ABSTRACT

This study is to investigate the cooling performance of the battery in the electric vehicle depending on the attachment of the cooling plates and materials to the battery cells. Research focused on the numerical comparison of forced convective heat transfer coefficients with case 1(cell-Al, cooling plate-None), case 2(cell-Al, cooling plate-Al), case 3(cell-Al, cooling plate-C), and case 4(cell-C, cooling plate-Al). Normalized local Nusselt number of the cooling area at the normalized width position indicated that the heat transfer coefficient of the case 1 was averaging at 7, 14.5, 11.9% lower than that of case 2, case 3, and case 4. Based on case 3, the cooling performance with six different types of mass flow rates (0.05, 0.075, 0.0875, 0.1, 0.125, 0.15 kg/s) were compared. Normalized local Nusselt number at the normalized width position indicated that the heat transfer coefficient of 0.0875 kg/s was averaging at 35.8, 11.9% higher than that of 0.05, 0.075 kg/s and 12.3, 36.4, 60% lower than that of 0.1, 0.125, 0.15 kg/s. Ultimately, the best optimization design for air-cooling performance was case 3 with mass flow rate of 0.125 kg/s.

-

KEYWORDS: Secondary battery, Electric vehicle, Battery cooling, Convective cooling, Energy storage system, Virtual fluid dynamics

-

KEYWORDS: 2차 전지, 전기자동차, 배터리 냉각, 대류 냉각, 에너지 저장 장치, 가상유체역학

1. 서론

최근 심각해져가는 지구 온난화와 대기 오염으로 인해 세계에 심각한 악영향을 미치고 있는 가운데 이런 문제들의 주된 원인으로 자동차 배기가스가 지목되어 왔다. 이러한 이유들로 인해 최근 자동차 제조기업들은 전기자동차와 같은 신재생 에너지를 기반으로 하는 친환경 자동차 개발 및 연구가 활발히 이루어지고 있다. 그에 따라 에너지 저장 시스템의 매체인 배터리에 대한 개발 및 연구가 활발히 진행되고 있으며 그 중에서 2차 전지이며 에너지 밀도와 효율이 타 배터리에 비해 우수한 리튬 이온 배터리가 주를 이루고 있다. 하지만 리튬 이온 배터리를 전기 자동차용으로 사용하기 위해선 안전성과 오랜 수명 조건을 충족시켜야 한다. 배터리는 충·방전 시 전자와 원자 이온이 산화·환원 반응을 통하여 비가역 열과 가역 열이 발생한다.

1 리튬 이온 전지는 특성상 충격과 고온에 약하기 때문에 고온에 장시간 노출되면 배터리의 수명이 짧아지고 심하면 열 폭주 현상으로 폭발 사고로 이어지게 된다.

2 또한, 다수의 셀이 밀집되어 있는 배터리 팩의 중심에 위치한 셀의 온도가 타 셀들에 비해 과도하게 상승할 수 있다. 셀들 간의 온도 편차로 셀 간 내부저항의 불균형이 생기면 셀들 간의 성능 차이로 배터리 팩의 수명이 저하된다.

3 따라서 전기자동차에 사용되는 고전압 배터리의 냉각 시스템에 대한 연구는 필수적이다. 그에 따라 공냉식과 수냉식 냉각 방법이 주를 이루고 있으며 부가적으로 냉각판을 부착하여 냉각 성능을 향상시킨다. 냉각판의 재질은 흔히 알루미늄, 구리 등의 금속 기반 냉각판을 많이 적용하고 있지만, 무게와 가격 측면에서 단점이 있다. 최근에 열전도율과 내열성이 우수한 팽창 그래파이트와 그래파이트 기반의 탄소나노 튜브 등 그래파이트 소재에 관심이 커지고 있다.

4 그래파이트는 자연에서 쉽게 얻을 수 있는 탄소 물질로 가격이 저렴하다. 배터리 냉각에 관한 기존 연구들은 루프형 히트파이프를 이용한 냉각 성능연구,

5 출입구 기울기에 따른 공냉식 배터리의 냉각 성능 연구,

6 배터리의 전기화학적 반응을 반영한 모델링에서 다양한 작동 조건에서 구조에 따른 온도 분포를 예측하여 최적 냉각 설계를 하는 연구,

7 평판형 알루미늄 재질에 다수의 모세관 채널로 이루어진 써모사이폰을 배터리 팩의 냉각 시스템에 적용한 연구,

8 배터리 팩 내부의 냉각에 사용되는 유체의 유속을 가급적 빠르고 균등하게 유지할 수 있는 구조 및 팬의 위치를 설정하여 냉각 효과를 극대화하는 연구,

9 공기의 유입구와 유출구의 형상과 면적을 변형하여 냉각하는 연구,

10 냉각판의 두께, 냉각수의 개수, 냉각판의 접촉 형태를 변수로 한 냉각 연구,

11 배터리 셀 사이 간극에 따른 냉각 연구,

12 바플에 따른 배터리 팩의 냉각 연구

13 등이 있지만 실제 차량용 배터리의 설계 간극에서 냉각판의 부착에 따른 냉각 성능 연구, 셀 및 냉각판 재질에 따른 냉각 성능 연구, 팬에 의한 공기 질량 유량에 따른 냉각 성능 연구는 거의 수행되지 않았다.

본 연구는 고속 주행 시에 냉각팬을 이용한 강제 공냉 시스템에서 실제 배터리 셀의 간극 0.5 mm를 기준으로 냉각판의 유무와 셀 및 냉각판의 재질(알루미늄, 그래파이트)에 따라 4가지 설계 형태로 분류한 후, 그에 따른 대류 및 전도에 의해 냉각된 셀의 표면 온도를 수치적으로 해석하여 우수하게 냉각된 설계 형태를 채택할 것이며, 그 설계 형태에서 냉각팬에 의한 공기의 질량 유량을 6단계로 분류하여 셀의 표면 온도 분포를 수치적으로 해석하고 최적의 공기의 질량 유량을 채택하여 공냉식 배터리 냉각 방법의 최적 설계를 하는 것이 이번 연구 목표이다.

2. 해석 모델링 및 설계 조건

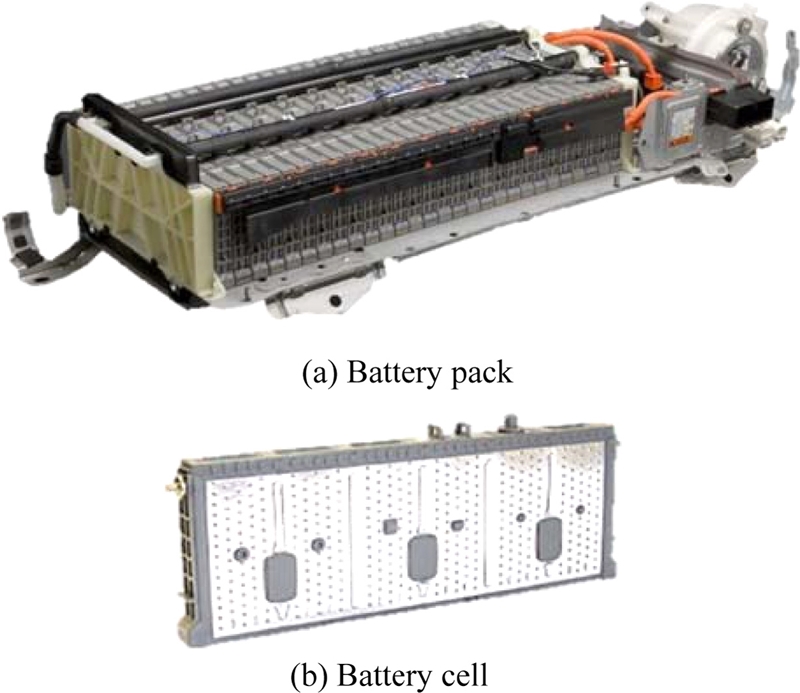

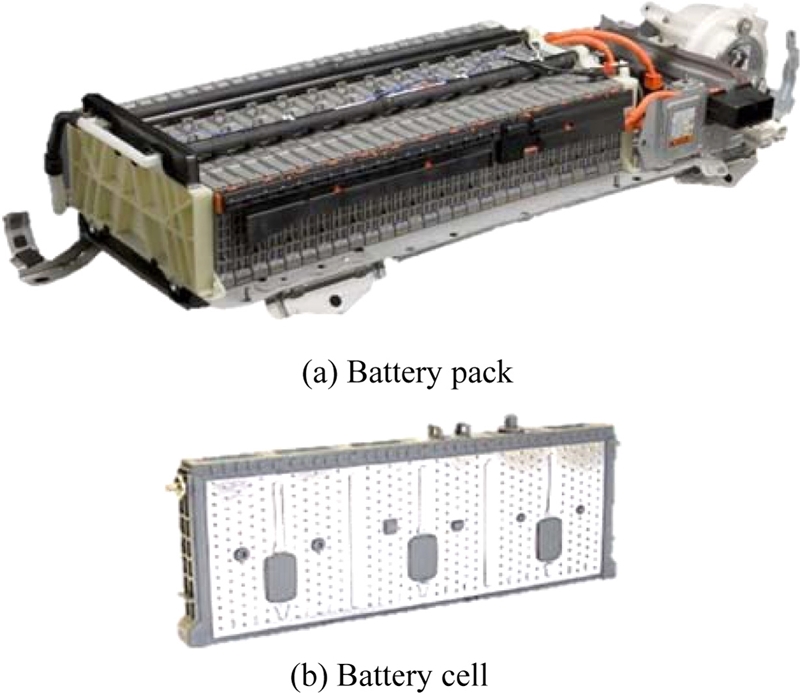

Fig. 1은 글로벌 완성차 업체 ㈜T사 전기자동차에 장착되는 실제 사진이며,

Fig. 1(a)는 실제 배터리 팩,

Fig. 1(b)는 실제 배터리 셀이다. 셀에 적용된 충·방전을 위한 단자부, 팩 모듈에 고정을 위한 고정부, 냉각 면적을 넓히기 위한 돌기 부분, 굴곡진 부분 등 유동해석에 불필요하다고 판단되는 부분을 단순화하였다. 셀 표면에 있는 돌기 부분을 단순화한 이유는 최근 많은 배터리 제조업체에서 출시하는 배터리 셀은 가공 공정상의 복잡성과 비용 등의 이유와 냉각 성능에 큰 차이가 없어 돌기 부분을 제거하는 형태로 개발되기 때문에 단순화하였다.

12

Fig. 1 Actual image of battery pack and cell

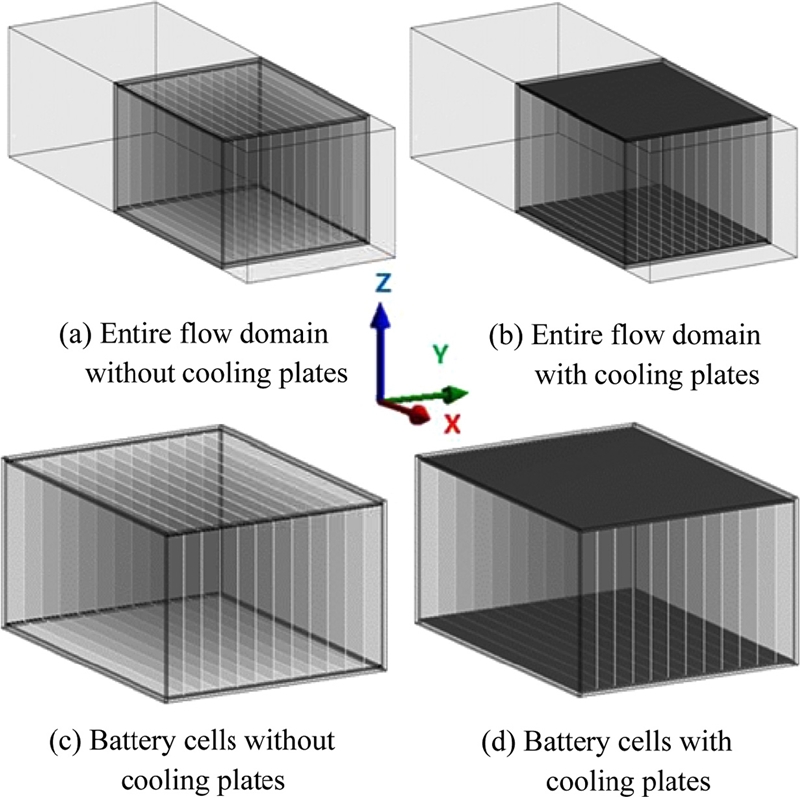

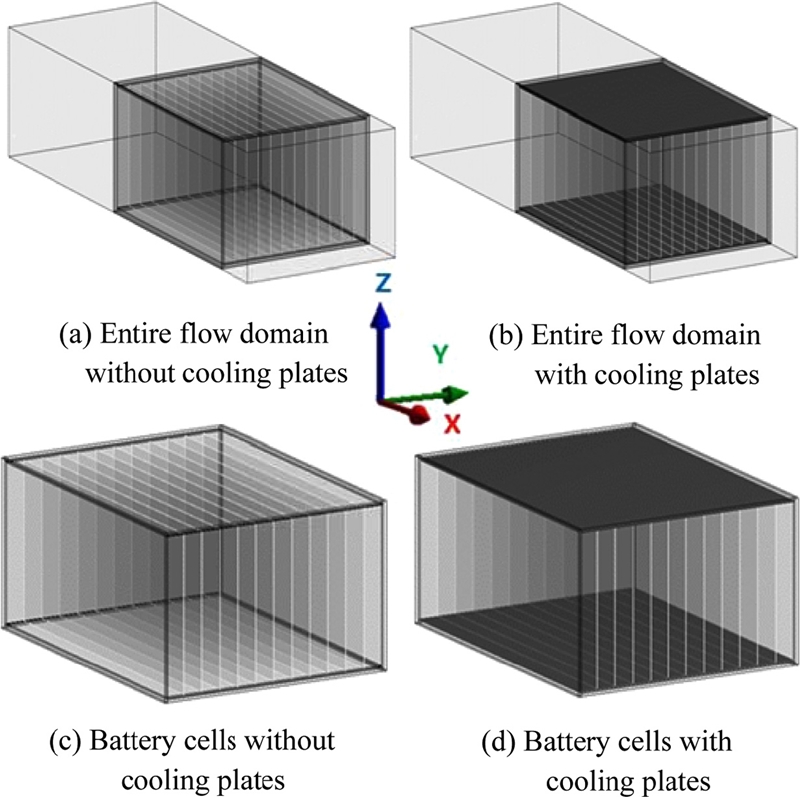

Fig. 2는 CATIA V5R21을 사용하여 모델링한 후 ANSYS V19.3로 형상을 임포트(Import)한 전체 유동장과 배터리 셀 및 냉각판의 형상이다.

Figs. 2(a)와

2(b)의 입·출구 유동장 수정 형상은 입구의 안정화된 대기 유입의 표현과 출구로 방출되는 공기의 안정화 및 원활한 해석을 위해 셀 폭(X축)만큼 입구 0.25배, 출구 1배로 수정한 형상이며, 입·출구를 제외한 유동장과 셀 12개로 실제 형상을 나타내었다. 실제 단순 형상에서 냉각판의 부착에 따른 냉각 성능과 냉각판 및 셀의 재질을 알루미늄과 그래파이트로 적용하였을 때 냉각 성능을 정량적으로 파악하고 비교하기 위하여 냉각판의 유무, 재질 선택에 따라 분류하였고,

Figs. 2(a)와

2(c)는 각각 냉각판이 부착되지 않은 전체 유동장 형상, 배터리 팩의 형상이며,

Figs. 2(b)와

2(d)는 각각 냉각판이 부착된 전체 유동장 형상, 배터리 팩의 형상이다. 좌표 방향으로는 셀 두께 방향(Y축), 셀 높이(수직) 방향(Z축), 셀 폭(수평) 방향(X축)으로

Figs. 2(a)부터

2(d)는 전부 동일하게 설정하였고, 입·출구는 X(셀 폭)축을 기준으로 동일한 수평선으로 설정하였다.

Fig. 2 Imported geometries of entire flow domains and battery pack with cooling plates

Table 1 Physical dimensions of battery pack

Table 1

|

Width (L)

[mm] |

Thickness (T)

[mm] |

Height (H)

[mm] |

EA |

|

Battery cell |

275 |

17 |

105 |

12 |

|

Cooling plate |

275 |

209.5 |

1 |

2 |

|

Battery pack |

620 |

217.5 |

113 |

1 |

2.1 유동해석 조건

유동해석 조건은 유체와 고체를 분류하여 상호 간의 열교환을 위해 대류 및 전도 열전달 해석 커플링을 하여 FSI (Fluid Structure Interaction-구조를 가진 고체와 내부 혹은 주변 유체 유동을 상호작용하여 해석하는 기법)을 활용하였고, 유체 유동 및 열전달 해석을 위해 열전도, 질량 보존 법칙, 운동량 보존 방정식, 에너지 보존 법칙을 적용하였고, 작동 유체의 최대 유속이 압축성 유동 고려대상인 음속의 0.3배에 훨씬 못 미치는 44.4 m/s로 계산됨으로 ANSYS FLUENT V19.3로 비압축성 유동해석을 하였다. 12개의 배터리 셀과 셀 사이의 간극을 기준 길이로 설정하여 내부 유동의 최대 레이놀즈 수가 9,216으로 계산되어 난류 해석을 진행하였으며, 경계층 흐름에 대해 더 많은 계산을 수행하고 해석 결과의 정확도를 향상시키기 위해 난류 모델 K-Omega Standard를 선택하여 사용하였다. 배터리 셀의 재질은 설계 형태에 따라 알루미늄과 그래파이트를 적용하였고, 냉각판의 재질도 설계 형태에 따라 알루미늄과 그래파이트를 적용하였으며, 표면에 점착 조건(No Slip Condition)을 주며 열교환을 위해 열전도를 설정하였다. 배터리 셀의 최적 작동 온도는 293-323 K이며, 333 K 초과할 시 배터리 셀의 효율이 급격히 감소하게 된다. 외기 온도 298.15K와 배터리 셀의 한계 작동 온도 333 K를 고려하여 일정 열 유속(590 W/m2)을 열 경계 조건으로 사용하였다. 유동장의 표면에는 Wall 조건, 점착 조건을 설정하였다. 유체(공기) 온도는 상온을 기준으로 하여 298.15 K를 부여하였고, 입구 조건은 글로벌 완성차 업체 ㈜T사의 차량 배터리 냉각용 팬에서 일반 주행 시 200 CMH (Cubic Meter per Hour)를 유입하고, 고속 주행 시 냉각팬의 RPM 수가 증가하게 된다. 본 연구에서는 일반 주행 대비 30% 고속 주행 시를 가정하여 260 CMH를 선정하였고 0.0875 kg/s의 질량 유량을 도출하였다. 출구는 대기압으로 가정하여 계기압력 0 Pa을 부여하였다.

Table 2는 열 및 유동해석을 위한 경계 조건들을 표로 나타낸 것이며,

Table 3은 열 및 유동해석에 사용된 셀 및 냉각판 재료의 물성치를 표로 나타낸 것이다.

Table 2Design boundary conditions

Table 2

|

Design boundary conditions |

|

Turbulence model |

K-Omega |

|

Material |

Battery cell |

Aluminum, Graphite |

|

Cooling plate |

Aluminum, Graphite |

|

Fluid |

Incompressible air |

|

Inlet |

Mass flow rate [kg/s] |

0.0875 |

|

Temperature [K] |

298.15 |

|

Outlet |

Pressure [Pa] |

0 |

|

Battery cell |

Heat flux [W/m2] |

590 |

Table 3Material property

Table 3

|

Material property |

ρ

[kg/m3] |

Cp

[J/kg·K] |

k

[W/m·K] |

|

Aluminum |

2719 |

871 |

202.4 |

|

Graphite |

2210 |

709 |

1950 |

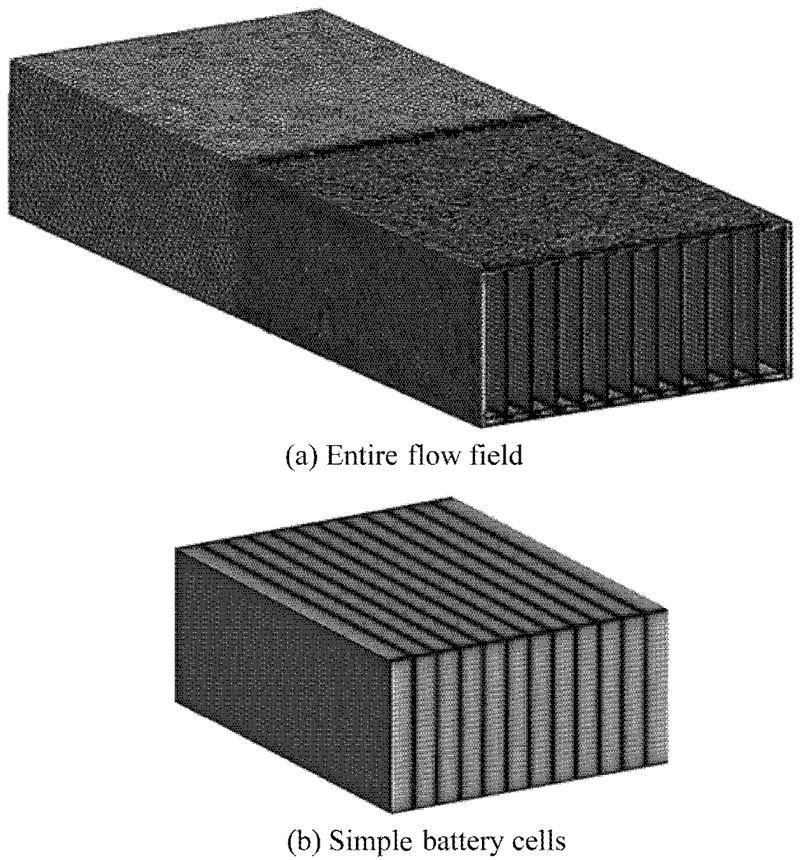

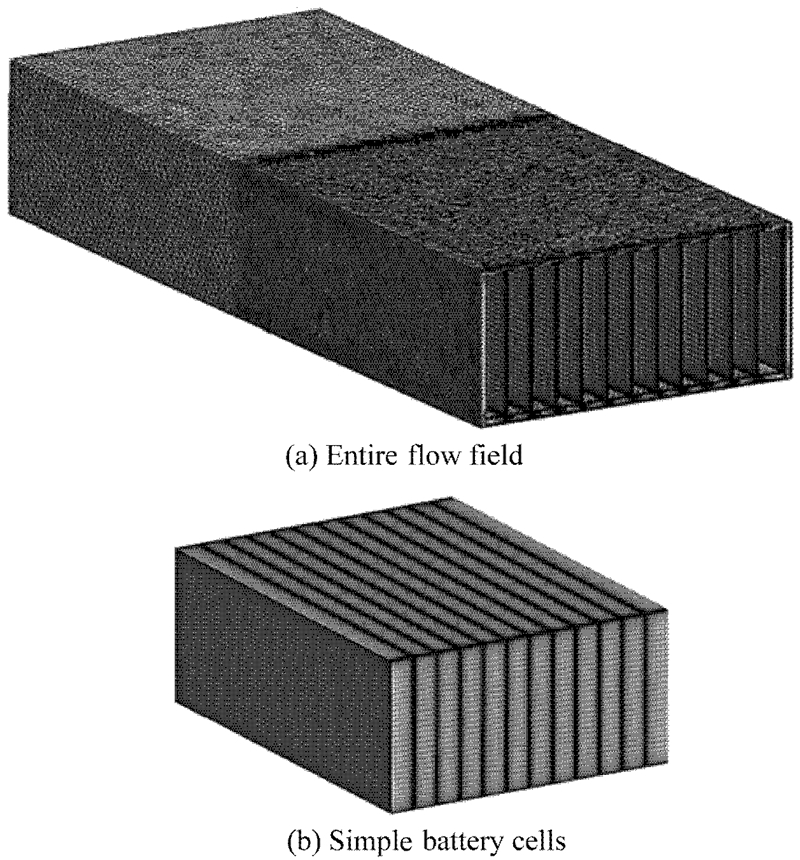

2.2 그리드 생성

유동장의 유체 부분과 배터리의 셀 및 냉각판 부분의 고체 부분을 분류하여 격자를 생성하였다. 유동해석을 위한 전체적인 유동장 형상에 비해 실제 셀 간극(0.5 mm)은 매우 좁고 점성 유동으로 인해 포물선 형태의 속도 분포가 존재하여 조밀한 격자 생성이 중요하기 때문에 유동장을 분할하여 셀 간극들을 각각의 유동장으로 만들었다. 서로 다른 유동장의 격자를 이어주어 해석 진행에 영향이 없도록 하였으며, 격자 의존도 테스트를 통해 최적의 격자를 생성하였다. 배터리와 유동장의 전체 격자 생성은 ANSYS MESH를 사용하였고 격자는 셀 간극에서는 Hexa 격자를 사용하여 직육면체의 조밀한 격자를 생성하였다. 셀 사이의 간극과 셀 주위의 유동장에는 Body Sizing으로 1 mm로 동일하게 주었다. 셀과 냉각판에는 Body Sizing으로 1.5 mm를 주었으며 나머지 전체 유동장 부분은 원활한 해석, 해석 시간, 격자의 품질 향상을 고려하여 Method에서 Tetra 격자로 설정하고 Body Sizing을 5 mm로 생성하였다. 그리하여 전체 배터리 유동장의 전체 격자수는 냉각판을 부착하지 않았을 경우 총 3,588만 개, 냉각판을 부착하였을 경우 총 3,613만 개로 생성하였다. 2,200만 개, 3,780만 개와 비교하였을 때 전체 유동장의 최고속도와 최고온도에서 오차율이 2,200만 개에서는 각각 5.1%, 5.2%의 큰 오차율이 발생하였고, 3,780만 개에서 각각 1.5%, 1.3%의 오차율이 발생하였다. 해석의 수렴과 시간을 고려하여 3,588만 개의 격자를 선택하였다. Y Plus (Y+) 값은 0-16.975 값을 유지하였다.

Fig. 3Grid of at entire flow domain and battery cells

3. 결과 및 고찰

본 연구는 원활한 해석을 위해 배터리 셀의 형상을 단순화하여 ANSYS FLUENT V19.3을 활용하였고, 현재 글로벌 완성차 업체 ㈜B사에 적용하고 있는 실제 간극(0.5 mm)의 배터리 팩에서 냉각판의 유무와 냉각판 및 셀의 재질(알루미늄, 그래파이트)에 따라 냉각 성능을 정량적으로 비교하기 위해 Case 1(셀-알루미늄, 냉각판-미부착), Case 2(셀-알루미늄, 냉각판-알루미늄), Case 3(셀-알루미늄, 냉각판-그래파이트), Case 4(셀-그래파이트, 냉각판-알루미늄)의 4가지 설계 형태로 분류하여 유동해석을 진행하였고, 해석 이후 유동해석의 경향과 신뢰성을 확인하기 위해 속도 및 온도 분포를 확인하였다. 4가지 설계 형태에 대해 정량적으로 냉각 성능을 비교 및 분석하기 위해 12개의 셀 중에 냉각 성능이 가장 취약한 셀을 선택한 후, 셀의 표면 온도 분포 편차가 큰 국소적 X 위치(셀의 폭, 공기 유동 방향)에 대해 무차원 열전달 계수 해석을 진행하였고, 4가지 설계 형태 중에 냉각 성능이 가장 우수하다고 판단되는 설계 형태를 채택하여 그 설계 형태에서 질량 유량에 따른 정량적인 냉각 성능을 비교하기 위하여 질량 유량을 0.05, 0.075, 0.0875(기준 질량 유량), 0.1, 0.125, 0.15 kg/s으로 6단계로 분류하고 냉각이 가장 취약한 셀을 선택한 후, 셀의 표면 온도 분포 편차가 큰 국소적 X 위치(셀의 폭)에서의 무차원 열전달 계수 해석을 통해 냉각 성능을 비교 및 분석하여 최적의 설계 방안을 도출하였다. 정밀한 계산을 통해 해석의 신뢰성을 높이기 위해 KISTI에서 제공하는 Intel Xeon Phi 7250(KNL) 모델 68 코어 16 GB*6, 6Ch per CPU의 성능을 가진 슈퍼컴퓨터를 사용하였다.

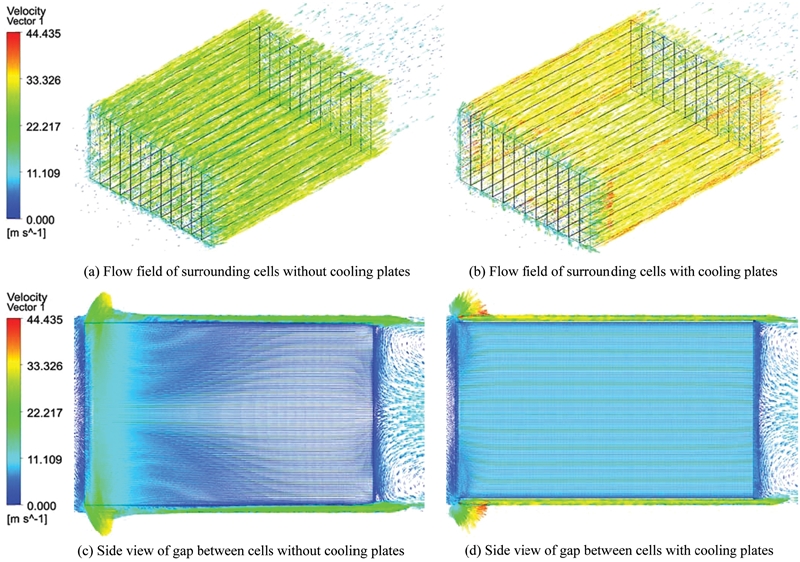

3.1 속도 분포

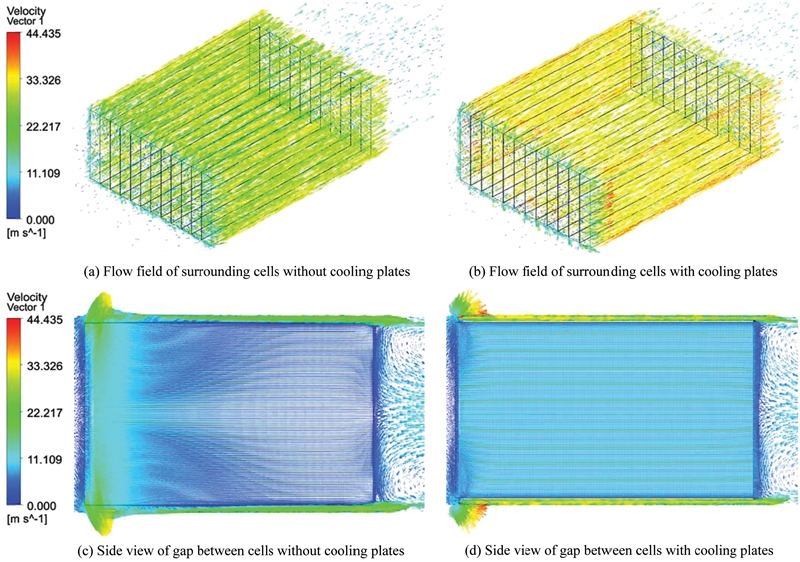

Fig. 4Velocity vectors depending on attachment of cooling plates to battery pack

속도벡터는 배터리 팩의 상하부에 냉각판의 부착 유무에 따라 분류하였고 2가지의 경우 공통적으로 최고속도는 셀 간극 내부로 공기 유입이 시작되는 셀의 입구 위치에서 발생하며 냉각판이 부착된 경우에서 44.43 m/s, 냉각판이 부착되지 않은 경우에서 36.56 m/s로 각각 나타났다. 셀 간극 내부로 공기 유입이 시작되는 셀의 입구 위치에서 면적이 급격하게 줄어들어 최고속도가 나타나는 것을 확인할 수 있었으며, 배터리 팩의 상하부에 냉각판의 부착으로 인해 면적이 좁아져 최고속도가 7.87 m/s 증가함을 볼 수 있었다. 전체적으로 셀 간극 내부에서 공기의 유동에 따라 셀 벽면에서 점착이 발생하여 공기의 속도가 감소하는 모습을 확인할 수 있었다. 냉각판이 부착되지 않은 경우는 셀 간극 내부로 유입된 공기가 위아래로 퍼져나가는 형상을 관찰할 수 있었고, 냉각판이 부착된 경우는 냉각판에 의해 셀 간극 내부로 유입된 공기가 위아래로 퍼져나가지 못하고 직선 방향으로 유동하여 셀 간극 내부로 유입된 공기의 유량 손실을 감소시킬 수 있었다. 속도벡터

Figs. 4(c)와

4(d)의 셀의 측면에서 보았을 때, 배터리 셀 뒷부분에 면적이 급격히 증가하여 와류가 발생하는 것을 확인할 수 있었다.

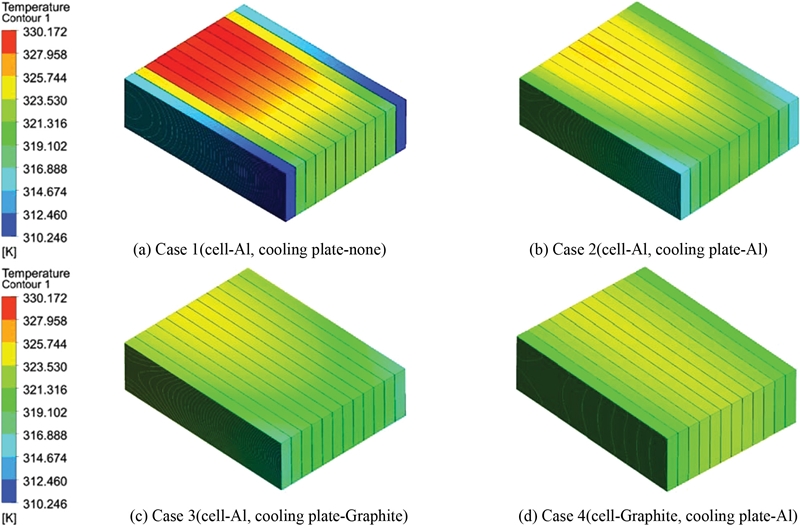

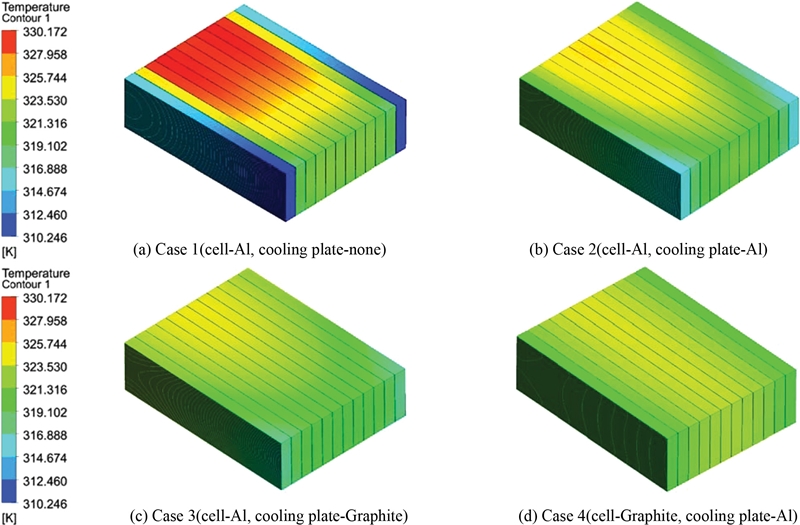

Fig. 5는 일정하게 발열하는 배터리 셀이 기준 질량 유량 0.0875 kg/s을 적용한 강제 대류에 의해 냉각되어 나타난 냉각판 부착 유무와 냉각판 및 셀의 재질(알루미늄, 그래파이트)에 따른 배터리 셀의 표면 온도 분포를 나타낸 그림이다.

Fig. 5Surface temperature of the battery cells with different materials of cells and cooling plates

셀의 표면 온도 편차가 가장 큰 셀 폭의 위치(공기 유동 방향)에서 무차원의 기준 길이(X

+)를

식(1)을 통해 계산하였다.

여기서 X는 셀 폭(공기 유동 방향)의 국소적 위치, L은 셀 폭의 전체 길이이다. X+ = 0은 셀 간극 내부로 공기 유입이 시작되는 셀의 입구 위치를 무차원으로 나타내었고, X+ = 1은 셀 간극 내부로 유입된 공기가 외부로 빠져나가는 셀의 출구 위치를 무차원으로 나타내었다.

Fig. 5(a)는 냉각판이 부착되지 않고 셀의 재질을 알루미늄으로 적용하였을 때의 냉각된 셀 표면의 온도 분포이며, 최고온도는 12개의 셀 중에서 중간에 위치한(왼쪽 기준 6번째) 셀의 출구 근처 위치(X

+ = 0.9)에서 330.172 K가 나타났고, 최저온도는 왼쪽 기준으로 1번째 셀의 입구 위치(X

+ = 0)에서 310.246 K가 나타났다.

Fig. 5(b)는 알루미늄 재질의 냉각판을 알루미늄 재질의 셀에 부착하였을 때의 냉각된 셀 표면의 온도 분포이며 최고 온도와 최저온도는

Fig. 5(a)와 동일한 위치에서 각각 326.685, 315.266 K로 나타났다.

Fig. 5(c)는 그래파이트 재질의 냉각판을 알루미늄 재질의 셀에 부착하였을 때의 냉각된 셀 표면의 온도 분포이며, 최고온도와 최저온도는

Fig. 5(a)와 동일한 위치에서 각각 324.654, 317.044 K로 나타났다.

Fig. 5(d)는 알루미늄 재질의 냉각판을 그래파이트 재질의 셀에 부착하였을 때의 냉각된 셀 표면의 온도 분포이며, 최고온도와 최저온도는

Fig. 5(a)와 동일한 위치에서 각각 323.882, 319.786 K로 나타났다. 공통적으로 셀 간극 내부로 유입된 공기가 셀의 출구 방향으로 유동하는 과정에서 가열이 되어 12개의 셀 중에 중간에 위치한(왼쪽 기준 6번째) 셀을 기준으로 셀의 입구 위치(X

+= 0)에 비해 출구 근처 위치(X

+= 0.9)에서 0.6-7.8 K 높은 온도가 나타남을 확인할 수 있었다. 냉각판이 부착되지 않은

Fig. 5(a)의 경우 12개의 셀들에서 표면 온도 편차가 19.9 K로 나타났고, 냉각판이 부착된

Figs. 5(b)부터

5(d)의 경우 12개의 셀들에서 표면 온도 편차가 4.1-11.4K로 나타나는 것을 확인할 수 있었으며, 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6 번째) 셀에서 최고 표면 온도가

Fig. 5(a)에 비해 3.5-6.3 K 낮아지는 것을 확인할 수 있었다. 특히, 그래파이트를 셀 및 냉각판에 적용한

Figs. 5(c)와

5(d)에서 전체적으로 균일한 냉각이 나타났음을 확인할 수 있었다.

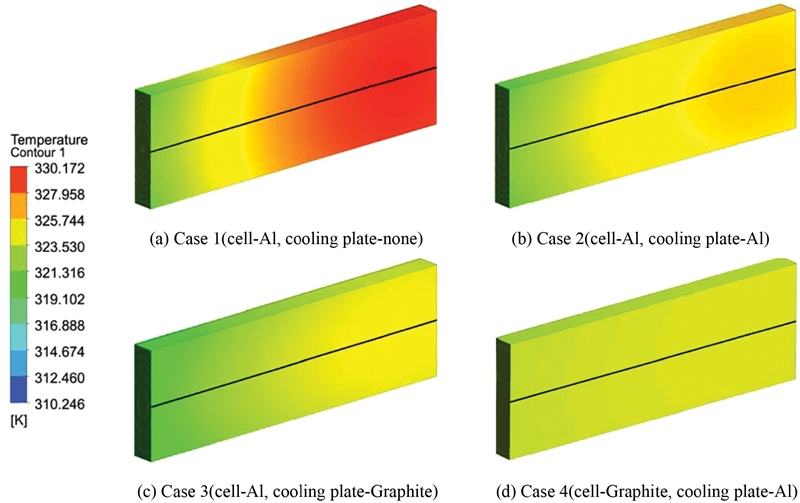

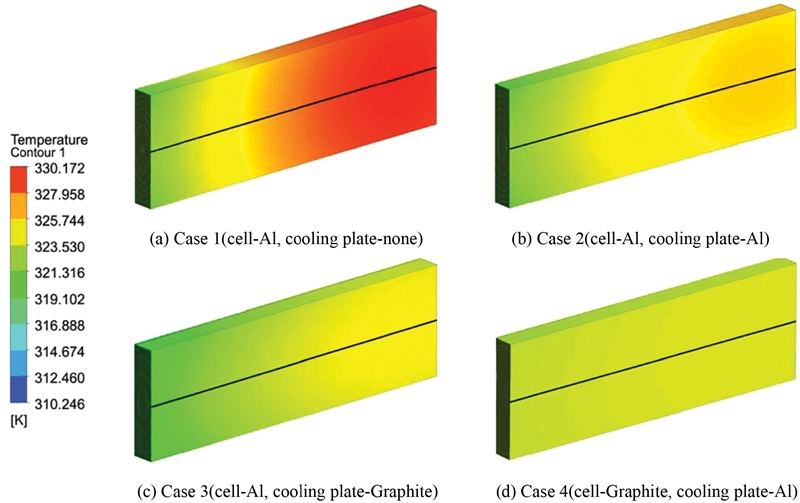

Fig. 6은 냉각판의 유무와 셀 및 냉각판의 재질(알루미늄, 그래파이트)에 따라 냉각 성능을 정량적으로 비교하고 표현하기 위해 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀을 선택한 후, 냉각의 편차가 가장 큰 위치인 셀 폭(공기 유동 방향)에 흑색 실선의 수평선을 나타낸 그림이다. 냉각판이 부착되어 있지 않은

Fig. 6(a)의 경우 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀에서 표면 온도 편차가 7.8K만큼 나타났고,

Figs. 6(b)부터

6(d)의 경우 냉각판으로 인해 냉각이 가장 취약한 중간에 위치한 셀에서 표면 온도 편차가

Fig. 6(a)에 비해 낮아져 표면 온도 편차가 0.6-5 K 나타나는 것을 확인할 수 있었다. 냉각판의 유무와 셀 및 냉각판의 재질에 따른 냉각 성능을 정량적으로 비교하기 위해 12개의 셀 중에 냉각이 가장 취약한 셀(왼쪽 기준 6번째)에서 표면 온도 분포 편차가 가장 큰 지점인 셀 폭 위치(X)를 범위로 설정하여 국소적 X 위치(셀의 폭, 공기 유동 방향)에서의 열전달 계수를 계산하고 Nusselt 수로 무차원화하여 냉각 성능을 비교하였다. Nusselt 수는 대류 열전달에 대한 유체내의 전도 열전달의 상대적인 비를 나타내는 무차원 파라미터로 열전달 계수의 무차원 파라미터이다.

Fig. 6Surface temperature of 6th cell with horizontal axis with different materials of cells and cooling plates

Table 4는 기준 질량 유량 0.0875 kg/s을 적용한

Fig. 6의 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀에서 표면 온도 분포 편차가 큰 셀의 폭 위치(공기 유동 방향)의 수평선상 온도 분포를 무차원 기준의 위치(X

+)에 따라 셀의 표면 온도(T

s)와 대기 온도(T

∞)의 차이(ΔT)를 나타내며, 셀 폭(X)에서 가장 냉각이 취약한 부분과 냉각 성능 비교를 위해 12개의 셀들에서 셀 폭 위치(X)를 고정하고 셀의 높이(Z), 두께(Y) 위치에 상관없이 가장 높은 셀의 표면 온도인 T

max를 나타낸 표이다.

Table 3에 나타난 T

max는 왼쪽 기준 6번째 셀 표면에서 모두 나타났으며, 셀의 표면 온도(T

s)와 대기 온도(T

∞)의 차이(ΔT)를 통해 열전달 계수를 계산하고 Nusselt 수로 무차원화하여 냉각 성능을 비교하였다. X

+ = 0은 셀 간극 내부로 공기 유입이 시작되는 셀의 입구 위치이고, X

+ = 1은 셀 간극 내부로 유입된 공기가 외부로 빠져나가는 셀의 출구 위치이다. Nusselt 수로 무차원화하여 냉각 성능을 비교해본 결과 4가지 설계 형태 모두 셀 입구 위치(X

+ = 0)에서 가장 높은 냉각 성능을 확인할 수 있었고, 셀 간극 내부로 유입된 공기가 셀의 출구 방향으로 유동하면서 가열되어 셀의 출구 근처 위치(X

+= 0.9)에서 가장 낮은 냉각 성능을 확인할 수 있었다.

Table 4Numerical data of temperature difference and maximum temperature for horizontal position (X) on the side surface of 6th cell with different materials of cell and cooling plate

Table 4

|

Type |

Case 1 |

Case 2 |

Case 3 |

Case 4 |

|

Battery cell |

Aluminum |

Aluminum |

Aluminum |

Graphite |

|

Cooling plate |

None |

Aluminum |

Graphite |

Aluminum |

|

X+

|

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

|

0 |

24.3 |

322.4 |

23.5 |

321.7 |

22.2 |

320.4 |

25.1 |

323.3 |

|

0.1 |

25.4 |

323.5 |

24.3 |

322.5 |

22.9 |

321.1 |

25.2 |

323.4 |

|

0.2 |

26.9 |

325.0 |

25.2 |

323.4 |

23.7 |

321.9 |

25.3 |

323.5 |

|

0.3 |

28.2 |

326.3 |

26.1 |

324.3 |

24.4 |

322.6 |

25.4 |

323.6 |

|

0.4 |

29.4 |

327.5 |

26.8 |

325.0 |

25.0 |

323.2 |

25.5 |

323.7 |

|

0.5 |

30.4 |

328.5 |

27.4 |

325.6 |

25.5 |

323.7 |

25.6 |

323.8 |

|

0.6 |

31.2 |

329.3 |

27.9 |

326.1 |

26.0 |

324.2 |

25.7 |

323.9 |

|

0.7 |

31.7 |

329.8 |

28.3 |

326.5 |

26.3 |

324.5 |

25.7 |

323.9 |

|

0.8 |

32.1 |

330.2 |

28.5 |

326.7 |

26.5 |

324.7 |

25.7 |

323.9 |

|

0.9 |

32.1 |

330.2 |

28.5 |

326.7 |

26.5 |

324.7 |

25.7 |

323.9 |

|

1 |

31.9 |

330.0 |

28.3 |

326.5 |

26.3 |

324.5 |

25.7 |

323.9 |

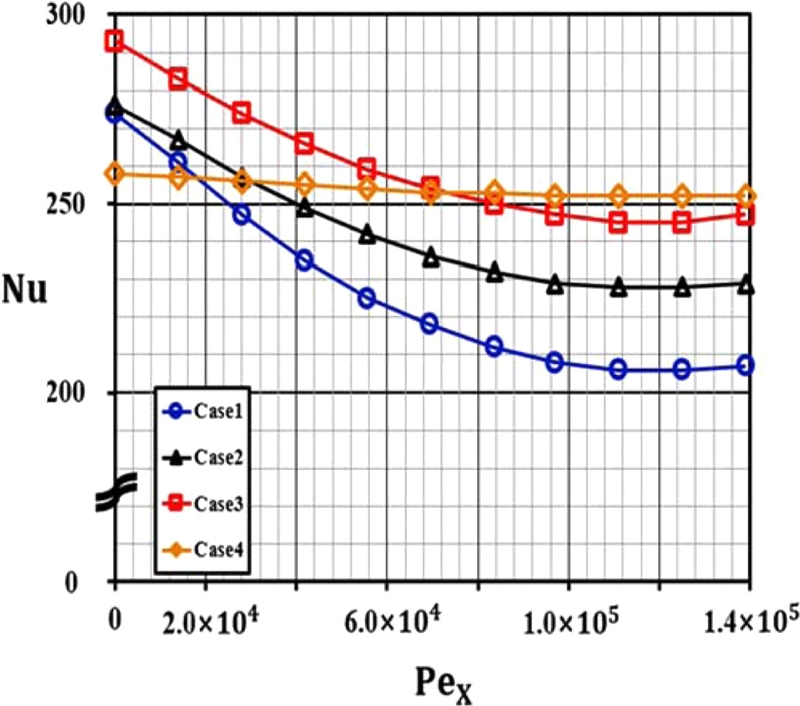

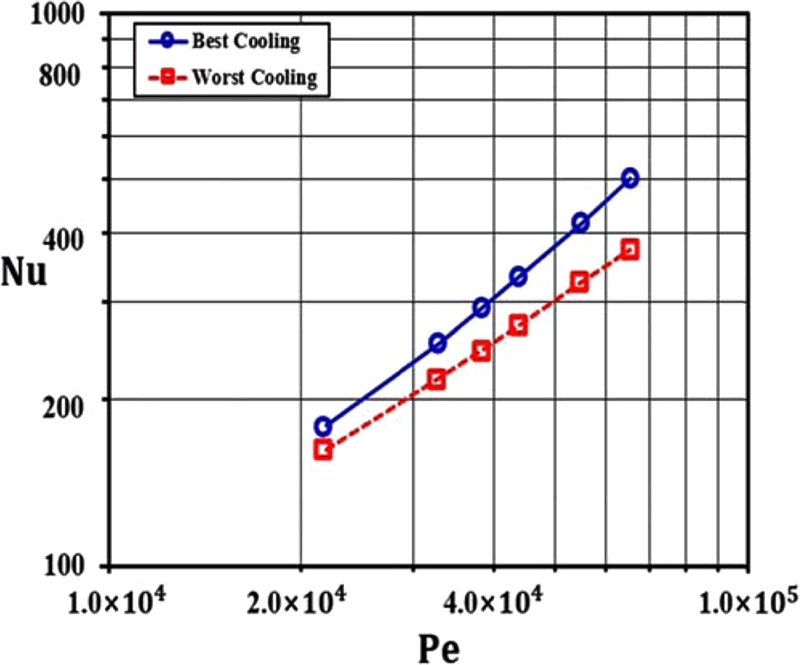

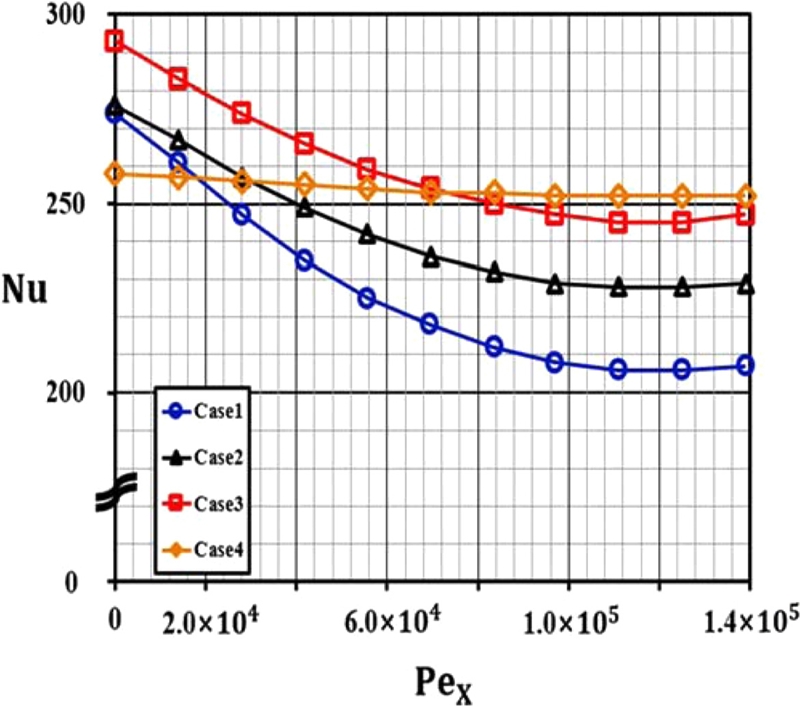

Fig. 7은 기준 질량 유량 0.0875 kg/s을 적용한

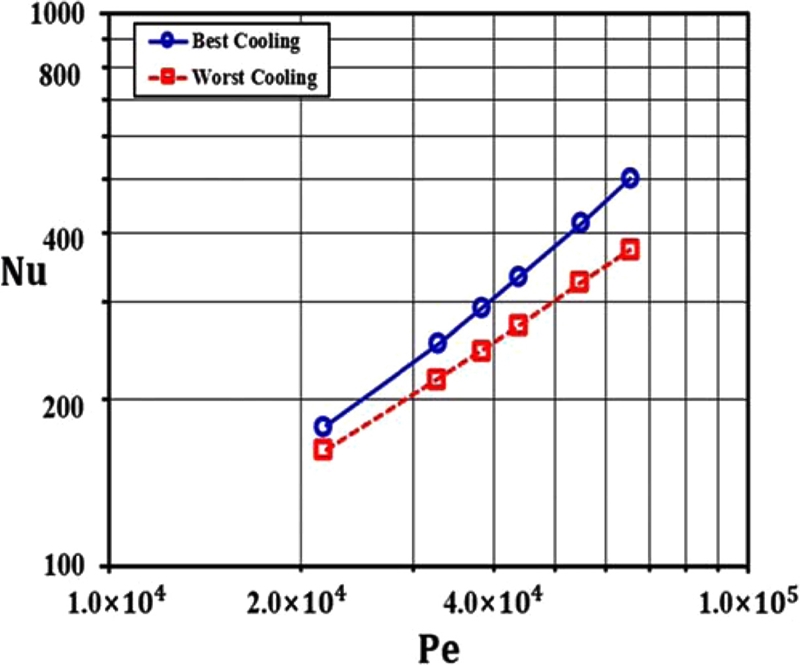

Fig. 6의 12개의 셀 중에 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀을 선택한 후, 셀의 표면 온도 분포 편차가 가장 큰 셀의 폭 위치(공기 유동 방향)에서 냉각판의 부착 유무와 냉각판 및 셀의 재질(알루미늄, 그래파이트)에 따라 나타난 냉각된 셀의 표면 온도를 Nusselt 수로 무차원화하여 Peclet 수에 대한 냉각 정도를 한눈에 파악하기 위하여 정량적으로 나타낸 그래프이다. Peclet 수는 유체 전도 열전달률에 대한 유동 대류 열전달률의 비를 나타내는 무차원 파라미터이며, Peclet 수의 식은

식(2)이다.

Fig. 7Nusselt number vs. Peclet number (X) at the 6th cell

식(2)에서 나타난 기준 길이 L은 셀의 표면 온도 분포 편차가 가장 큰 위치를 기준으로 하여 셀 폭(공기 유동 방향)의 전체 길이를 적용하였고, Pr은 Prandtl 수를 나타내며, Prandtl 수는 운동량확산 계수와 열확산 계수의 비를 나타내는 무차원 파라미터이며, 작동 유체 온도에 따라 고려하여 적용하였다.

4가지 설계 형태의 냉각 성능을 수치적으로 비교해보면 셀 간극 내부로 공기 유입이 시작되는 셀의 입구 위치(X+ = 0)에서의 냉각 성능은 Case 1(셀-알루미늄, 냉각판-미부착)에 비해 Case 2(셀-알루미늄, 냉각판-알루미늄), Case 3(셀-알루미늄, 냉각판-그래파이트)가 각각 0.7, 6.9%로 높게 나타났고, Case 4(셀-그래파이트, 냉각판-알루미늄)는 5.8%로 낮게 나타났다. 냉각이 가장 취약한 지점인 셀의 출구 근처 위치(X+ = 0.9)에서의 냉각 성능은 Cases 2부터 4가 Case 1에 비해 각각 10.7, 18.9, 22.3% 높게 나타났다. 평균 냉각 성능은 Cases 2부터 4가 Case 1에 비해 각각 7, 14.5, 11.9% 높게 나타났으며, 4가지의 설계 형태 중 Cases 3과 4에서 우수한 냉각 성능을 확인할 수 있었다. Case 3은 Case 4보다 2.3%로 미소하게 높아 냉각 성능에서 차이가 거의 없었고, Case 2보다는 7% 높은 냉각 성능을 확인함으로써 냉각판의 재질에 따라 높은 냉각 성능 차이가 나타나는 것을 확인할 수 있었다. 냉각판은 배터리 셀의 냉각 성능을 향상시키고 균일한 냉각을 도와주는 장치로써 균일하고 우수한 열전도의 장점을 가진 그래파이트를 냉각판에 적용하는 것이 적합하다고 판단되고, 현재 많은 배터리 제조업체에서 배터리 셀의 외부 재질로 알루미늄을 많이 적용하고 있는 점을 고려하여 본 연구에서는 Case 3을 선택하였다.

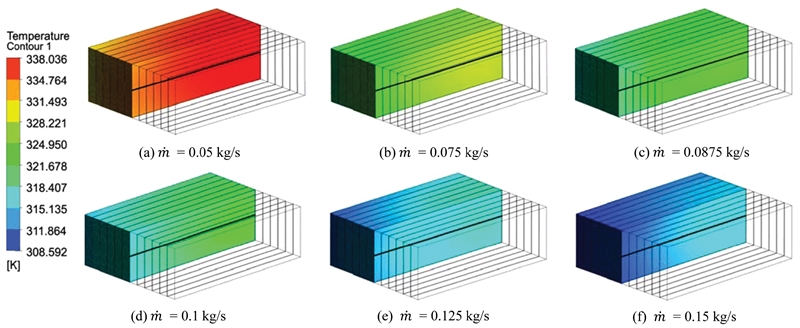

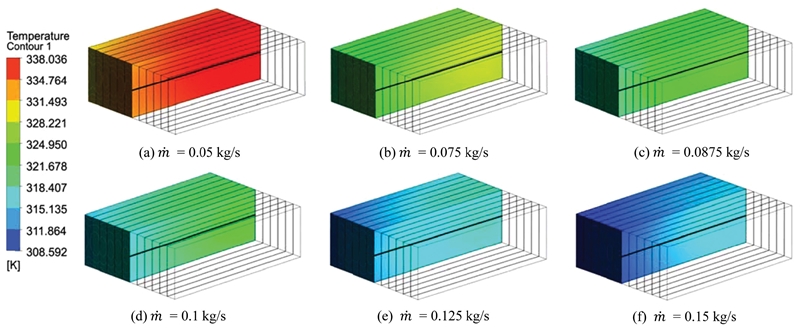

Fig. 8은 Case 3(셀-알루미늄, 냉각판-그래파이트)에서 질량 유량에 따른 냉각 성능을 정량적으로 비교하고 표현하기 위해 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀을 선택한 후, 냉각의 편차가 가장 큰 위치인 셀 폭(공기 유동 방향)에 흑색 실선의 수평선을 나타낸 그림이며 흑색 실선을 나타내기 위해 대칭한 셀 표면 온도 분포는 투명하게 나타냈다.

Figs. 8(a)부터

8(f)는 Case 3(셀-알루미늄, 냉각판-그래파이트)에서 각각 공기의 질량 유량이 0.05, 0.075, 0.0875, 0.1, 0.125, 0.15 kg/s일 때 냉각된 셀의 표면 온도 분포이다.

Fig. 8Surface temperature of 6th cell with horizontal axis at six different mass flow rates of case 3

Case 3(셀-알루미늄, 냉각판-그래파이트)을 기준으로 질량 유량에 따른 냉각 성능을 정량적으로 비교하기 위해 질량 유량을 0.05, 0.075, 0.0875, 0.1, 0.125, 0.15 kg/s으로 6단계로 분류하여 유동해석을 진행하였고, 12개의 셀 중에 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀을 기준으로 냉각 성능을 비교하였다. 6단계 전부 동일하게 최고 표면 온도는 중간에 위치한(왼쪽 기준 6번째) 셀의 출근 근처 위치(X+ = 0.9)에서 나타났고, 최저온도는 왼쪽 기준 1번째 셀의 입구 위치(X+ = 0)에서 나타났다. 0.05 kg/s의 경우 최고온도와 최저온도는 각각 338.036, 330.234 K로 나타났고, 0.075 kg/s의 경우 327.748, 320.232 K, 0.0875 kg/s의 경우 324.398, 317.044 K, 0.1 kg/s의 경우 321.77, 314.57 K, 0.125 kg/s의 경우 317.931, 311.002 K, 0.15 kg/s의 경우 315.282, 308.592 K로 각각 나타났다.

질량 유량에 따른 냉각 성능을 정량적으로 비교하기 위해 Nusselt 수와 Peclet 수를 계산하여 냉각 성능을 비교 및 분석하였고, Peclet 수의 기준 길이는 속도 편차가 가장 큰 셀 폭 위치(X)를 기준으로 적용하였고 Prandtl 수는 작동 유체의 온도에 따라 고려하여 적용하였다.

Table 5는

Fig. 8의 12개의 셀 중에 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀을 선택한 후, 셀의 표면 온도 편차가 가장 큰 셀의 폭 위치(공기 유동 방향)의 수평선상 온도 분포를 무차원 기준의 위치(X

+)에 따라 셀의 표면 온도(T

s)와 대기 온도(T

∞)의 차이(ΔT)를 나타내며, 셀 폭(X)에서 가장 냉각이 취약한 부분과 냉각 성능 비교를 위해 12개의 셀들에서 셀 폭 위치(X)를 고정하고 셀의 높이(Z), 두께(Y) 위치에 상관없이 가장 높은 셀의 표면 온도인 T

max를 나타내는 표이다. T

max는 모두 왼쪽 기준 6번째 셀의 표면에서 나타났다. 6단계의 질량 유량 모두 X

+ = 0에서 가장 우수한 냉각 상태가 표시되었고 X

+ = 0.9에서 가장 취약한 냉각 상태가 표시되었다.

Table 5Numerical data of temperature difference and maximum temperature for horizontal position (X) on the side surface of 6th cell with six different mass flow rates of case 3

Table 5

Mass flow rate

[kg/s] |

0.05 |

0.075 |

0.0875 |

0.1 |

0.125 |

0.15 |

|

X+

|

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

ΔT

[K] |

Tmax

[K] |

|

0 |

36.3 |

334.2 |

25.6 |

323.5 |

22.2 |

320.1 |

19.5 |

317.6 |

15.6 |

313.5 |

12.9 |

310.9 |

|

0.1 |

37.0 |

334.9 |

26.4 |

324.3 |

22.9 |

320.9 |

20.2 |

318.3 |

16.2 |

314.1 |

13.5 |

311.5 |

|

0.2 |

37.7 |

335.6 |

27.1 |

325.0 |

23.7 |

321.6 |

21.0 |

319.1 |

17.0 |

314.9 |

14.3 |

312.3 |

|

0.3 |

38.3 |

336.2 |

27.8 |

325.7 |

24.4 |

322.3 |

21.7 |

319.8 |

17.8 |

315.7 |

15.0 |

313.0 |

|

0.4 |

38.8 |

336.7 |

28.4 |

326.3 |

25.0 |

322.9 |

22.3 |

320.4 |

18.4 |

316.3 |

15.7 |

313.7 |

|

0.5 |

39.3 |

337.2 |

28.9 |

326.8 |

25.5 |

323.4 |

22.9 |

321.0 |

19.0 |

316.9 |

16.3 |

314.3 |

|

0.6 |

39.7 |

337.6 |

29.3 |

327.2 |

26.0 |

323.9 |

23.3 |

321.4 |

19.4 |

317.3 |

16.7 |

314.7 |

|

0.7 |

40.0 |

337.9 |

29.6 |

327.5 |

26.3 |

324.2 |

23.6 |

321.6 |

19.8 |

317.7 |

17.1 |

315.1 |

|

0.8 |

40.1 |

338.0 |

29.8 |

327.7 |

26.5 |

324.4 |

23.8 |

321.8 |

20.0 |

317.9 |

17.3 |

315.3 |

|

0.9 |

40.1 |

338.0 |

29.8 |

327.7 |

26.5 |

324.4 |

23.8 |

321.8 |

20.0 |

317.9 |

17.3 |

315.3 |

|

1 |

39.9 |

337.8 |

29.6 |

327.5 |

26.3 |

324.2 |

23.6 |

321.6 |

19.8 |

317.7 |

17.2 |

315.2 |

Fig. 9는

Fig. 8의 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀에서 온도 분포 편차가 가장 큰 위치인 셀 폭(공기 유동 방향) 중에 냉각이 가장 우수한 지점인 셀의 입구 위치(X

+ = 0)와 가장 취약한 지점인 셀의 출구 근처 위치(X

+ = 0.9)를 기준으로 하여 공기의 질량 유량별로 Peclet 수와 Nusselt 수를 계산하여 무차원화를 통해 냉각 정도를 한눈에 파악하기 위해 정량적으로 나타낸 그래프이다. 파란색의 실선은 공기의 질량 유량에 따른 냉각이 가장 우수한 지점인 셀의 입구 위치(X

+ = 0)에서의 냉각 성능을 나타내며, 붉은색의 점선은 공기의 질량 유량에 따른 냉각이 가장 취약한 지점인 셀의 출구 근처 위치(X

+ = 0.9)에서의 냉각 성능을 나타낸다. 냉각 성능은 공기의 질량 유량에 따라 증가하는 경향을 띠었고, 냉각이 우수한 셀의 입구 위치(X

+ = 0)에서의 냉각 성능은 0.05, 0.075 kg/s가 0.0875 kg/s에 비해 각각 38.9, 13.7% 낮게 나타났으며, 0.1, 0.125, 0.15 kg/s에서는 0.0875 kg/s에 비해 각각 13.7, 42.3, 72% 높게 나타났다. 냉각이 가장 취약한 셀의 출구 근처 위치(X

+ = 0.9)에서의 냉각 성능은 0.05, 0.075 kg/s가 0.0875 kg/s에 비해 각각 34.4, 10.9% 낮게 나타났고, 0.1, 0.125, 0.15 kg/s에서는 0.0875 kg/s에 비해 각각 11.3, 32.8, 52.6% 높게 나타났다. 평균 냉각 성능은 0.05, 0.075 kg/s가 0.0875 kg/s에 비해 각각 35.8, 11.9% 낮게 나타났으며, 0.1, 0.125, 0.15 kg/s에서는 0.0875 kg/s에 비해 각각 12.3, 36.4, 60% 높게 나타났다.

Fig. 9Nusselt number vs. Peclet number at the 6th cell with six different mass flow rates of case 3

질량 유량을 증가시킬수록 12개의 셀 중에 냉각이 가장 취약한 중간에 위치한(왼쪽 기준 6번째) 셀의 최고 표면 온도는 10.3-22.7 K 감소하였고, 셀의 표면 온도 편차는 3.8-4.4 K 증가하였다. 배터리 셀의 표면 온도가 333 K을 초과할 시 배터리의 수명이 급격히 감소하게 되는 것을 고려할 때 0.05 kg/s 이하의 질량 유량은 적용이 적절하지 않다고 판단되며, 질량 유량의 유입을 증가시키기 위해서는 냉각팬의 RPM 수를 증가시켜야 하는데 그로 인한 소음과 진동을 고려하고 계절 및 가혹 조건을 생각할 경우 0.125 kg/s가 가장 적절하다고 판단되며, 0.15 kg/s와 비교하여도 큰 온도 차이가 발생하지 않으므로 375 CMH (Cubic Meter per Hour) 성능의 냉각팬 채택이 적절하다고 판단된다.

4. 결론

본 연구는 배터리 팩의 상하부에 냉각판 부착 유무와 셀 및 냉각판의 재질(알루미늄, 그래파이트)에 따라 4가지 설계 형태 Case 1(셀-알루미늄, 냉각판-미부착), Case 2(셀-알루미늄, 냉각판-알루미늄), Case 3(셀-알루미늄, 냉각판-그래파이트), Case 4(셀-그래파이트, 냉각판-알루미늄)로 분류하여 그에 대한 정량적인 냉각 성능을 파악하기 위하여 속도 및 온도 분포를 수치적으로 해석하여 냉각 성능을 비교하였고, 그 중에서 냉각이 가장 우수한 설계 형태를 채택한 후, 공기의 질량 유량에 따른 냉각 성능을 수치적으로 분석 및 비교하고 최적의 공기 질량 유량을 채택하여 배터리 팩의 공냉식 냉각 방법의 최적 설계를 제안하는데 중점을 두고 연구하였다. 셀의 냉각이 취약한 부분과 우수한 부분의 편차가 가장 큰 위치인 셀 폭(공기 유동 방향)을 기준으로 설정하여 무차원의 기준 길이를 Peclet 수로 나타내고, 각각의 위치에 따라 나타난 셀의 표면 온도를 기반으로 냉각 성능을 나타내는 열전달 계수를 계산하고 무차원 Nusselt 수로 무차원화하여 냉각 성능을 비교하였다. 이에 따른 결론을 다음과 같이 정리하였다.

(1) 배터리 팩의 상하부에 냉각판을 부착하였을 때와 부착하지 않았을 때 모두 동일하게 전체 유동장에서 최고속도는 셀 간극 내부로 공기 유입이 시작되는 셀의 입구 위치에서 발생하였고 냉각판이 부착되었을 때 냉각판으로 인해 유동장과 배터리 팩 사이의 간극 면적이 줄어들어 최고속도가 더 높게 나타나는 것을 확인할 수 있었다. 배터리 팩에 냉각판을 부착하지 않았을 경우 배터리 셀 간극 내부로 유입된 공기가 위아래로 빠져나가는 것을 확인할 수 있었고, 냉각판이 부착되었을 경우 냉각판에 의해 셀 간극 내부로 유입된 공기가 위아래로 빠져나가지 못하고 직선 방향으로 유동하면서 셀 간극 내부로 유입된 공기 유량 손실을 감소시킬 수 있었다. 또한, 셀의 출구 위치에서 면적이 급격히 넓어져 와류가 발생하는 것을 확인할 수 있었다.

(2) 배터리 팩 내에서 좁은 간극으로 셀들이 밀집되어있어 팩 내의 가운데 위치한 셀에서 최고온도가 나타났고, 배터리 팩 내의 바깥쪽에 위치한 첫 번째와 마지막 번째에 위치한 셀들에서 최저온도가 나타났다. 또한, 셀 간극 내부로 유입된 공기가 셀의 출구 방향으로 갈수록 가열되어 셀의 표면 온도가 높아지는 것을 확인할 수 있었다.

(3) 배터리 팩의 상하부에 냉각판 부착 유무와 셀 및 냉각판의 재질(알루미늄, 그래파이트)에 따른 평균 냉각 성능으로는 Case 1(셀-알루미늄, 냉각판-미부착)에 비해 Case 2(셀-알루미늄, 냉각판-알루미늄), Case 3(셀-알루미늄, 냉각판-그래파이트), Case 4(셀-그래파이트, 냉각판-알루미늄)가 각각 7, 14.5, 11.9% 높게 나타났다.

(4) 냉각 성능을 나타내는 열전달 계수로 비교해본 결과 Case 3(셀-알루미늄, 냉각판-그래파이트)의 평균 열전달 계수가 Case 4(셀-그래파이트, 냉각판-알루미늄)에 비해 2.3%로 미소하게 높아 냉각 성능의 차이가 거의 없었고, Case 2(셀-알루미늄, 냉각판-알루미늄)보다는 7% 높은 우수한 냉각 성능을 확인함으로써 냉각판의 재질에 따라 높은 냉각 성능의 차이가 나타나는 것을 확인할 수 있었다. 균일하고 우수한 열전도의 장점을 가진 그래파이트를 냉각판에 적용하는 것이 적합하다고 판단되고, 현재 많은 배터리 제조업체에서 배터리 셀의 외부 재질로 알루미늄을 많이 적용하고 있는 점을 고려하여 본 연구에서는 Case 3을 선택하여 질량 유량에 따른 냉각 성능 연구를 하였다.

(5) Case 3(셀-알루미늄, 냉각판-그래파이트)을 기준으로 공기 질량 유량을 0.05, 0.075, 0.0875, 0.1, 0.125, 0.15 kg/s으로 6단계로 분류하여 유동해석한 결과 평균 냉각 성능은 0.05, 0.075 kg/s가 0.0875 kg/s에 비해 각각 35.8, 11.9% 낮게 나타났으며, 0.1, 0.125, 0.15 kg/s에서는 0.0875 kg/s에 비해 각각 12.3, 36.4, 60% 높게 나타났다.

(6) 계절, 고속주행, 가혹 상황을 고려하고 공냉식 냉각팬에 의한 소음 및 진동을 감안하면 0.125 kg/s가 가장 적절하다고 판단되며, 0.15 kg/s와 큰 온도 차이가 발생하지 않아 375 CMH 성능의 냉각팬 채택이 적절하다고 판단된다.

(7) 본 연구를 기반으로 공냉식 냉각을 전기차에 적용 시 보다 균일하고 우수한 냉각을 가능하게 할 것이고, 냉각판의 재료에 따른 냉각 연구가 활발하게 진행되어 공냉식 냉각 성능을 향상시킬 수 있을 것이라 판단된다.

(8) 본 연구를 기반으로 추후 연구에서는 현재 개발 및 연구가 활발하게 진행되고 있는 탄소 기반의 그래핀과 탄소 섬유 재질을 배터리 셀 및 냉각판에 적용한 냉각 성능 연구와 냉각판의 형태 및 위치를 변수로 적용한 냉각 성능 연구로 본 연구에서 확인한 냉각이 취약한 위치와 단점을 보완하여 강제 공냉 시스템에서 배터리 셀의 냉각 성능을 향상시킬 것이다.

REFERENCES

- 1.

Yoon, J. H., “Thermal Modeling of Lithium-Ion Battery Pack System,” M.Sc. Thesis, Hanyang University, 2014.

- 2.

Kang, M. W., “Analysis of the Thermal Management System Using the New Material and Analysis of the Effectiveness at the System Level,” M.Sc. Thesis, Kookmin University, 2018.

- 3.

Ryu, M. Y., “Measurement of Heat Generation of Lithium-Ion Battery for Electric Vehicles in Dynamic Condition and Analysis of Cooling Characteristics with a Dynamic Model of Thermal Management System for Indirect Water Cooling Battery Pack,” M.Sc. Thesis, Hongik University, 2019.

- 4.

Lee, S. T., “Thermal and Mechanical Properties Improvement of Epoxy Composites Including Expanded Graphite and Multi-Walled Carbon Nanotubes Hybrid Fillers,” M.Sc. Thesis, Sejong University, 2016.

- 5.

Jang, J. C., Rhi, S. H., and Kim, S. K., “Electric Automotive Battery Cooling System with Heat Pipe,” Proc. of the Fall Annual Conference on the Korean Society of Mechanical Engineers, pp. 2596-2600, 2010.

- 6.

Nam, D. S. and Park, H. S., “Analysis of Li-Ion Battery Cooling Performance According to Slope of Inlet and Outlet Using Air-Cooling,” Proc. of the Spring and Fall Conference on the Korean Society of Mechanical Engineers, pp. 4086-4087, 2015.

- 7.

Gu, B. R., “Analysis of the Thermal Behaviors of a Lithium-Ion Battery Pack for Electric Vehicle Applications,” M.Sc. Thesis, Ajou University, 2015.

- 8.

Lee, J. Y., “Thermal Characterization of an Aluminum Flat Plate Multi-Mini Channel Thermosyphon for Electric Vehicle Battery Cooling,” M.Sc. Thesis, Pukyong National University, 2019.

- 9.

Kim, J. B., “Cooling Efficiency Improvement of Battery Pack for Electric Vehicle (II),” Journal of Korean Industrial and Engineering Chemistry, Vol. 14, No. 1, pp. 117-121, 2003.

- 10.

Jeong, S. H. and Suh, H. K., “Predictions of the Cooling Performance on an Air-Cooled EV Battery System According to the Air Flow Passage Shape,” Transactions of the Korean Society of Mechanical Engineers B, Vol. 40, No. 12, pp. 801-807, 2016.

10.3795/KSME-B.2016.40.12.801

- 11.

Baek, S. K. and Park, S. J., “Thermal Analysis of a Battery Cooling System with Aluminum Cooling Plates for Hybrid Electric Vehicles and Electric Vehicles,” Transactions of the Korean Society of Automotive Engineers, Vol. 22, No. 3, pp. 60-67, 2014.

10.7467/KSAE.2014.22.3.060

- 12.

Hyun, S. B., Kim, B. Y., Song, J. H., and Lee, D. R., “A Study on the Convective Cooling Performance of the Secondary Battery in Electric Vehicle,” Journal of the Korean Society for Precision Engineering, Vol. 37, No. 4, pp.271-282, 2020.

- 13.

Jiaqiang, E., Yue, M., Chen, J., Zhu, H., Deng, Y., et al., “Effects of the Different Air Cooling Strategies on Cooling Performance of a Lithium-Ion Battery Module with Baffle,” Applied Thermal Engineering, Vol. 144, pp. 231-241, 2018.

10.1016/j.applthermaleng.2018.08.064

Biography

- Byeong Yeop Kim

B.S. Student in the School of Mechanical and Automotive Engineering, Catholic University of Daegu. His research interest is Electric Vehicle and Future Alternative Energy.

- Dong-Ryul Lee

Professor in the School of Mechanical and Automotive Engineering, Catholic University of Daegu. His research interest is Heat Transfer, Fluid Engineering, and Electric Vehicle.