ABSTRACT

The pipe inspection robot using the MFL non-destructive inspection equipment, has high inspection efficiency in the pipe with high magnetic permeability. However, this equipment generates attractive force between the pipe and the permanent magnet, requiring a high driving force for the robot, and sometimes causes the robot to be incapable of driving. In this study, the development of a spiral running type magnetic leakage detection pipe inspection robot system is described. Multi-body dynamics analysis was performed on the designed robot, to confirm the robot's driving performance. After that, the performance of the robot was verified, by testing the manufactured robot in a standardized test bed.

-

KEYWORDS: Pipe inspection robot, Non-Destructive test, Magnetic flux leakage inspection, Spiral driving, Multi-Body dynamics

-

KEYWORDS: 배관 검사 로봇, 비파괴 검사, MFL 검사, 나선 주행, 다물체 동역학

NOMENCLATURE

Inspection Area of MFL Module

Wheel Contact Circle Diameter of Drive Module

Drive Module Wheel Contact Force

Drive Module Traction Force Exerted by Lower Wheel

Drive & Inspection Module Spring Stiffness

Initial Length of Wheel Link

Link Linear Travel Distance

Rotation Number of Inspection Module

Inspection Module Wheel Velocity

Drive & Inspection Module Spring Compliance

Link Angle Apart from Module Center Line

Coefficient of Dynamic Friction

Coefficient of Rolling Resistance

Inspection Wheel Tilt Angle

Angle between Line from Point A to Wheel Center and Horizontal

1. 서론

최근 OECD 국가들은 신규 기반 시설에 대한 투자를 줄이는 반면 시설관리에 필요한 예산을 확대하고 있으며, 주요 국가들도 급증할 기반 시설의 유지관리 수요를 전망하고 투자 비중을 늘리고 있다. 이러한 주요국들의 행보는 앞으로 시설의 확장보다는 설치된 시설의 유지관리 필요성을 시사하고 있다

[1].

국내에서도 1970년대부터 본격적으로 진행된 기반 시설 투자로 현재 배관(Pipe)을 통한 한국의 상수도 보급률이 99.3%에 이르고 있고, 설치된 배관들은 활용 수명을 감안하여 주기적으로 유지 보수되어야 하지만, 특수목적건물과 선박을 제외한 대부분의 배관이 파손 방지와 미관 보존을 목적으로 지하에 매립되기 때문에, 검사를 통한 상태 판단이 까다로운 문제점을 내포하고 있다. 또한, 매립된 환경에 따라 예상 수명보다 실제 사용 수명이 단축되어 배관 파열 등의 문제를 일으키기도 한다. 이와 같은 배관 사고는 시설의 분포가 넓을수록, 노후관 비율이 높아질수록 빈도가 잦아질 것으로 예측할 수 있다. 따라서, 한국도 배관 시설의 확장과 더불어 설치된 배관의 관리에도 관심을 두어야 할 시점이다

[2].

이와 같은 배관 문제를 예방하기 위하여 청소 로봇, 갱생 로봇, 검사 로봇 등 다양한 종류의 배관 유지관리 로봇이 연구되고 있다. 특히, 청소 로봇은 통수 과정에서 발생한 배관 내 슬러지(Sludge), 녹 등의 이물질을 제거하는 로봇이고, 갱생 로봇은 노후화되어 부식되고 얇아진 배관을 라이닝 공법(Lining Method)으로 내부를 코팅하여 통수 효율을 높이는 배관 건설 로봇이다. 이 중에서 검사 로봇은 배관의 결함을 검출하는 로봇으로 일반적으로 비파괴검사 장비가 탑재된다. 검사 종류로 육안검사, 자기누설탐상, EMAT (ElectroMagnetic Acoustic Transducer) 등이 있다

[3-

8].

카메라를 적용한 검사 로봇은 영상으로 배관 내부 결함을 검출한다. 이 카메라에 의존한 검사는 직관적으로 배관 결함을 찾을 수 있지만, 작업자의 경험과 역량이 검사 효율에 지배적이고 배관 내표면이 슬러지 등 이물질로 덮여 가시성이 확보되지 않으면 결함 검출이 불가능한 단점이 있다. MFL 장비를 장착한 로봇은 배관 내부 환경에 영향을 받지 않고 투자율이 큰 강자성체 배관에서는 결함 검출 성능이 우수하나, 넓은 배관 면적을 검사하기 위하여 다량의 영구 자석이 장착되어 주행 저항이 높아 큰 견인력이 필요하고 곡관 통과 시 자석과 배관의 접촉으로 주행 불가능 위험이 있다

[9-

14].

따라서, 본 논문에서는 MFL 모듈이 탑재된 배관 검사 로봇 개발에 대하여 기술하였다. 3개 모듈로 이루어진 로봇은 중심에 하나의 검사 모듈과 양쪽 2개의 구동 모듈로 구성되고 검사 모듈에는 2개의 MFL 모듈이 장착되었다. 나선 주행 메커니즘으로 MFL 모듈에 의한 주행 저항을 줄였고, 2개의 MFL 검사 모듈로 전방위 검사가 가능하여 기존 MFL 검사 로봇에 비하여 요구 견인력이 작다. 이러한 로봇은 다물체 동역학 해석(Multi-Body Dynamics Analysis, MBD)으로 요구 토크를 확인하여 모터와 감속기 용량을 선정하였고, 주행과 등반 성능을 확인하였으며, 표준 규격 테스트베드에서 로봇의 성능을 검증하였다.

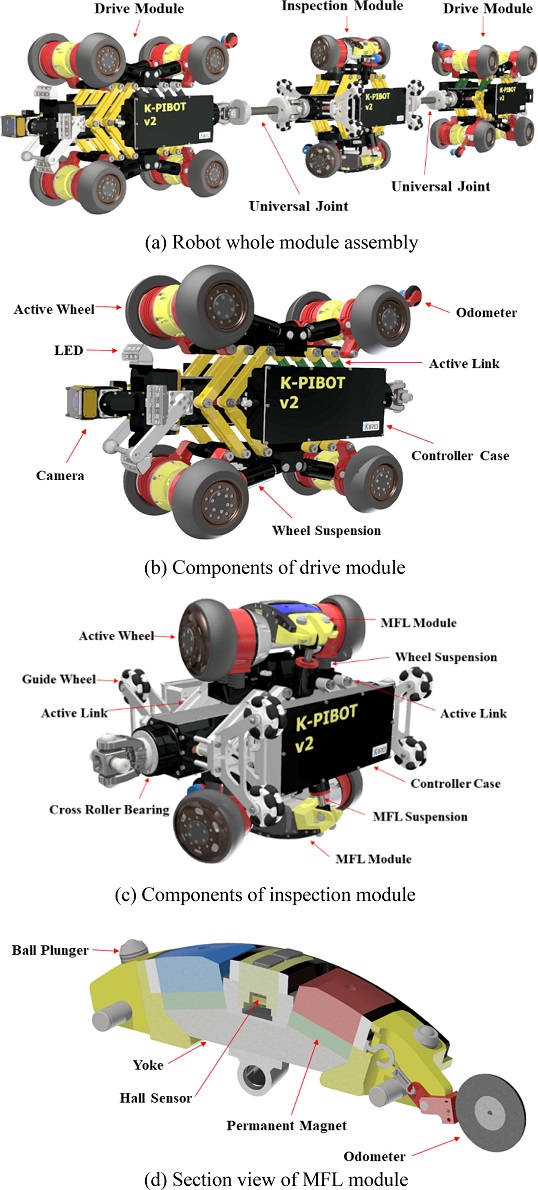

2. 배관 검사 로봇의 구성

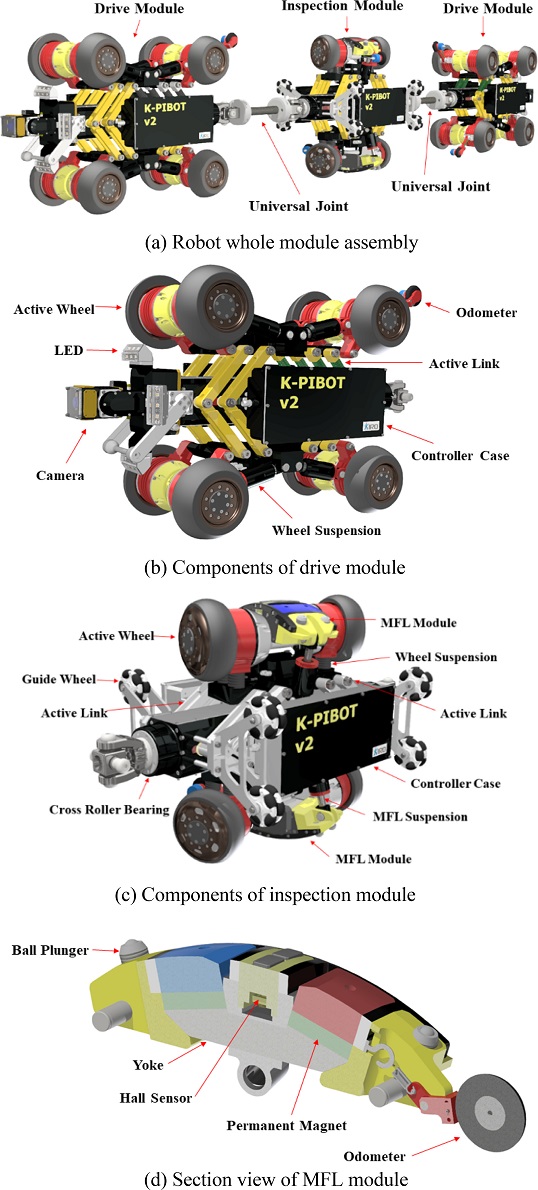

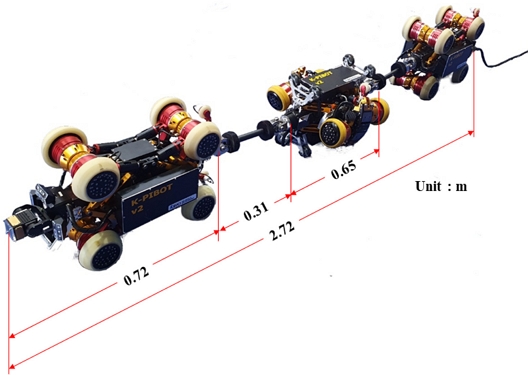

Fig. 1(a)는 설계된 배관 검사 로봇의 전체 조립도를 나타낸다. 로봇은 500 mm 상수도관에 적용하기 위한 크기로 총 3개의 모듈로 구성되고, 각 모듈은 곡관을 통과하기 위해 유니버셜 조인트(Universal Joint)로 연결되었다. 중심의 검사 모듈을 기준으로 양측에 견인력 발생이 목적인 구동 모듈이 위치하여 상대적으로 바퀴 접지력 생성이 불리한 검사 모듈을 견인한다. 로봇의 전원은 48 V로 후단 구동 모듈의 커넥터를 통해 공급받으며 이더넷 통신으로 로봇과 연결된다. 또한, 내부에 슬립링(Slip Ring)을 장착하여 검사 모듈의 회전에 의한 케이블 단선을 방지하였다.

Fig. 1 Components of pipe inspection robot

2.1 구동 모듈의 구성

Fig. 1(b)에 구동 모듈의 구성을 도식화하였다. 구동 모듈은 총 8개의 구동 바퀴가 장착되어 큰 견인력을 발생시킨다. 각 구동 바퀴는 구동 링크 동작으로 높이가 조절되며, 바퀴에 스프링을 연결하여 진동을 줄이고 접지력을 향상시켰다. 편단의 구동 링크는 모듈 중심에 위치한 모터와 나사에 의해 직선 운동하며, 링크의 이동 거리 측정을 위해 리니어 엔코더가 부착되었다. 각 구동 모듈에는 LED와 짐벌(Gimbal) 형태의 카메라가 장착되어 전후방 결함을 영상으로 확인 가능하고, 로터리 엔코더(Rotary Encoder)를 이용한 누적 거리 측정 센서로 주행거리를 적산할 수 있다.

2.2 검사 모듈의 구성

Fig. 1(c)는 검사 모듈의 구성을 보여준다. 검사 모듈은 4개의 구동 바퀴와 2개의 MFL 검사 모듈로 구성되었다. 각 바퀴는 배관과 축방향 기준으로 65

o 틀어져 배관 내부를 나선형 주행한다. 양단의 구동 링크는 로봇 중심의 중공 타입 모터와 나사로 모듈의 바퀴 높이를 조절하고 자립 불가능한 모듈의 파손 방지를 위해 옴니 휠(Omni-Wheel)로 구성된 보조 바퀴가 양측에 장착되었다.

Fig. 1(d)는 반단면도 상태에서 MFL 모듈의 구성을 나타낸다. MFL 모듈은 자기장 형성을 위한 영구자석과 요크 및 홀 센서로 구성된다. 또한, 볼 플런저(Ball Plunger)로 MFL 모듈과 배관 사이 거리를 일정하게 유지하여 주행 저항을 감소시켰고 누적 거리 측정 센서를 장착하여 모듈의 나선 주행 거리 측정이 가능하다.

3. 배관 검사 로봇의 설계와 해석

배관 검사 로봇 설계에 앞서 로봇의 목표 성능을 설정하였고, 그 값을

Table 1에 기재하였다. 적용 대상 환경은 상수관 또는 산업용 용수공급 배관을 기준으로 가장 널리 사용되는 내경 기준 500 mm 배관을 고려하였으며, 통상 용수 관망의 통수 압력을 고려한 환경을 모사하여 성능 검증을 위한 목표 사양을 선정하였다. 로봇의 중량은 30 kg 기준으로 단위 모듈의 대해 작업자 2명이 취급 가능한 무게를 고려하였다. 로봇을 이용한 주행 및 검사 최대 길이는 주행 견인력과 케이블 부하 등을 고려하여 직선거리 기준 50 m로 설정하였다. 주행거리는 케이블 무게와 저항을 고려하여 50 m로 선정하였고, 투입 후 검사 모듈이 나선 주행하며 검사를 수행하는 면적은 총 주행 면적의 30% 수준으로 설정하였다.

Table 1 Objective of pipe inspection robot spec

Table 1

|

Target pipe size [mm] |

500 |

|

A module weight [kg] |

> 30 |

|

Driving distance [m] |

50 |

|

Climbing angle [o] |

45 |

|

Inspection area [%] |

< 30 |

3.1 구동 모듈의 설계

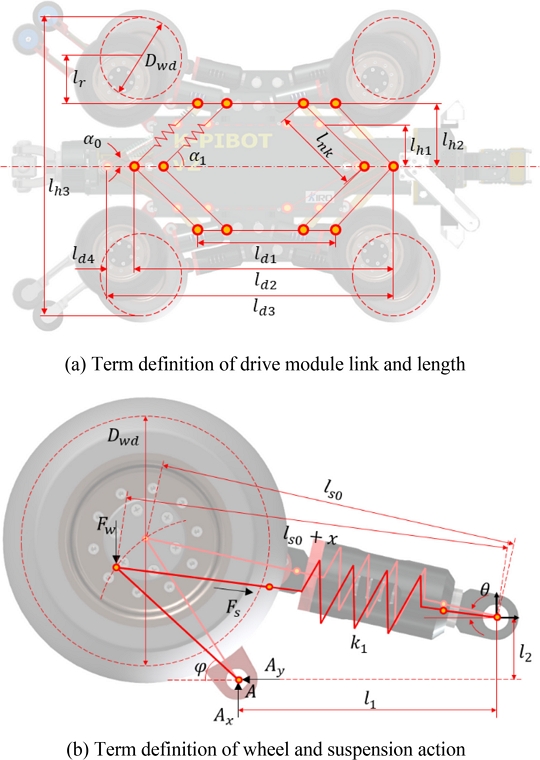

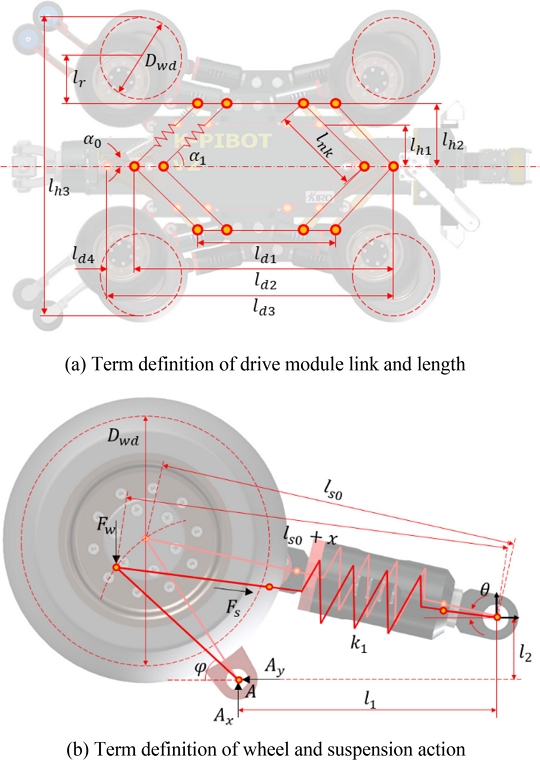

Fig. 2(a)에 구동 모듈의 기구학적 해석을 위한 링크를 정의하였다. 모듈의 바퀴 높이는 구동 링크로 조절되고 이러한 구동 링크 각도 변화에 의한 로봇 높이 변화는

식(1)로 계산한다. 링크의 각도가 변화하며 움직이는 링크의 직선 이동 거리는

식(2)로 계산되며 상부 바퀴와 배관이 접촉하는 구동 링크의 직선 이동 거리는 약 50.71, 링크의 최대 이동 거리는 약 114.85 mm이다. 이때 로봇의 높이는 약 472.08 mm이고, 스프링이 최대로 압축되는 위치이다.

Fig. 2Drive module term definition and free body diagram

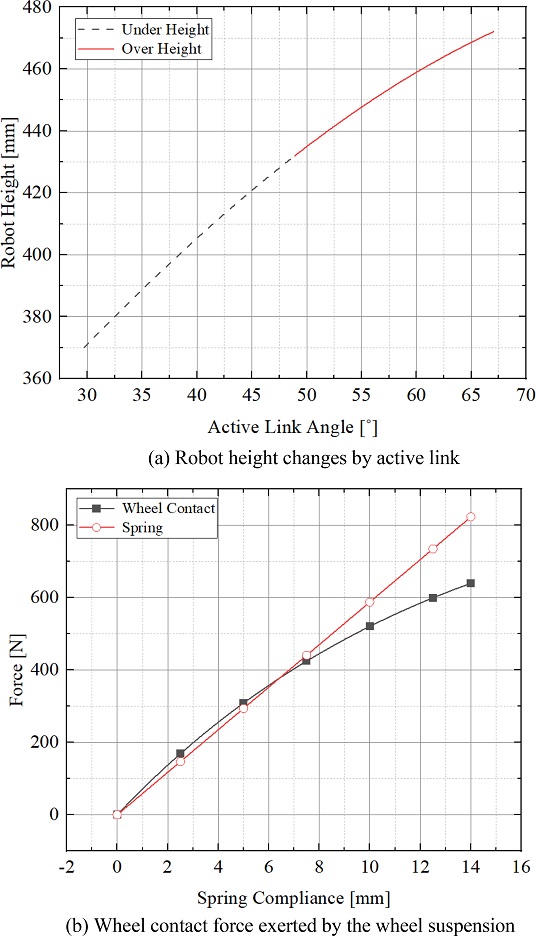

이와 같은 계산 결과를

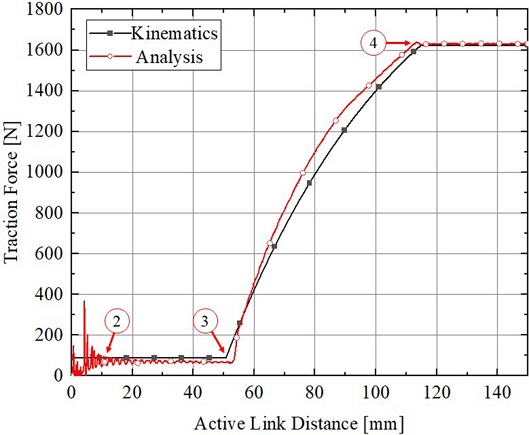

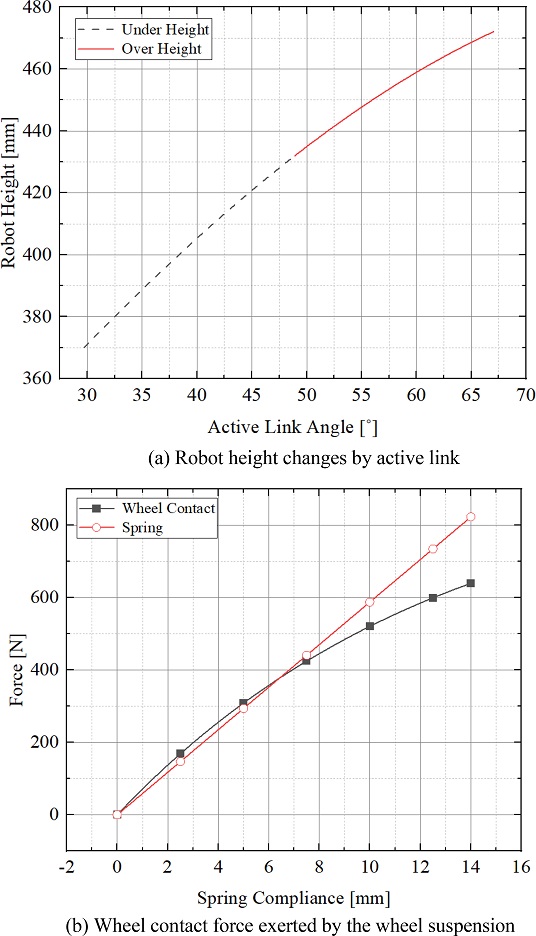

Fig. 3(a)에 도시하였다.

Fig. 3(a)는 링크의 각도 변화에 따른 로봇 전체 높이 변화 그래프이고, 상부 바퀴의 비접촉 높이를 파선으로, 접촉 높이를 실선으로 표현하였다.

Fig. 3Result diagram of kinematics

Fig. 2(b)는 바퀴에 작용하는 힘을 나타낸다. 구동 링크가 스크류에 의해 모듈 중심으로 움직이며 바퀴와 연결된 스프링을 압축하고, 이 압축된 힘은 바퀴의 접지력을 향상시킨다. 스프링에 의한 바퀴 접지력은

식(3)으로 계산하고, 그 결과를

Fig. 3(b)에 도시하였다. 스프링 변위에 의한 힘은 선형으로 변하지만 그 힘이 온전히 바퀴 접지력으로 전달되지 않는 것을 확인하였고 약 632 N의 접지력을 확인하였다.

식(2)와

식(3)으로 계산된 값을 사용하여 구동 링크 이동 거리에 따른 구동 모듈의 견인력 변화를

Fig. 5에 도시하였다. 스프링이 압축되기 위한 조건은 8개 구동 바퀴가 모두 배관과 접한 상태이다. 따라서

Fig. 3(b)의 스프링 압축 과정은

식(2)로 계산된 구동 링크의 직선 이동 거리 50.71와 114.85 mm 사이에 발생한다. 또, 상부 바퀴의 접촉 전 견인력은 아래 4개 구동 바퀴와 로봇 무게에 의해 발생하고, 크기는

식(4)로 표현 가능하다. 계산된 값은 88.29N으로 이 값은 상부 바퀴가 배관과 접촉하기 전인 50.71 mm까지 유지된다.

모터의 요구 토크는 바퀴의 배관 접촉 직경을 기준으로 산출하였고 계산식은

식(5)와 같다. 계산 과정에서 바퀴의 구름 저항 계수는 바퀴의 압축과 복원 과정에서 발생하는 마찰 계수로 바퀴 재료의 탄성이 클수록 이 저항 계수는 증가한다. 바퀴에 적용된 재료는 쇼어 경도(Shore Hardness) 90의 우레탄으로 일반적인 자동차 타이어 재료보다 탄성이 크지 않을 것으로 판단하였고, 모터 토크에 여유를 두기 위하여 0.1을 적용하였다. 이와 같이 계산된 모터 필요 토크는 최대 9.72 Nm이다.

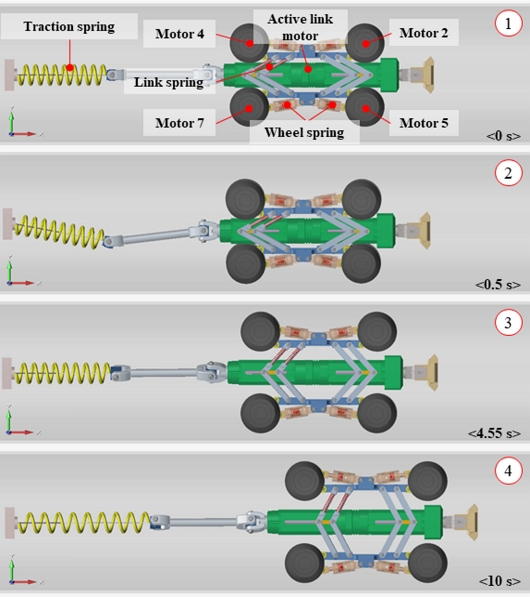

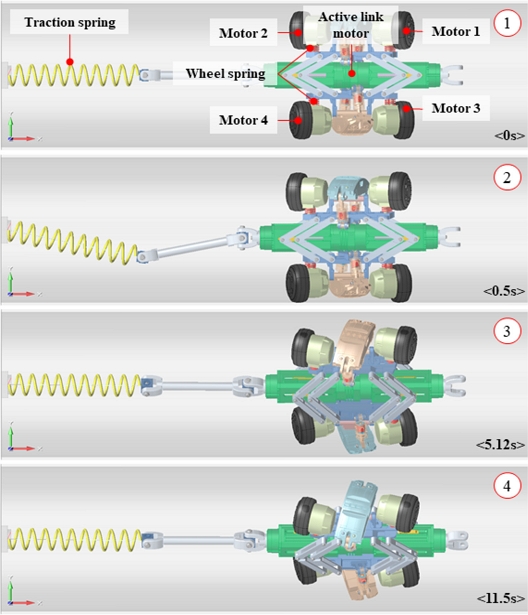

3.1.1 구동 모듈의 다물체 동역학 해석

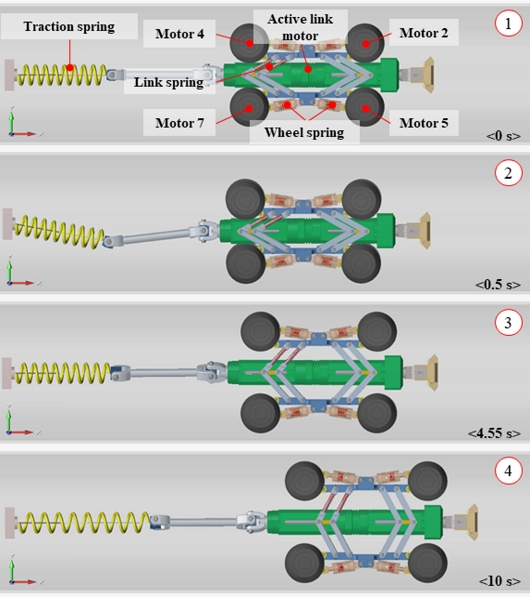

구성된 구동 모듈 모델에 대하여 다물체 동역학 해석으로 기구학으로 계산된 견인력을 확인하고 설계 요소의 건전성을 검증하였다. 해석에는 Altair 사의 Inspire를 사용하였고, 사용된 스프링과 모터의 위치는

Fig. 4에 표현하였으며, 각 요소의 재료와 해석 조건은

Tables 2와

3에 각각 기재하였다. 구성된 모델의 견인력을 측정하기 위하여 주행 방향 반대편에 스프링을 생성하여 스프링에 가해지는 힘을 기준으로 모듈의 견인력을 확인하였다. 생성된 스프링 위치는 모듈의 8개 바퀴가 모두 배관에 접지한 위치에서 로봇 중심과 일치하여 스프링의 수평 방향 힘을 측정하였다. 모듈은 초기에 모든 바퀴가 배관과 비접촉 상태이고, 해석이 시작되면 중력 방향으로 낙하하며 배관과 바퀴의 접지 조건에 의하여 접촉한다.

Fig. 4Multi-Body dynamics analysis process of drive module

Table 2Module material

Table 2

|

Part |

Material |

Modulus of

elasticity [GPa] |

Yield strength

[MPa] |

|

Center body |

AL6061-T6 |

68.9 |

276 |

|

Link |

|

Universal joint |

|

Spring rod |

SUS304 |

193 |

215 |

|

Center screw |

Table 3Conditions of multibody dynamics

Table 3

|

Component |

Value |

|

Motor |

Wheel |

Velocity [rpm] |

60 |

|

Time [s] |

0-15 |

|

Active link |

Velocity [rpm] |

336 |

|

Time [s] |

0-10 |

Stiffness

[N/mm] |

Wheel spring |

58.8 |

|

Link spring |

15 |

|

Traction spring |

200 |

|

Coefficient |

Static friction |

0.5 |

|

Kinetic friction |

0.2 |

|

Weight [kg] |

29.83 |

|

Time [second] |

15 |

Fig. 4의 해석 시간 0초는 해석 초기 상태로 구동 모듈과 배관이 이격된 상태이고, 0.5초에 중력 방향으로 힘을 받으며 배관과 하부 바퀴가 접촉한다. 4.55초에 구동 링크의 동작으로 모든 바퀴가 배관과 접지하고, 10초에 구동 링크가 최대로 확장되어 스프링 압축량이 최대이다.

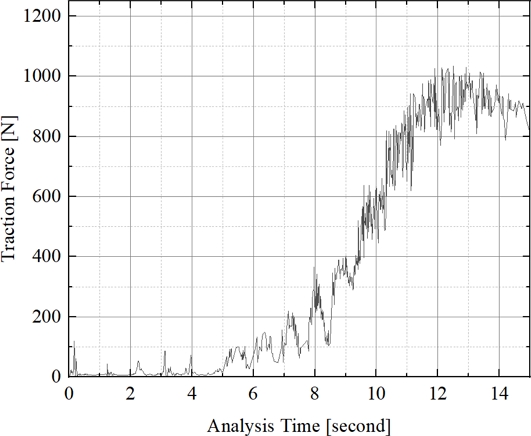

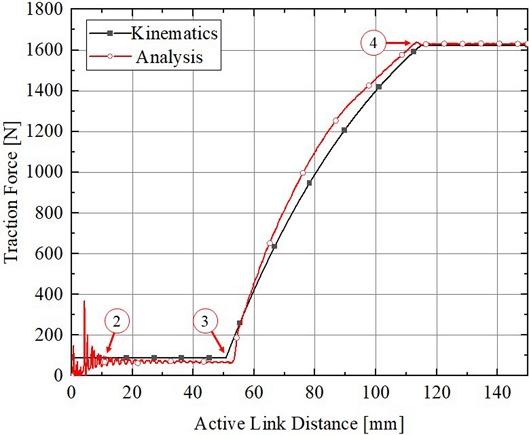

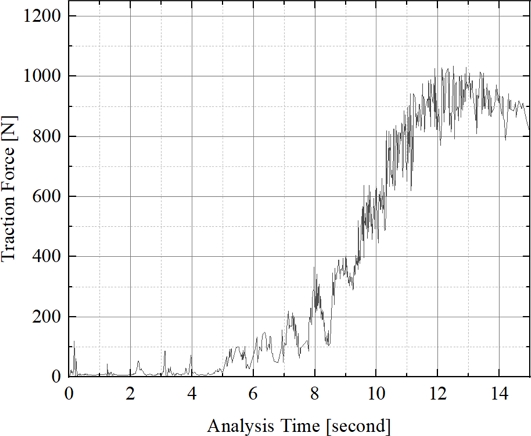

이와 같은 해석 결과를

Fig. 5에 도시하여 앞서 계산한 구동 모듈의 견인력 결과와 비교하였다. 결과는 구동 아래 바퀴 4개가 접지한 구간, 8개 바퀴가 접지한 구간 및 구동 링크가 최대로 확장하여 스프링이 완전히 압축된 구간인 총 3개 구간으로 나누어 각 구간의 오차 평균을 계산하였다. 이와 같은 3개 구간을

Fig. 5에 나타내었으며 기구학 계산 결과와 다물체 동역학 해석 결과 비교 값을

Table 4에 기재하였다.

Fig. 5Changes in traction force due to movement of active links

Table 4Comparison of kinematics and multibody dynamics result

Table 4

|

Section |

Average error

[%] |

Mean traction force [N] |

|

Kinematics |

Analysis |

|

2-3 |

20.95 |

88.29 |

69.79 |

|

3-4 |

8.17 |

989.32 |

1,070.4 |

|

4 |

0.43 |

1,623,54 |

1,630.4 |

첫 구간은 해석을 진행하며 구동 모듈의 낙하에 의한 진동으로 가해진 불안정한 힘을 제외한 상태에서 오차를 계산하였으나 8개 바퀴가 배관과 접촉하지 않은 상태에서 해석이 진행되어 스프링의 진동이 감쇄되지 않아 오차가 크게 발생하였다. 또 오차 계산 시 기준이 되는 힘의 크기가 작아 오차가 더욱 크게 계산되었을 것으로 판단된다.

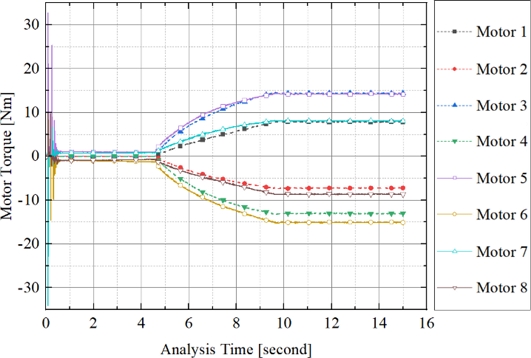

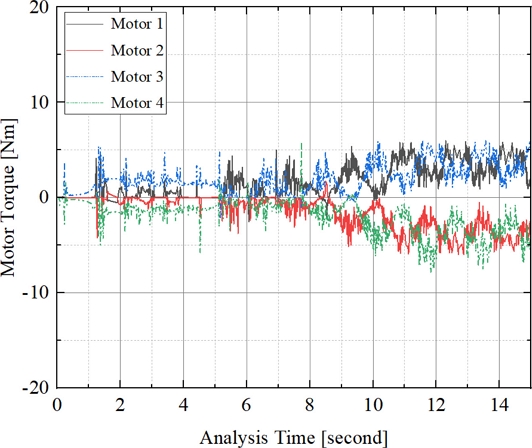

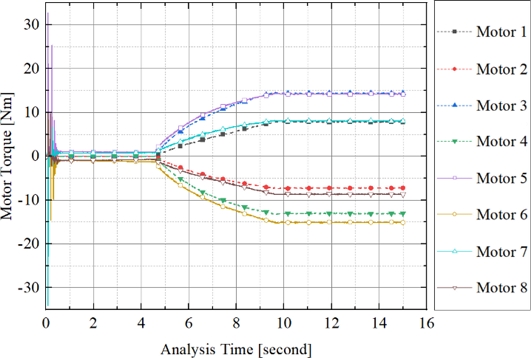

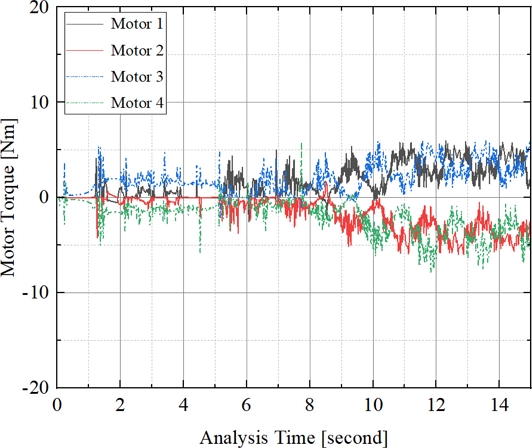

구동 모듈의 다물체 동역학 해석으로 얻은 모터 토크 결과를

Fig. 6에 나타내었다. 모터 1부터 4는 상부 바퀴의 구동 모터로 파선으로 도시하였고, 모터 5부터 8은 하부 바퀴의 구동 모터로 실선으로 표시하였다. 모터 토크는 회전 방향에 따라 CW는 양수, CCW는 음수 값으로 해석되었고 4초 이후 상부 바퀴가 배관과 접촉한 순간부터 모터의 토크가 증가하여 최대 15 Nm의 모터 요구 토크를 확인하였다.

Fig. 6Multi-Body dynamics analysis result of motor torque for drive module

3.2 검사 모듈의 설계

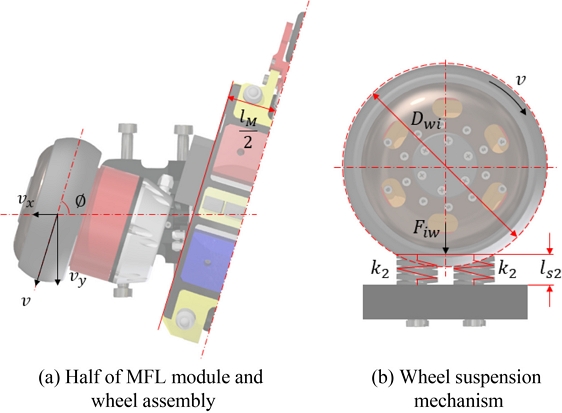

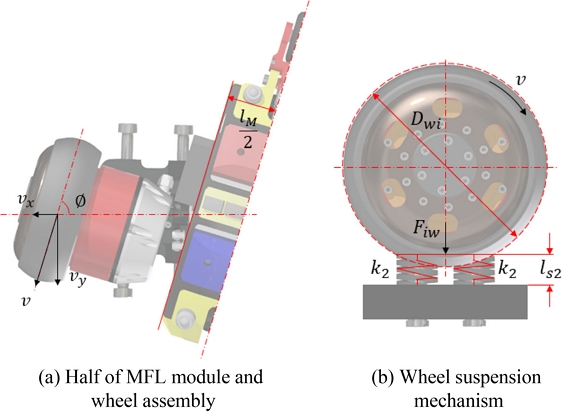

Fig. 7에 검사 모듈의 구동 바퀴 자유 물체도를 나타내고 있다.

Fig. 7(a)는 MFL 모듈과 구동 바퀴의 조립도로, 구동 바퀴는 검사 모듈 중심축과 65

o를 형성하여, 바퀴의 회전으로 배관 내부를 나선 주행한다.

Fig. 7(b)는 바퀴 스프링 메커니즘을 나타낸다. 검사 모듈은 바퀴 접지력과 스프링 압축 방향이 수평을 이루어 스프링 압축력이 온전히 바퀴 접지력으로 전달된다. 이러한 바퀴 접지력은

식(6)과 같이 계산된다.

Fig. 7Term definition of inspection module

이때, 바퀴 자중에 의한 스프링 압축량은 미소할 것으로 가정하고 무시하였다. 검사 모듈의 회전 속도는 구동 모듈과 동기화 과정에서 전체 로봇의 주행 속도를 결정한다. 반경 방향으로 회전하는 모듈의 직선 주행 속도는

식(7)로 계산 가능하다.

검사 모듈의 나선 주행 메커니즘은

식(8)로 기술하였다. 모듈의 나선 주행 거리는 나사의 피치(Pitch)와 리드(Lead) 개념으로 계산 가능하고, 이때 피치는

식(8)의 Y와 같다.

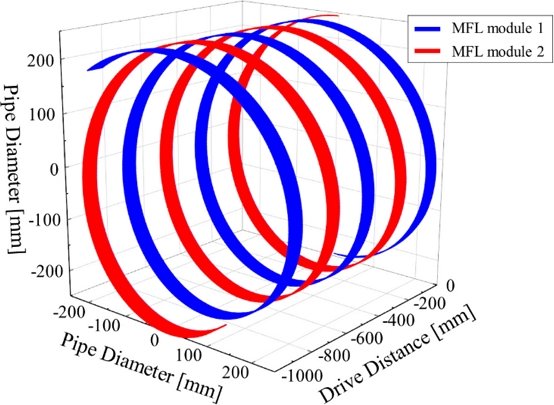

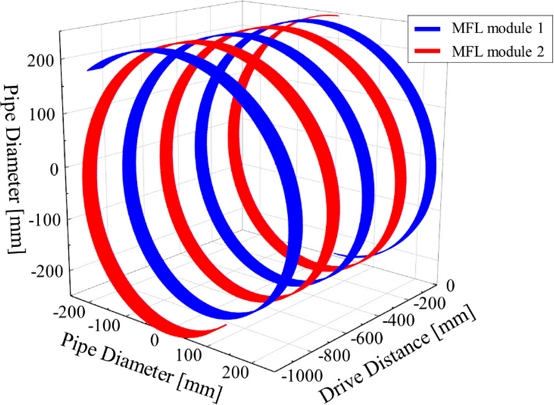

3.2.1 MFL 모듈에 의한 검사 면적

검사 모듈이 1 m 주행하며 수행하는 MFL 모듈의 검사 면적을

Fig. 8에 도시하였다. 검사 면적 계산식인

식(9)는

식(8)의 나선 주행 거리에 MFL 모듈의 자석 너비만큼 곱하여 구하였고, 2개의 MFL 모듈의 검사 면적이 중복되지 않아

식(9)와 같은 식을 수립하였다. 이러한 배관 검사 비율은 단위 길이당 약 35.31%로 계산되었다. 설계에 앞서 설정한 목표 성능을 만족했음을 확인하였다.

Fig. 8Inspection area diagram of MFL modules

3.2.2 검사 모듈의 다물체 동역학 해석

검사 모듈의 다물체 동역학 해석을 통하여 단일 모듈 상태에서 견인력을 측정하였다. 해석에는 Altair 사의 Inspire를 사용하였고, 사용된 스프링과 모터의 위치는

Fig. 8에 표현하였으며 각 요소의 재질과 해석 조건은 구동 링크 모터를 제외하고

Tables 2와

3과 같다. 구동 링크 모터 회전속도는 150 rpm이고, 구동 시간은 11초이다.

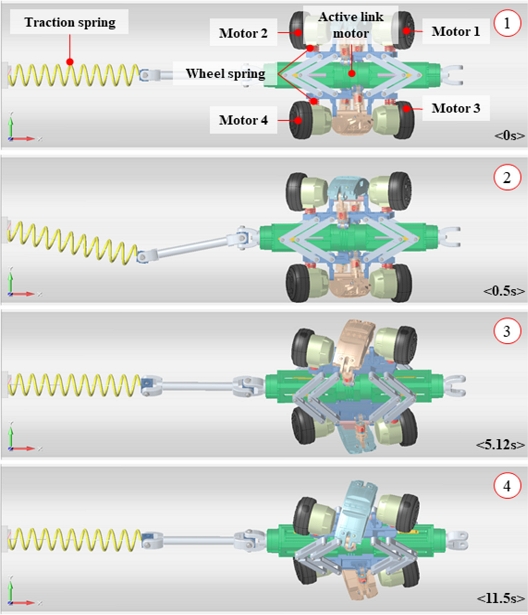

Fig. 9는 검사 모듈의 다물체 동역학 해석 과정을 나타낸다. 해석 시간 0초는 검사 모듈이 정지한 상태이고, 0.5초에 중력방향으로 떨어져 배관에 접지한 상태가 된다. 이때부터 바퀴는 동작 중에 있으며 링크도 확장을 시작한다. 해석 시간 5.12초에 모든 바퀴가 배관과 접지하고, 11.5초에 링크가 확장된 후 바퀴 스프링이 완전히 압축된다.

Fig. 9Sequence of inspection module multi-body dynamics

이와 같은 해석의 결과로

Fig. 10에 견인력 그래프를 도시하였다. 구동 모듈의 해석 결과와 차이점은 바퀴가 모두 접지한 상태에서도 스프링의 진동이 감쇄되지 않는 점이다. 4개 구동 바퀴가 모두 접촉하는 5.12초부터 견인력의 상승은 관측할 수 있지만, 진동 또한 지속적으로 발생한다. 이는 나선 주행 메커니즘으로 검사 모듈이 자립할 수 없어 모듈이 비틀어지며 구동 바퀴와 배관의 이격과 접촉이 반복되어 발생하였을 것으로 판단된다. 해석 결과로 검사 모듈의 평균 견인력은 약 977.31 N으로 측정되었다.

Fig. 10Analysis result of traction force for inspection module

검사 모듈의 다물체 동역학 해석으로 얻은 바퀴 모터 토크 정보를

Fig. 11에 도시하였다. 상부 바퀴의 구동 모터는 파선으로, 하부 바퀴 모터는 실선으로 표현하였으며 모터의 회전 방향에 따라 CW는 양수, CCW는 음수로 해석되었다. 그래프를 통해 5초부터 증가한 모터 토크는 최대 9.3 Nm이 필요한 것으로 확인하였다. 이러한 요구 토크는 구동 모듈의 해석 결과보다 작으므로 구동 모듈에 적용된 모터와 감속기를 사용하여 모듈의 안정성을 높였다.

Fig. 11Analysis result of motor torque for inspection module

3.3 배관 검사 로봇의 시뮬레이션

설계된 배관 검사 로봇의 45o 경사관에서 등반 성능을 확인하고 설계 요소의 건정성을 판단하기 위하여 구동 모듈과 검사 모듈이 통합된 배관 검사 로봇의 다물체 동역학 해석을 수행하였다. 해석은 Altair 사의 Inspire를 사용하였다.

각 요소의 해석 조건은 앞서 각 모듈의 견인력 측정을 위해

Table 3에 기재한 값과 동일하다. 각 모듈은 유니버셜 조인트로 연결하였고 검사 모듈의 회전을 위하여 원통 축으로 구속하였다.

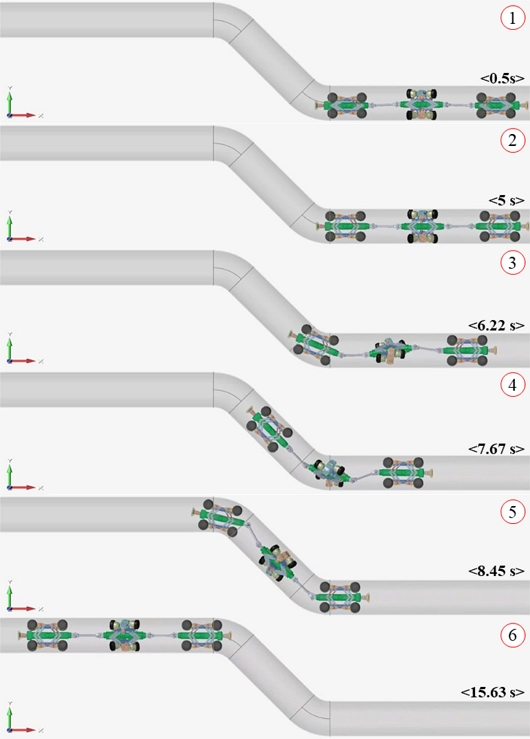

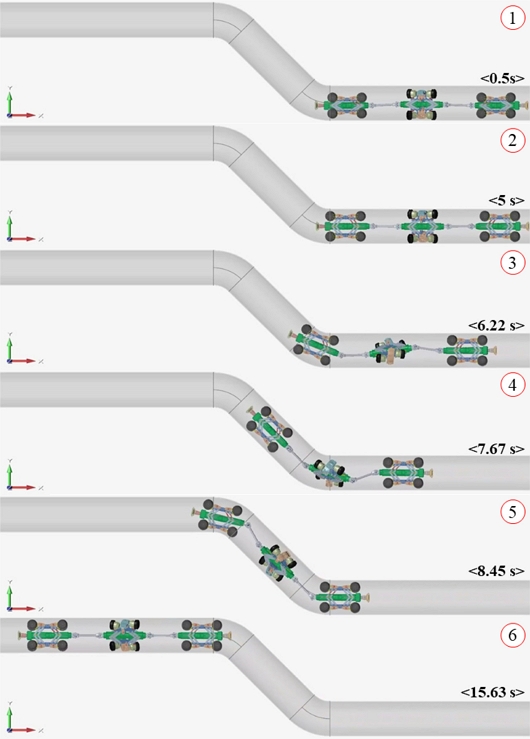

Fig. 12는 통합된 배관 검사 로봇의 다물체 동역학 해석 과정을 도시하였고 각 해석 시간을 표시하였다.

Fig. 12Sequence of multi-body dynamics analysis for integrated pipe inspection robot

Fig. 12의 해석 시간 0.5초에 로봇이 중력과 바퀴 접촉 조건에 의하여 배관과 접지하고, 5초에 각 모듈의 상부 바퀴가 배관과 접지한다. 그 후 6.22초에 전방 구동 모듈이, 7.62초에 검사 모듈이, 8.45초에 전방 구동 모듈과 후방 구동 모듈이 상하부 곡관을 통과하며 15.63초에 등반을 완료한다.

Fig. 12의 해석 시간 7.67초에 검사 모듈이 바퀴 접지력을 상실하고 구동 모듈에 의하여 견인되어가는 모습을 확인하였다. 구동 모듈의 바퀴 스프링보다 검사 모듈의 스프링을 짧게 적용한 것과 링크 제어의 부재를 접지력 상실 원인으로 판단하였다. 이러한 검사 모듈은 구동 모듈의 견인에 의하여 45

o 경사관 등반을 성공하였고, 통합된 배관 검사 로봇의 등반 능력을 확인하였다.

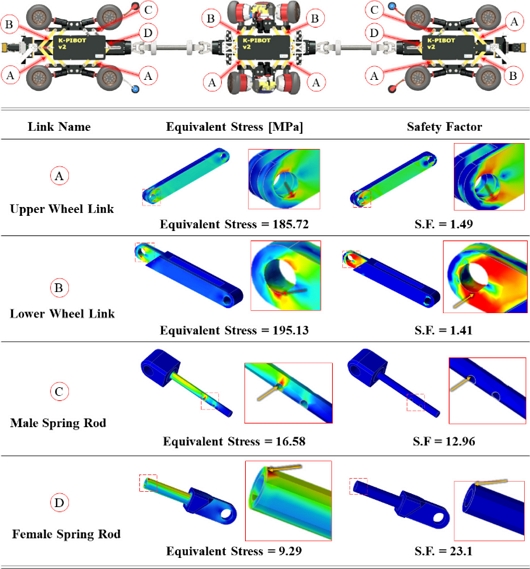

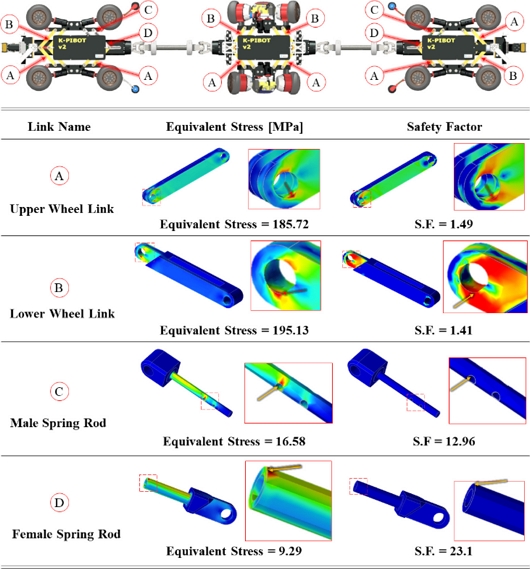

이와 같은 다물체 동역학 해석 결과를 기반으로 로봇 링크 부재의 구조해석을 진행하여 안전성을 판단하였다. 해석은 다물체 동역학 해석에 사용한 Altair 사의 Inspire를 사용하였고, 링크에 적용된 재질은

Table 2와 같다. 각 링크의 위치와 해석 결과를

Fig. 13에 나타내었으며 부재의 등가 응력과 안전 계수를 확인하여 안전성을 판단하였다. 링크 A와 B는 구동 모듈의 고정 링크와 검사 모듈의 구동 링크에 적용된 바퀴 높이 조절 링크이고, 링크 C와 D는 구동 모듈의 구동 링크에 적용된 스프링 가이드이다.

Fig. 13Link structure analysis forced by MBD

해석 결과는 SUS304 재질인 링크 C와 D는 안전율이 높게 계산되었고, 상대적으로 항복 응력이 낮은 AL6061-T6 재질이 적용된 링크 A와 B는 안전율이 각각 1.49와 1.41로 계산되었다. 해석 결과가 45o 기울어진 배관을 등반하며 발생한 최대 힘을 기준으로 계산된 결과이므로 일반적인 수평 배관과 수평 곡관에서는 이보다 작은 응력이 발생할 것으로 예상하였고 이러한 조건 하에 링크 부재가 건전한 것으로 판단하였다.

4. 배관 검사 로봇의 성능 실험

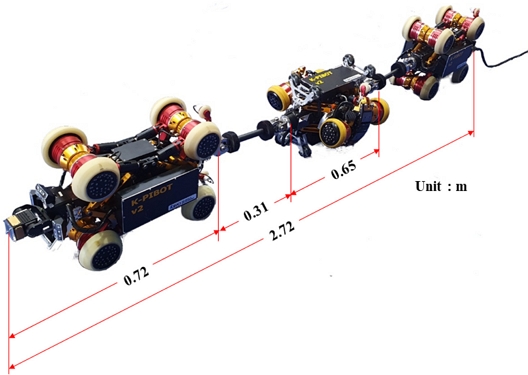

해석 결과를 바탕으로 제작된 배관 검사 로봇을

Fig. 14에 도시하였다. 설계된 바와 같이 구동 모듈 2대와 검사 모듈 1대로 이루어지고 검사 모듈은 평지에서 자립이 불가능하여 양쪽 가이드 휠에 의하여 지지되는 모습을 확인할 수 있다. 이와 같이 통합된 로봇의 견인력 실험과 테스트베드 실험으로 주행 성능과 등반 성능을 검증하였다.

Fig. 14 Pipe inspection robot with MFL inspector

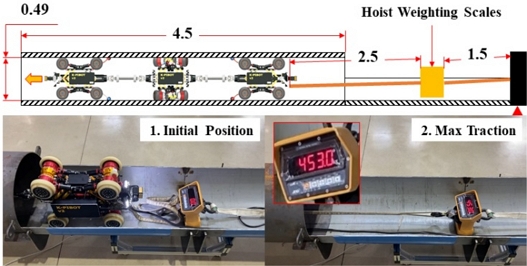

4.1 견인력 실험

견인력 실험은 수평관에서 진행하였고 전체 로봇 길이보다 충분히 긴 배관을 구성하여 통합된 로봇의 견인력을 측정하였으며, 이러한 실험의 구성은

Fig. 15와 같다. 실험에 사용한 CASS 사의 호이스트 저울은 최대 1,000 kg까지 측정 가능하고 최소 눈금은 0.5 kg이다. 실험은 500 mm의 배관에서 진행하였고 슬링 벨트(Sling Belt)로 반개관과 호이스트 저울, 호이스트 저울과 로봇을 각각 연결하였다. 호이스트 저울과 로봇을 연결하는 슬링 벨트는 모든 모듈이 배관에 진입한 후 실험이 진행되도록 길게 연결하였다.

Fig. 15Test of robot traction force and components of experiment

실험 결과로 구동 링크를 최대로 확장한 상태에서 측정된 견인력은 4,443.93 N이다. 해석된 구동 모듈과 검사 모듈의 견인력은 각각 1,630.4와 977.31 N으로 세 모듈의 견인력 합은 4,238.11 N이고, 측정 결과와 약 4.86%의 오차가 있다. 오차는 우레탄 재질로 이루어진 바퀴 타이어 형상의 가공 정밀도 한계와 바퀴 구름 저항 계수 차이 및 모듈 동기화 과정에서 발생하였을 것으로 판단하였고, 이러한 실험 결과로 측정된 견인력은 목표 주행거리 50 m를 만족할 것으로 판단하였다.

4.2 등반 능력 실험

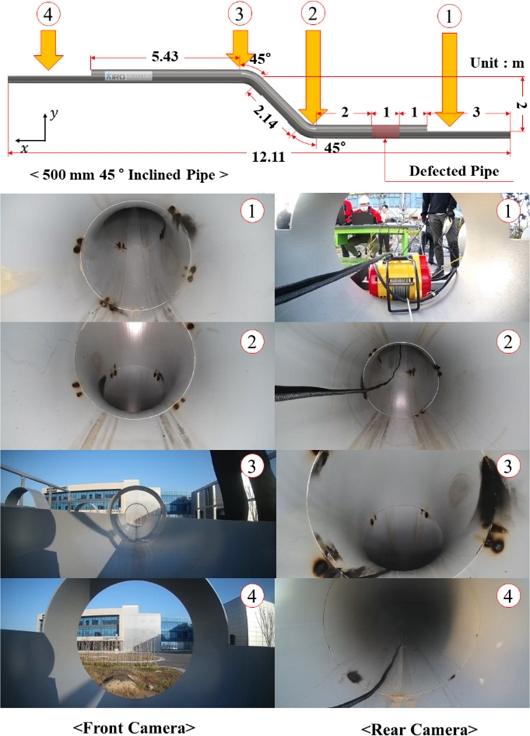

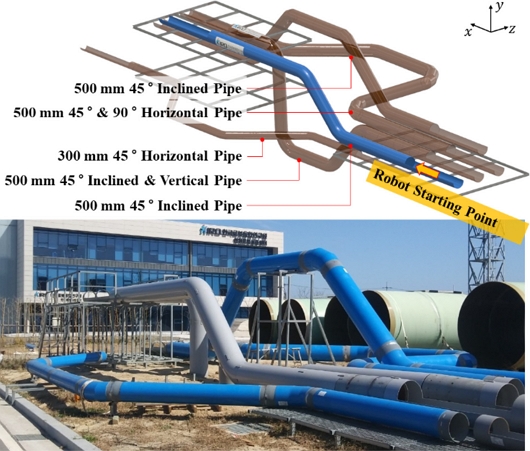

테스트베드의 구성과 실제 모습은

Fig. 16과 같으며 테스트베드는 총 5개의 배관으로, 300 mm 배관 1개와 500 mm 배관 4개로 구성되었다. 300 mm 배관은 2개의 45

o 곡관으로 구성되고, 500 mm 배관은 수평관과 수직관이 45와 90

o 규격으로 제작되어 배관 로봇의 수평 곡관 주행 성능과 경사관 및 수직관의 등반 능력을 확인할 수 있다.

Fig. 16Configuration of the testbed and installed structure

제작된 검사 로봇의 실험을 진행한 테스트베드 구성과 크기는

Fig. 16에 나타내었다. 개발된 검사 로봇의 주행 시험을 진행한 배관은 500 mm의 45

o 곡관 2개로 이루어진 경사관으로 내경은 약 490 mm이다. 총 주행 거리는 15.5 m이고, 초입부에 결함 배관이 구성되어 MFL 모듈의 검사 성능 시험이 가능하며 테스트베드 양단에 반개관이 구성되어 로봇의 투입 및 회수가 용이하다. 결함의 형상을 특정하기 위하여 정해진 크기의 결함을 인위적으로 생성하였다.

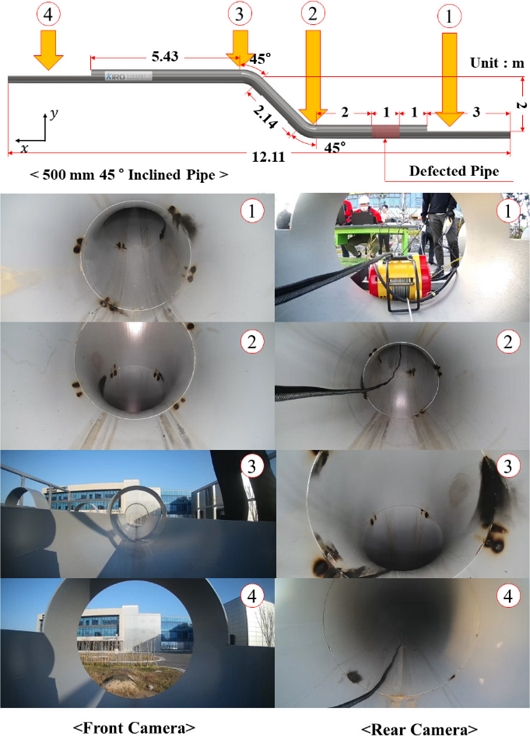

로봇의 등반 성능 실험 과정을

Fig. 17에 나타내었다.

Fig. 17은 구동 모듈의 전후방 카메라를 통해 저장된 영상으로 주행 과정을 배관 정면도에 도시하였다. 로봇의 회수가 불가능할 경우를 대비하여 로봇 후단에 견인 장치를 장착하였다.

Fig. 17Experimental result of the pipe inspection robot with testbed layout

실험 결과는 로봇이 45

o 경사관을 등반하였고 결함 배관을 통과하며 MFL 모듈을 사용하여 검사 데이터를 습득할 수 있었다. 이러한 실험 결과로 로봇 목표 성능인 45

o 경사관에서의 등반 성능을 만족하였다 판단하였고,

Table 1의 모든 목표 성능에 도달한 것을 확인하였다.

5. 결론

본 논문에서는 나선 검사 기법을 활용한 배관 검사 로봇의 개발에 대하여 기술하였다. 정역학과 기구학을 이용한 모듈별 바퀴의 접지력과 견인력, 모터 토크를 계산하였다. 계산 결과를 다물체 동역학 해석 결과와 비교하여 로봇의 성능을 예측하였고, 비교한 결과를 기반으로 구동 모터와 감속기를 선정하였다. 검사 모듈의 구동 메커니즘을 수학적으로 표현하였고, 이 식을 기반으로 나선 검사 기법에 의한 검사 면적을 확인하였으며 다물체 동역학 해석으로 전체를 통합한 로봇의 45o 경사관 등반 능력을 확인하였다. 역학과 해석을 바탕으로 제작된 로봇에 대하여 견인력 실험을 진행하였고 그 결과를 해석 결과와 비교하여 제작된 로봇의 주행 성능을 검증하였다. 또한, 로봇의 테스트베드 실험으로 등반 능력을 검증하였으며 MFL 검사 모듈로 결함을 검출하였다.

추후에 추가적인 실험을 통하여 배관 내 환경에 따른 견인력 영향 요소를 고려하여 개발 로봇의 최대 주행 거리를 측정하고, 결함 배관 데이터를 추가 수집하여 결함 종류의 데이터베이스를 구축한 후 개발 플랫폼의 활용성 및 유효성을 추가적으로 확인할 예정이다.

ACKNOWLEDGMENTS

본 논문은 행정안전부 재난안전산업육성지원 사업의 지원을 받아 수행된 연구임(No. 20010079).

REFERENCES

- 1.

Ministry of Environment, (2021), Infrastructure management plan.

- 2.

Ministry of Environment, (2021), 2020 Water supply statistics.

- 3.

Lee, J.-Y., Hong, S.-H., Jeong, M.-S., Suh, J.-H., Chung, G.-B., Han, K.-R., Choi, I.-S., (2017), Development of pipe cleaning robot for the industry pipe facility, The Journal of Korea Robotics Society, 12(1), 65-77.

10.7746/jkros.2017.12.1.065

- 4.

Lee, J., Hong, S., Jung, M., Han, K., Suh, J., (2018), Development of the robot for in-pipe cleaning from 250 to 500 A pipes, Journal of the Korean Society for Power System Engineering, 22(5), 13-26.

10.9726/kspse.2018.22.5.013

- 5.

Jeong, M.-S., Lee, J., Hong, S.-H., Jang, M., Shin, D., Hahm, J., Seo, K.-H., Seo, J.-H., (2021), Development of the pipe construction robot for rehabilitation work process of the water pipe lines, The Journal of Korea Robotics Society, 16(3), 223-231.

10.7746/jkros.2021.16.3.223

- 6.

Jang, M. W., Jeong, M. S., Hahm, J. H., Hong, S. H., Seo, K. H., Seo, J. H., Lee, J. Y., (2021), Development of high traction in-pipe robot adjustable 500-800 mm pipe and verification of the capability, Journal of Power System Engineering, 25(4), 52-61.

10.9726/kspse.2021.25.4.052

- 7.

Park, J. H., Kim, H. M., Park, G. S., (2016), A study on the signal correction for multiple defects in MFL type nondestructive testing system, Journal of the Korean Magnetics Society, 26(1), 24-30.

10.4283/JKMS.2016.26.1.024

- 8.

Ahn, B.-Y., Kim, Y.-J., Kim, Y.-G., Lee, S.-S., (2004), Development of an EMAT system for detecting flaws in pipeline, Journal of the Korean Society for Nondestructive Testing, 24(1), 15-21.

- 9.

Lim, J.-S., Park, T.-S., Ha, S.-J., Park, I.-K., (2018), Development of a multi-joint robotic ultrasonic inspection system to secure the integrity of composite structures, Journal of the Korean Society for Nondestructive Testing, 38(2), 120-125.

10.7779/JKSNT.2018.38.2.120

- 10.

Choi, C.-H., Park, B.-S., Jung, H.-K., Jung, S.-H., (2008), Inch-worm robot with automatic pipe tracking capability for the feeder pipe inspection of a PHWR, Journal of Institute of Control, Robotics and Systems, 14(2), 125-132.

10.5302/J.ICROS.2008.14.2.125

- 11.

Jung, S. W., Park, K. W., (2019), Development of carrier robot system equipped with magnetic flux leakage tool for pipe inspection, Proceedings of the Korean Society of Civil Engineering 2019 Convention, 2019(10), 1049-1050.

- 12.

Kim, H. M., Yoo, H. R., Park, G. S., (2018), A new design of MFL sensors for self-driving NDT robot to avoid getting stuck in curved underground pipelines, IEEE Transactions on Magnetics, 54(11), 1-5.

10.1109/TMAG.2018.2846283

- 13.

Kwon, S. J., Lee, D. H., Seo, J. W., Kim, J. C., (2014), Evaluation of non destructive inspection interval for running safety of railway axle, Journal of the Korean Society for Precision Engineering, 31(9), 777-782.

10.7736/KSPE.2014.31.9.777

- 14.

Lee, K. S., Suh, J. H., Min, J. T., Lee, Y. J., (2005), Development of real-time remote detection system for crane wire rope defect, Journal of the Korean Society for Precision Engineering, 22(1), 53-60.

Biography

- Min-Woo Jang

Researcher of Integrated Robotics Systems Research Center in Korea Institute of Robotics and Technology Convergence. His research interest is pipe robot.

- Jae-Youl Lee

Principal Researcher & Head of Integrated Robotics System Research Center in Korea Institute of Robotics & Technology Convergence. His research interest is pipe robotics, professional service robot.

- Myeong-Su Jeong

Senior Researcher of Integrated Robotics Systems Research Center in Korea Institute of Robotics and Technology Convergence. His research interest is pipe robot, sensor convergence.

- Sung-Ho Hong

Senior Researcher of Integrated Robotics Systems Research Center in Korea Institute of Robotics and Technology Convergence. His research interest is embedded control system.

- Dong-Ho Shin

Researcher of Integrated Robotics Systems Research Center in Korea Institute of Robotics and Technology Convergence. His research interest is embedded control system.

- Kap-Ho Seo

Chief Researcher & Director with the Korea Institute of Robots and Convergence. His research interest is system control, disaster robotics, and medical robotics.

- Jin-Ho Suh

Professor in the Major of Mechanical System Engineering, Division of Energy Transport Systems Engineering, College of Engineering, Pukyong National University. His research interest is disaster response robot, underwater robots, and system control & integration in field robotics.