ABSTRACT

Rubber is positioned as an important material and essential tool and means for mass production of products in all industries due to its unique properties such as sealing, elasticity and shock absorption. However, in the case of conventional press rubber molding, its energy efficiency is low due to considerable heat loss, and the deviation of the temperature distribution of the molding mold is high due to the indirect heating method in which heat is transferred to the upper and lower molds installed on hot plates. The upper and lower heating plates were heated by several heaters installed on the hot plates. The high deviation of the temperature distribution causes unformed defects. Among the rubber mold working methods that consume considerable energy, this study attempted to reduce energy consumption by directly heating the mold via installing a heater inside the upper and lower molds in a compression mold with large energy loss. As a result, compared to the conventional method of transferring heat to the mold by heating the hot plate of the press, energy was saved by 30%, the initial mold heating time was shortened by 20 minutes, and the product defect was reduced with a rate of 25%.

-

KEYWORDS: Energy saving, Direct heating, Rubber, Vulcanization, Compression forming mold, Hot plate

-

KEYWORDS: 에너지 절감, 직접가열, 고무, 가황, 압축 성형 금형, 열판

1. 서론

금형은 소재의 소성(Plasticity), 전연성(Malleability), 유동성(Fluidity) 등의 성질을 이용하여 재료를 성형가공 후 제품을 생산하는 도구로서 동일한 상품을 대량으로 생산하기 위한 필수적인 생산 기반 핵심 뿌리기술이다. 금형에 의한 가공은 제품의 생산시간 단축, 생산원가 절감, 품질 균일화, 제품의 품질 및 디자인에 크게 기여하게 된다. 또한 우리나라의 주력산업인 반도체, 디스플레이, 모바일, 자동차, 조선, 전기전자, 생활용품 등의 핵심부품을 대량 생산하기 위한 필수 도구이자 수단으로서 전후방산업을 연결하는 중요한 산업이다. 이러한 전방위 산업발전을 위해서 사용되는 부품 소재 중의 하나로 고무(Rubber)를 들 수가 있는데, 이는 탄성이라는 독특한 성질로부터 밀봉성, 탄력성 및 충격 흡수성 등의 우수한 특성을 발휘하는 소재로서 전 산업분야로 확대 적용되어 널리 쓰이는 중요한 소재로 자리잡았다.

고무 금형은 작업 방법에 따라 압축(Compression), 트랜스퍼(Transfer), 분사(Injection) 및 CRB (Cold Runner Block) 성형으로 분류할 수 있으며, 많은 에너지를 소비하게 되는데, 여기서는 압축 성형(Compression Molding)을 중심으로 논하고자 한다. 프레스 압축 성형 공정은 소재의 준비, 성형 및 가황(Vulcanization) 공정을 거쳐 완성제품 성형이 이루어진다. 준비 공정은 입고된 원재료를 성형에 적합하도록 최적 중량을 일정한 규격으로 재단하는 과정으로서 성형 품질을 결정하는 가장 중요한 요소이다. 가황은 가장 많은 시간이 소요되는 과정으로 고무의 특성을 향상시키게 된다[

1].

이처럼 고무의 고유한 특성을 최대한 발휘하도록 하기 위한 연구와 가공 공정 개선에 관한 노력이 계속되고 있으며[

2,

3], 특히 에너지 절감에 대한 요구가 높아지고 있어 이에 대한 연구가 최근 들어 활발하게 이루어지고 있다[

4,

5,

9]. 고무 금형에 의한 제품 성형은 프레스 열판(Hot Plate)으로부터 금형에 전달되는 열과 가해지는 압력에 의해 캐비티(Cavity) 내 압력과 열분포에 따라 제품의 성형 품질이 달라지게 된다[

6,

7]. 핫프레스 압축 성형기는 구조가 비교적 간단하지만 압력 조절과 금형의 균일한 온도 조절이 어렵고, 프레스 자체에 가열 구조를 갖는 열판에 장착되는 금형으로 열을 전달하는 방식으로 열저항이 발생하는 구조로서 열 손실이 크다. 또한 성형 작업을 시작하기 전에 열판을 가열하여 열전달을 통해서 금형을 성형이 가능한 온도까지 올리고, 성형 작업 중 금형의 온도를 일정하게 유지하도록 재가열하는 과정에서 열전달에 의한 금형을 간접가열함으로서 에너지 절감면에서 비효율적이라고 할 수 있다[

8].

따라서 본 연구는 프레스 압축 성형 고무 금형에 관한 것으로 금형에 열원을 직접장착하여 가열하는 직접가열(Direct Heating) 방식으로 작업 초기 금형 가열 시간 단축과 금형 내부 온도 편차를 줄이고, 성형 작업 중 재가열 온도 유지를 용이하게 할 수 있다. 이는 공정 효율을 높여 균일한 성형 품질 유지로 불량률을 낮추고, 에너지 소비가 큰 고무 성형 공정에 있어서 에너지 절감이 가능할 것이다.

2. 프레스 성형기의 고무 금형 가열

2.1 열판 가열에 의한 열전달 방식

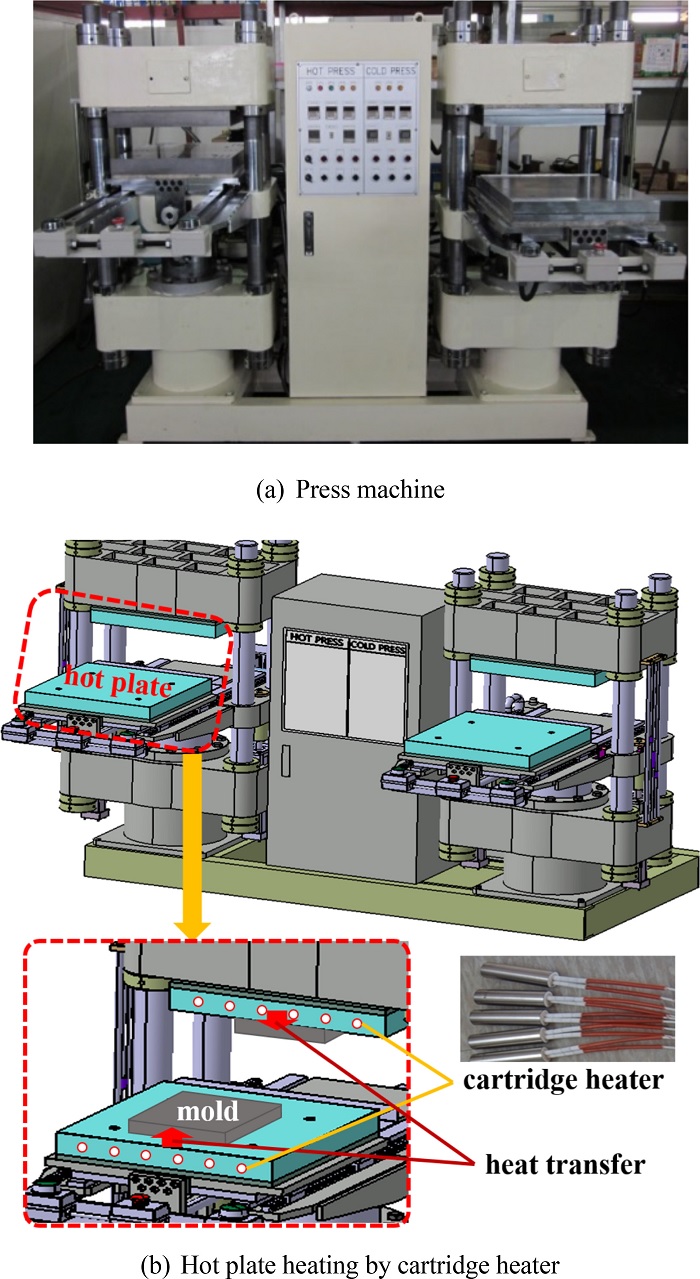

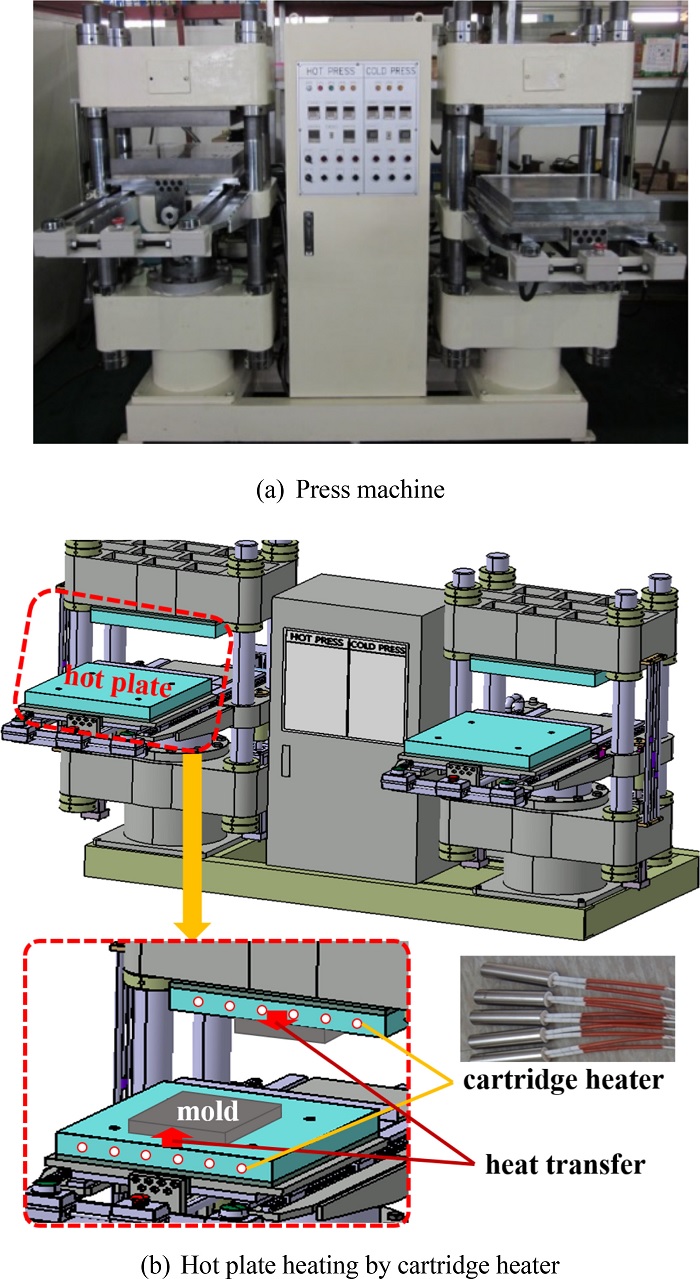

고무 성형은 설비 의존도가 높고, 자동화 및 제품 정밀도 수준에 따라 생산원가 및 품질이 좌우되며, 국내 산업 발전과 함께 고무 성형 기술력도 한층 높아졌다. 고무 성형은 일반적으로

Figs. 1(a)와 같은 형태의 프레스를 이용하여

1(b)와 같이 상하열판에 설치한 카트리지 히터(Cartridge Heater)로 가열하여 고무 금형으로 열을 전달하여 간접적으로 금형을 가열하는 핫프레스 방식의 압축 성형이 주를 이루고 있다[

9]. 성형기는 유압에 의해서 압착 및 탈착하는 구조로서 열판 사이에 장착되어 가압되는 다양한 형상의 금형 안에서 투입된 고무가 가황되어 제품성형이 이루어지게 된다. 열전달에 의한 고무 금형을 가열하는 방식으로 초기 온도 상승 및 안정화 시간이 많이 걸리고, 온도조절이 용이하지 않다. 이는 성형기 컨트롤 패널에 설정된 온도와 열판의 히터 온도, 열판 온도, 금형 온도, 금형 내 제품 캐비티 온도가 각각 다르므로 열전달 시 열저항(Heat Resistance) 등으로 균일한 적정 온도 제어가 어렵다. 그러므로 금형 내부의 온도 편차가 크고, 에너지 소비가 큰 단점이 있다.

Fig. 1General hot press forming machine

따라서 이러한 문제점을 해결하고자 성형기 자체의 열판의 히터를 제거하고, 금형 내부에 히터를 직접 배치함으로서 열판의 온도 편차로 인한 제품 불량요인을 제거하고, 제품 취출 시에도 열손실에 의한 온도 강하를 최소화하여 금형 내 온도를 일정하게 유지하고자 하였다.

2.2 금형의 직접가열 방식

본 연구는 모회사의 원형 압력패킹을 실제로 생산하는 과정에서의 많은 문제점들을 호소함에 따라 진행되었다. 제품 성형을 위해서는 작업 시작 전에 금형을 성형이 가능한 온도로 가열해야 하는데 평균적으로 1시간이 소요되어 작업시간이 줄어들어 생산성이 떨어지고, 열판을 가열하면서 열전달에 의해서 금형을 간접적으로 가열하는 방식으로 열손실이 많아 에너지 소비가 컸다. 또한 열전달에 의한 금형 내 온도 편차를 최소화해야 하지만 이 또한 편차가 크고, 균일한 열분포를 유지하기 힘든 상황이었다. 따라서 간이 금형을 이용한 직접가열 방식의 유효성을 확인하고, 실제로 제품 금형을 직접가열할 수 있는 고무 성형 금형 개발을 진행하였다.

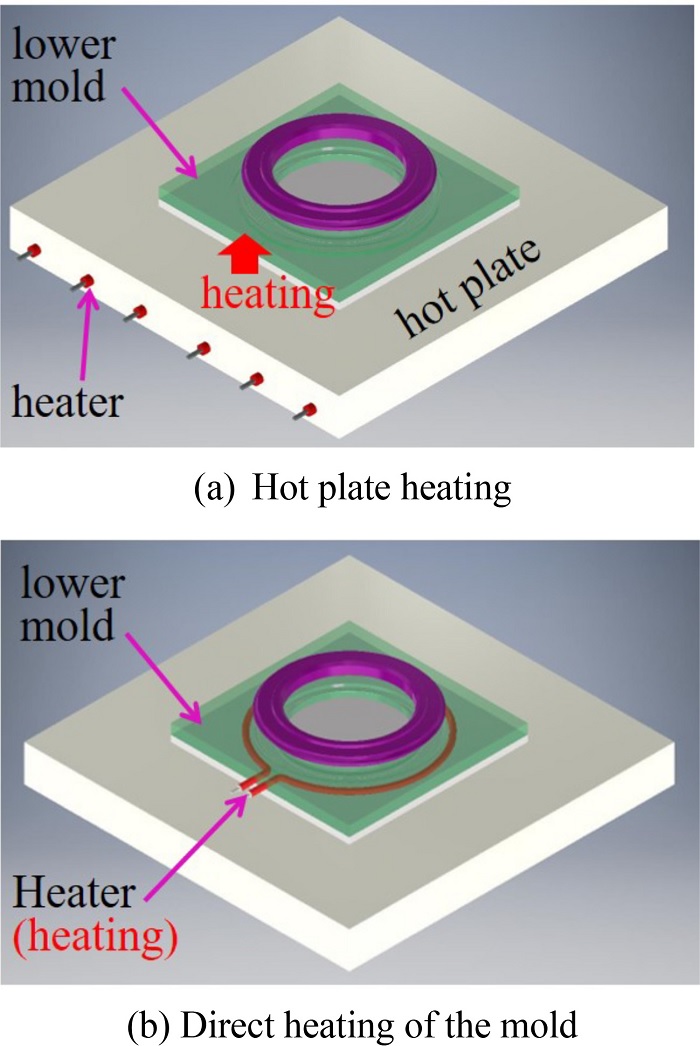

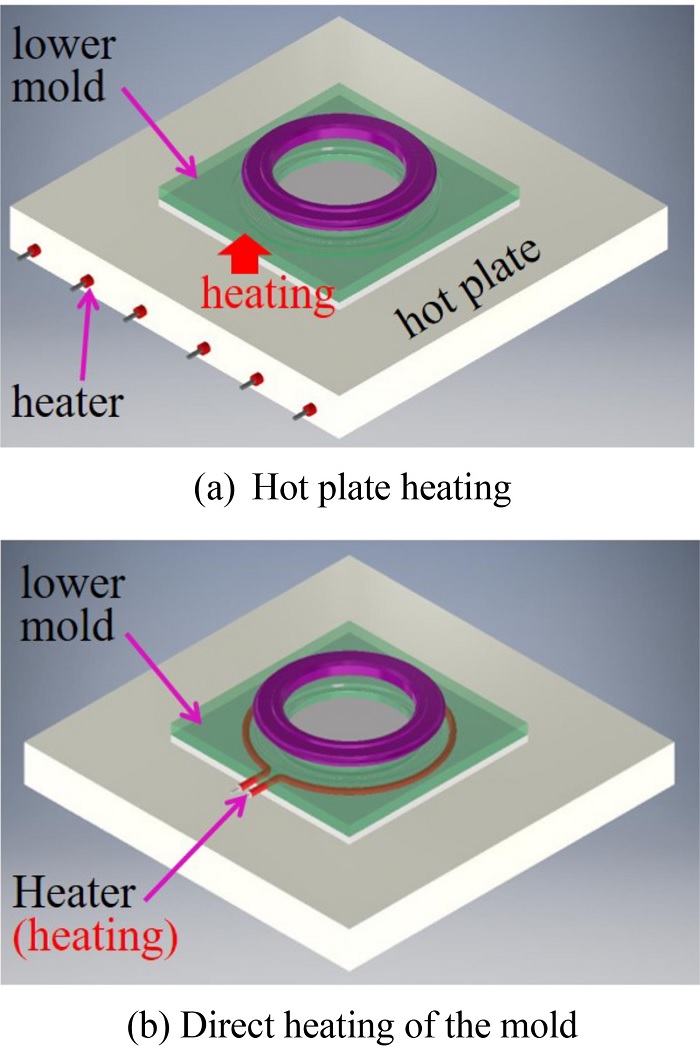

Fig. 2에 고무제품 프레스 금형 가열 방법으로 열판을 가열하여 금형으로 열을 전달하는 간접가열과 금형을 직접가열하는 직접가열 방식의 개념도를 나타내었다.

Fig. 2Comparison of heating mathods of rubber molds

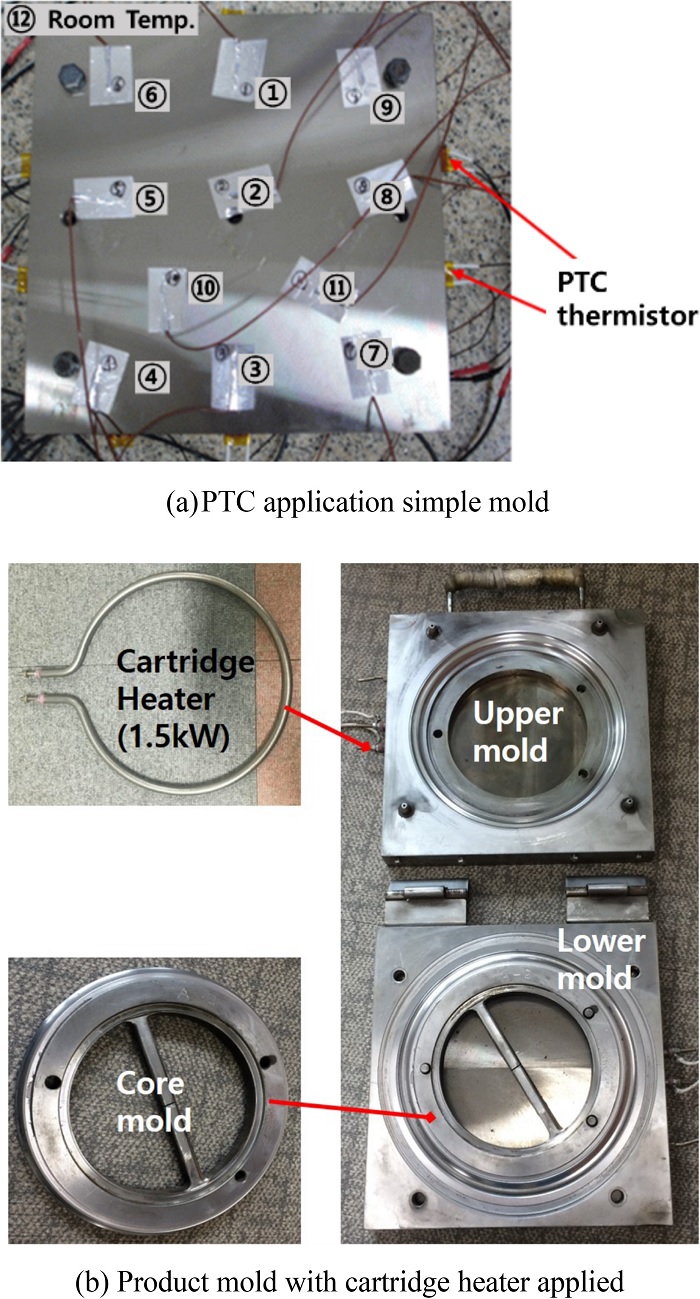

먼저 기존 방식은 금형의 온도 제어를 위해 센서를 부착하고 온도데이터를 토대로 전원의 On/Off 제어로 장치 구조가 복잡하고, 온도 제어가 원활하지 않다. 그래서 이를 개선하고 일정한 온도 유지가 용이한 가열원으로서 PTC (Positive Temperature Coefficient Resistor) 히터를 이용하였다. PTC는 전원을 인가하면 초기에 전력소모가 조금 높고 큐리온도에 도달하면 안정화 되어 전력소모가 줄어들면서 일정한 온도를 유지하게 되어 에너지 소비를 줄일 수 있고, 별도의 온도 제어가 필요 없는 특징이 있다. 성형 캐비티를 가공하지 않은 250 × 250 × t30 mm 간이 금형을 제작하고, 금형 내부에 큐리온도 245°C, 15 × 46 × t2.75mm 사이즈의 PTC 히터 10개를 배치하여 고무 금형의 직접가열 방식의 가능성을 확인하였다[

10].

그리고 실제로 원형의 압력패킹 생산이 가능한 성형 금형을 제작하고, 원형 제품의 캐비티 형태에 맞춰 원형의 1.5 kW 카트리지 히터를 상형 및 하형 금형에 설치하여 금형을 제작하였다. 카트리지 히터의 원형 제작은 급격한 밴딩으로 인한 히터 내부의 단락 또는 파손이 우려되므로 밴딩속도, 밴딩량 등을 고려하여 순차적으로 밴딩량을 증가시키며 제작하였다.

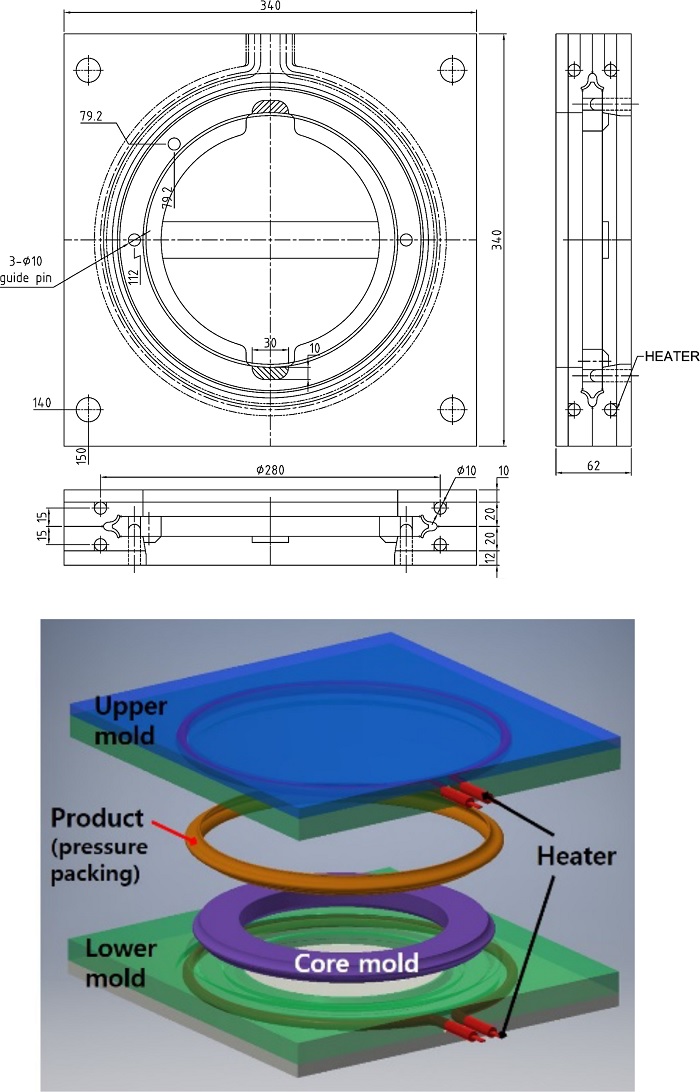

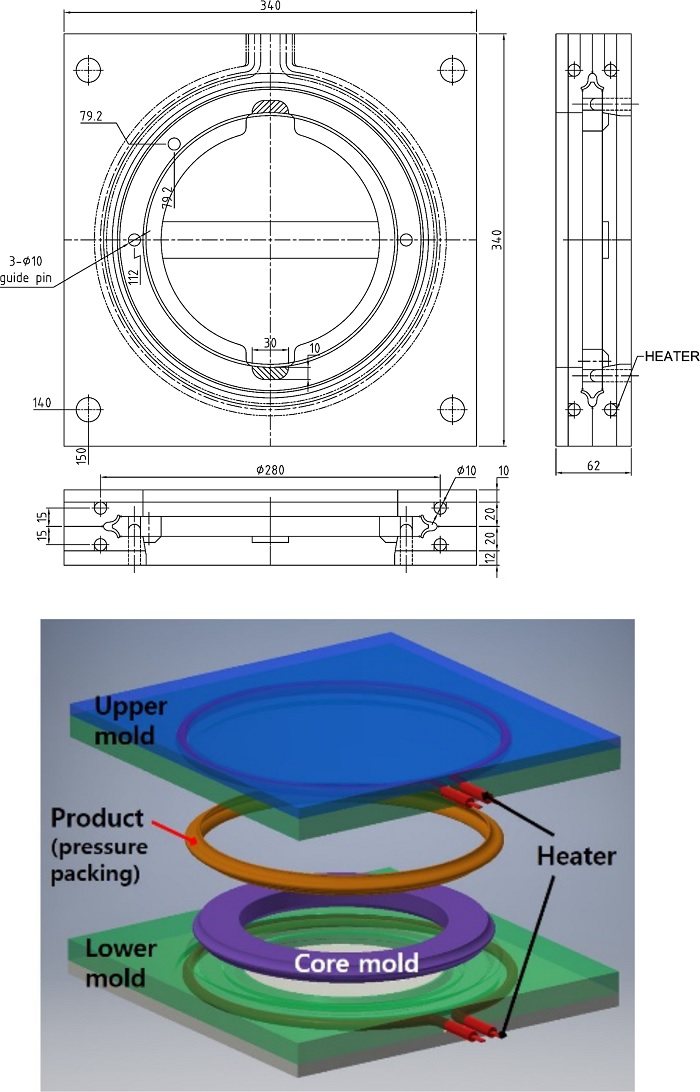

Figs. 3에 생산제품 금형의 도면 및 구조 모델링을 나타내었고, 4에 제작된 간이 금형과 실제 생산을 위해 제작한 프레스 고무 금형을 나타내었다.

Table 1에 금형 규격을 나타내었다. 압력패킹 외경은 255 mm이고, 금형 외형은 340 × 340 × t62 mm로 실제 상형 및 하형 금형의 두께는 20 mm이고, 금형강을 사용하여 제작하였다. 그리고 Ø10 mm인 히터가 들어갈 수 있도록 U자형으로 가공하여 히터를 삽입한 후 두께 12 mm 고탄소공구강 판재로 고정하였다. 금형 방향 쪽으로 U자의 라운드 부분이 향하도록 함으로서 금형 쪽과의 면접촉에 의해 열전달이 잘되도록 하였고, 고정판의 경우는 선 접촉되도록 하여 열전달 및 손실을 최소화하는 구조로 설계 제작하였다.

Fig. 3Schematic diagram of direct heating mold

Table 1Product mold with cartridge heater applied

Table 1

|

External size |

340 × 340 × t62 [mm] |

|

Mold material |

NAK80 |

|

Heater fixing plate |

SK4 |

|

Heater capacity |

220 [V], 2 × 1.5 [kW] |

|

Heater diameter |

10 [mm] |

|

Heater inner diameter |

260 [mm] |

3. 직접가열 금형의 성형 테스트

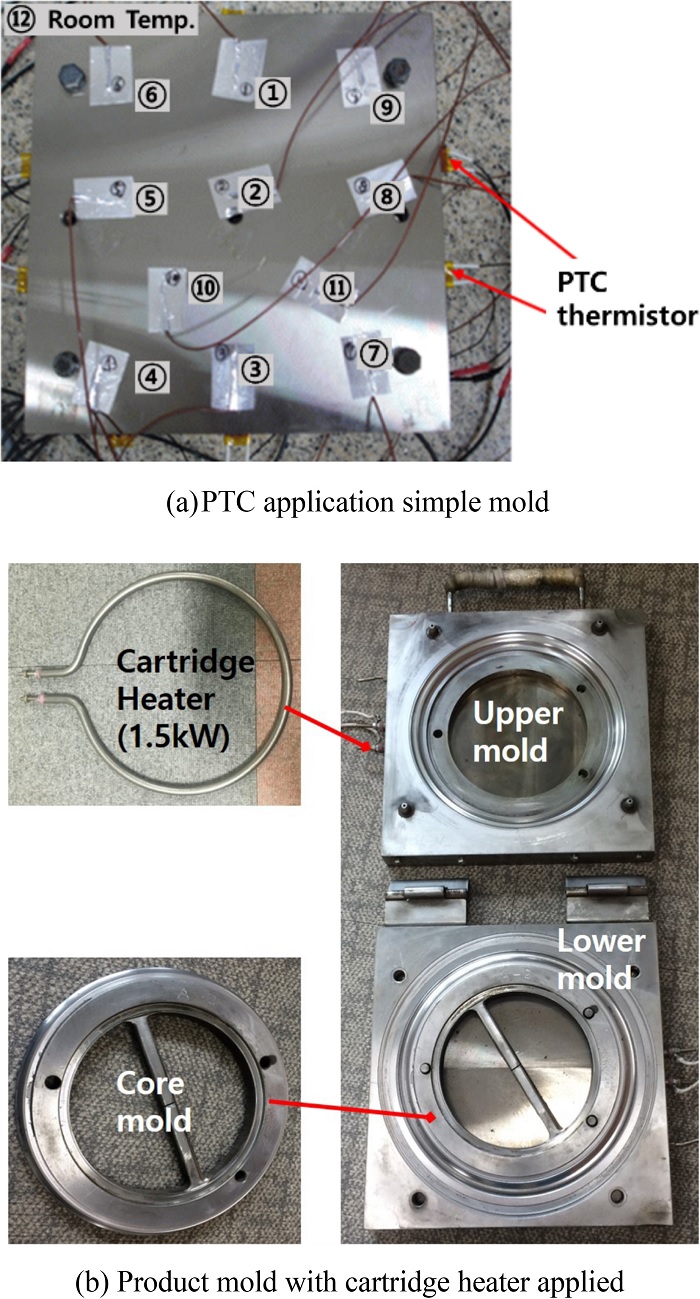

PTC를 사용한 간이 금형의 직접가열 테스트를 진행하기 위해서

Fig. 4(a)의 11개 포인트에서 온도를 측정한 결과 고무 성형이 가능한 온도 160°C까지 도달하는데 30-45분 정도 소요되었으며, 시간이 지남에 따라 각 포인트 간의 온도 편차가 줄어들었다. PTC 소자의 배치, 갯수 및 위치 등을 최적화한다면 보다 더 빠르게 가열이 가능할 것으로 사료되며, 프레스 고무 금형의 직접가열에 의한 제품 성형의 유효성을 확인하였다[

10].

Fig. 4 Direct heating mold

그리고 카트리지 히터를 사용한 가열방법으로서 기존 프레스 열판을 가열하여 금형으로 열을 전달하는 간접가열 방식의 프레스 고무 금형과 금형 내부에 제품 형상의 원형 카트리지 히터를 적용하여 금형을 직접가열하는 방식으로 개발된 프레스 고무 금형을 활용하여 모사의 압력패킹제품에 대해서 실제로 성형 비교 테스트를 실시하여 에너지 소비량과 품질 및 생산성에 대해 비교하였다.

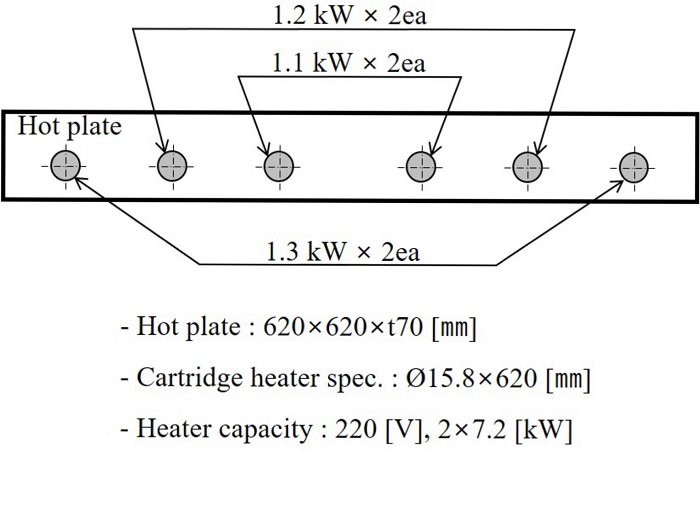

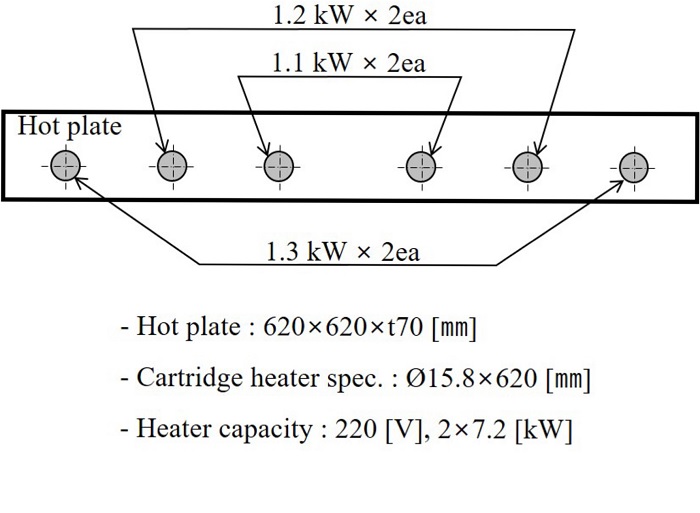

비교 테스트를 위하여 실제로 제품생산에 사용하던 고무 성형 프레스를 사용하였고, 열판 가열에 사용된 카트리지 히터의 배치 및 규격과 열판을

Fig. 5에 나타내었다. 용량이 큰 히터를 열판 외측에 배치하고 내측은 용량이 조금 작은 것을 사용하였으며, 상하 열판 용량은 각각 7.2 kW이다.

Fig. 5 Specification of hot plate heating method

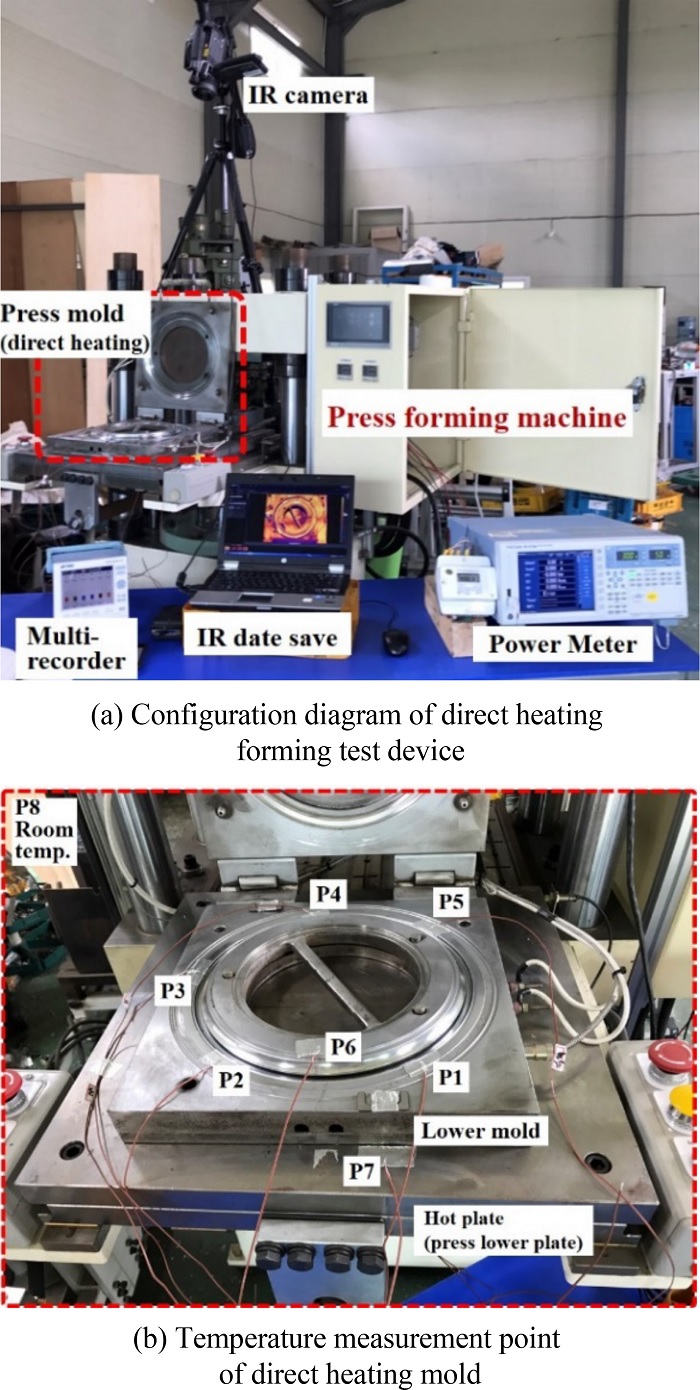

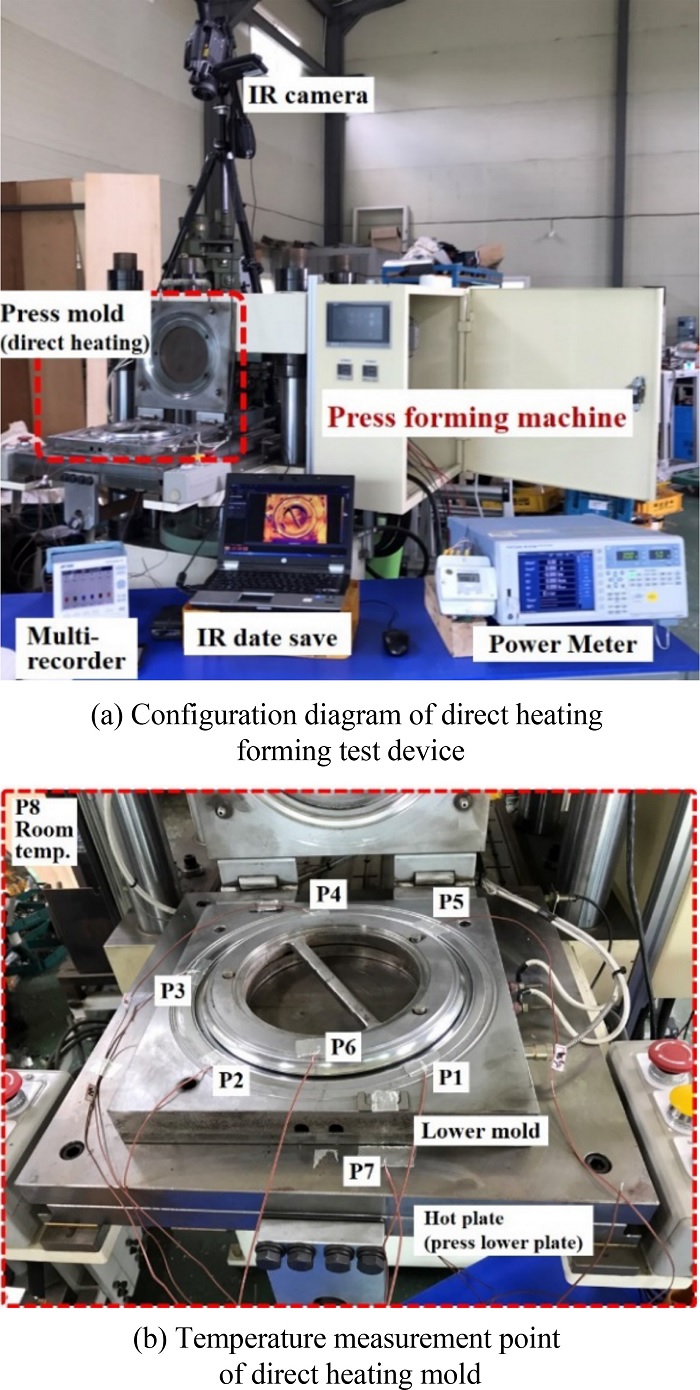

반면에 본 연구에서 개발된 상형 및 하형 금형을 직접가열하는 원형 히터는 각각 1.5 kW, 1개씩을 사용하였으며 확연한 용량 차이가 있음을 알 수 있다. 모사의 제품에 사용되는 원형 압력패킹 생산 과정에서 테스트를 실시하였으며, 장치는

Figs. 6(a)와 같이 구성하였고,

6(b)와 같이 고무 금형의 온도 분포 측정을 위해 K-Type 열전대를 설치하였으며, 그 위치는 성형부가 P1-P5, 코어 금형은 P6, 프레스 하판 P7과 주변온도 측정을 위해서 P8을 설치하였다.

Fig. 6 Rubber molding test of direct heating mold

금형의 전체 온도 분포 경향 측정을 위해서 적외선 열화상 카메라(IR Camera; SC620, FLIR) 및 동영상 저장 시스템(Research IR SW)를 설치하였고, 각 포인트의 온도 측정을 위한 멀티레코더(MV1000, Yokogawa)와 소비전력 측정을 위해서 파워분석장치(WT1800, Yokogawa)를 이용하였다.

주변온도 17°C에서 압력패킹 성형 작업을 위해서 상하 금형을 결합하고, 압력을 가한 상태에서 간접가열을 위해서 열판을 7.2 kW× 2 set로 가열하고, 직접가열은 1.5 kW × 2 set로 성형이 가능한 온도 150°C까지 금형을 가열하였다. 직접가열 방식의 경우 처음 10분 정도는 온도가 급격하게 상승하다가 완만하게 증가하는 경향을 보였다. 금형의 성형부에서 먼저 온도가 균일하게 상승하고, 30분 정도 지나면 코어 금형도 동일하게 가열되어 10°C 정도 낮은 온도로 균일하게 분포함을 알 수 있었다.

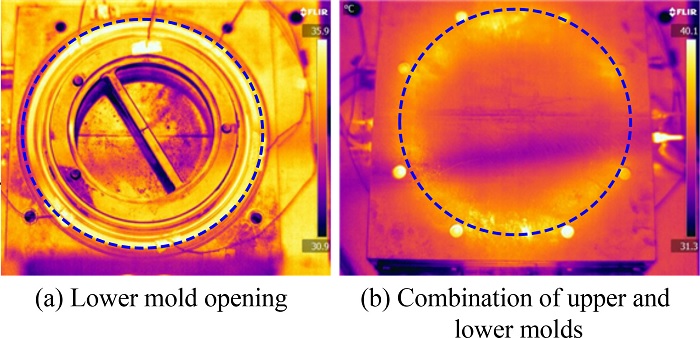

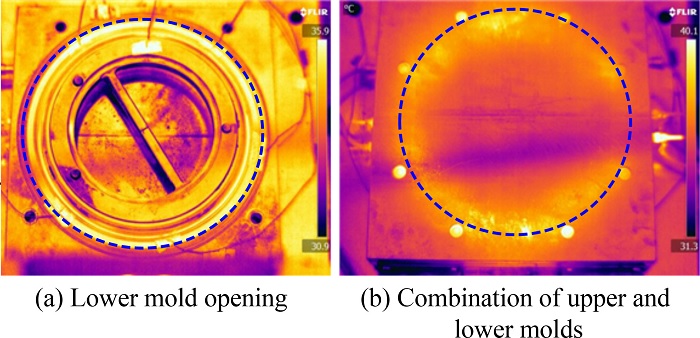

Fig. 7은 설치된 열화상 카메라 영상으로 금형의 개방 및 결합상태의 온도 상승 분포를 정성적으로 검토하기 위해서 직접가열 금형을 가열 시작 1분 후의 온도 분포를 나타내었다. 원형 히터가 장착된 파란색 점선 안쪽의 성형부가 균일하게 주위보다 빨리 상승하는 것을 알 수 있었다. 정확한 온도 분포 검토를 위해서 열전대의 온도 측정 데이터를 분석한 결과 직접가열 방식은 40분만에 가열이 가능하였고,

Table 2에서 알 수 있듯이 40분 후의 성형부 온도가 8°C 이내로 균일하게 분포되었고, 열판가열에 의한 간접가열 방식은 60분 정도 지나면 성형이 가능한 온도 150°C까지 도달함을 알 수 있었다. 특히 직접가열 방식은 성형 작업 중에도 금형의 성형부 온도가 10°C 이내로 균일한 온도 유지가 가능함을 알 수 있었다[

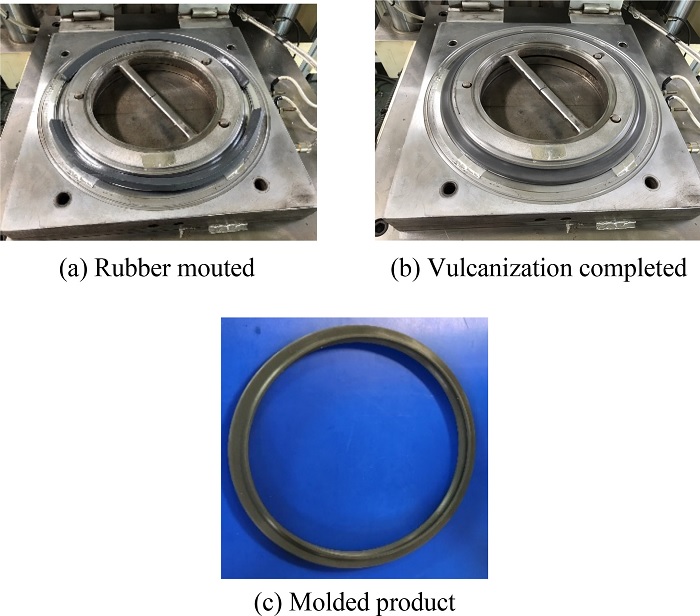

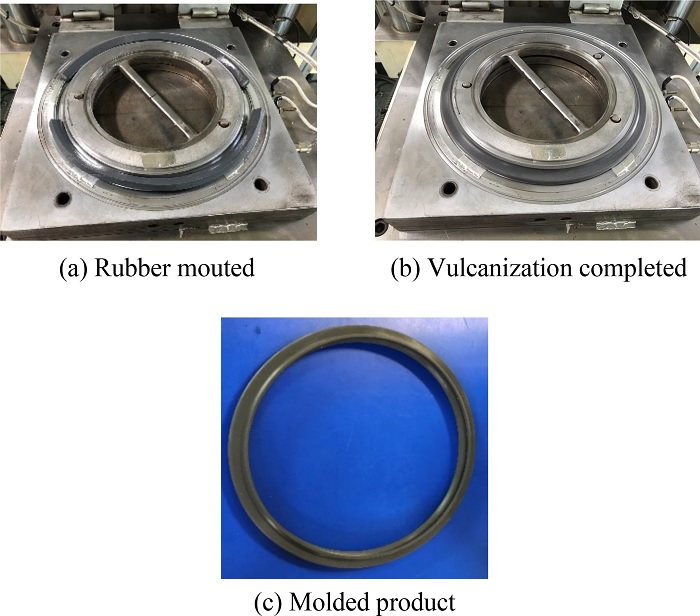

10]. 성형 가능 온도에 도달하면 350 × 14 × t7.5-8.0 mm, 95±1.5 g의 실리콘 고무 2개를

Fig. 8(a)와 같이 하형 금형에 넣고, 상형 금형을 덮어 결합한 상태에서 금형을 가압하여 고온의 가황 과정을 거쳐 압력패킹 성형 작업을 실시하였다. 기존 간접가열 방식에 의한 생산 과정 테스트는 전력소비량 측정만 진행하여 그 결과를 산출하였으며, 불량률 및 생산성은 기존 현장의 생산 데이터를 근거로 비교하였다.

Fig. 7 IR inspection of temperature distribution in direct mold

Table 2 Temporal temperature of direct heating mold

Table 2

|

Time [min] |

Temperature of each point of mold [°C] |

|

P1 |

P2 |

P3 |

P4 |

P5 |

|

0 |

31.4 |

30.4 |

30.1 |

30.3 |

30.7 |

|

10 |

81.9 |

82.2 |

86.2 |

82.8 |

77.3 |

|

20 |

111.9 |

114.9 |

115.3 |

111.6 |

106.3 |

|

30 |

137.6 |

141.1 |

138.6 |

135.9 |

137.4 |

|

40 |

155.5 |

157.7 |

153.0 |

150.5 |

158.5 |

Fig. 8 Press compression molding of pressure packing

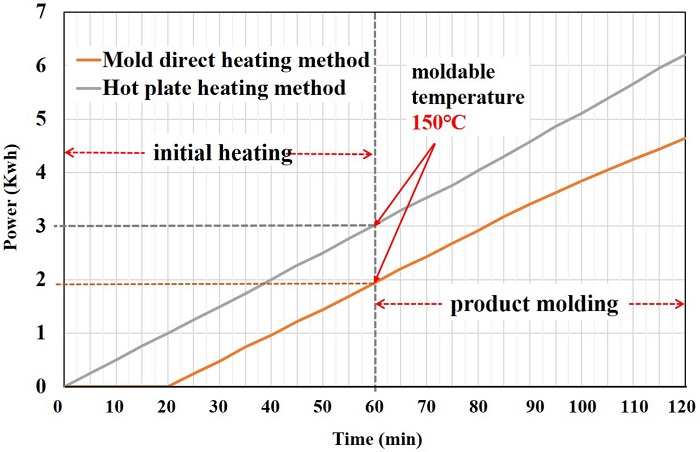

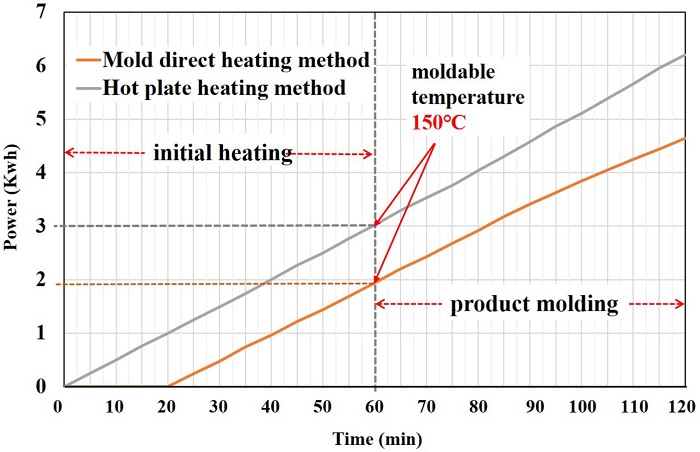

열판가열에 의한 금형의 간접가열과 금형을 직접가열하는 방식에 있어서 소비전력 비교 측정은 성형 가능 온도 150°C까지 금형을 가열하는 과정과 1시간 동안 실제 성형 테스트에 따른 각 소요 전력량에 대한 결과를

Fig. 9에 나타내었다. 그 결과 초기 금형 가열과 60분 동안 고무 성형 작업을 추가한 동안의 전력소모를 비교해보면 직접가열의 경우 1.94, 4.65 kW의 전력이 사용되었고, 열판 가열에 의한 간접가열 방식의 경우 3.02, 6.20 kW의 전력을 소비하였다. 간접가열 방식은 고무 금형보다 약 8배 정도 큰 체적의 열판을 가열하여 금형으로 열을 전달하고, 실온에 노출되는 부분도 많으며 금형과의 열저항으로 인한 열손실이 커서 초기 가열 시 약 55.8%, 추가로 제품 성형 작업 포함 시 33.3% 정도의 전력이 더 소비되었다.

Fig. 9 Power consumption during initial heating and molding

직접가열 금형의 경우 열판에 비해 체적이 1/8로 적은 히터 용량으로 직접가열하고, 성형 작업 시 금형의 외부 노출에 따른 열손실이 적은 온도 하강에 따른 재가열 시 적은 에너지로도 빠르게 일정한 온도 유지가 가능하므로 에너지 소비가 줄어들었다고 판단된다.

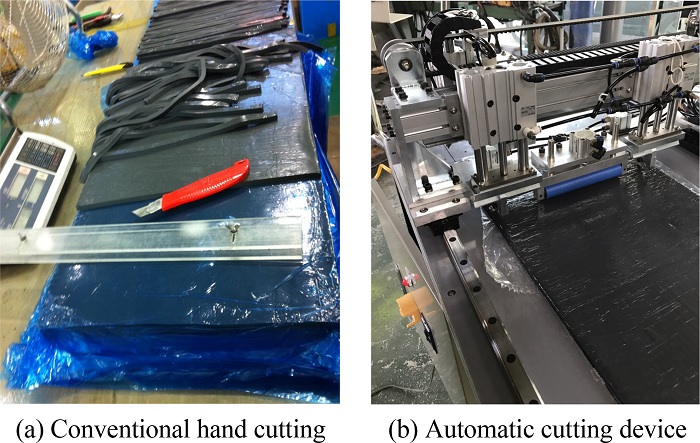

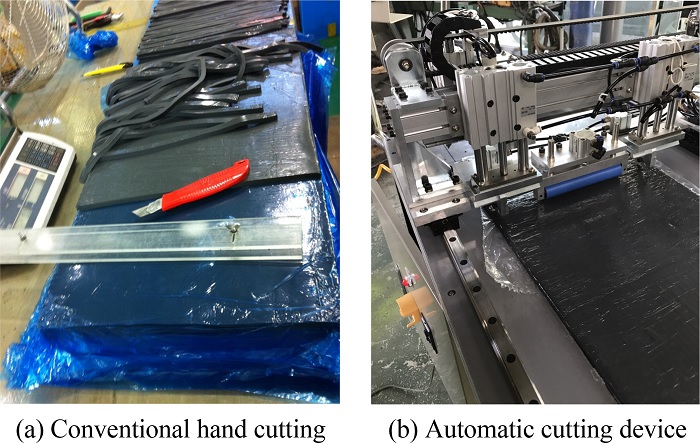

본 연구에서 개발한 직접가열 방식의 압축 성형 고무 금형의 에너지 소비는 금형의 초기 가열 후 시간당 20개 제품을 성형하는 기준에서 기존 열판가열에 의한 간접가열 방식 대비 25.0%의 에너지 절감이 가능하였다. 또한 8시간/일(초기 가열시간 포함) 기준으로 6시간 20분 동안 성형 작업으로 126개의 생산이 가능하였다. 이는

Figs. 10(a)의 수작업에 의한 정량 규격 고무절단 작업을 위해서 10(b)와 같은 정량 규격 절단 장치를 개발하여 적용하였고, 기존의 성형 작업은 수작업 고무 절단에 1시간이 소요되므로 실제 성형시간은 5시간으로 100개의 성형 수량 대비 생산성도 향상되었다. 이는 고무의 정량 규격 절단 방식을 기존 수작업에서 자동 절단 장치를 추가적으로 개발하여 적용한 결과이다. 또한 열판 가열에 의한 성형 시에는 금형의 열손실이 크고, 부위별 온도 편차가 15-18°C 이상 발생함으로서 금형 내부에서 고무의 부위별 수축량이 달라져 미성형에 의한 치수 불량 등이 일반적으로 10% 이상 발생한다.

Fig. 10 Quantitative rubber cutting operation

반면에 본 연구에서 개발된 직접가열 금형은 성형부의 온도편차를 10°C 이내로 줄임으로서 온도 편차량의 작은 차이지만 성형 시 발생할 수 있는 고무의 수축량 편차를 크게 줄일 수 있어 치수불량이 거의 발생하지 않았으며, 크랙, 흑점 및 이물질 혼입으로 인한 각 1개씩의 불량만 발생하여 1일 작업 총 생산량 126개 중에서 3개로 불량률이 2.4%에 그쳤다.

이상과 같이

Table 3에 기존 금형 가열 방식과 직접가열 방식을 비교한 결과에서 알 수 있듯이 압축 성형 고무 금형 자체에 히터를 직접 장착하는 형태의 직접가열 프레스 고무 금형을 개발함으로서 에너지 절감과 동시에 고무 절단 자동화로 생산시간 증대, 고무 소재의 빠른 정량 절단과 금형 캐비티 내의 온도균일도 향상을 통해 불량률을 획기적으로 낮춤으로서 생산성을 향상시킬 수 있었다.

Table 3 Productivity comparison by mold heating method

Table 3

|

Mold heating method |

Direct heating |

Hot plat heating |

|

Initial mold heating time [min] |

40 |

60 |

|

Rubber cutting method |

Automatic |

Handwork |

|

Cutting time |

- |

60 min |

|

Actual forming time |

6 hr 20 min |

5 hr |

|

Daily production [ea] |

126 |

100 |

|

Defective rate [%] |

2.4 |

10 |

|

Reference work |

8 hr/1 day, 20 ea/1 hr |

4. 결론

본 연구는 고무 압축 성형 시 프레스의 열판을 가열하여 금형으로 열을 전달하여 간접적으로 금형을 가열하는 일반적인 방식을 개선하여 금형을 개발하였다. 이는 금형 내의 성형부에 맞춰 히터를 내장함으로서 금형을 직접가열하는 방식의 금형으로서 성형장치 및 온도 제어 시스템이 간단하고, 열손실을 최소화함으로서 25.0%의 에너지를 절감할 수 있었다. 또한 성형 과정에서 열손실로 인한 금형 성형부의 온도를 빠르고 균일하게 유지함으로서 고무의 수축량 변화를 줄임으로서 치수 편차와 미성형에 따른 불량률을 감소시킬 수 있었다. 또한 작업 시작을 위해서 초기 금형을 성형이 가능한 온도로 가열하는 시간을 단축하고, 고무의 정량 규격 절단 자동화장치를 개발하여 적용함으로서 작업시간이 증대되고, 금형 내 성형부의 온도 편차를 줄임으로서 불량률 감소로 생산성을 향상시킬 수 있었다.

REFERENCES

- 1.

Oh, S. H., Kim, H. S., Cheong, S. K., Shin, K. H., (2018), Evaluation of accelerated life of high-temperature deteriorated rubber by stress relaxation, Journal of the Korean Society of Manufacturing Technology Engineers, 27(1), 7-13.

10.7735/ksmte.2018.27.1.7

- 2.

Thiruvarudchelvan, S., (1993), Elastomers in metal forming: A review, Journal of Materials Processing Technology, 39(1-2), 55-82.

10.1016/0924-0136(93)90008-T

- 3.

Valanis, K., Landel, R. F., (1967), The strain-energy function of a hyperelastic material in terms of the extension ratios, Journal of Applied Physics, 38(7), 2997-3002.

10.1063/1.1710039

- 4.

You, J.-H., Lee, J.-W., Oh, S.-H., Park, K., (2021), Conformal mold heating and cooling using a carbon nanotube film heater and additively manufactured cellular metamaterial, International Journal of Precision Engineering and Manufacturing-Green Technology, 1-14.

10.1007/s40684-021-00407-7

- 5.

Oh, S.-A., Ko, Y.-B., Cha, B.-S., Park, K., (2020), A study on thermal and flow characteristics of an injection mold using a detachable core module with embedded heating, Journal of the Korean Society for Precision Engineering, 37(5), 371-379.

10.7736/JKSPE.020.002

- 6.

Kim, S., Kim, T., Lee, S., Jun, O., Kim, S., (2003), Application of reverse engineering system for improvement of press forming process, Proceedings of the Korean Society for Machine Tools Autumn Conference, 412-419.

- 7.

Kum, J., Park, O., Hong, S., (2016), Tough high thermal-conductivity tool steel for hot press forming, Journal of the Korean Society of Manufacturing Process Engineers, 15(3), 130-134.

10.14775/ksmpe.2016.15.3.130

- 8.

Kim, M. H., (2011), Development of rapid cross-link rubber material and rubber injection process, Ph.D. Thesis, Pusan National University.

- 9.

Cho, Y. T., Lee, C. H., Ma, S. D., (2013), Direct heating method using PTC’s press mold, Proceedings of the Spring Conference on the Korean Society of Manufacturing Technology Engineers, 303.

- 10.

Cho, Y. T., (2019), Development of direct heating press mold for energy saving in rubber press molding, Journal of the Korean Society of Manufacturing Technology Engineers, 28(2), 86-92.

10.7735/ksmte.2019.28.2.86

Biography

- Young Tae Cho

An Associate Professor in the Department of Basic Science, College of Engineering, Jeonju University. His research interests are mechanical design, FEM analysis and non-destructive testing.