ABSTRACT

Since most commercialized DLP 3D printers fabricate 3D structures by sinking materials to Vat using a bottom-up method, it is difficult to use various materials simultaneously and there are many restrictions on printing composite materials. Especially, composite resin mixed with various functional powders in photo curable resin generally has high viscosity, causing difficult material flow in the bottom-up method when using Vat. Additionally, most of the previously presented methods for fabricating multi-material structure use individual curing for each material, so the adhesion force at the contact surface is less than 50% compared to single material. Thus, in this paper, we propose a new type of DLP 3D printer that combines Material Extrusion and the DLP system. The proposed equipment can supply high viscosity composite material resins to a specific area to cure various materials simultaneously. This method will enable fabrication of multiple composite material structures with sufficient adhesion force. The tensile test will be performed to verify suitability of the proposed method.

-

KEYWORDS: Multi-material, Composite material, High viscosity resin, Material extrusion, DLP printer

-

KEYWORDS: 다종 재료, 복합 재료, 고점도 수지, 재료 압출, DLP 프린터

1. 서론

자외선과 광중합 반응을 일으키는 액상 수지(Resin)를 면 단위의 빔 프로젝터 또는 점 단위의 레이저로 조형하는 광경화 방식 3D 프린터는 빠르고 정밀한 공정이 가능하여 많이 활용되고 있다. 그러나 일반적으로 액상 수지를 수조에 침지하여 재료를 공급하는 방식이기 때문에 원활한 재료 공급을 위해 사용 가능한 소재가 주로 저점도 단일 소재로 제한적이다.

최근에는 다양한 산업에 활용될 수 있는 3D 프린팅 소재로 기본 광경화 수지에 세라믹, 카본 파이버, 금속 등의 기능성 분말을 혼합한 복합소재에 관한 연구가 활발하다.

1-3 하지만, 일반적으로 마이크로 혹은 나노 사이즈의 미소 분말 소재를 혼합할 경우 수지의 흐름성을 방해하여 점도가 급격히 증가하게 된다. 이에 기존 복합소재 프린팅 연구에서는 주로 점도를 낮추기 위한 다양한 방법들이 시도되었다. 가장 많이 시도되면서 동시에 경화 특성에 크게 영향을 미치지 않는 방법은 분말 사이즈 분포를 조절함과 동시에 분산제를 도포하는 것이다.

4,5 이를 통해 동일 분말 함량에서 점도를 50%가량 낮추는 것이 가능하였다. 하지만, 여전히 기존 장비에서 출력 가능한 수준의 저점도를 유지하기 위해서는 첨가 가능한 분말의 최대 함량이 제한적이다. 특히, 복합소재는 혼합하는 분말의 비율에 따라 기능성 및 물리적 특성 개선 정도가 달라지기 때문에 고기능성 구조물 출력을 위해서는 더욱 높은 함량의 분말 혼합이 가능해야만 한다. 이에 Wang, J. C. 등이 최근 발표한 논문에서는 더 높은 함량의 분말 함유 광경화 수지를 위해서 솔벤트인 메틸알코올을 함께 혼합하여 점도를 개선하고자 하였다.

6 하지만, 이 경우에도 고함량 복합 수지의 경우 상당히 높은 점도를 지니게 되어 기존 상용 DLP (Digital Light Processing) 장비로는 출력이 어렵게 된다.

또한 기존 대부분의 DLP 공정은 단일 소재에 국한된 출력만이 가능하였다. 다양한 기능성 소재에 대한 출력 시도가 이루어지면서 점차 다종 재료 출력에 대한 요구도 증대되고 있다. 이러한 다종 재료 출력은 현재까지는

Fig. 1에 보인 것과 같은 재료 분사(Material Jetting, MJ) 방식이나 재료 압출(Material Extrusion, ME) 방식에서 주로 많이 이루어졌다. 하지만, 이러한 출력 방식으로는 높은 정밀도를 유지한 채 분말이 혼합된 복합 재료를 출력하는 것이 불가능하였다. 기존 DLP에서는 주로 재료가 담긴 수조를 이동시키면서 소재를 변경하여 다종 재료 출력을 진행하였다.

7-9 하지만, 이러한 방식의 경우 사용되는 소재의 개수에 비례하여 장비 크기가 커진다는 문제로 인해 2, 3종 이상의 재료에 적용하는 것은 공간적 제약으로 매우 어렵게 된다. 또한, 재료 수조가 이동하면서 순차적으로 다종 재료가 적층되기 때문에 재료 간 물성이 다르거나 재료 간 경계면에서 충분한 중첩이 일어나지 못하면 강도와 접합면 형상 정밀도가 크게 저하된다는 단점도 지니고 있다.

9

Fig. 1 Examples of multi-material 3D printing by MJ printer

이에 본 연구에서는 앞서 제기된 다종복합소재 출력의 한계를 극복하기 위하여 새로운 형태의 장비와 공정을 제안하고자 한다. 제안 공정은 다양한 복합소재 출력이 가능하도록 고점도 소재 공급 및 도포가 용이하면서 동시에 최소한의 공간 구성으로 다종소재를 동시 경화 가능하도록 구성하고자 한다. 제안된 공정의 효용성을 검증하기 위해 두 가지 고점도 복합소재로 구성된 다종소재 인장 시편을 제작하고 이를 기존 공정 시편과 비교 실험하였다.

2. 다종복합소재 압출식 DLP 3D 프린터 개발

2.1 기술 개요

앞서 언급한 바와 같이 액상 수지를 수조에 부어두고 조형을 진행하는 기존의 광경화 3D 프린팅 방식은 소재의 유동성이 매우 중요하므로 고점도 소재 사용이 제한적이다. 또한 부차적으로 액상 상태의 광경화 수지가 개방된 공간에 상시 노출이 되기 때문에 작업 환경적 측면에서도 많은 단점을 유발한다. 이러한 기존 상용 광경화 방식은 다량의 수지를 수조에 부은 후 공정이 진행되므로 재료 교체를 위해서는 수조 전체에 대한 기존 재료 제거와 세척, 재공급이 반복적으로 진행되어야 하므로 사실상 재료 교체가 매우 어렵게 된다. 다중 수조를 활용한 소재 교체시에도 각 소재별로 순차적으로 경화를 진행하게 되므로 각 소재의 개별 경화 과정에서 소재가 수축하는 현상이 발생하여 이종 재료 간 접합면에서 불완전한 접합으로 인해 구조적 강도가 크게 저하된다.

10

이에 본 연구에서는 고점도 복합소재를 다중으로 동시 출력 가능한 공정을 제안하고자 한다. 이를 위해 일반적으로 점도가 높은 재료의 토출이 용이한 재료 압출 방식과 조형 정밀도가 우수한 광경화 방식 각각의 장점을 살린 복합 방식을 사용하려고 한다.

11-13 즉,

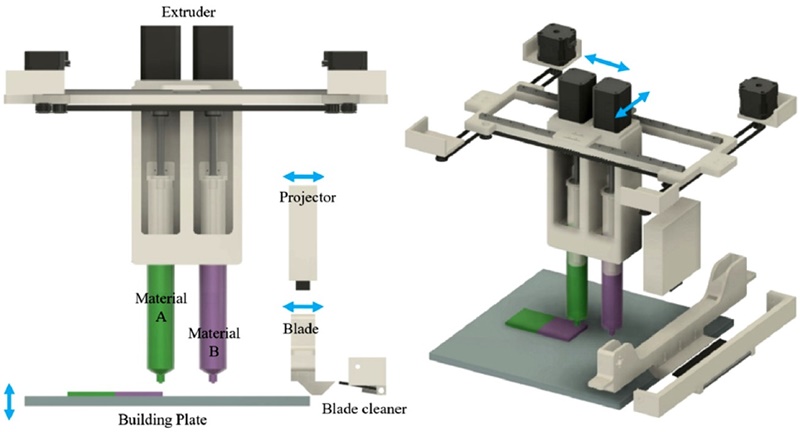

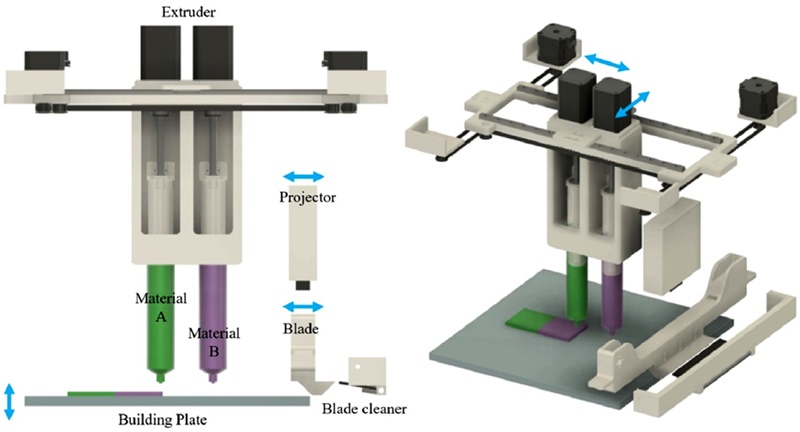

Fig. 2에 보인 바와 같이 고점도 소재의 원하는 부위로의 공급은 시린지 펌프 구조를 사용한 재료 압출 방식을 활용하고, 압출된 소재의 고정밀 형상으로의 조형은 DLP에 기반한 광중합 방식을 사용하여 새로운 방식의 3D 프린터 형태인 가칭 MEPP (Material Extrusion-Photopolymerization)를 제안한다. 이 방식은 기존 공정과 달리 고점도 액상 광경화 수지를 사용할 경우 시린지 펌프에서 토출된 후에도 어느 정도 형상을 유지한다는 점에서 착안하여 원하는 부위에 대략적인 소재 공급 후 다른 부위에 다음 소재를 공급하여 동일 층에 이종의 재료를 동시에 위치시킨 후 블레이딩 및 광경화 과정을 다종소재에 대해 동시 진행하는 방식이다. 이는 기존 순차 경화와 달리 이종 재료가 동시 수축 경화되면서 경계면에서 간극이 생기지 않는 데다가 소재 간 경계면에서 소재 혼합이 일부 자연스럽게 일어남으로써 이종소재 간 결합력이 비약적으로 개선될 것으로 기대된다. 또한, 별도의 수조나 조형물 세척 과정이 불필요하므로 조형 속도도 기존 상용 장비 대비 큰 차이가 없을 것으로 예상된다.

Fig. 2Schematic diagram of MEPP 3D printer

제안된 MEPP 장비의 각 파트는 크게 재료 압출용 시린지,광경화용 DLP 프로젝터, 소재 블레이드, 블레이드 세척부, 조형 베드로 구성된다. 각 파트는 상호 동작에 방해가 되지 않는 한도에서 공간 효율성을 최대한 높일 수 있는 구조로 배치하였고 PC와 아두이노를 활용하여 제어하였다.

2.2 장치 구성

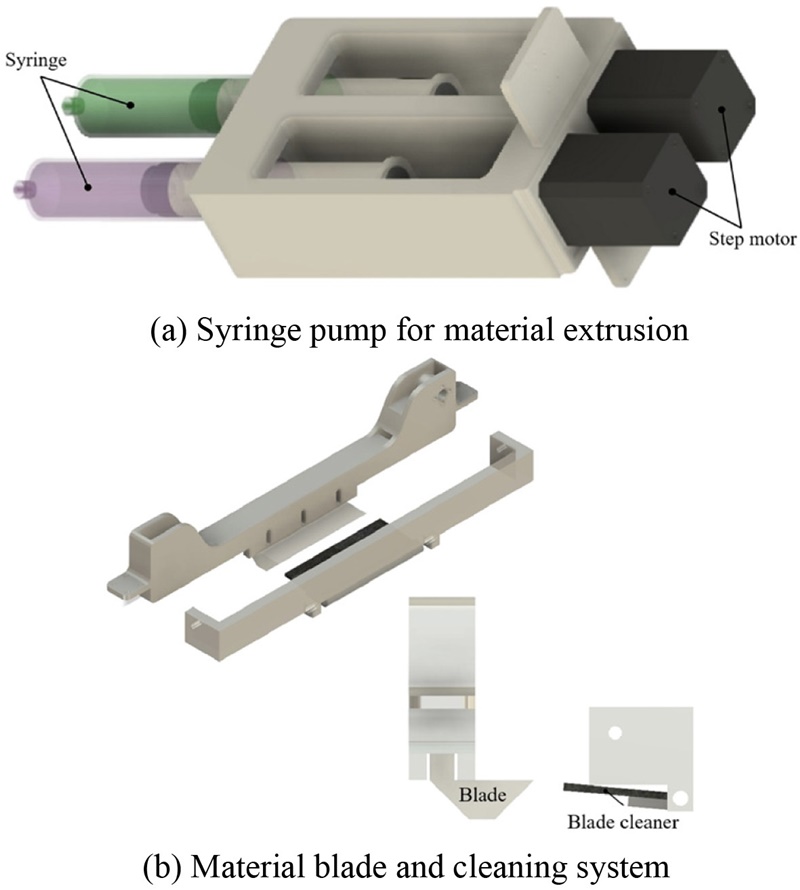

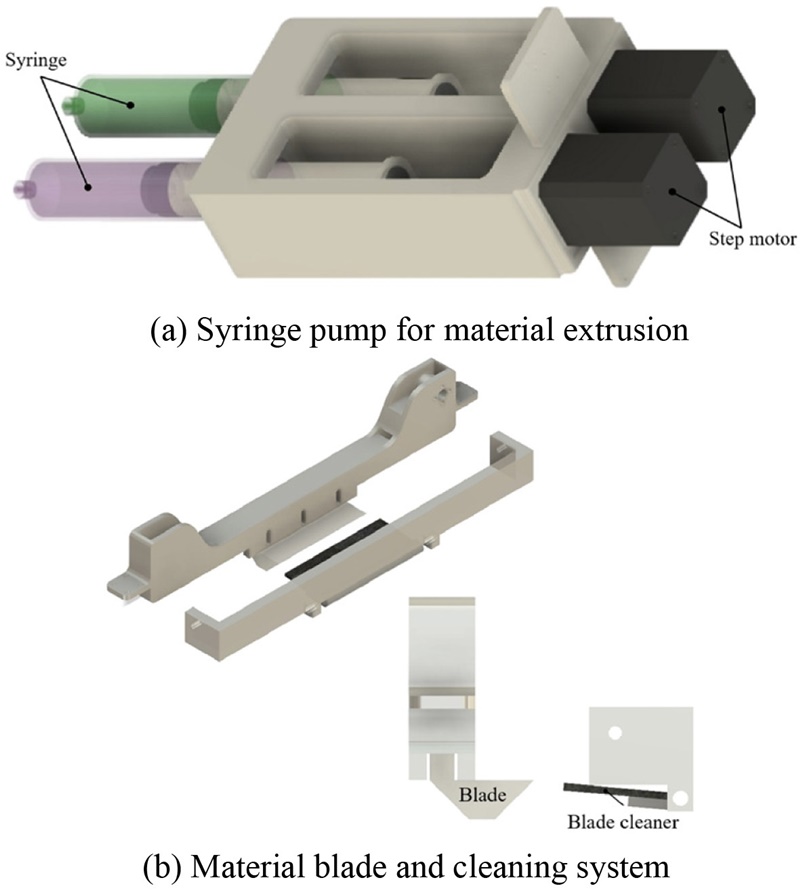

2.2.1 압출용 시린지 및 조형 베드

원활한 다종복합소재 3차원 형상 조형을 위해

Fig. 3(a)에 보인 바와 같은 2개의 시린지 펌프를 H-Bot 구조

14 이송부에 설치하여 고점도 재료를 선택적으로 원하는 위치에 공급하였다. 우선은 이종소재를 출력하는 것을 목표로 하였으며 일반 재료 압출형 프린터와 달리 재료 압출부가 형상 정밀도를 결정하는 부분은 아니기 때문에 고점도 재료 공급이 용이하도록 토출부 직경은 0.7 mm 내경을 가진 중공관을 사용하였다. 시린지 펌프를 통한 균일한 재료 공급을 위해 2상 스텝 모터(Aplus, Nema 17 6.0)를 사용하였으며 충분한 전류 공급과 위치 제어를 위해 마이크로 스텝용 드라이버(Aplus, A4988)를 사용하였다. 이를 통해 실험결과 20,000 cps 이상의 점도 소재까지 무리 없이 압출이 가능함을 확인하였다.

Fig. 3Main part for the material supply

공급된 재료를 3차원으로 적층하기 위해 H-Bot 구조의 수평 이송부 아래에 수직으로 이송가능한 조형 베드를 설치하였다. 조형 베드는 소재 압출부뿐만 아니라 광경화부에서도 매 층 적층 시마다 적절한 높이로 이송되어야 하므로 독립 동작 구조로 제작되었다. 이를 위해 조형 베드 양쪽에 2개의 스텝 모터를 설치하여 재료가 적층됨에 따라 조형 베드의 무게가 증가하더라도 정밀한 이송을 가능케 하였다. 조형 베드의 크기는 사용된 DLP 프로젝터에서 조형 가능한 최대 면적인 89.6 × 56 mm2를 기준으로 좀 더 크게 제작하였으며 최대 적층 높이는 50 mm를 기준으로 수직 이송부를 설계하였다. 이 경우 최대 면적으로 조형 시 필요한 소재 부피는 250.88 cc이므로 장비 크기를 고려하여 이종소재를 동시 출력할 경우 최대 1회 수준의 재료 교체가 이루어지도록 시린지 펌프의 용량은 60 cc로 선정하였다.

2.2.2 광경화 DLP 프로젝터

UV 광경화 수지 기반 복합소재의 고정밀 형상 조형을 위해서 상용 DLP 프로젝터를 사용하였다. 제안된 장비는 재료 수조에 기반한 기존 상용 광경화 방식 프린터와 달리 재료 압출을 위한 시린지 구조가 조형 영역 위를 자유롭게 움직이기 위한 공간 확보가 필수적이다. 하지만, 시린지 이송부 상부에 DLP 프로젝터를 위치시킬 경우 초점거리 증가로 인해 픽셀 사이즈가 상대적으로 커지게 되어 정밀한 형상 조형이 어렵게 된다. 이에 재료 압출부 공간 및 DLP 프로젝터의 초점거리 확보 그리고 장비 크기 최소화를 위해 DLP 프로젝터가 수평 이송이 가능하도록 구조를 설계하였다. 이를 통해 재료 압출 시에는 DLP 프로젝터가 장비 구석으로 이송되어 대기하다가 광경화 시에만 조형 영역 위로 이동하여 재료를 경화함으로써 ME (Material Extrusion)와 PP (Photopolymerization) 구조가 상호 간섭없이 순차 동작이 가능하도록 하였다.

사용된 DLP 프로젝터는 앞서 설명한 이송 동작 구조에 장착이 용이하도록 크기가 작고 발열량이 적은 LED 광원 기반의 WXGA급 프로젝터(캐리마, CE-12)를 사용하였다. 해당 장비는 광원으로 405 nm 파장을 지니는 2 W급 LED를 사용하고 있으며 DLP 해상도는 1280 × 800이다. 조형 영역에서 충분한 정밀도와 광출력을 확보하기 위해 픽셀 사이즈는 70 mm가 되도록 초점거리를 설정하였으며 이때의 최대 조형 면적은 89.6 × 56 mm2이다. 장시간 사용 시 안정성을 확보하기 위해 광파워는 최대 출력의 80% 수준으로 고정하였으며 이때 조형면에서 UV 광량 측정기(USHIO, UIT-250)로 실측된 광출력은 6 mW/cm2이다.

2.2.3 소재 블레이드 및 세척부

제안된 장비는 Top-Down 형태로 적층이 이루어지므로 재료 공급 후 적층 두께를 일정하게 유지하기 위해 블레이드를 설치하였다. 장착된 블레이드의 왕복 수평 이동을 통해 시린지 펌프에 의해 압출된 재료 표면을 균일한 두께로 평탄화하였다.

15 매번 균일하고 평탄한 재료 표면을 얻기 위해서는 블레이드의 청결도 유지가 매우 중요하다. 이를 위해 블레이드 세척부를 추가하여 매 층마다 자동으로 세척 과정이 이루어지도록 하였다. 이러한 세척부는

Fig. 3(b)에 보인 것과 같이 탄성이 있는 고무 소재로 제작하여 조형 영역 바깥쪽에 고정하였다. 이를 통해 블레이딩 후 원위치 이동만으로 블레이드에 남아있는 잔여물이 세척이 되도록 하였다. 또한, 공정 중 혹은 세척 시 블레이드 오염을 최소화하기 위해 일반적으로 수지에 대한 이형력이 우수하다고 알려진 테프론 재료로 블레이드 표면을 제작하였다. 최종적으로

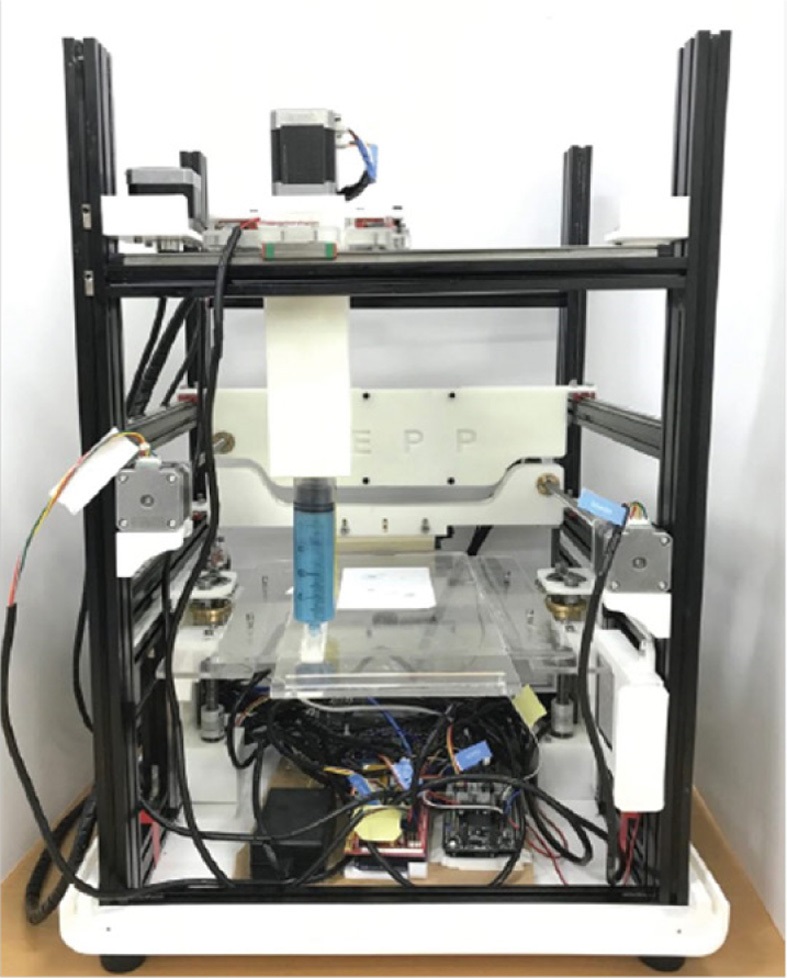

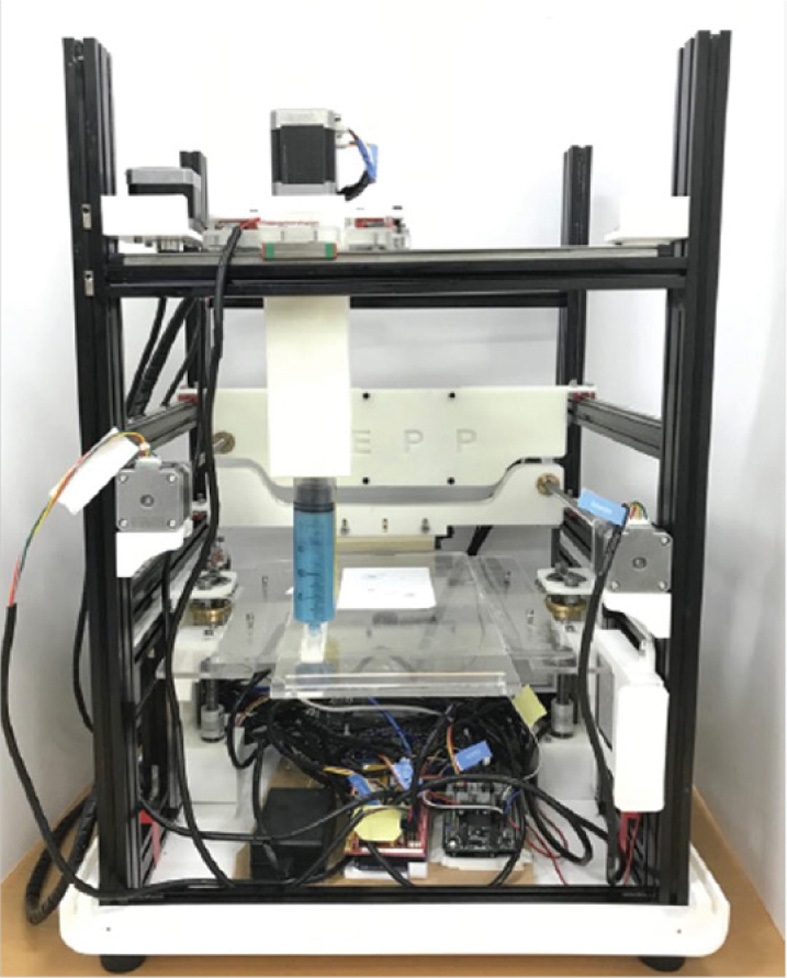

Fig. 4에 보인 것과 같이 장비를 제작하였으며 구체 사양은

Table 1과 같다.

Fig. 4MEPP 3D printer

Table 1Specification of proposed MEPP equipment

Table 1

|

Machine size |

440 × 470 × 635 mm |

|

Build size |

89.6 × 56 × 50 mm |

|

X-Y pixel resolution |

70 μm |

|

Curing power |

6 mW/cm2 at 405 nm |

|

Volume per syringe |

60 cc |

|

Extrusion nozzle dia. |

0.7 mm |

2.3 복합소재 제작

일반적으로 광경화성 복합 수지는 광경화성 수지에 기능성 분말을 혼합하여 제작된다. 본 제안 장비에 적절한 DLP 경화용 고점도 상용 소재가 없는 관계로 본 연구에서는 제안 공정 및 장비의 타당성을 확인하기 위해 복합소재를 별도로 제작하였다. 기능성 증대를 위해 분말의 함량 비율을 높일 경우 점도가 비약적으로 증가한다. 따라서 분말 함량은 최대한 높이면서 유동성을 확보하기 위해 기본 광경화 수지는 상온에서 300-500 cps 수준의 점도를 가지는 상용 투명 수지(TINT, STD-Resin)를 사용하였다. 여기에 일반적으로 기본 수지와 혼합 시 경화가 용이한 실리카 분말(DAIHAN Scientific, SI.5210)을 혼합하였다. 공정 중 소재 간 밀도 차이에 의한 침강 현상 등을 최소화하면서 동시에 미소 표면적으로 인한 뭉침 현상을 방지하기 위해 분말의 직경 분포는 D50 35.45 μm, D90 48.30 μm인 제품을 사용하였다. 이는 일반적인 광경화 조형 공정에서 사용하는 각 층의 적층 두께인 50-200 μm보다 작으므로 소재 도포에도 큰 무리가 없을 것으로 판단된다. 최종적으로 이종소재 조형의 가능성을 확인하기 위해 앞서 제시된 소재에 각각 노란색과 회색의 액상 안료를 첨가하여 서로 다른 색상의 이종 수지를 제작하였다. 혼합되는 분말이나 기본 수지를 달리하여 물성이 다른 이종소재를 제작할 경우 재료에 따른 특성이 결과에 크게 영향을 미치게 되므로 장비 자체의 특성 파악이 어려울 수 있어서 본 연구에서는 동일 소재에 색상을 달리한 것으로 실험을 진행하였다.

준비된 소재를 혼합 시 실리카 분말의 함량을 과도하게 높일 경우 점도가 급격히 상승하면서 재료 토출에 많은 문제가 발생하였다. 이에 본 연구에서는

Table 2에 제시한 바와 같이 수지와 혼합 분말의 부피비를 약 1 : 1로 고정하였다. 이렇게 혼합된 분말과 수지는 고르게 분산되도록 충분히 교반 후 압출용 시린지 펌프에 투입하였다.

Table 2Density and volume ratio of the mixed materials

Table 2

|

Material |

Density (g/cc) |

Volume ratio (%) |

|

Silica powder |

2.5 |

50 |

|

Base resin |

1.06 |

49.75 |

|

Color ink |

- |

0.25 |

2.4 적층 공정

Table 3에 보인 것처럼 제작된 복합소재 각각에 대한 UV 조사 시간별 경화 두께 측정을 진행하였다. 그 결과 사용 중인 DLP의 광출력이 충분하므로 제작된 소재를 경화하는데 문제가 없음을 확인하였다. 이에 본 실험에서는 시편 제작의 편의성을 위해 각 적층 두께를 300 μm로 고정하여 사용하였으며 이때의 노광 시간은 경화가 상대적으로 느린 소재의 경우에도 충분한 층간 결합이 발생할 수 있도록 6초로 고정하여 진행하였다.

Table 3Cured depth according to UV exposure time

Table 3

|

UV exposure time (s) |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

Yellow

(μm) |

258 |

314 |

472 |

534 |

654 |

695 |

785 |

Gray

(μm) |

314 |

480 |

594 |

675 |

712 |

811 |

826 |

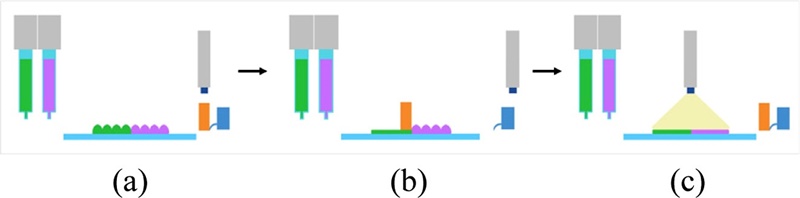

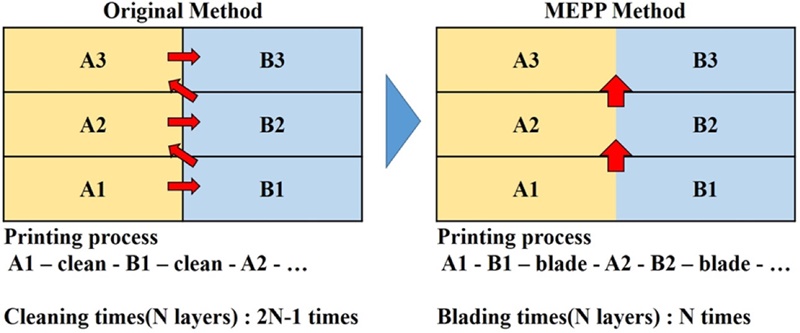

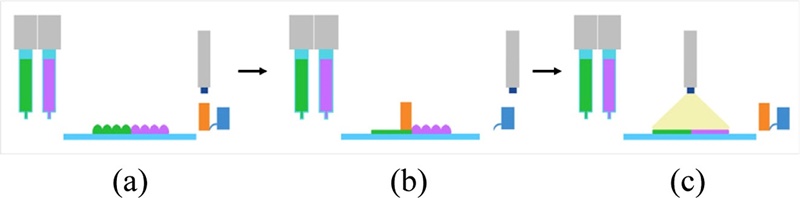

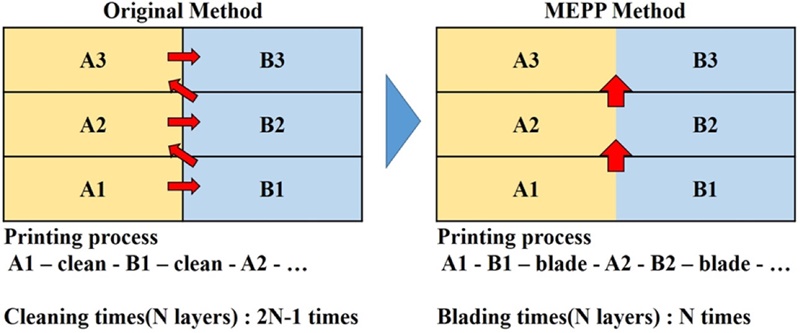

하나의 적층 단면에 두 소재가 동시에 공급되어 경화되어야 다종복합소재 구조를 제작할 수 있기 때문에

Fig. 5에 보인 것과 같은 순서로 적층을 진행하였다. 먼저 각각의 고점도 복합소재를 원하는 위치에 순차적으로 압출한다. 그 다음 소재 블레이드가 압출된 재료 위를 적층 두께인 300 μm만큼 간격을 두고 지나가면서 평탄화 공정을 진행하게 된다. 이후 오염된 블레이드는 고정되어 있던 세척용 고무 브러시에 닿으면서 잔여물이 닦이게 된다. 마지막으로 광경화 DLP 프로젝터가 조형 위치로 이동하여 6초 동안 해당 적층 단면 형상을 UV 조사한다. DLP 프로젝터 영상이 꺼지고 다시 원위치로 돌아가면 한 층이 완성된다. 이 과정을 반복하여 3차원 구조물을 제작한다. 최종 출력물은 IPA에 충분히 담가 미경화부를 세척 후 건조 과정을 거쳐 완성하였다.

Fig. 5Schematic diagram of the suggested MEPP process: (a) Composite materials extrusion, (b) Resin flattened using blade, and (c) Photo curing

3. 실험 및 분석

3.1 결과물 분석

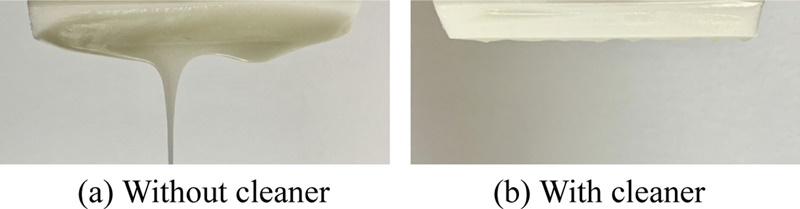

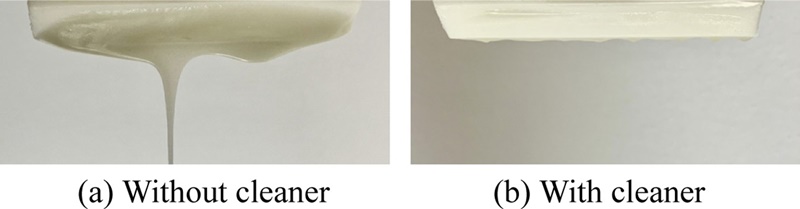

본 연구에서는 소재 간 교차 오염을 최소화하고 빠른 공정을 진행하기 위하여 고무 패드를 통한 블레이드 세척 구조를 제안하였다. 제안된 공정의 유용성을 확인하기 위해 세척부 유무에 따른 블레이드 오염 정도를 확인하였다. 그 결과

Fig. 6(a)에 보인 바와 같이 블레이드를 설치하지 않은 경우에는 블레이딩 직후 표면에 묻은 다량의 잔여 소재가 흘러내림으로써 다음 공정에 오염원으로 작용할 여지가 충분해 보이지만 세척부를 설치한 경우에는

Fig. 6(b)와 같이 대부분의 잔여 소재가 제거됨으로써 오염 정도를 크게 줄일 수 있음을 확인할 수 있었다.

Fig. 6Residual resin at blade according to cleaner

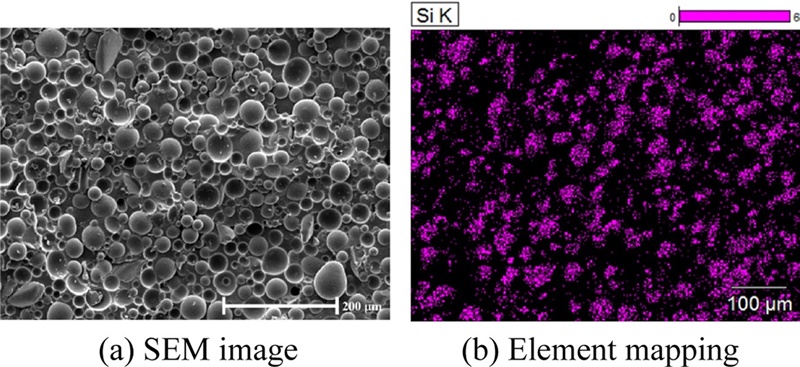

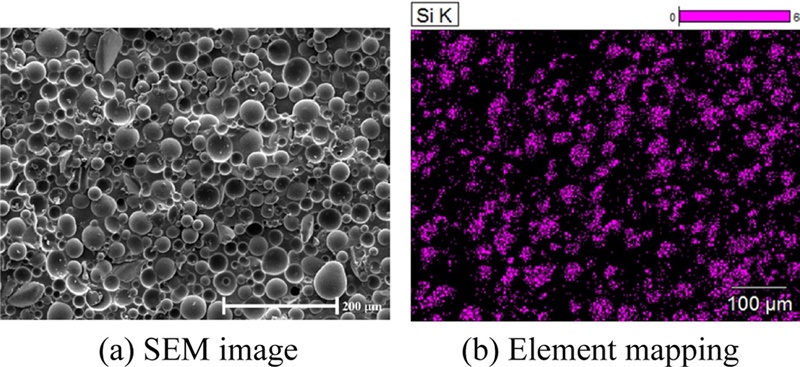

또한, 본 연구에서 사용된 소재와 같이 분말이 혼합된 복합소재의 경우 공정 중 침강 문제가 크게 대두되므로 이에 대한 확인을 진행하기 위해 출력된 시편을 파단하여 단면을 전자현미경으로 촬영 후 원소 매핑을 통해 분산 정도를 확인하였다. 적층 공정은

Fig. 7(a)의 좌측에서 우측 방향으로 이루어졌으며 3개 층에 해당하는 영역을

Fig. 7(b)에 보인 바와 같이 실리카 원소 매핑으로 관찰한 결과 별다른 침강 문제나 분산도 문제를 관찰할 수 없었다. 이는 높은 분말 함량으로 인해 상용 수지에 비해 점도가 크게 증가함으로써 침강 현상이 감소되었기 때문이다.

Fig. 7Powder distribution after printing

3.2 인장시험

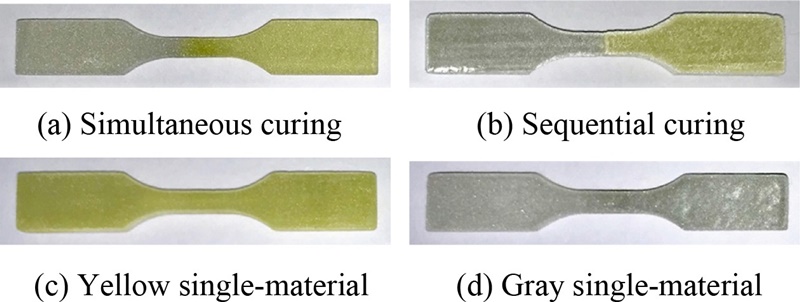

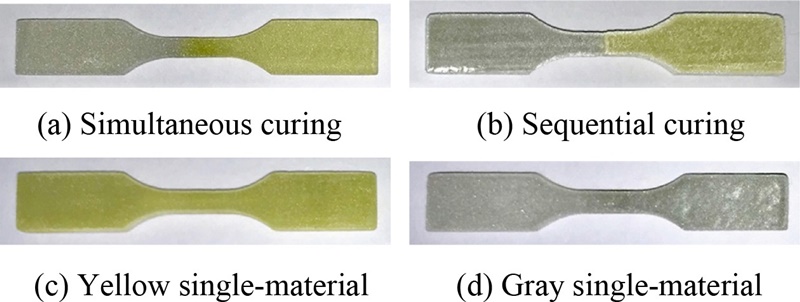

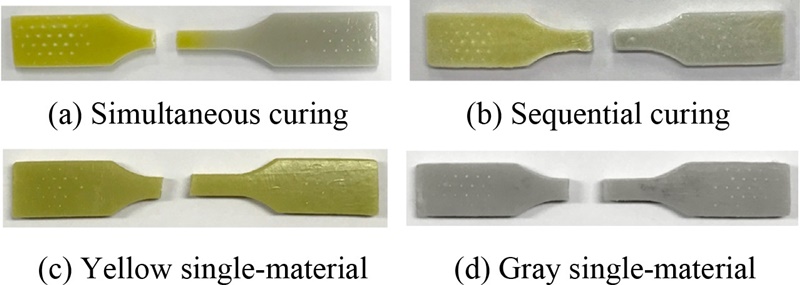

기존 연구들에서 이종소재를 순차 경화한 경우 소재 간 접합부에서 결합력이 크게 떨어지는 것을 확인하였다. 이에 본 제안 공정의 실효성을 검증하기 위해

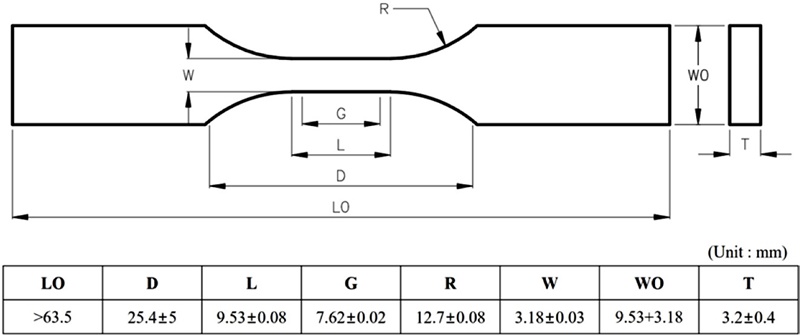

Fig. 8에 보인 것과 같이 기존 다종소재 출력 방식과 동일한 방법으로 경화한 순차 경화 시편과 제안 공정으로 출력한 동시 경화 시편을 각각 제작하여 소재 간접합부에 수직 방향으로 인장시험을 진행하여 그 결합력을 측정하였다. 즉, 순차 경화 시편은 먼저 회색 복합소재를 압출 후 블레이딩을 하고 인장 시편의 절반 영역에 해당하는 이미지를 조사하여 국부 경화한다. 이후 미경화된 영역에 잔류하는 소재를 IPA로 충분히 세척하여 제거한다. 다음으로 노란색 복합소재를 해당 영역에 압출 후 이전과 동일한 공정을 반복하여 한 층을 완성하게 된다. 반면에 동시 경화 시편은 앞서 2.4절에 설명한 바와 같이 회색과 노란색 복합소재를 각각 해당 영역에 압출을 진행한 후 한 번에 블레이딩과 경화를 진행하여 시편을 제작한다. 이와 별개로 제작된 복합소재 자체의 물성을 파악하기 위하여 단일 재료 시편도 별도 출력하여 비교 평가하였다. 출력 시 경화 순서 외에는 모두 동일한 조건을 유지하기 위하여 소재 및 경화 시간, 경화 출력, 장비 구성 등은 고정하여 진행하였다. 현재 제작된 MEPP 장비의 최대 조형 영역이 89.6 × 50 mm

2이고 사용된 소재가 실리카 분말이 들어간 취성 성질을 가진 재료이므로

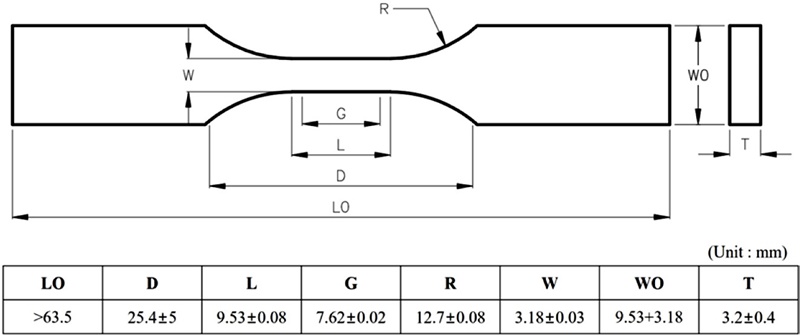

Fig. 9에 보인 것과 같이 ASTM D638 인장시험 규격 중 Type V 시료 형태로 출력을 진행하였다. 출력한 시편은 색상 차이에 의해 경화 정도에서 차이를 보일 수 있으므로 IPA로 세척 후 경화기에 넣어 2시간 30분간 동일하게 충분히 경화하였다. 시험 시편은 오차를 줄이기 위해 모두 3개씩 출력하여 인장시험하였다.

Fig. 10과 같이 출력된 시편의 물성 시험을 위해서 만능 재료시험기(DRTECH, DR-101)를 이용하여 인장시험을 진행하였다. 인장시험 속도는 1 mm/min로 고정하였다.

Fig. 8Build-up sequence for multi-material

Fig. 9Design of ASTM D638 type V specimen

Fig. 10Printed tensile specimen

3.3 인장시험 결과

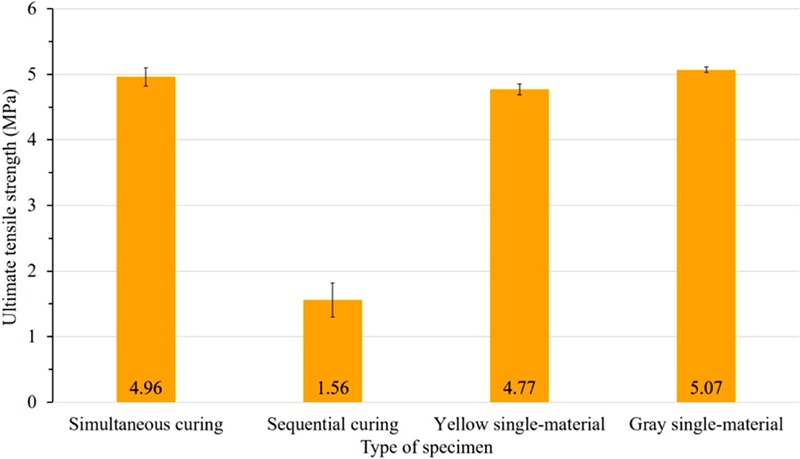

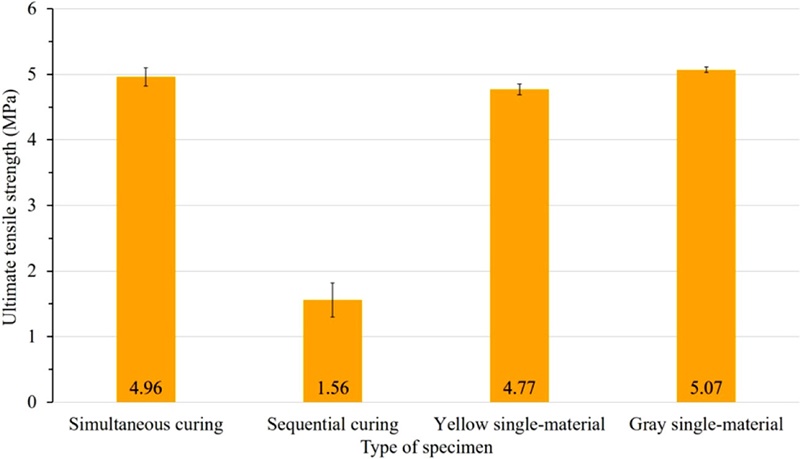

인장시험 결과는

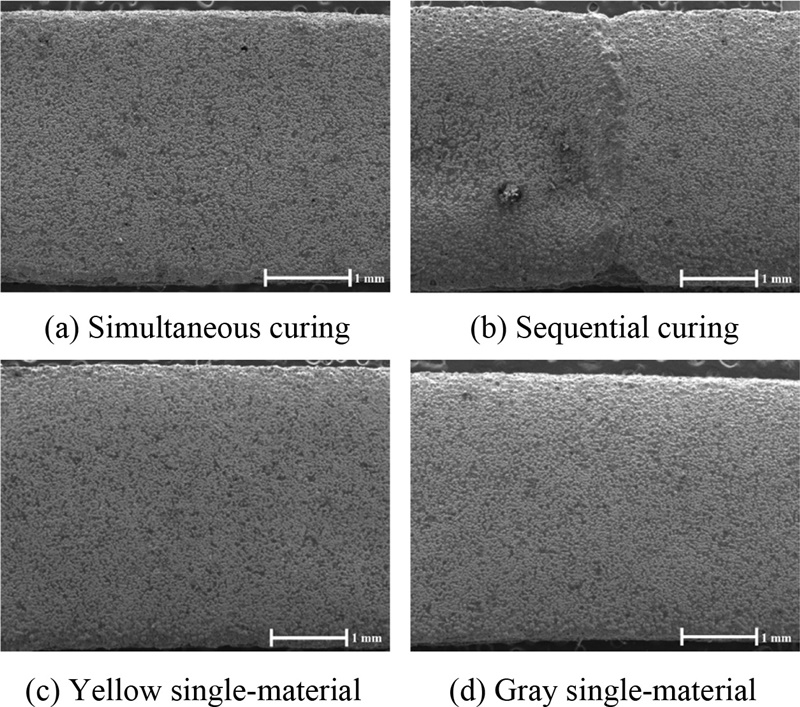

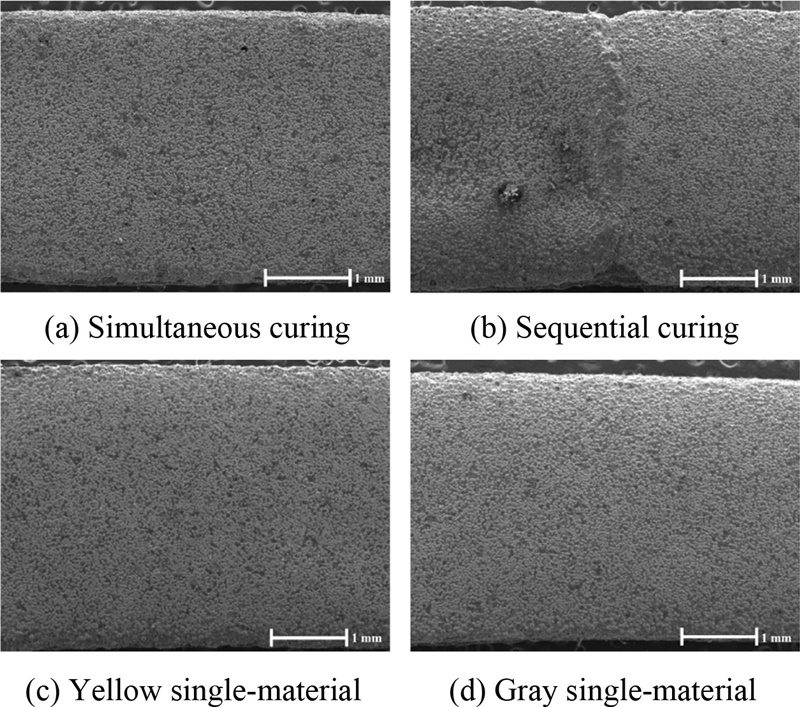

Fig. 11과 같이 측정되었다. 단일 소재의 경우 모든 소재 조성이 동일하고 안료 색상만 다르기 때문에 두 소재 간 인장 강도의 차이는 약 6% 정도로 차이가 작았다. 이는 앞선 광경화 두께 테스트의 같은 경화 시간에서 회색 수지의 경화 두께가 두꺼운 결과를 보였으나 후경화 과정을 통해 이 차이가 보완되었기 때문이다. 하지만, 순차 경화 시편의 경우에는 단일 소재 시편의 절반 이하의 인장 강도로 확연히 낮은 결과값을 보였다. 이는 이전 연구들에서 언급된 바와 같이 순차 경화 방식으로 조형 시 소재의 수축으로 인해 경계면의 수지 분자 간 결합력이 약해지기 때문이다. 경계면을 전자주사현미경(Tescan, Tescan Vega3)을 이용하여 촬영한 결과

Fig. 12(b)에서 볼 수 있듯이 순차 경화 시편의 경우 타 시편과 달리 소재 간 경계면이 뚜렷하게 나타났다. 반면,

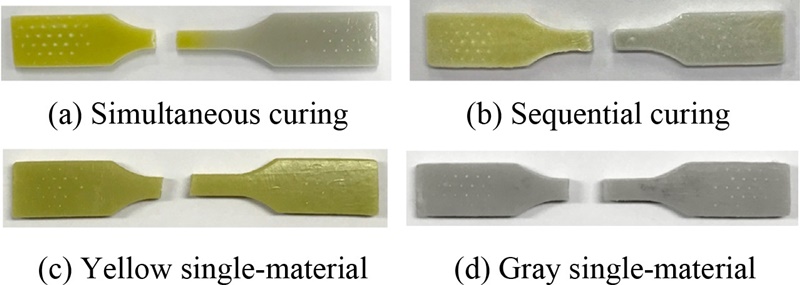

Fig. 12(a)에서 보듯이 동시 경화 시편의 경우에는 단일 소재 시편의 경우와 동일하게 경계면이 관찰되지 않았다. 이러한 이유로 인해 순차 경화 시편은 인장시험 후 시편의 파단 지점 및 형상 또한 타 시편과 다른 양상을 보였다.

Fig. 13에서 볼 수 있듯이 동시 경화 시편 및 단일 소재 시편의 경우에는 반복 인장시험 시 파단 지점 및 형상이 무작위로 발생하였다. 하지만, 순차 경화 시편의 경우에는 모든 경우의 인장시험에서 동일한 지점인 소재 경계면을 따라서 파단이 발생하여 경계면에서의 결합력이 타 부위에 비해 확연히 낮음을 확인할 수 있었다.

Fig. 11Result of the tensile strength test

Fig. 12SEM image of printed specimen

Fig. 13Specimens after tensile test

반면, 동일하게 이종소재를 이용하여 조형하였지만 본 연구에서 제안된 MEPP 장비와 공정으로 동시 경화한 시편의 경우에는 개별 소재를 인장시험한 결과와 4% 정도의 차이만 보여 단일 소재 시편의 물성과 크게 다르지 않은 강도를 보임을 확인할 수 있었다. 즉, 이는 제안된 공정을 통해 이종복합소재 구조물을 제작할 경우 소재 간 결합력 저하를 최소화하고 소재 고유의 강도를 지니는 구조물 제작이 가능함을 확인하였다.

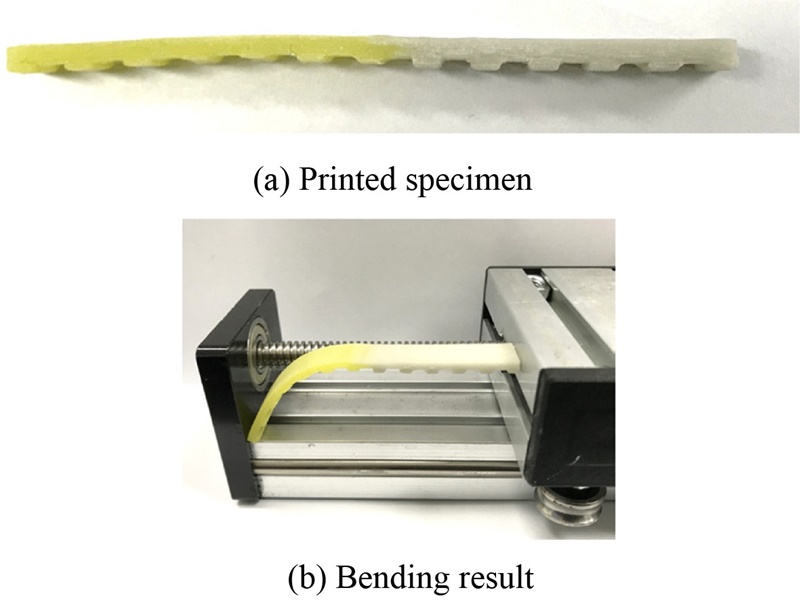

3.4 이종소재 출력

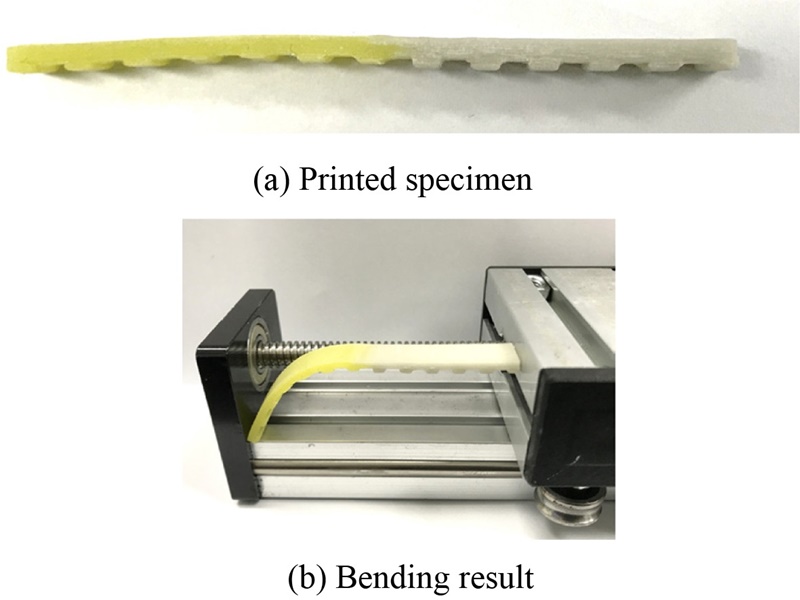

본 연구를 통해 제안된 장비 및 공정으로 다종복합소재 출력 및 물성 확보가 원활히 가능함을 확인하였으므로 이를 기반으로 실제 기계적 물성 및 분말 함량이 상이한 이종소재에 대한 동시 출력을 진행하였다. 이를 위해

Fig. 14(a)에 보인 것과 같이 길이 80 mm의 막대형 구조를 출력하였다. 출력 시 우측 영역에는 앞선 실험들에서 사용된 상용 투명 수지에 회색 안료를 첨가한 후 50 Vol%의 실리카와 혼합한 복합소재를 사용하였으며 나머지 좌측 영역에는 상용 유연 수지(Flexible Resin, XYZ)에 노란색 안료를 첨가한 후 25 Vol%의 실리카와 혼합한 복합소재를 각각 사용하였다. 출력물을 1축 이송 스테이지에 장착하여 이송을 통한 굽힘을 유도한 결과

Fig. 14(b)에 보인 바와 같이 유연 복합 수지 부분인 노란색 영역만 굽힘이 발생하고 강도가 상대적으로 높은 회색 부분은 변형이 관찰되지 않았음을 볼 수 있다. 또한, 소재 물성이 바뀌는 출력물의 가운데 부분에는 두 소재가 블레이딩 공정 중 자연스럽게 혼합된 복합 영역이 미소 존재하여 급격한 소재 변화에 따른 물성 변화의 완충 역할을 할 수 있게 된다. 이를 통해 실제 이종 물성의 복합소재 출력도 가능함을 확인하였다.

Fig. 14Printing result of multiple composite materials

4. 결론

본 연구에서 제안하는 다종복합소재 압출식 DLP 3D 프린터는 DLP 방식의 최대 장점인 저비용으로 높은 정밀도를 지닐 수 있는 강점은 유지하면서 동시에 저점도 단일 소재만 사용이 가능했던 기존 방식의 단점을 보완한 새로운 방식의 3D 프린터이다. 본 장비에서 사용된 압출형 재료 공급 방식으로 20,000 cps 수준의 고점도 기능성 복합 수지 사용이 가능하였으며 이를 통해 분말 비율 50 Vol% 이상의 고함량 다종복합소재 사용이 가능케 되었다.

특히 본 제안 장비와 공정의 효용성을 확인하기 위하여 기존의 다종 재료 3D 프린터에서 문제시되었던 접합부 체결력과 접합면 형상 정밀도 문제를 인장시험을 통해 상호 비교 분석하였다. 그 결과 MEPP 3D 프린터의 동시 경화 방식으로 출력한 시편이 기존의 다종 재료 3D 프린터의 개별 경화 방식으로 출력한 시편보다 소재 간 결합력이 월등히 우수하여 최대 인장 강도가 약 3배 이상 우수함을 알 수 있었다. 또한 접합면의 형상 정밀도도 개선되어 단일 소재 출력물과 차이가 없었다. 이를 통해 본 제안 장비와 공정의 가능성을 확인하였으므로, 향후 실제 소재 물성이 다른 물질에 대한 출력을 진행하여 기능성 및 경사 기능 특성 등을 부여할 수 있을 것으로 기대한다.

ACKNOWLEDGMENTS

본 연구는 산업통상자원부가 지원하는 산업핵심기술 개발사업(No. 10051680, 3D 프린팅용 친환경 고강도 고분자 소재 개발)에 의해 지원되었습니다.

REFERENCES

- 1.

Joyee, E. B., Lu, L., and Pan, Y., “Analysis of Mechanical Behavior of 3D Printed Heterogeneous Particle-Polymer Composites,” Composites Part B: Engineering, Vol. 173, Paper No. 106840, 2019.

10.1016/j.compositesb.2019.05.051

- 2.

Mao, D., Chen, J., Ren, L., Zhang, K., Yuen, M. M., et al., “Spherical Core-Shell Al@ Al2O3 Filled Epoxy Resin Composites as High-Performance Thermal Interface Materials,” Composites Part A: Applied Science and Manufacturing, Vol. 123, pp. 260-269, 2019.

10.1016/j.compositesa.2019.05.024

- 3.

Scordo, G., Bertana, V., Scaltrito, L., Ferrero, S., Cocuzza, M., et al., “A Novel Highly Electrically Conductive Composite Resin for Stereolithography,” Materials Today Communications, Vol. 19, pp. 12-17, 2019.

10.1016/j.mtcomm.2018.12.017

- 4.

Zhang, K., Xie, C., Wang, G., He, R., Ding, G., et al., “High Solid Loading, Low Viscosity Photosensitive Al2O3 Slurry for Stereolithography Based Additive Manufacturing,” Ceramics International, Vol. 45, No. 1, pp. 203-208, 2019.

10.1016/j.ceramint.2018.09.152

- 5.

Chen, Z., Li, J., Liu, C., Liu, Y., Zhu, J., et al., “Preparation of High Solid Loading and Low Viscosity Ceramic Slurries for Photopolymerization-Based 3D Printing,” Ceramics International, Vol. 45, No. 9, pp. 11549-11557, 2019.

10.1016/j.ceramint.2019.03.024

- 6.

Wang, J. C. and Dommati, H., “Fabrication of Zirconia Ceramic Parts by Using Solvent-Based Slurry Stereolithography and Sintering,” The International Journal of Advanced Manufacturing Technology, Vol. 98, Nos. 5-8, pp. 1537-1546, 2018.

10.1007/s00170-018-2349-3

- 7.

Choi, J. W., Kim, H. C., and Wicker, R., “Multi-Material Stereolithography,” Journal of Materials Processing Technology, Vol. 211, No. 3, pp. 318-328, 2011.

10.1016/j.jmatprotec.2010.10.003

- 8.

Wicker, R. B. and MacDonald, E. W., “Multi-Material, Multi-Technology Stereolithography: This Feature Article Covers a Decade of Research into Tackling One of the Major Challenges of the Stereolithography Technique, Which Is Including Multiple Materials in One Construct,” Virtual and Physical Prototyping, Vol. 7, No. 3, pp. 181-194, 2012.

10.1080/17452759.2012.721119

- 9.

Park, S. W., Jung, M. W., Son, Y. U., Kang, T. Y., and Lee, C., “Development of Multi-Material DLP 3D Printer,” Journal of the Korean Society of Manufacturing Technology Engineers, Vol. 26, No. 1, pp. 100-107, 2017.

10.7735/ksmte.2017.26.1.100

- 10.

Park, S. and Moon, J. S., “Analysis of the Shrinkage and Warpage of Wafer Lens during UV Curing,” Journal of the Korea Academia-Industrial Cooperation Society, Vol. 15, No. 11, pp. 6464-6471, 2014.

10.5762/KAIS.2014.15.11.6464

- 11.

He, Y., Qiu, J., Fu, J., Zhang, J., Ren, Y., et al., “Printing 3D Microfluidic Chips with a 3D Sugar Printer,” Microfluidics and Nanofluidics, Vol. 19, No. 2, pp. 447-456, 2015.

10.1007/s10404-015-1571-7

- 12.

Hong, S., Sanchez, C., Du, H., and Kim, N., “Fabrication of 3D Printed Metal Structures by Use of High-Viscosity Cu Paste and a Screw Extruder,” Journal of Electronic Materials, Vol. 44, No. 3, pp. 836-841, 2015.

10.1007/s11664-014-3601-8

- 13.

Raney, J. R., Compton, B. G., Mueller, J., Ober, T. J., Shea, K., et al., “Rotational 3D Printing of Damage-Tolerant Composites with Programmable Mechanics,” Proceedings of the National Academy of Sciences, Vol. 115, No. 6, pp. 1198-1203, 2018.

10.1073/pnas.1715157115

- 14.

Weikert, S., Ratnaweera, R., Zirn, O., and Wegener, K., “Modeling and Measurement of H-BOT Kinematic Systems,” Proc. of the American Society for Precision Engineering, Vol. 52, pp. 274-277, 2011.

- 15.

Spath, S. and Seitz, H., “Influence of Grain Size and Grain-Size Distribution on Workability of Granules with 3D Printing,” The International Journal of Advanced Manufacturing Technology, Vol. 70, Nos. 1-4, pp. 135-144, 2014.

10.1007/s00170-013-5210-8

Biography

- SoRee Hwang

M.Sc. candidate in the Graduate School of Nano IT Design Fusion, Seoul National University of Science & Technology. Her research interest is Multi-material 3D printing.

- JongWon Lee

M.Sc. candidate in the Graduate School of Nano IT Design Fusion, Seoul National University of Science & Technology. His research interest is 3D print and dental.

- SoHyang Lee

M.Sc. candidate in the Graduate School of Nano IT Design Fusion, Seoul National University of Science & Technology. Her research interest is UX design and HCI.

- DaeGi Hong

M.Sc. candidate in the Graduate School of Nano IT Design Fusion, Seoul National University of Science & Technology. His research interest is Product design and packaging.

- MinSoo Park

Professor in the Graduate School of Nano IT Design Fusion, Seoul National University of Science & Technology. His research interests are Metal/ceramic 3D printing, laser processing and micro machining.