ABSTRACT

Social interest in the 4th industry, intelligent factories, and smart manufacturing is continually growing along with the core technologies like big data and artificial intelligence, which can generate meaningful information by collecting and accumulating sensor data. Demand for industrial automation equipment is increasing worldwide due to the efforts needed to modernize manufacturing facilities, reduce automation and cycle time, and improve quality. Currently, the majority of research is focused on the development of automation facilities and improving productivity. The research on the contents of real-time data considering the characteristics of the cutting machine plasma machine is insufficient. In this study, based on the current data measured according to cutting current and cutting speed, a reference value for cutting quality is presented and the optimal process parameter has been selected. A model for predicting cutting quality by introducing the Mahalanobis Distance Method is presented. An attempt has been made to derive selection and optimal cutting process variables. Based on the predictive model, threshold values were specified and used in real-time data to consider the correlations between multivariate variables and evaluate the degree of scattering around the average of specific values of each variable. Also, process parameters suitable for surface roughness were calculated.

-

KEYWORDS: Plasma cutting, Real-time data, Mahalanobis distance method, Cutting quality monitoring

-

KEYWORDS: 플라즈마 절단, 실시간 데이터, 마할라노비스 거리법, 절단 품질 모니터링

1. 서론

4차 산업혁명은 ICT (Information and Communication Technology) 기반 기술과 첨단 디지털 기술이 빅뱅(Big-Bang)으로 융합된 디지털화(Digitalization) 사회라 불리고 있다. 최근에는 정보통신기술 ICT 및 컴퓨팅 기술 발전에 따라 산업용 자동화 설비의 활용 범위가 점점 확대되고 있다. 특히 제조시설 현대화, 자동화, Cycle Time 단축, 품질개선 노력으로 인해 전 세계적으로 산업용 자동화 설비의 수요가 지속적으로 증가하고 있다. 이처럼 국내 제조 산업은 제품의 생산성, 작업 공정 및 운영의 효율성을 향상하기 위하여 스마트팩토리의 자동화 설비 기술 개발에 집중하고 있다. 스마트팩토리의 디지털 트윈 모델을 정의하기 위해 시뮬레이션 기술로 현실 시스템을 디지털 모델로 구현한다. 이처럼 구현한 디지털 모델은 시스템 운영을 위해 프로그램에 연결된 빅데이터를 이용하는데, 이때 대표적으로 사용하는 방법은 머신러닝(Machine Learning) 기법이다. 머신러닝 기법은 프로그래밍 없이 컴퓨터가 학습하는 능력을 갖추게 하는 데이터 분석기법 중에 하나이다. 이 기법은 광범위한 제조업 분야에 적용할 수 있고, 제조공정 구현은 실험 데이터를 이용하여 디지털 트윈 모델 유도에 많이 적용되고 있다.

1-3

스마트팩토리의 자동화 설비를 살펴보면 전체 공정의 절반 이상이 절단으로 이루어지고 있음에 따라 절단의 품질이 경쟁력 제고에 절대적인 영향을 미친다. 이러한 제조공정의 요소인 절단 품질의 연구 동향으로 기계적인 절단 모델을 이용하여 절단과 형상을 예측하려는 연구

4,5와 함께 Haferkamp

6는 실시간으로 공구 상태 및 절단 상태 모니터링을 위한 연구를 수행하였다. 이같이 절단 중 발생하는 실시간 오차를 예측 및 측정하여 새로운 공구 경로 결과에 대한 데이터로 전송하여 정밀한 가공 방법이 연구되고 있다.

7

센서를 이용한 절단가공시스템에 관련하여 Park은 비전시스템으로 절단 위치를 자동으로 설정하는 이송시스템을 개발하였다.

8 Kaebernick는 주파수 특성 분석으로 절단 소모품 상태 감시 시스템을 개발하여 절단 품질 안정화 및 생산성 향상에 기여를 하였다.

9 Kim은 러너 자동 절단용 Tool 시스템을 개발하고, 정밀 절단 및 연마 작업을 위한 알고리즘을 제안하였다. Lee는 군집 분석을 이용하여 절단 공정 중에 발생하는 절단 정보의 수집 및 수집된 절단데이터를 기반으로 절단 품질을 확인하고자 하였다.

10 Cus는 GA (Genetic Algorithm) 기반 알고리즘을 이용하여 구조물의 절단 변형 저감 방안을 제시하였다.

11 Ganapathy는 2차원 직교 절단 시 팁과 작업물에 발생하는 절단력을 계산하여 절단 여부를 판별하였다.

12 Yoon은 칩 브레이커 형상의 변수에 대하여 신경망 기법으로 최적화를 구현하였다. Lho는 플라즈마 절단을 통하여 아크 효율성과 절단폭 예측하였다.

13

플라즈마 절단 형상 연구로 Um은 플라즈마 아크를 이용한 절단 형상 연구하였다.

14 Nho는 플라즈마 절단의 효율과 절단 장치를 연구하였다.

15 이러한 선행연구는 생산성 증대와 연계하여 생산성 향상에 대한 기계적인 절단 및 절삭의 연구

16에 집중되어있다. 하지만 생산 자동화의 핵심 요인인 플라즈마 절단의 특성을 고려한 실시간 절단 품질 제어에 대한 내용의 연구는 미흡한 실정이다. 또한 대부분의 절단은 기계적 절단을 적용한 공정이 대부분이며, 여러 변수가 절단 품질에 미치는 영향을 분석한 연구만 진행되고 있어, 현재까지 최적의 절단 조건을 선정하기 위한 머신러닝 기법을 적용한 관련된 연구가 전무한 실정이다. 따라서 최근 산업 현장에서 많이 쓰이고 있는 플라즈마 절단의 최적 조건에 관한 머신러닝 기법의 연구가 시급한 것으로 사료된다. 이처럼 플라즈마 절단의 특성을 고려하여 최적의 절단 조건 선정 후 표면거칠기를 실시간으로 측정한 데이터를 기반으로 머신러닝 기법을 이용한 버의 발생 구간과 미절단 구간을 예측하고자 하였다.

본 연구에서는 스마트팩토리의 플라즈마 절단 공정 제어를 통하여 절단 품질을 확보하기 위하여 스마트팩토리의 생산되는 SA516-70로 스마트제조화에 필요한 핵심 인자들을 규명하고 이들을 활용하여 품질 제어에 필요한 최적의 알고리즘을 개발하는 것이다. 이러한 목표를 달성하기 위하여 SA516-70 재질 평판에 최적의 절단 조건들이 버 및 미절단과 같은 결함 발생의 주요 인지인 표면거칠기에 미치는 영향과 절단 품질에 대하여 연구하였다.

절단 가공 시 실시간으로 획득한 절단전류 데이터를 사용하여, 각각의 공정변수에 따라 측정된 전류 데이터로 절단 품질의 기준값을 제시하고, 선정된 최적의 절단전류는 마할라노비스 거리법(Mahalanobis Distance, MD)을 도입하여 다변량 변수들 간의 상관관계를 이용하여 결함을 예측하였다. 마지막으로 각 변수들의 특정값의 평균치를 중심으로 산포 정도를 정량적으로 평가하고자 하였다.

2. 절단 실험

2.1 실험 장치 구성 및 방법

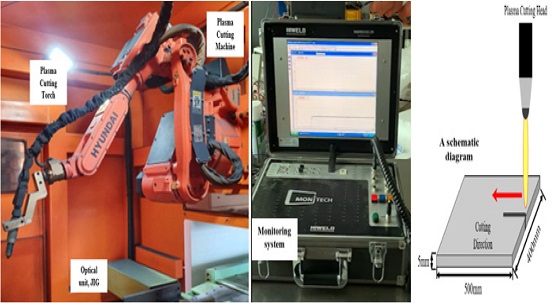

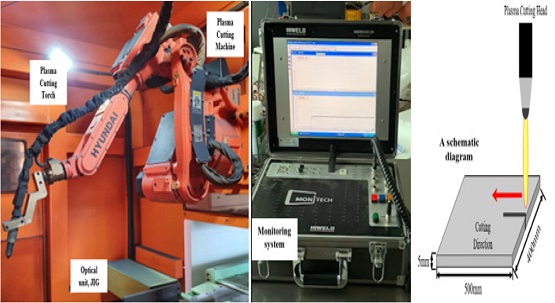

플라즈마 절단 공정의 표면거칠기 형상을 예측하기 위하여 플라즈마 절단기, 토치 구동부, 절단캐리지로 시스템을 구성하여 실험을 실시하였다. 또한 점화를 위하여 자동점화 장치를 사용하였다. 아울러 보호 가스는 자동으로 절단기를 통해 공급되도록 구성하였으며, 절단 토치와 모재와의 거리는 20 mm로 고정하였다. 그리고 토치 각도는 수직 각도를 선정하였으며, 절단 품질에 미치는 주요 인지로 절단전류 및 절단속도를 입력변수로 선정하였다.

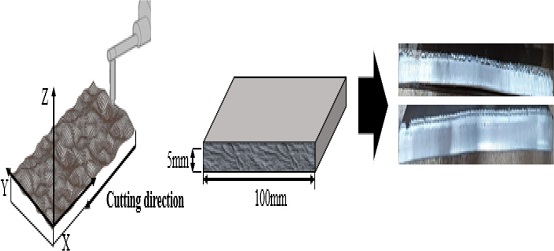

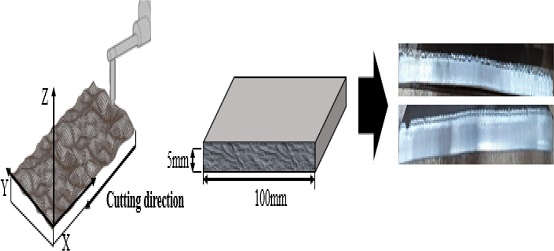

연구에 사용한 평판은 400 × 500 × 5 mm 규격의 SA516-70(ASME SA516-Grade70 Steel)의 재질로 플라즈마 절단 장비를 사용하여 시험편으로 제작하였다. 평판에 절단이 수행 시 발생하는 변형 및 응력 집중을 최소화하고, 안정적인 절단을 확보하기 위하여 전체 절단 길이를 100 mm로 설정하였으며, 평판 시험편에 9회의 절단 실험을 수행하였다. 그리고 시험편에 절단하고자 하는 표면부의 녹, 스케일, 산화물 등 이물질이 비정상 절단의 원인이 되지 않도록 Stainless Wire-Brush로 시험편을 깨끗이 청소하였다.

체계적인 결과분석을 위하여 절단전류 및 절단속도는 모니터링 시스템을 이용하여 실시간으로 수집되도록 하였다. 시험편의 기계적 성질 및 화학적 조성은

Table 1에 각각 나타내었다.

Fig. 1은 절단 실험을 위한 전체시스템 구성을 나타낸다. 다음과 같은 실시간 모니터링 시스템을 구축하여 전류신호를 실시간으로 계측하여 DAQ (Data Acquisition) 시스템에 데이터를 저장하였다.

Table 1Chemical composition of base metal

Table 1

|

Material |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

V |

|

SA516-70 |

0.186 |

0.369 |

1.089 |

0.018 |

0.004 |

0.03 |

0.01 |

0.014 |

0.013 |

Fig. 1Experimental setup and specimens

2.2 실험계획

절단 실험에 사용된 실험계획은 이원배치법을 적용하여 실험계획을 수립하였으며, 사용한 이원배치법은 2개의 인자에 대해 영향을 분석할 때 광범위하게 이용되고 있다. 또한 인자의 수준 수는 다를 수 있으며, 모든 수준 조합에 대하여 실험을 수행하여 반복적으로 실험을 통해 각각 인자에 대한 상관관계를 간략히 단순화하는 특징을 가지고 있다.

이에 대한 입력변수(절단속도 및 절단전류)의 적정 수준 및 범위는

Table 2에 입력변수의 레벨을 나타낸다. 따라서 공정변수에 따른 출력변수로 표면거칠기를 측정하기 위한 목적으로 실험이 진행되었으며, 표면거칠기에 주요 변수로 절단전류 및 절단속도로 선정하여 플라즈마 절단 실험계획을 수립하였다. 또한 선정된 공정변수는 실험을 통하여 표면거칠기가 형성되는 범위 내에서 도출된 적정값인 절단전류 20-50 A, 절단속도 4.0-5.0 mm/sec로 선정하였다.

Table 2Cutting parameters and their levels

Table 2

|

Input parameter |

Unit |

Level |

|

Cutting current |

Amp |

20, 30, 40 |

|

Cutting speed |

mm/sec |

4.0, 4.5, 5.0 |

이같이 절단 실험계획으로 일반적으로 알려진 완전요인실험으로 구성하였으며, 반복이 없는 이원배치실험법(Two-Way Factorial Design)의 경우 실험의 대상으로 인자를 2개 선정하여 실험을 실시하는 방법으로 인자를 각각 A, B라 정의하였다. 수준(Level)은 중심점과 요인배치법의 수준값(절단전류)을 갖게 됨으로서 3개의 수준(절단속도)을 갖는 실험계획법으로 구성된다.

따라서 입력변수인 절단전류 및 절단속도로 설정할 경우 총 9회의 실험 조건이 생성된다. 고정변수인 토치 높이는 노즐을 모재에 근접시키면 더블아크가 발생하기 쉬우며 반대로 토치 높이가 증가하면 부하전압이 증가하여 전원의 허용전압을 초과하기 때문에 아크를 정상적으로 유지하기 어렵다. 그런 점에서 경사면 절단을 수행할 경우 기울어진 쪽으로 드로스가 부착되어 토치의 각도는 90°로 고정하였다.

2.3 마할라노비스 거리법을 이용한 절단 품질 분석

범주가 정해진 데이터를 학습데이터로 선정한 비지도 학습은 출력 정보가 없는 학습 데이터에 대해서 학습을 하는 것으로 입력 데이터에 포함되어 있는 패턴을 찾아내는 과정이다. 이처럼 데이터의 유사한 정도를 파악하여 집단으로 구분하는 군집화 등이 비지도 학습이다. 여기서 분류는 입력되는 데이터를 정해진 다수의 부류로 대응시키는 방법이다. 분류에서 학습 데이터는 입력 데이터 xi와 출력 yi로 구성된 {(x1, y1), (x2, y2), ..., (xy, yy)} 집합으로 주어진다.

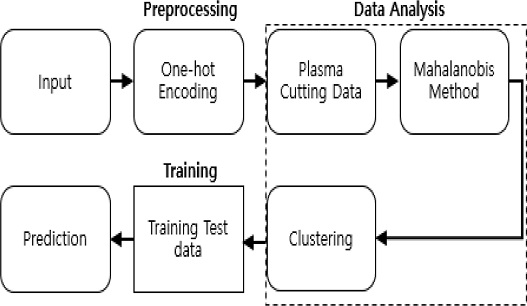

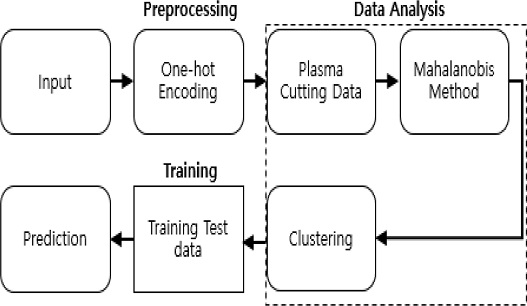

Fig. 2는 머신러닝 기법의 전체적인 흐름을 나타낸다. 데이터 전처리, 데이터 분석, 모델 학습, 결과 예측 순서로 진행된다. 데이터 전처리에서는 실험 데이터의 특정값을 범주형 변수값으로 만들어내고 데이터 선택을 수행하고 일반화를 진행한다. 데이터 분석은 다변량 이상치를 제거 후 플라즈마 절단 공정에서의 절단전류에 대한 마할라노비스 거리법을 적용하여 데이터의 결함을 정의한다. 아울러 정의된 데이터는 성능평가를 위해 기계 학습 알고리즘의 비지도 학습 데이터로 사용된다.

Fig. 2Flow chart of mahalanobis distance

데이터 분석을 위한 마할라노비스 거리법에서 이상치는 다른 데이터와 큰 차이가 나서 메커니즘에 의해 생성된 것이 아닌지 의심스러운 데이터를 정의한다. 데이터 분석에서 λ가 데이터의 결함을 의미하고, 이상치 유무에 따라 품질의 영향을 끼침을 확인할 수 있다.

여기서 Xp,q와 X'p,q는 각각 표준화 적용 전과 후의 행렬이고, mq와 σq는 각각 행렬 X의 평균과 표준편차이다. 표준화 과정은 변수들의 평균과 표준편차가 서로 다르기 때문이다. 위와 같이 표준화 과정을 적용한 후, 평균벡터 x¯∈Rm×1의 j번째 성분 xJ¯와 공분산 행렬 S ∈ Rm × m의 p번째 행 q번째 열의 성분은 각각 다음과 같이 계산된다.

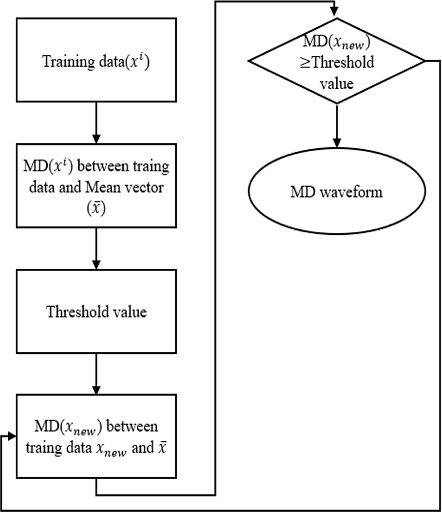

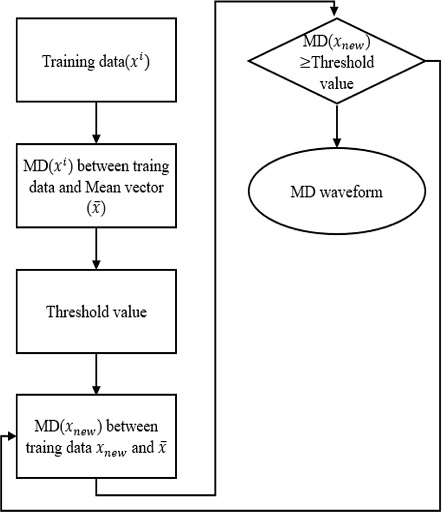

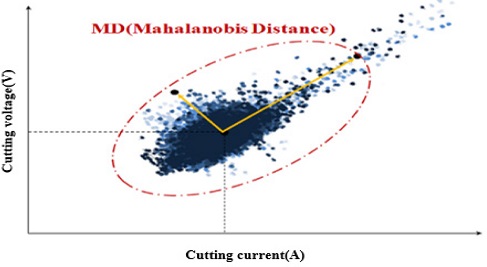

Fig. 3은 MD 기법의 프로그램 모식도를 나타낸다. 절단 실험 샘플을 MD의 문턱값을 설정하기 위해서 n개의 정상 샘플 x를 이용하여 MD(x)를 계산한다. 본 연구에서는 계산된 MD(x)의 백분위를 문턱값으로 설정하였다. 검증 단계에서는 샘플의 MD값이 문턱값은 미리 정의된 0보다 크거나 같을 경우 즉, 음의 값인 경우에 결함 신호를 생성한다.

Fig. 3MD algorithm based detection waveform procedures

MD는

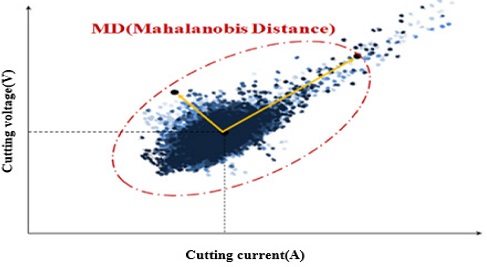

Fig. 4에서 보는 바와 같이 관찰하고자 하는 데이터가 정상데이터의 평균에서 얼마나 떨어져 있는지를 정확하게 파악하기 위해 데이터 평균, 표준편차 그리고 함수간 상관관계와 같은 분포의 특성을 고려하여 계산하기 때문에 다른 거리의 척도에 비해 시스템의 특성을 정확하게 반영하여 거리를 측정할 수 있는 특징을 가지고 있다.

Fig. 4Transform data group into Mahalanobis space

3. 실험 결과

3.1 절단 실험 결과

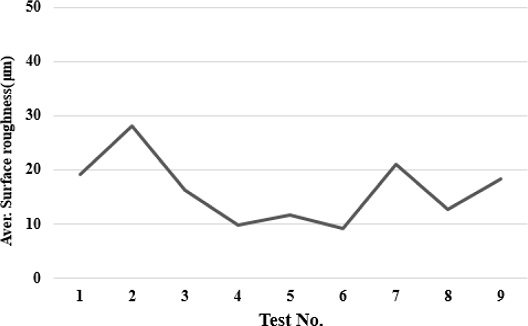

플라즈마 절단 실험 결과 실험 조건에서 매우 안정적인 표면거칠기가 형성됨을 확인하였으며, 일부 절단속도에 의하여 다량의 버와 함께 비정상 절단이 발생되어 불균일한 표면거칠기와 외관상 결함을 나타낸 것으로 확인하였다. 또한, 절단 조건에 따라 절단 형상에 미치는 영향을 판별하기 위해 단면 형상을 촬영하여 특성을 분석하였다. 이에 대한 절단부의 형상을 측정하기 위하여 절단이 완료된 시험편의 가로축 중간 부분을 띠톱절단기(Bandsaw Cutting Machine)를 사용하여 100 × 5mm의 크기로 절단하였다. 총 9회의 실험 조건의 표면거칠기를 측정하였다.

Fig. 5는 절단 실험 직후의 시편에 대한 표면거칠기 형상 측정으로 대표적인 단면 형상의 크기를 측정하는 화면을 나타낸다. 그에 따른 절단 실험 직후의 시편을 나타낸다.

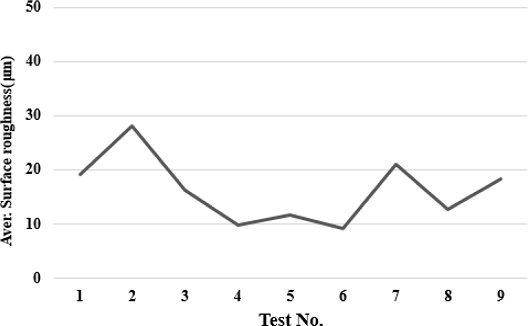

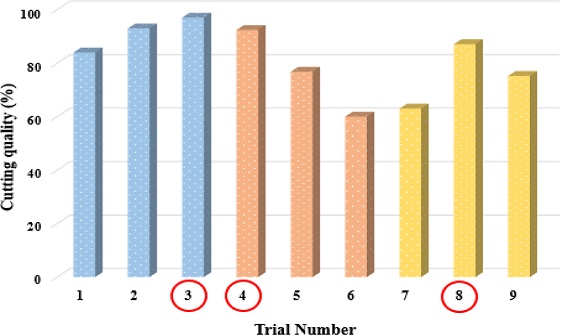

Fig. 6은 실험 결과에 따른 총 9회의 실험 조건에 따른 표면거칠기를 나타낸다.

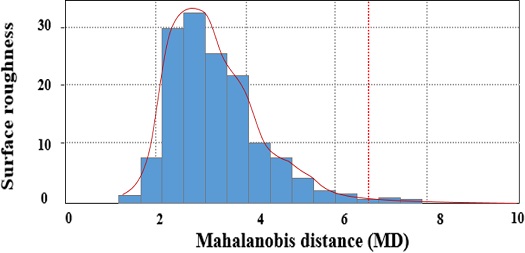

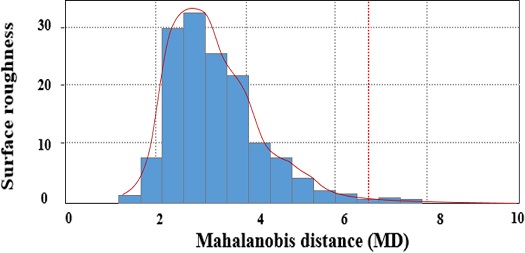

Fig. 7과 같이 평균벡터와 공분산행렬을 계산하기 전에 먼저 행렬의 각 성분들에 Z 스코어 표준화 과정을 적용한다. MD는 군집데이터 그룹이 정규분포를 가진다는 가정 하에 다변량 정규분포의 밀도함수로부터 통계적으로 확장하여 정의한다.

Fig. 5Measurement of surface roughness

Fig. 6Results of surface roughness for plasma cutting process

Fig. 7Distributions of MD values of training data

Fig. 7은 총 9회의 실험 조건에 따른 표면거칠기에 대해 정상 샘플의 정의와 MD에 의한 표면거칠기의 분산분포를 나타낸다. 표면거칠기의 분산분포의 형태는 오른쪽으로 길게 형성됨을 확인하였다. 학습된 샘플에 대해서 계산된 마할라노비스 거리법의 값과 발생된 정상 샘플 그룹으로 나타낸다. 이처럼 학습된 샘플은 커널 평활한 선으로 표면거칠기에 대해 품질 분석을 위해서 사용하였으며, 빨간색 세로 점선은 이상치의 백분위의 수를 나타낸다.

앞에서 절단 공정에서 진단하고자 하는 시스템은 플라즈마 절단의 전류신호를 통해 MD 기반의 분석을 적용하여 품질을 확인하였다. 이에 따른 수집된 플라즈마 절단의 실험 데이터들은 절단 결함 및 품질 탐지를 위해 선택되었다. 아울러 각 샘플들은 절단 길이를 100mm로 선정하였으며, 총 1,048,576개의 샘플들 중에서 26,201개의 샘플이 학습 샘플로 사용되고, 나머지 샘플은 검증 샘플로 사용된다. 동시에 학습 샘플들은 평균벡터와 공분산행렬의 계산, 이상치 설정을 위해서 사용하였다.

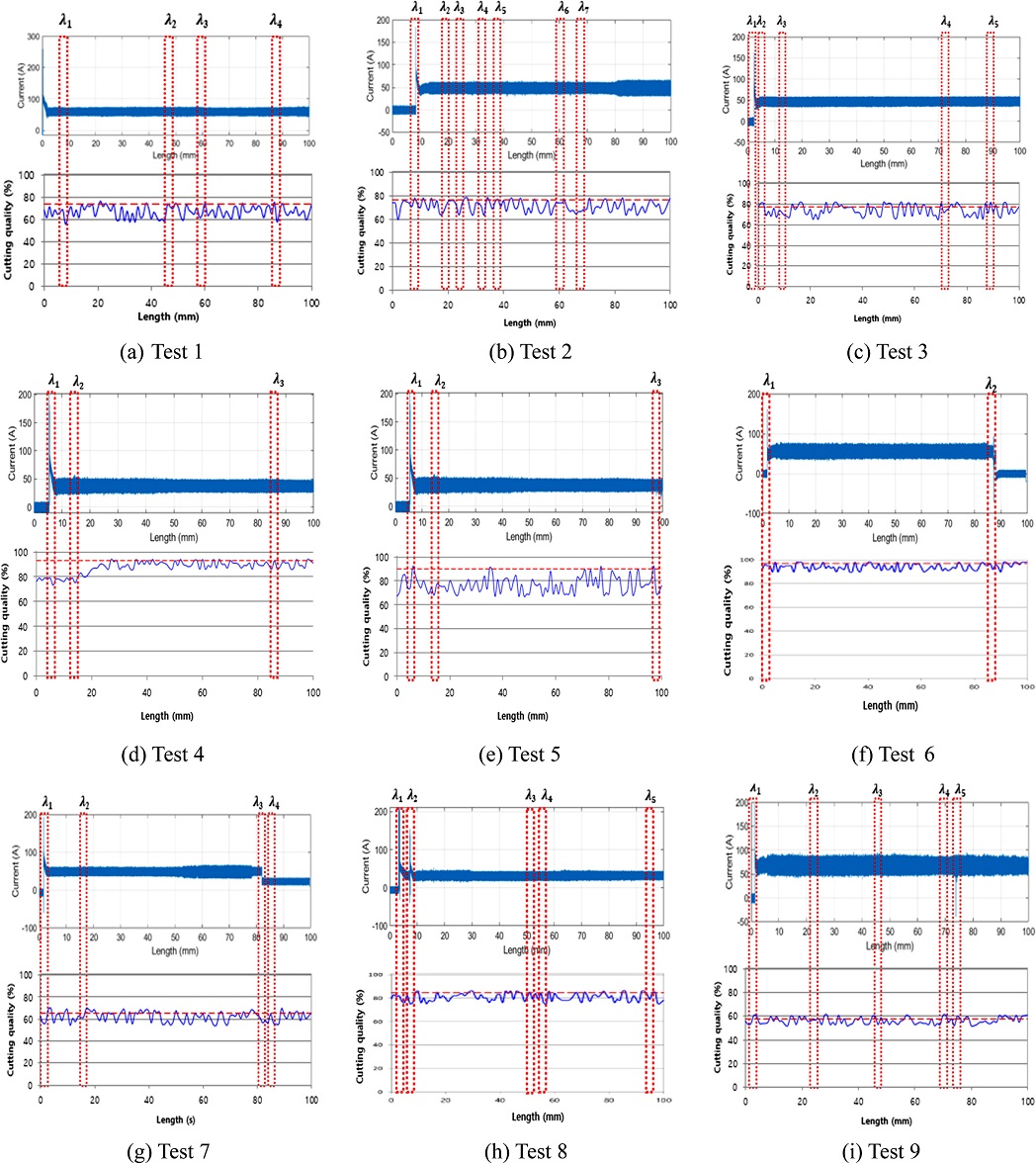

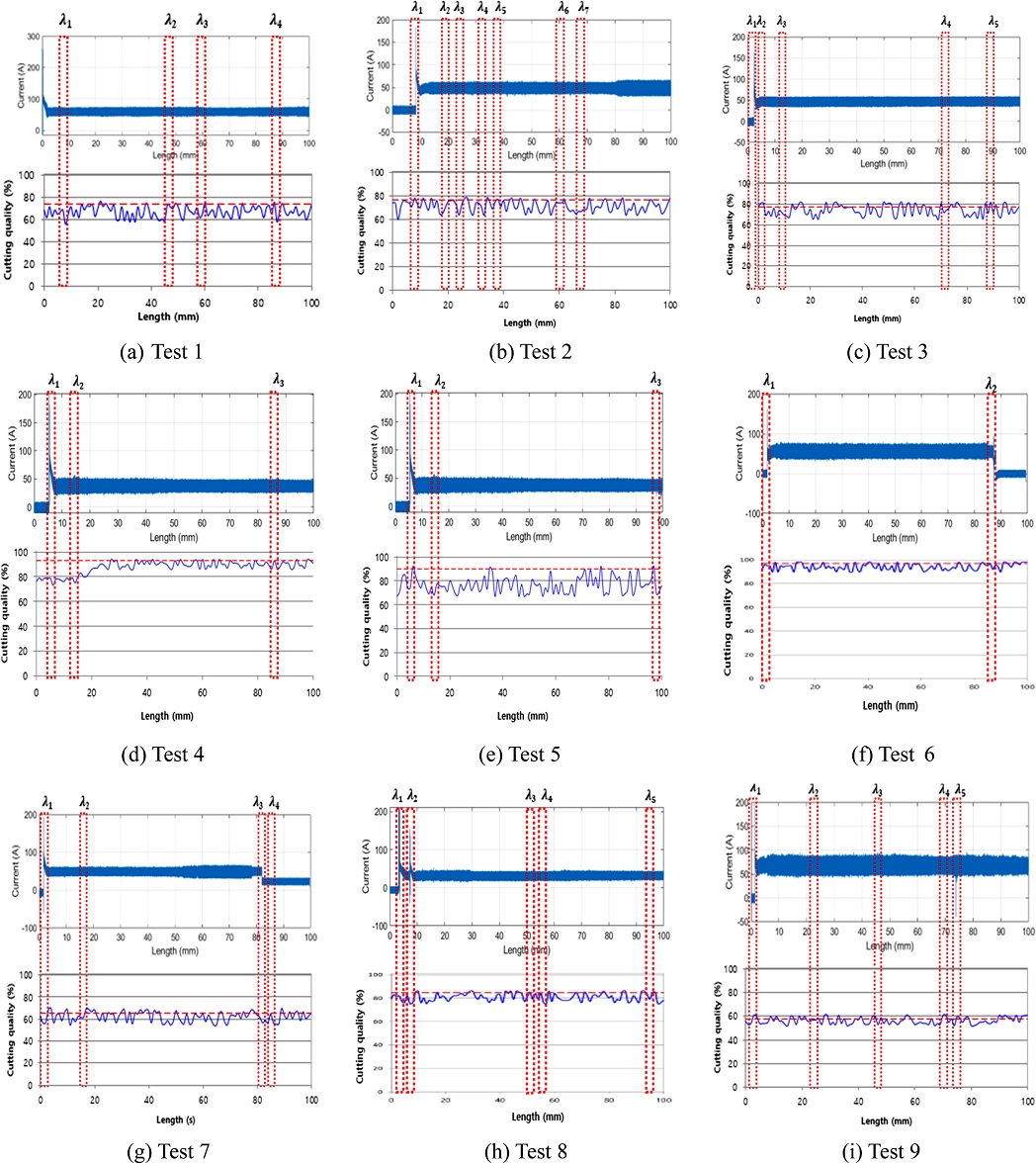

Fig. 8에서 나타낸 바와 같이, 플라즈마 절단으로 인해 품질 저하를 나타낸 시점은 굵은 빨간색 점선의 사각형(

λ)으로 표시되어 있고, 학습 샘플들에 의해서 계산된 이상치는 빨간색 가로 점선으로 표시하였다. 절단 실험 중 비정상이 형성될 경우 MD값은 이상치보다 작고, 그렇지 않을 경우에는 이상치보다 높다. 그런 점에서 플라즈마 절단 공정 변수에 대하여 마할라노비스 거리법을 적용하여 최적의 공정변수를 도출하고자 하였다. 이같이 총 9회의 실험 조건으로 절단속도(4.0-5.0 mm/sec)별로 분류하여 절단전류에 따른 절단 품질을 분석한 그래프를

Figs. 8(a)부터

8(i)를 나타낸다.

Fig. 8Results of cutting quality using Mahalanobis distance

절단 품질 분석에서 이상치를 나타내는 λ는 절단전류의 폭이 유지하다가 급격하게 떨어지는 것을 이상 진단으로 정의하였으며 기준 공간에서 거리가 멀어질수록 정상 그룹에서 벗어난 것을 의미한다.

Figs. 8(d)부터

8(f)는 절단속도의 4.5 mm/sec로

Fig. 8(e)의 Test 5에서 영향을 미치는

λ가 절단 품질을 현격하게 떨어지게 하는 절단 시작 지점에서 발생되었으며, 절단 길이가 10mm일 때 급격히 전류가 안정되면서 절단 품질에 영향을 미쳤으며 절단 품질은 90%로 나타났다.

Fig. 8(f)의 Test 6에서

λ는 절단 시작 지점과 끝 지점에서 절단전류가 순간적으로 높아져서 절단 품질이 97%가 나타남을 확인하였다.

Figs. 8(g)부터

8(i)는 플라즈마 절단 시 5.0 mm/sec의 플라즈마 절단속도에서 절단전류 파형이 다른 2가지 플라즈마 절단속도의 절단전류 파형보다 변화의 범위가 크며 속도에 의해 플라즈마 아크가 영향을 받아 슬러그가 시편 절단 방향으로 흘러내리는 현상에 의해 발생되는 전류 변화로 절단 품질에 크게 영향을 미친 것으로 사료된다. 전극 소모를 기준으로 비교하면 5.0, 4.5, 4.0 mm/sec 순으로 마모가 됨을 확인할 수 있었다.

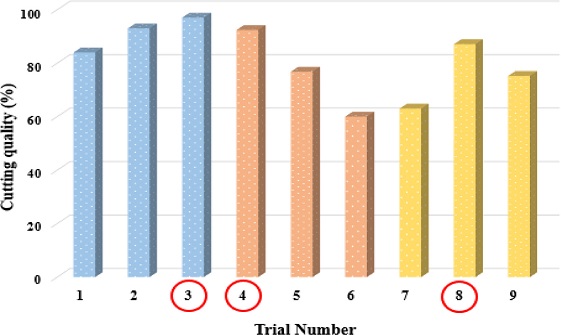

Fig. 9의 그래프에서도 동일하게 확인되었다. 절단속도가 빠를수록 절단 품질이 다소 하락하는 경향이 있으며, 같은 절단전류조건에서 거의 동일한 수치로 가장 낮은 값을 가진다. 4.0 mm/sec의 절단속도는 Test 3으로 40 A의 전류, 4.5 mm/sec의 절단속도는 Test 3으로 20 A의 전류, 5.0 mm/sec의 절단속도는 Test 8으로 30 A의 최적 공정변수로 선정하였다.

Fig. 9Optimization of cutting parameter according to cutting speed

4. 결론

본 연구에서는 플라즈마 절단 장비의 특성을 고려한 실시간 데이터에 대한 MD 기법을 적용하기 위해 총 9회의 실험 조건으로 절단속도(4.0-5.0 mm/sec)별로 분류하여 절단전류에 따른 절단 품질을 분석하였으며, 표면거칠기에 대한 절단 공정변수를 최적화하기 위하여 다양한 분석법과 예측기법을 적용하였다. 이처럼 실험을 통해 획득한 실시간 데이터를 활용하여 공정변수와 품질 간의 상관관계 분석을 수행함으로써 다음과 같은 결론을 얻을 수 있었다.

(1) 전체 절단 시간에 대한 절단 품질을 산출하였으며, 가장 안정적인 절단 조건을 선정하기 위해 절단 품질 결과를 분석하여 절단전류 파형과 절단 품질을 비교하였을 때 빠른 절단속도일수록 품질이 다소 하락하는 경향을 나타내며 같은 절단전류 조건에서 거의 동일한 수치로 낮음을 확인하였다.

(2) 검증 단계에서는 새로운 샘플과 평균벡터 간의 MD를 계산한 후, 그 값이 미리 계산된 이상치보다 크거나 같으면 절단 품질에 영향을 미치는 것을 신호로 나타낸다. 실험 결과는 MD 기반의 품질 분석으로 실시간 데이터를 활용하여 기준 공간에서 거리가 멀어질수록 정상 그룹에서 벗어나는 것을 보여준다.

(3) 4.0 mm/sec의 절단속도는 Test 1로 40 A의 전류, 4.5 mm/sec의 절단속도는 Test 4로 30 A의 전류, 5.0 mm/sec의 절단속도는 Test 8로 30 A의 최적 공정변수로 선정하였다.

MD 기법을 통해 개발된 예측 모델을 기반으로 이상치를 지정하여 실시간 데이터에 사용함으로써, 표면거칠기에 적절한 공정변수를 산출하였다. 플라즈마 절단 공정에서 획득한 실시간 데이터를 활용하여 절단부의 결함을 예측하기 어려운 부분에 효율적으로 적용된다. 안정된 절단 결과를 필요로 하는 플라즈마 절단의 실시간 예측 및 구성에 효과적인 기법으로 적합하다고 사료된다.

ACKNOWLEDGMENTS

This work was supported by the Project of Technology Development for Industry Core (No. 20004100, Package Concept of Pipe Spools, Platform as a Service, Digital Twin, Big Data) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea).

REFERENCES

- 1.

Lee, E. M., “4th Industrial Revolution and Changes in Industrial Structure,” Korea Information Society Development Institute, Vol. 27, No. 15, pp. 1-22, 2016.

- 2.

Xu, X. and Hua, Q., “Industrial Big Data Analysis in Smart Factory: Current Status and Research Strategies,” IEEE Access, Vol. 5, pp. 17543-17551, 2017.

10.1109/ACCESS.2017.2741105

- 3.

Wan, J., Yang, J., Wang, Z., and Hua, Q., “Artificial Intelligence for Cloud-Assisted Smart Factory,” IEEE Access, Vol. 6, pp. 55419-55430, 2018.

10.1109/ACCESS.2018.2871724

- 4.

King, R., “A Synoptic Review of High-Speed Machining from Salomon to the Present, High Speed Machining,” Proc. of the Winter Annual Meeting of ASME, 1984.

- 5.

Kim, H. T. and Kil, S. C., “High Quality Plasma Cutting and Laser Cutting Technology,” Journal of Welding and Joining, Vol. 35, No. 2, pp. 30-34, 2017.

10.5781/JWJ.2017.35.2.5

- 6.

Haferkamp, H., Goede, M., and Von Busse, A., “Quality Monitoring and Assurance for Laser Beam Cutting Using a Thermographic Process Control,” Optical Measurement Systems for Industrial Inspection, Vol. 3824, pp. 383-391, 1999.

10.1117/12.364276

- 7.

Chun, S. H., “Effects of Cutting Condition on Surface Roughness in the Spiral Up Milling of Aluminum Alloy,” Journal of the Korean Society of Manufacturing Process Engineers, Vol. 13, No. 4, pp. 83-90, 2014.

10.14775/ksmpe.2014.13.4.083

- 8.

Park, S. H., Cho, Y. T., and Jung, Y. G., “Roughness Variation of Cross Section for Hastelloy Substrate by Laser Cutting Condition,” Proc. of the Spring Conference on the Korean Society of Manufacturing Process Engineers, p. 161, 2013.

- 9.

Kaebernick, H., Jeromin, A., and Mathew, P., “Adaptive Control for Laser Cutting Using Striation Frequency Analysis,” CIRP Annals, Vol. 47, No. 1, pp. 137-140, 1998.

10.1016/S0007-8506(07)62802-9

- 10.

Lee, D., Patwa, R., Herfurth, H., and Mazumder, J., “Computational and Experimental Studies of Laser Cutting of the Current Collectors for Lithium-Ion Batteries,” Journal of Power Sources, Vol. 210, pp. 327-338, 2012.

10.1016/j.jpowsour.2012.03.030

- 11.

Cus, F. and Balic, J., “Optimization of Cutting Process by GA Approach,” Robotics and Computer-Integrated Manufacturing, Vol. 19, Nos. 1-2, pp. 113-121, 2003.

10.1016/S0736-5845(02)00068-6

- 12.

Ganapathy, B. and Jawahir, I., “Modeling the Chip-Work Contact Force for Chip Breaking in Orthogonal Machining with a Flat-Faced Tool,” Journal of Manufacturing Science and Engineering, Vol. 120, No. 2, pp. 49-56, 1998.

10.1115/1.2830110

- 13.

Lho, T. and Na, S. J., “Arc Efficiency and Kerf Width in Plasma Arc Cutting Process,” Journal of Welding and Joining, Vol. 5, No. 5, pp. 23-33, 1987.

- 14.

Um, K. and Kim, D., “A Study on the Plasma Arc Cutting Phenomena of Plate Materials,” Journal of Welding and Joining, Vol. 9, No. 4, pp. 69-74, 1991.

- 15.

Lho, T. and Na, S., “A Study on Development of Plasma-Arc Cutting System with Computer Numerical Control,” Journal of Welding and Joining, Vol. 8, No. 3, pp. 60-69, 1990.

- 16.

Kim, J. S., Kim, J., Kang, H. S., and Lee, J. Y., “Development of Diagnostic Algorithm for a Die-Casting Machine Using Real-Time Casting Parameters,” Proc. of the KSPE Autumn Conference, p. 259, 2019.

Biography

- Bo-Ram Lee

The Master degree in Mechanical Engineering at Mokpo National University. She is currently pursuing Doctor degree. She is currently studying on numerical studies on mechanical characteristics for plasma cutting.

- Tae-Jong Yun

The Master degree in Mechanical Engineering at Mokpo National University. He is currently pursuing Doctor degree. His area of research interest is automatic welding control. He is currently studying on optimization of cutting.

- Won-Bin Oh

The Master degree in Mechanical Engineering at Mokpo National University. He is currently pursuing Doctor degree. His area of research interest is automatic welding control. He is currently studying on prediction model.

- Chung-Woo Lee

He is currently pursuing his Master degree in Mechanical Engineering at Mokpo National University. His area of research interest is automatic control.

- Hak-Hyoung Kim

Doctor in the Department of Mechanical Engineering, Mokpo National University. His research interest is automation facilities.

- Yeong-Jae Jeong

Doctor in the Department of Mechanical Engineering, Mokpo National University. His research interest is artificial intelligence.

- Ill-Soo Kim

Professor of Mechanical Engineering, Mokpo National University. Dr. Kim worked as a researcher in industry and universities for over 20 years at University of Wollongong, Seoul National University, Mokpo National University. His area of research interest is automatic control.