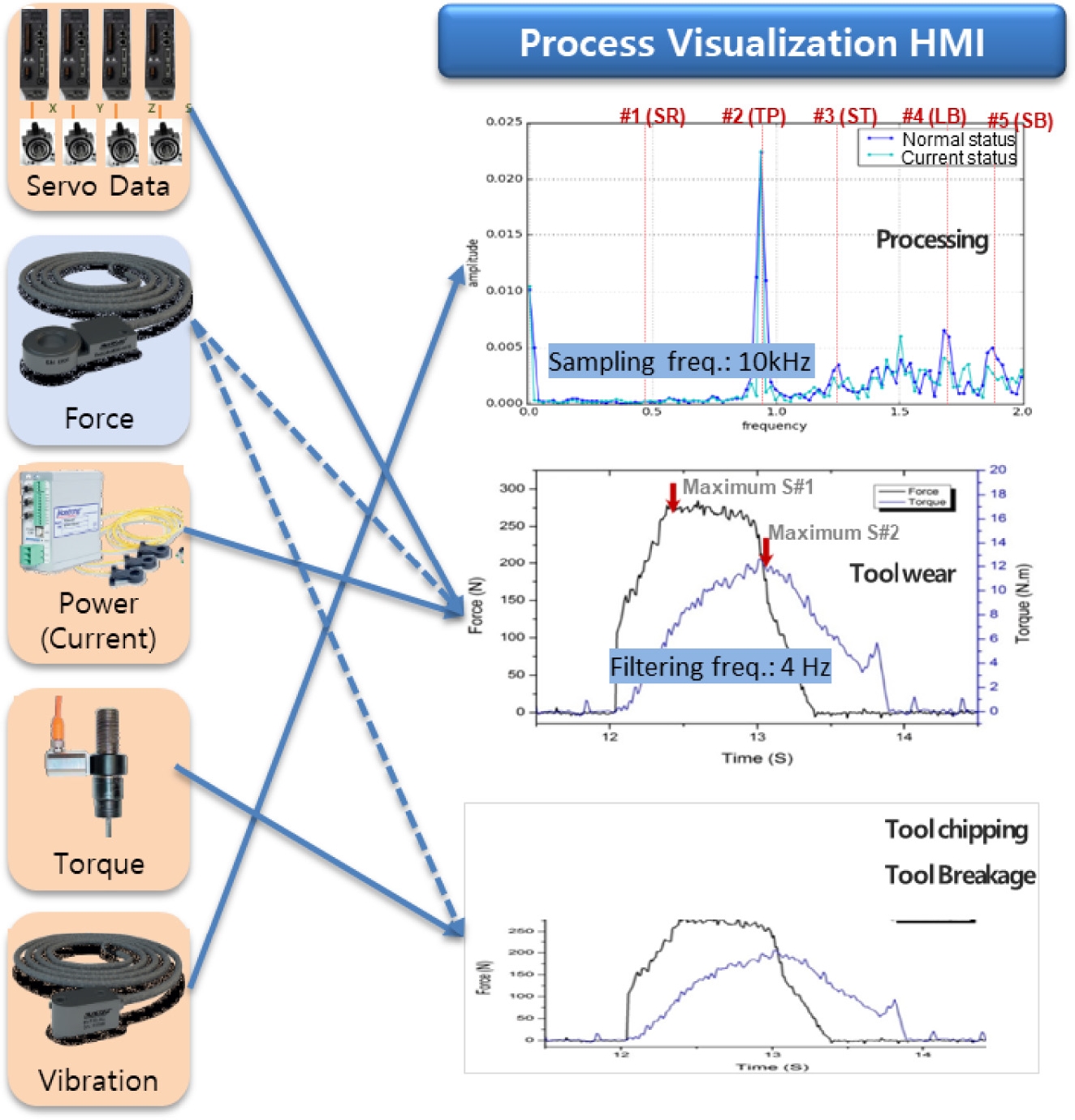

Fig. 19는 다중센서 모니터링 시스템을 가공장비에 연결한 개략도이며, 개방형 제어기가 장착된 초음파 스핀들 장비에 다중센서 모니터링을 위하여 주축과 이송 축에 전류센서, 스핀들 본체에 스마트 진동센서와 온도센서를 장착하였다.

Fig. 19Schematic diagram for multi-sensor monitoring system

관측 대상은 드릴링에 주요 절삭력인 Z 축 추력, 진행방향의 이송속도, 스핀들 회전수이다. 매 통신 주기마다 모니터링 시스템은 센서로부터 빠른 샘플링 주기로 취득한 신호를 분석하기 위하여 CNC로부터 받은 정보를 기반으로 결정하고 판단한다. 진동신호는 그 샘플링 주기가 통신주기보다 짧아서 샘플링 데이터를 상부 CNC로 전달하는 것이 어려우며, 자체적으로 분석기법을 활용하여 결정한 결과값만을 상부 CNC로 전달하여 후조치를 취하도록 한다.

가공결함 진동, 온도, 추력, 구동부 결함 진동신호를 실시간 취득하여 실시간으로 결함 도달 유무를 판단한 후 상위 CNC로 전달하게 된다.

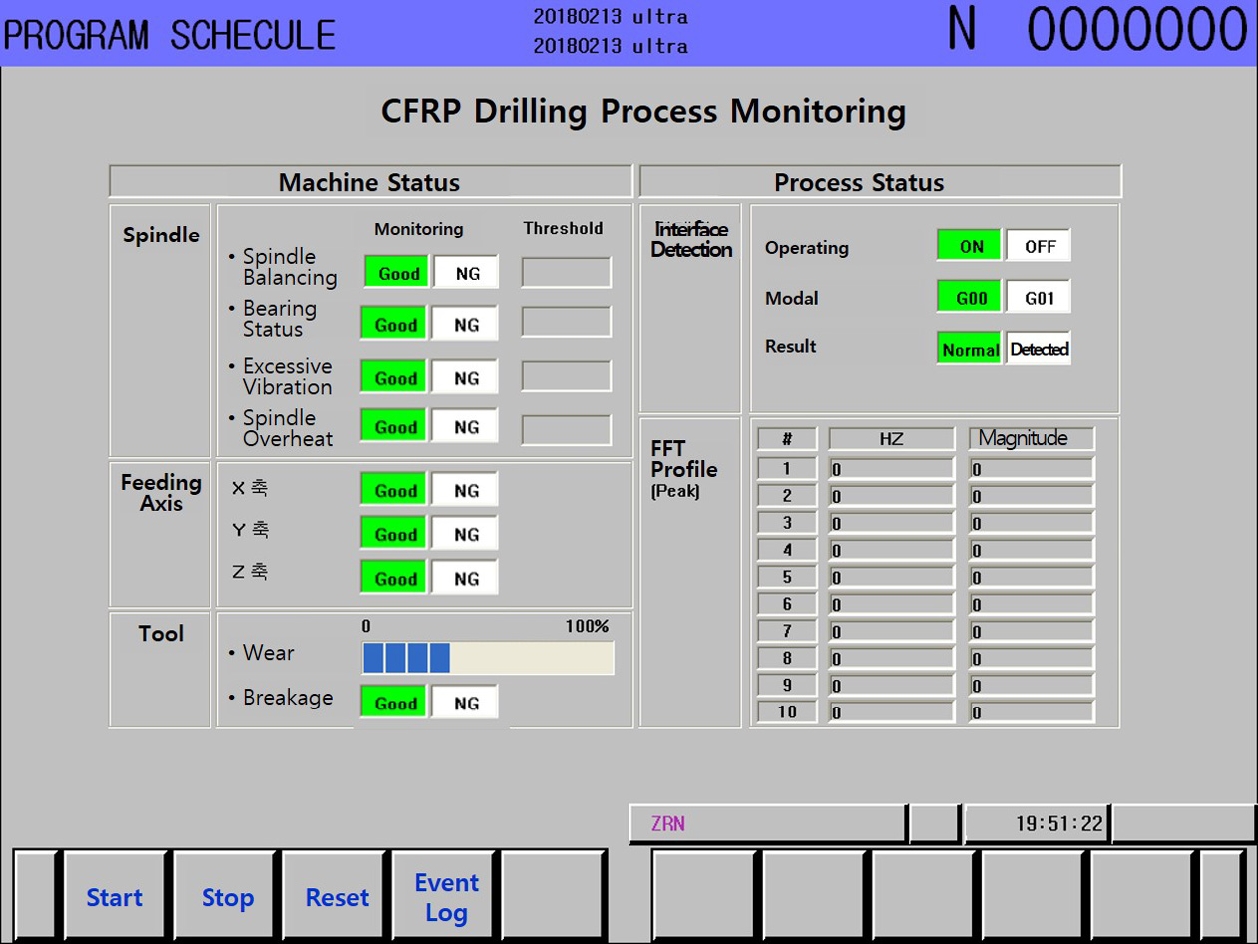

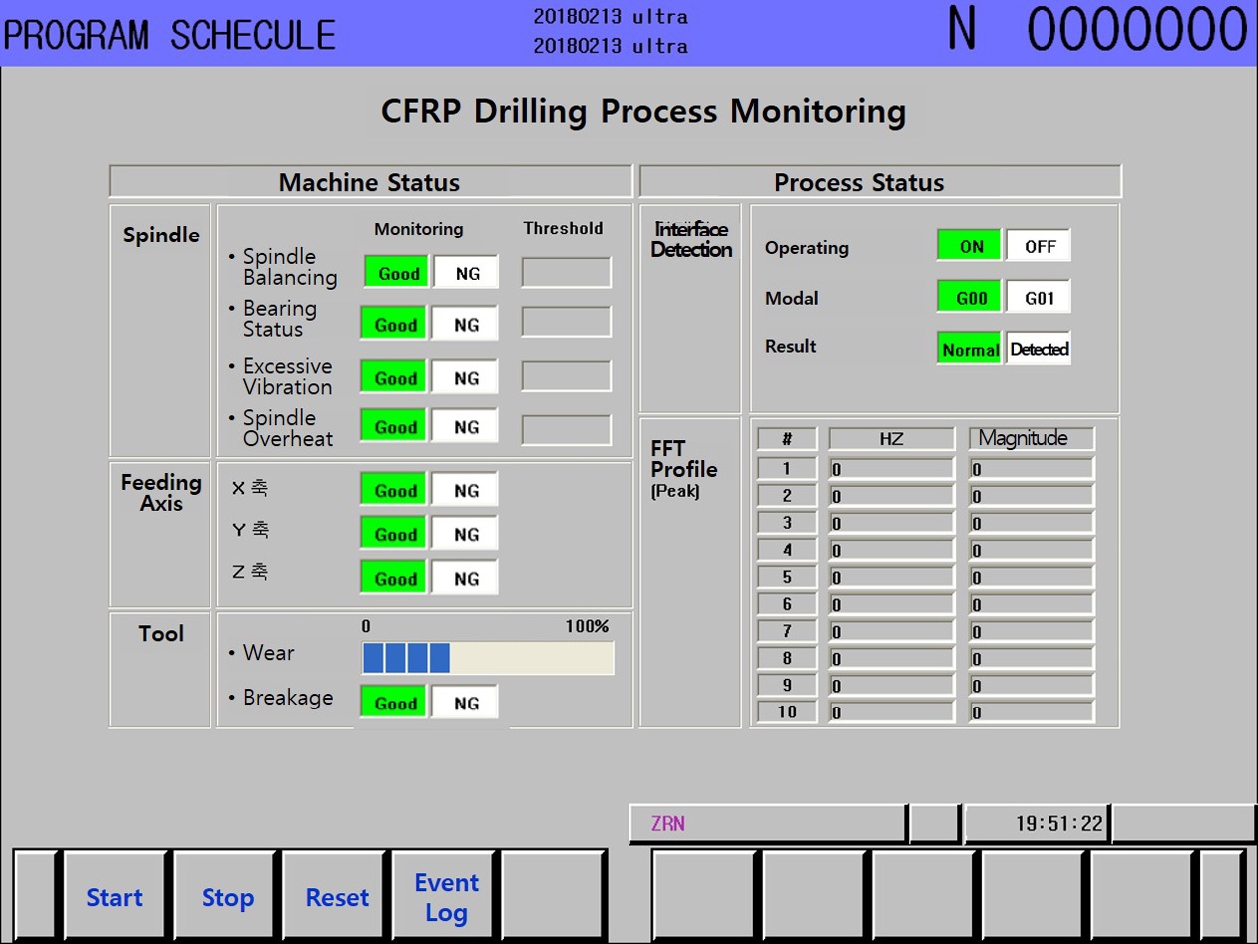

Fig. 20은 개방형 제어기에 탑제된 CFRP 드릴링공정 모니터링 기능 화면이며, 크게 장비상태 모니터링과 가공공정 모니터링으로 구분하였다. 장비 모니터링 대상은 주축 스핀들, XYZ 이송축, 그리고 공구이며, 가공공정은 CFRP multi-stack 소재의 드릴링시 경계면 검출 기능과 회전체 진동을 실시간으로 모니터링 하는 기능을 탑재하였다.

Fig. 20Monitoring screen for CFRP drilling process

3.5 CFRP 가공 공정의 Health 인덱스 설계

CFRP 드릴링 공정의 장비 진단과 공정 모니터링을 실제 장비에서 작업자에게 유용한 정보를 제공하기 위해서는 장비의 현 상태와 공정의 건전성을 종합하여 보여줄 수 있는 지시인자(Health Index)가 필요하며, 이를 자동으로 처리하거나, 최소한 작업자에게 건전성 정보를 전달할 수 있어야 한다. 궁극적으로는 머신 러닝 기법을 활용하여 축적된 가공 이력정보에 의한 통계적 데이터에 의한 판단 메커니즘을 개발하는 것이 최종목표이다. 현 단계에서는 중요인자와 결과 간의 직관적인 데이터 수집을 충분히 획득한 후에 진행하고자 한다.

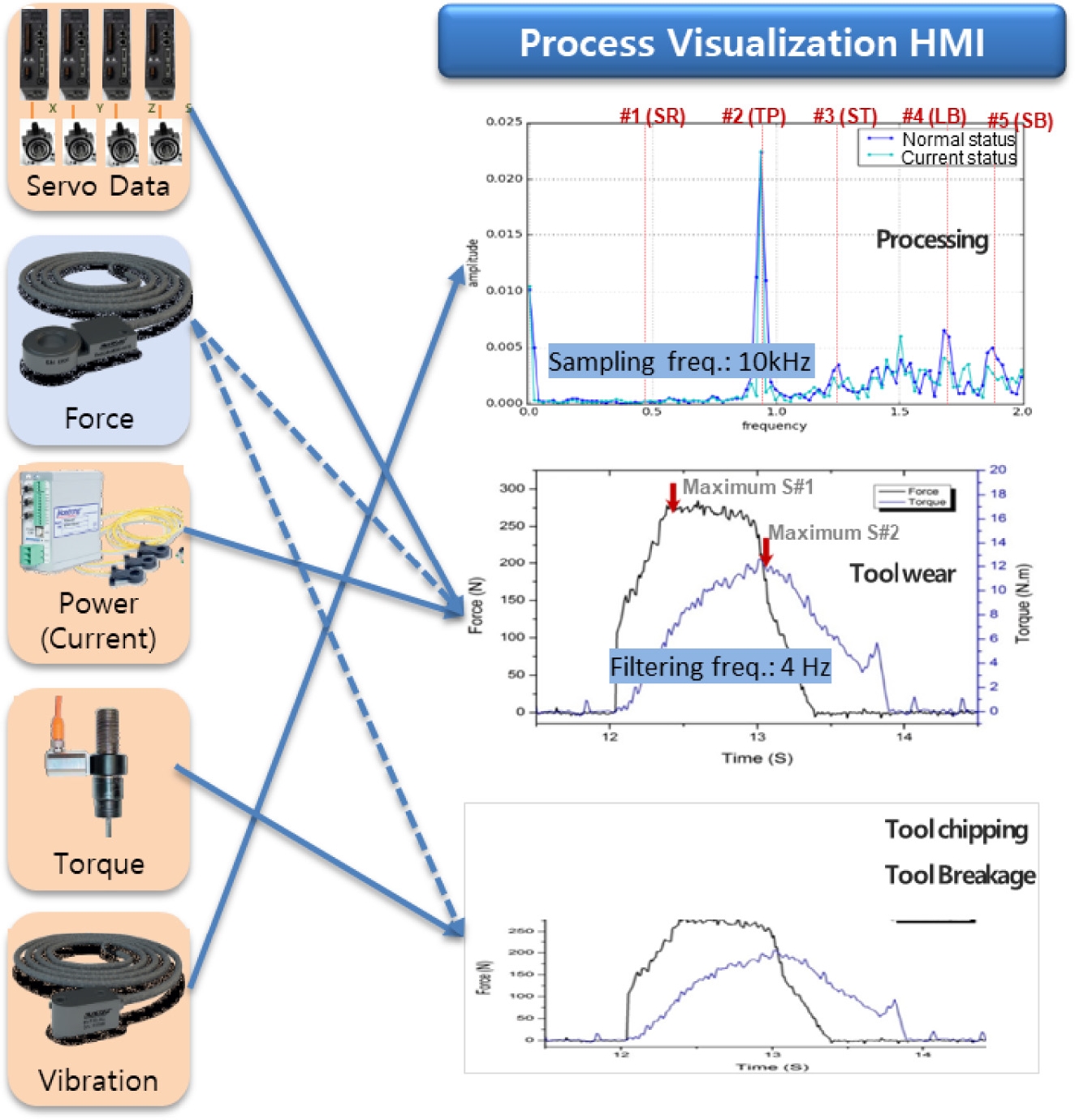

Fig. 21은 CFRP 가공장비의 건전성을 포함한 가공공정의 모니터링을 위하여 건전성 인덱스를 추출하기 위한 모니터링 설계안이다.

Fig. 21Health index planning for CFRP machine and machining process

측정 대상과 센서는 이송모터의 모터 토크값, 절삭력 (공구동력계), 절삭 추력(전류센서), 스핀들 부하(토크센서), 진동 주파수 와 크기(가속도계)이며, 고가의 공구동력계는 신호의 검증용으로 사용한다. 또한, 공정 가시화전략으로 진동신호는 FFT 프로파일을 정상상태와 현재 상태를 동시에 보여주어서 한계범위를 초과하는지를 검사하게 하고, 절삭 추력과 이송모터 토크는 공구 마모 진행상황을 %로 보여주며, 스핀들 부하 값은 공구 인선 치핑과 파손 신호로 사용한다. 최종적으로 CFRP 가공 장비와 공정 건전성 인덱스는 3종으로 세분하여 제시하고자 한다. 가공장비 지시인자(Machine Health Index), 공구 마모 지시인자(Tool Health Index), 가공물 지시인자 (Workpiece Health Index)로 통합 모니터링 하고자 한다.

Fig. 22는 CFRP 드릴가공시 공구 마모 지시인자를 도출하기 위한 설계안이다.

Fig. 22Tool health index planning for CFRP drilling process

4. 결론

CFRP의 드릴링 가공시 적층된 소재의 박리, 미절삭 등의 가공 결함을 최소화하거나 방지하고, 고가의 CFRP 전용 공구의 마모 추정을 위한 공정 모니터링을 지원하는 개방형 제어기를 개발하였으며, CFRP 소재에 특화된 가공공정 모니터링을 구현하였다. 또한, CFRP 가공장비의 건전성을 포함한 가공공정의 모니터링을 위하여 건전성 인덱스를 추출하기 위한 모니터링 설계안을 제시하였다. 향후, 충분한 CFRP 가공공정 데이터로부터 추출한 지시인자를 정제하여, 가공 공정시간단축 및 공작기계 부품 손상의 방지, 공구 마모 모니터링이 가능한 시스템을 상용 공급할 예정이다.

ACKNOWLEDGMENTS

본 연구는 산업통상자원부의 시스템산업 미래성장동력 사업의 일환으로 수행되었다[10053248, 과제명: 탄소섬유 복합재(CFRP) 가공시스템 개발].

REFERENCES

- 1.

Kim, W. and Sung, M., “Evaluation of EtherCAT Clock Synchronization in Distributed Control Systems,” Transactions of the Korean Society of Mechanical Engineers A, Vol. 38, No. 7, pp. 785-797, 2014.

10.3795/KSME-A.2014.38.7.785

- 2.

Lee, J., Kim, C., Kim, I., Kim, Y., and Kim, T., “Implementation and Validation of EtherCAT Support in Integrated Development Environment for Synchronized Motion Control Application,” Transactions of the Korean Society of Mechanical Engineers A, Vol. 38, No. 2, pp. 211-218, 2014.

10.3795/KSME-A.2014.38.2.211

- 3.

Omative Systems, “Adaptive Control and Monitoring(ACM) System for CNC Metal Cutting Optimization,”

http://www.omative.com/avcm (Accessed 18 DEC 2018)

- 4.

- 5.

Toyozawa, Y., Maeda, K., and Sonoda, N., “Tandem Control Method Based on a Digital Servomechanism,” US Patents, No. 5646495A, 1997.

Biography

- In Hugh Choi

Director in CNC biz. division, CSCAM Co., Ltd. His research interest is CNC, Motion Control System and Electric Vehicle Motor.

- Keyong Hoon Lee

Research Engineer in CNC biz. division, CSCAM Co., Ltd. His research interest is Motion Control System and Electric Vehicle Motor.