ABSTRACT

In this study, the structural integrity of an engine-generator support structure of hybrid drone is verified through finite element (FE) analysis and experimental investigation. From preliminary experiments, critical failures in four columns of the support structure were observed. Due to the repeated cyclic loads induced by the engine-generator operation, the results of the FE simulation pointed out that fatigue failure is the main cause. To improve the structural integrity, the geometric shape and the material of the structural members are modified and changed, and the safety factor is also reviewed using static structural analysis. The possibility of critical resonance is evaluated through FEM-associated modal analysis and a series of vibration tests. As result, it is confirmed that the re-designed support structure was structurally improved with enough safety margin through FE analysis and experimental investigation, and fatigue life by comparing the predicted value and S-N curve of the material used to the support structure was improved.

-

KEYWORDS: Hybrid drone, Support structure, Finite element analysis, Structural integrity

-

KEYWORDS: 하이브리드 드론, 지지구조물, 유한요소해석, 구조건전성

1. 서론

최근 감시·정찰·농업·운송 등의 분야로 드론(Drone)의 운용범위가 확대됨에 따라 비행 시간 증가의 필요성이 요구되는 추세이다[

1]. 현재 대부분의 드론은 배터리를 동력원으로 사용하는 전기추진 방식이 주로 채용되고 있다. 이러한 방식의 경우, 드론의 운용은 간편한 반면에 에너지 밀도가 낮아 최대 30분 정도로 비행 시간이 제한되는 문제가 발생하고 있다. 비행 시간을 증가시키기 위해서는 기존의 전기추진 방식을 대체할 수 있는 기술이 요구된다. 가솔린 연료는 드론용 전기추진 방식에 주로 사용되는 배터리의 경우보다 에너지 밀도가 높은 반면, 순간 방전율이 낮아 급기동 시 요구되는 성능을 구현하기가 어렵다는 단점이 있다. 이에 따라, 가솔린 엔진과 전기추진 방식을 결합하여 비행 시간을 증가시키기 위해 하이브리드 동력시스템 개발에 관한 연구가 활발히 진행 중이다[

2].

일반적인 하이브리드 방식은

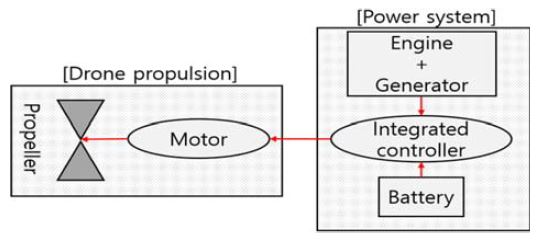

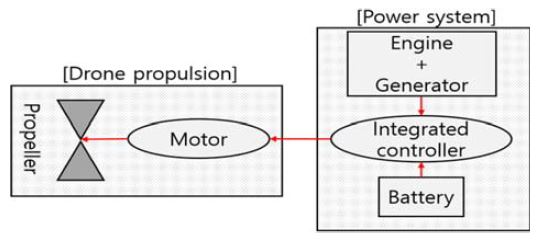

Fig. 1과 같이 엔진·발전기·배터리·통합제어기로 이루어진 동력시스템과 구동모터·프로펠러로 이루어진 드론 추진장치로 구성되며, 가솔린을 연료로 사용하는 엔진 구동을 통해 엔진 크랭크축에 장착된 발전기를 가동하여 전기에너지를 얻는다. 이후 전기에너지는 구동모터로 공급되어 프로펠러를 회전시켜 드론을 운용하게 된다. 추가적으로 배터리를 보조 동력으로 사용하여 발전기 출력을 보다 효율적으로 운용하고, 통합제어기를 통해 하이브리드 동력시스템을 안정적으로 운용한다. 이를 통해 하이브리드 동력시스템은 기존 전기추진 방식에 비해 비행 시간을 최대 4배 이상 증가시킬 수 있다는 장점을 가진다[

2].

Fig. 1 Schematic view of hybrid system configuration for drones

하이브리드 동력시스템에 사용되는 드론용 엔진은 경량화 및 고출력화 등이 가능한 2-행정 방식의 왕복엔진이 많이 사용되며, 발전기는 경량화와 효율성 측면에서 유리한 외전형 방식이 주로 채택된다[

2]. 엔진과 발전기를 드론 내부 프레임에 장착하기 위해서는 별도의 지지구조물이 필요하다. 하이브리드 드론 운용 시, 왕복엔진 실린더 내부 피스톤의 왕복 운동과 외전형 발전기 회전자의 회전 운동으로 인해 주기하중(Torque)이 발생된다. 이때, 발생한 주기하중이 드론 내부로 전달되면 하드웨어 및 소프트웨어의 안정성을 위협할 가능성이 높아지게 된다. 따라서 지지구조물은 진동 전달을 최소화함과 동시에 구조건전성이 확보되어야 한다.

본 연구에서는 하이브리드 드론용으로 개발된 엔진-발전기 지지구조물의 초기 모델이 구조건전성을 평가하기 위한 구조시험 과정 중 파손되었으며, 파손의 원인을 유한요소해석을 통해 파악하였다. 이후 하이브리드 드론의 운용 시 발생할 수 있는 구조적 문제를 미연에 방지하기 위해 형상과 소재 변경을 통해 구조건전성을 개선하였으며, 추가적인 유한요소해석과 실험을 통해 개선된 지지구조물 모델의 구조건전성 검증에 관한 연구를 수행하였다.

2. 구조시험 및 하중 측정시험

하이브리드 드론용으로 초기 설계 및 시제작 된 엔진-발전기 지지구조물의 구조건전성을 검증하기 위해 구조시험을 수행하였다. 엔진과 발전기 구동 시에 발생되는 주기하중으로 인해 생성되는 진동이 드론 내부로 전달되는 것을 방지하기 위해 방진 마운트를 지지구조물에 체결한 상태에서 구조시험을 진행하였다. 드론용 2-행정 왕복엔진은 일반적으로 5,000-7,000 RPM의 운용영역을 가짐에 따라[

3],

Table 1과 같이 엔진-발전기 지지구조물 구조시험 모델은 평균 7,000 RPM에서 6.4시간 동안 구동하는 경우와 평균 5,000 RPM에서 10.9시간 동안 구동하는 경우 2가지로 구분하여 수행하였다. 그 결과

Fig. 2와 같이 엔진-발전기 지지구조물의 기둥 부분이 파손됨을 확인하였다.

Table 1 Structural tests of support structure

Table 1

|

Model |

Time [hr] |

Average RPM |

No. of cycles |

Result |

|

1 |

6.4 |

7,000 |

5,376,000 |

Broken |

|

2 |

10.9 |

5,000 |

6,540,000 |

Broken |

Fig. 2 Failure example of engine-generator support structure

구조시험 과정에서 발생한 파손의 원인을 파악하기 위해 수행되는 유한요소해석에는 기본적으로 하중 데이터가 필요하기 때문에

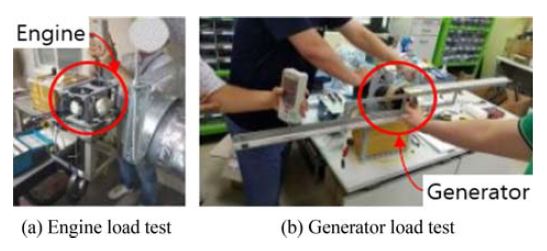

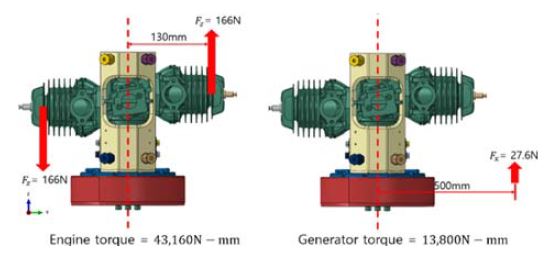

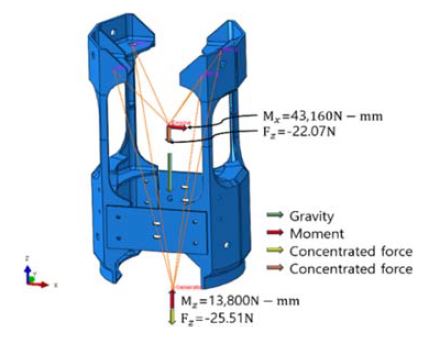

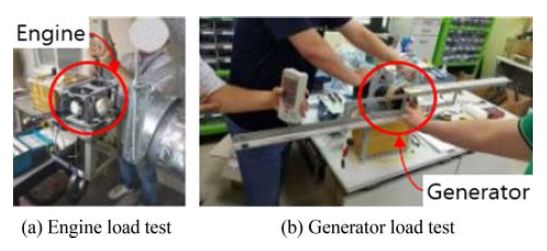

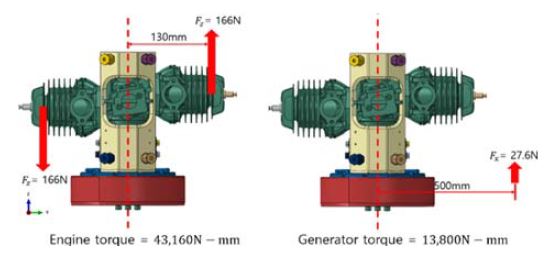

Fig. 3에서와 같이 하중 측정시험을 수행하였으며, 120 cc 용량의 2-행정 왕복엔진(Dessert Aircraft 사의 DA120)을 사용하였고, 외전형 발전기(Sullivan 사의 S67 6-600F-01)를 커스터마이징(Customizing)하여 엔진의 크랭크축에 장착하였다. 왕복엔진은 중심축으로부터 양쪽으로 130mm 떨어진 위치에 Push-Pull Gauge와 무게추를 적용하였고, 발전기는 중심축으로부터 500 mm 떨어진 위치에 Push-Pull Gauge를 이용하여 하중 측정시험을 진행하였다. 하중 측정시험을 통해

Fig. 4와 같이 엔진과 발전기에서 43,160 및 13,800 N-mm의 토크가 각각 측정되었다.

Fig. 3 Load measurement tests of engine and generator

Fig. 4 Load diagram of engine and generator

3. 엔진-발전기 지지구조물 파손 원인 분석

3.1 유한요소 모델링

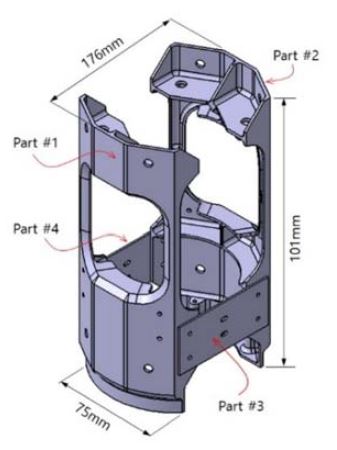

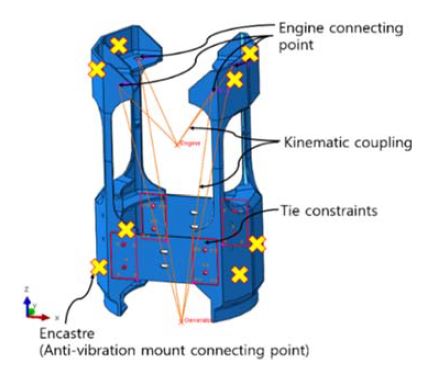

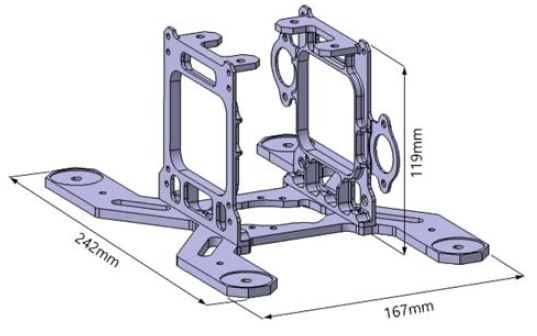

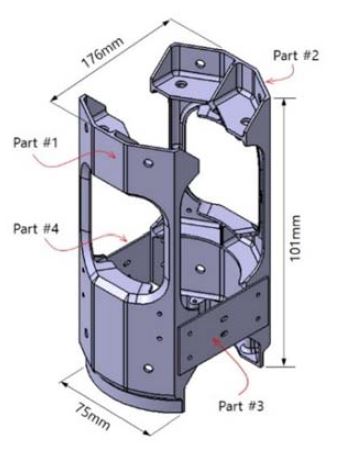

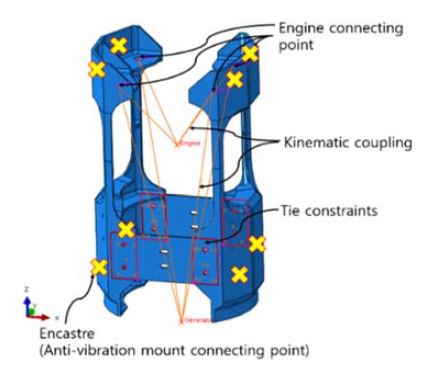

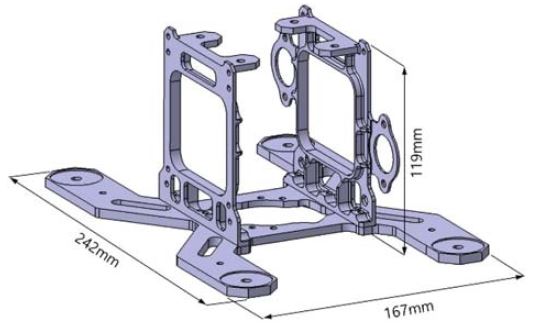

엔진-발전기 지지구조물은

Fig. 5와 같이 4개의 파트를 3차원 형상으로 각각 모델링한 후 조립하였다. 지지구조물에 적용된 소재는 AA6061-T6이며, 기계적 물성을

Table 2에 요약하여 나타내었다. 구조해석을 위해 상용 유한요소해석 프로그램인 ABAQUS를 사용하였으며,

Fig. 5에 도시된 Part #1 및 Part #2 부분은 856,239개의 사면체 요소로 이산화하였으며, Part #3과 Part #4 부분은 11,030개의 육면체 요소로 구성하였고, 유한요소 이산화 과정에 적용된 요소 특성은

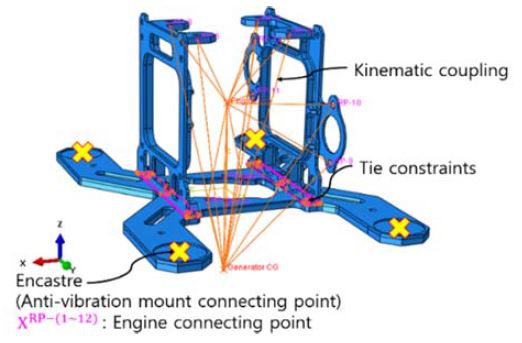

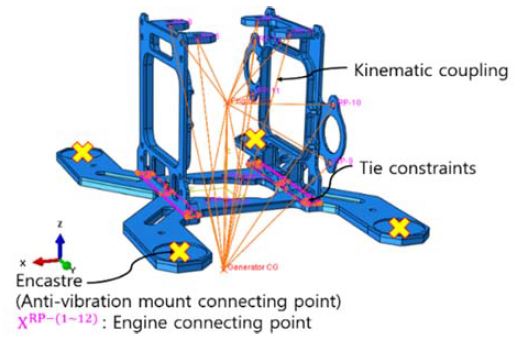

Table 3에 정리하였다. 유한요소법 기반의 구조해석을 위해

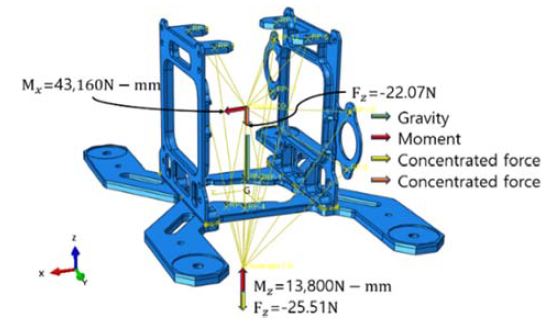

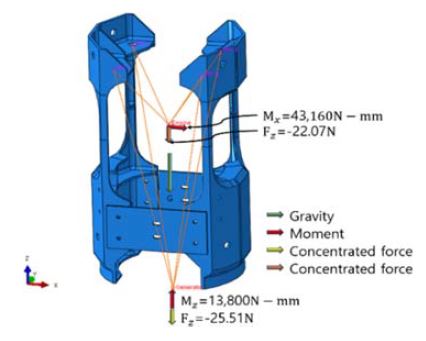

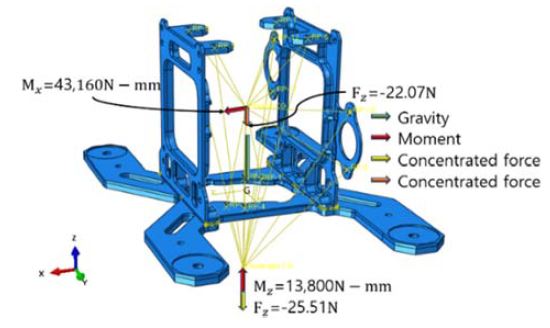

Fig. 6과 같은 구속조건 및 경계조건을 부여하였다. 엔진 실린더 내부 피스톤의 왕복운동과 더불어 엔진 크랭크축을 기준으로 발전기의 회전자가 회전하며 주기하중인 토크가 발생한다. 따라서,

Fig. 4에서 제시된 하중 측정시험을 통해 얻어진 하중 데이터를

Fig. 7과 같이 부여하였고, 엔진의 무게 중심에

x-축을 회전축으로 43,160 N-mm 및 발전기의 무게 중심에

z-축을 회전축으로 13,800 N-mm의 모멘트를 하중조건으로 설정하였다. 본 연구에서 사용된 엔진의 무게는 2.25 kg이므로 엔진 무게 중심에 22.07 N, 발전기의 무게는 2.6 kg이므로 발전기 무게 중심에 25.51 N의 집중 하중을 부여하였고, 엔진-발전기 지지구조물 자체의 무게 또한 고려하였다.

Table 2Material properties of AA6061-T6

Table 2

|

Density [g/cc] |

Poisson’s ratio |

Young’s modulus [GPa] |

Yield strength [MPa] |

Ultimate strength [MPa] |

|

2.70 |

0.33 |

68.9 |

241 |

290 |

Fig. 5Support structure assembly geometry

Table 3Mesh details of support structure

Table 3

|

Element type |

Element shape |

Geometric order |

No. of elements |

No. of nodes |

|

C3D10 |

Tetrahedral |

Quadratic |

856,239 |

1,373,164 |

|

C3D8R |

Hexahedral |

Linear |

11,030 |

Fig. 6Interaction and boundary conditions of support structure

Fig. 7Load conditions of support structure

3.2 유한요소 해석

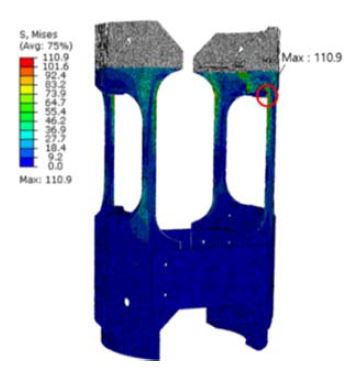

하이브리드 드론용 엔진-발전기 지지구조물에 적용된 소재인 AA6061-T6는 연성 소재(Ductile Material)에 해당함에 따라 정적 구조해석은 von Mises 항복조건을 기준으로 수행하였다[

4].

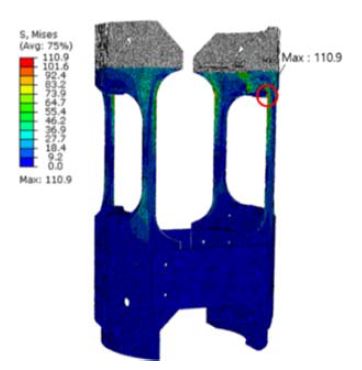

Fig. 8에 제시된 정적 구조해석 결과를 살펴보면, 최대 유효응력은 약 110.9 MPa로 예측되었으며, 발생 지점이

Fig. 2의 구조시험에서 확인된 파손 지점과 일치함을 확인하였다. 이에 따라, 지지구조물의 기둥 부분이 구조적으로 취약한 것으로 판단되었다. 그러나 예측된 최대 유효응력은 적용된 소재의 항복응력(약 241.0 MPa)에 비해 낮은 수준이며, 약 2.17의 안전 계수를 나타냄에 따라 정적 하중조건이 엔진-발전기 지지구조물의 파손 발생에 영향을 주지 않는 것으로 나타났다[

5].

Fig. 8Effective stress distribution of support structure

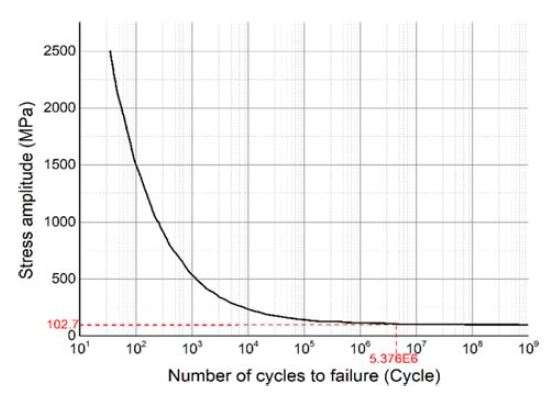

3.3 파손 원인 분석

정적 구조해석을 통해 확인된 결과를 요약하면, 엔진-발전기 지지구조물은 안전계수 약 2.17로 정적 구조건전성에 특별한 문제점이 없는 것으로 나타났으므로, 엔진-발전기 지지구조물 파손은 정적 하중조건이 원인이라고 판단하기에는 다소 무리가 있다고 할 수 있으므로, 다른 원인으로 피로파괴(Fatigue Failure) 현상을 고려하였다. 일반적으로 반복되는 하중조건일 때, 정적하중조건에서의 파손보다 낮은 응력 조건에서 파손이 발생하게 된다[

6]. 엔진과 발전기를 구동하게 되면 반복적인 주기하중이 발생함에 따라, 피로 누적에 의한 파손으로 유추되어 구조시험에서 파손이 발생했던 사이클과 AA6061-T6 소재에 대한 피로선도에서 해당 수치와의 비교 연구를 수행하였다[

7].

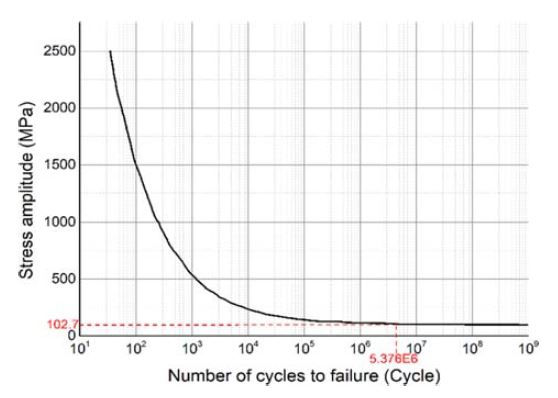

Table 1에 제시된 구조시험 결과로부터 평균 7,000 RPM으로 엔진을 구동하였을 경우, 지지구조물이 약 5,376,000 사이클에서 파손이 발생함을 알 수 있으므로,

Fig. 9에 제시된 AA6061-T6 소재의 피로 선도를 기준으로 실험을 통해 확인된 파손 조건을 고려할 경우, 응력 진폭(Stress Amplitude)은 약 102.7 MPa 수준임을 알 수 있다.

Table 4에 요약한 바와 같이, 앞서의 정적구조해석을 통해 얻어진 최대 유효응력(약 110.9MPa)과 AA6061-T6 소재의 피로 선도에서 산출한 약 102.7 MPa의 응력 진폭은 그 차이가 약 7.9%로 나타났으며, 이를 통해 엔진-발전기 지지구조물의 파손 원인은 피로파괴에 의한 것으로 판단되었다.

Fig. 9S-N curve of AA6061-T6 [7] (Adapted from Ref. 7 on the basis of OA)

Table 4Comparison between stress amplitude and maximum effective stress of support structure

Table 4

|

Max. effective stress [MPa] |

Stress amplitude [MPa] |

Error [%] |

|

110.9 |

102.7 (at 5,376,000 Cycle) |

7.9 |

4. 엔진-발전기 지지구조물 구조건전성 개선

4.1 엔진-발전기 지지구조물 형상 개선

지지구조물의 피로파괴 현상을 방지하기 위해 전체 형상을 변경함과 동시에 경량의 고강도 소재를 적용하는 방안을 고려하였다. 개선된 3차원 형상이

Fig. 10에 제시되어져 있으며, 바닥부 지지구조와 상부의 엔진 체결부위 형상이 변경되었음을 확인할 수 있다. 이와 더불어, 개선된 지지구조물 형상의 소재는

Table 5에서 제시된 기계적 특성을 가지는 AA7075-T6로 변경하였다. 정적 구조해석과 모드해석(Modal Analysis)을 수행하기 위해

Figs. 11에서와 같이 구속조건 및 경계조건을 포함한 유한요소 모델을 구성하였고, 12에서와 같은 하중조건을 부여하였다. 그리고

Table 6은 유한요소 모델에 적용된 요소 이산화 결과를 요약한 것이다.

Fig. 10Modified support structure assembly geometry

Table 5Material properties of AA7075-T6

Table 5

|

Density [g/cc] |

Poisson’s ratio |

Young’s modulus [GPa] |

Yield strength [MPa] |

Ultimate strength [MPa] |

|

2.81 |

0.33 |

71.7 |

503 |

572 |

Fig. 11Interaction and boundary conditions of modified support structure

Table 6Mesh details of modified support structure

Table 6

|

Element type |

Element shape |

Geometric order |

No. of elements |

No. of nodes |

|

C3D10 |

Tetrahedral |

Quadratic |

896,109 |

1,477,495 |

|

C3D8R |

Hexahedral |

Linear |

52,880 |

4.2 유한요소 해석

Figs. 10에서 도시된 개선된 엔진-발전기 지지구조물 형상과 더불어

11과

12에서와 같은 구속조건 및 경계조건 그리고 하중조건이 적용된 유한요소 모델을 이용하여 구조해석을 재수행하였다.

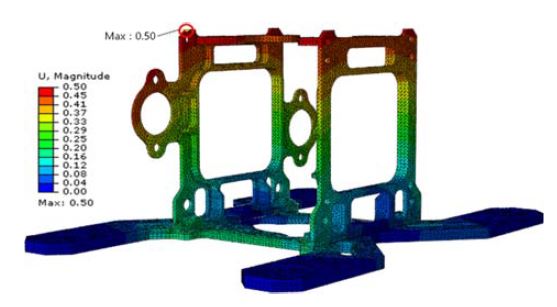

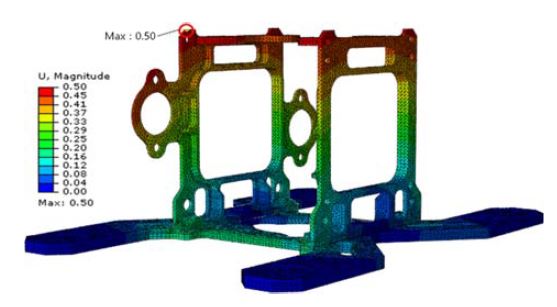

Fig. 13은 엔진-발전기 지지구조물의 개선 모델에 대한 정적 구조해석 결과를 보여주고 있으며, 바닥부 지지구조의 내측 코너부에서 약 134.5 MPa의 최대 유효응력이 예측되었다.

Table 5에 제시된 AA7075-T6 소재의 항복응력(약 503 MPa)을 기준으로 안전계수를 검토해 본 결과, 약 3.74로 개선전의 안전계수(약 2.17)보다 약 72.35% 정도 향상된 것으로 파악되었다. 이와 더불어,

Fig. 14는 변위 분포를 나타낸 것으로, 최대 변위는 약 0.5 mm로 예측되었으며, 이를

Table 7에 정리하였다. 구조물에 가해지는 외력의 반복주기와 고유진동수가 근접하거나 일치하게 되면, 진폭이 급격하게 증가하여 구조물의 구조건전성을 위협하는 공진 현상이 발생한다. 따라서, 엔진-발전기 지지구조물개선 모델의 고유진동수를 확인하여 공진 발생 가능성을 예측하고, 진동에 의한 변형 형상을 파악하기 위해 모드해석을 수행하였다[

8].

Fig. 12Load conditions of modified support structure

Fig. 13Effective stress distribution of modified support structure

Fig. 14Deformation of modified support structure

Table 7Results of static structure analysis for modified model

Table 7

|

Analysis model |

Max. effective stress [MPa] |

Max. displacement [mm] |

Safety factor |

|

Modified |

134.5 |

0.5 |

3.74 |

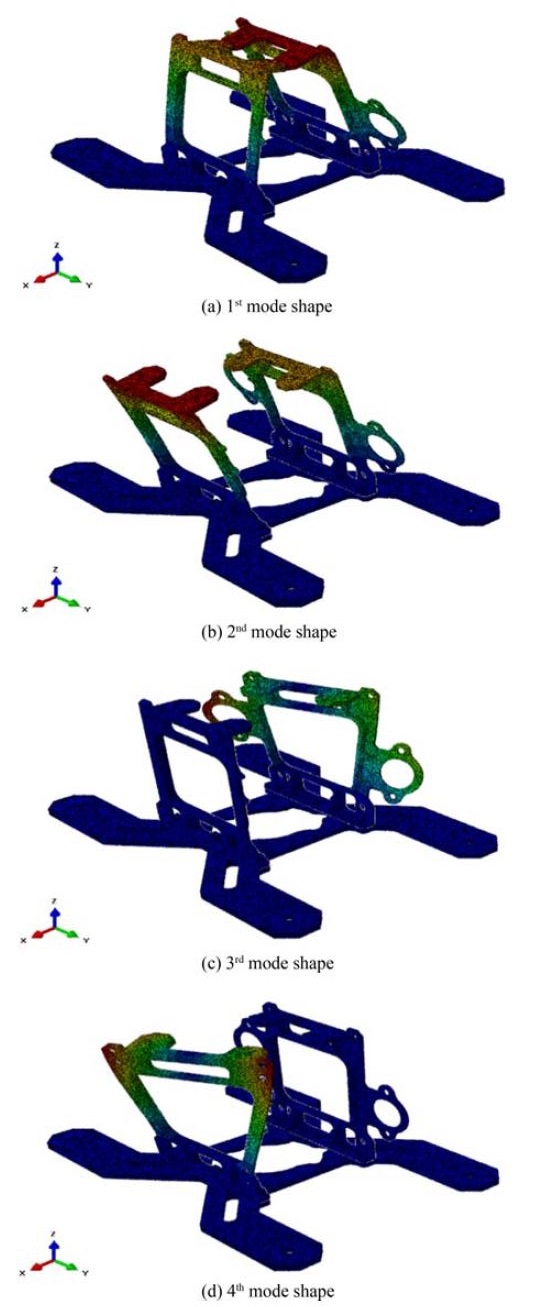

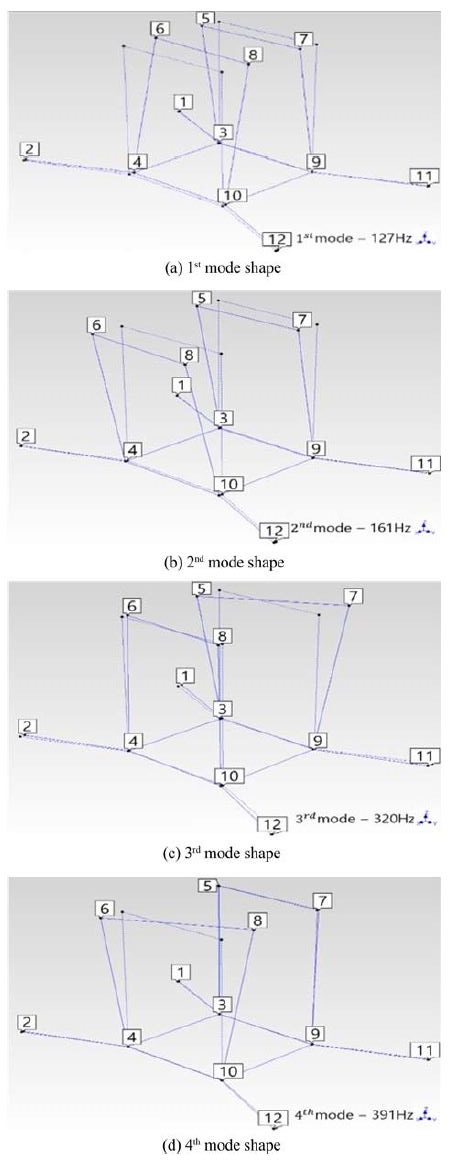

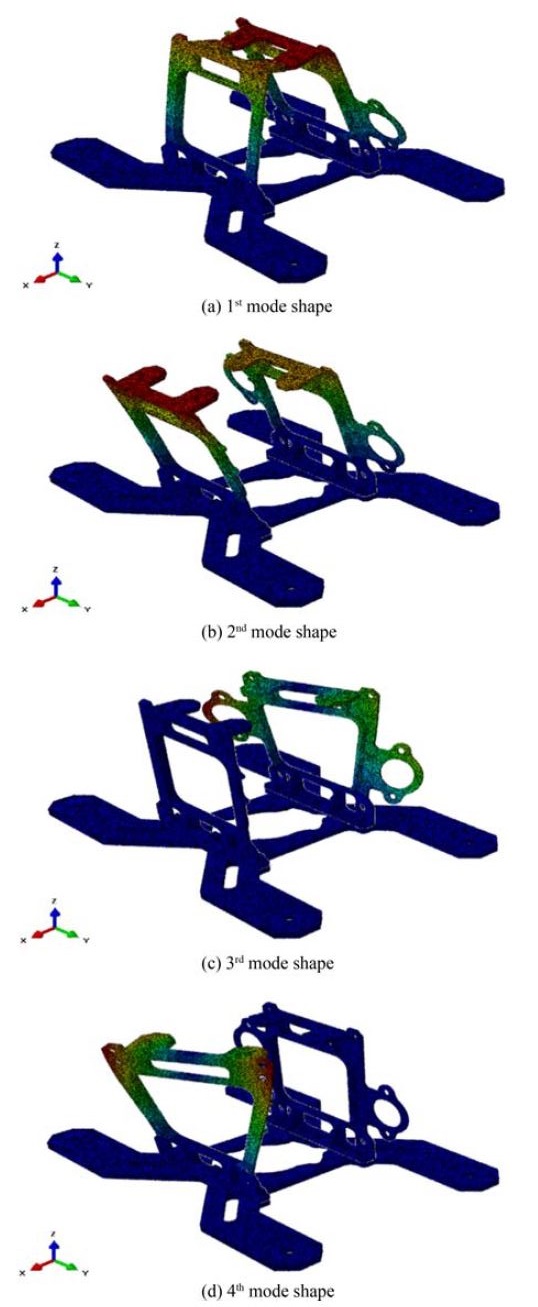

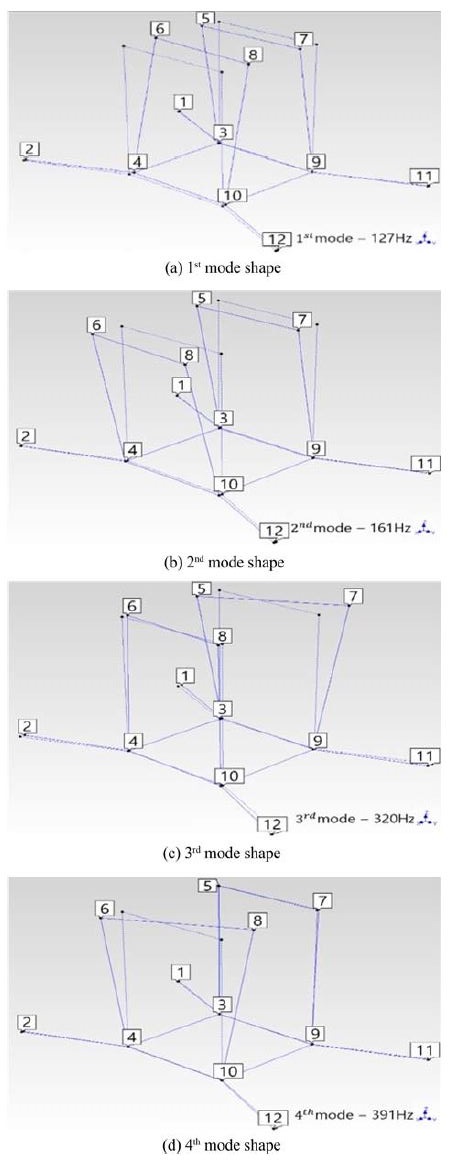

모드해석은 하중조건이 없는 자유진동 상태에서 수행됨[

9]에 따라 방진 마운트가 체결되는 4곳에

Fig. 11과 같이 병진과 회전 자유도가 존재하지 않는 경계조건만 부여하여 고정하였다. 모드해석을 통해 확인된 결과로서 엔진-발전기 지지구조물 개선 모델의 고유진동수를 살펴보면 1차 모드는 약 128 Hz, 2차 모드는 약 141 Hz, 3차 모드는 약 331 Hz 그리고 4차 모드는 약 390 Hz의 고유진동수를 가짐을

Table 8에 요약된 결과를 통해 알 수 있으며 각 모드 별 형상을

Fig. 15에 나타내었다. 1, 2차 모드에서는

x-축 방향으로 1차 굽힘, 그리고 3, 4차 모드에서는

z-축 방향으로 1차 비틀림이 각각 나타났다. 1-4차 모드 형상 측면에서 엔진-발전기 지지구조물 개선 모델의 기둥 부위에서 주된 변형이 공통적으로 발생함을 확인할 수 있었다.

Table 8Natural frequencies obtained from modal analysis

Table 8

|

Mode |

Natural frequency [Hz] |

Mode shape |

|

1 |

128 |

x-axis 1st bending |

|

2 |

141 |

x-axis 1st bending |

|

3 |

331 |

z-axis 1st twisting |

|

4 |

390 |

z-axis 1st twisting |

Fig. 15Mode shapes obtained from modal analysis

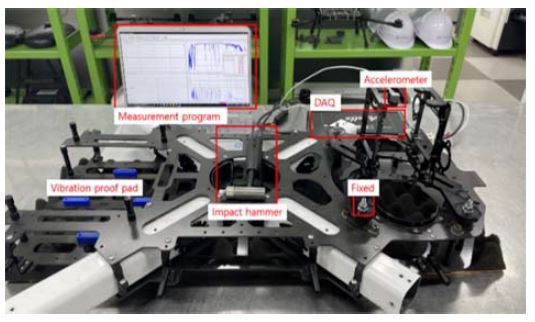

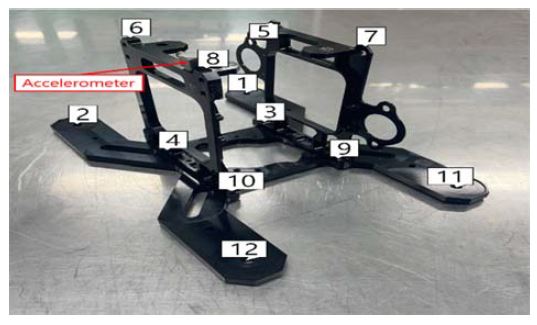

4.3 진동실험

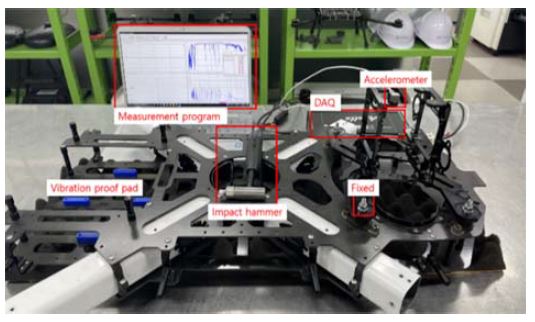

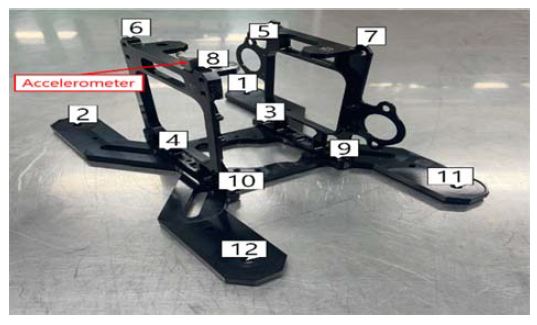

앞서의 엔진-발전기 지지구조물 개선 모델에 대한 모드해석 결과를 검증하기 위해 방진 마운트 체결을 통해 드론 내부 프레임에 지지구조물을 고정한 상태에서

Fig. 16과 고유진동수 측정실험을 수행하였다. 개선된 엔진-발전기 지지구조물이 비대칭 형상임을 고려하여 자유진동 상태를 구현하기 위해 방진 패드에 측정 대상을 올려놓고 고유진동수 측정 실험을 진행하였다. 또한,

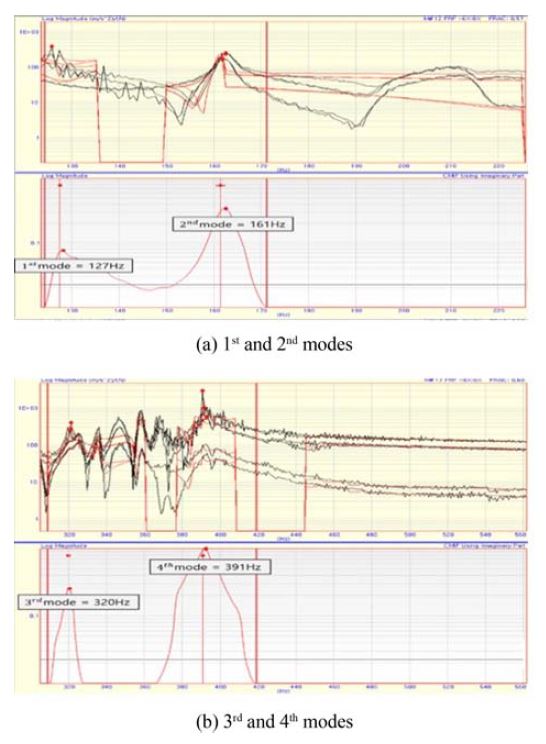

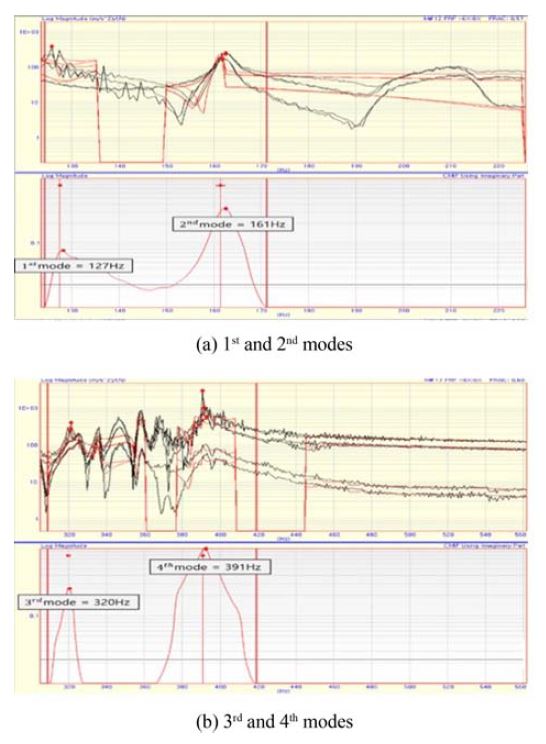

Fig. 17과 같이 엔진-발전기 지지구조물 개선 모델에 12개의 응답점(Response Points)을 선정하고, 임팩트 해머(Impact Hammer)를 이용하여 각 응답점에 순차적으로 충격을 가하였다. 임팩트 해머에 의해 인가된 진동은 8번 응답점에 부착된 가속도 센서와 데이터 획득 장치(DAQ)를 통해 획득하였으며, 데이터 후처리 프로그램을 사용하여 주파수 응답 함수(Frequency Response Function, FRF) 선도를

Fig. 18과 같이 도출하였다. 또한,

Fig. 18에 도시된 주파수 선도별 극댓값들을 추출하여 각 모드 별 고유진동수로 결정하였다(

Table 9 참조). 또한, 엔진-발전기 지지구조물 개선 모델의 각 응답점을 기준으로 단순화된 3차원 모델을 이용하여 각 모드 별 형상을 가시적으로 구현하여

Fig. 19에 나타내었다[

10].

Fig. 16Vibration experiment setup

Fig. 17Response points of modified support structure

Fig. 18Frequency diagrams obtained by frequency response function

Table 9Natural frequencies obtained from vibration experiment

Table 9

|

Mode |

Natural frequency [Hz] |

Mode shape |

|

1 |

127 |

x-axis 1st bending |

|

2 |

161 |

x-axis 1st bending |

|

3 |

320 |

z-axis 1st twisting |

|

4 |

391 |

z-axis 1st twisting |

Fig. 193D visualization of mode shapes by vibration experiment

4.4 유한요소해석 및 진동실험 결과 분석

하이브리드 드론용 엔진-발전기 지지구조물의 정적 구조해석을 수행한 결과, 개선 모델은

Fig. 14와 같이 0.5 mm의 최대 변위가 예측되었으나, 엔진의 고정 결합부 주위임을 감안하면 실질적인 변형은 무시할 수 있을 것으로 예상되었다. 또한, 엔진-발전기 지지구조물의 초기 모델과 개선 모델의 안전계수들은 각각 약 2.17 및 약 3.74로 나타났으며, 형상 개선과 구조물의 소재 변경을 통해 결과적으로 약 72.35% 수준의 안전계수 강화 효과를 기대할 수 있음을 확인하였다. 그리고,

Tables 8과

9의 모드해석과 진동실험을 통한 각각의 고유진동수 예측 결과를 살펴보면, 개선된 엔진-발전기 지지구조물의 고유진동수는 2차 모드에서 약 12.42% 수준의 오차를 보임을 알 수 있었다. 그러나,

Figs. 15의 모드해석과 19의 고유진동수 측정 실험의 3차원 가시화 결과를 비교할 경우, 매우 유사한 경향과 유의미한 결과를 나타냄을 확인하였다.

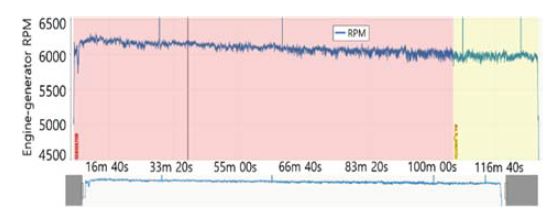

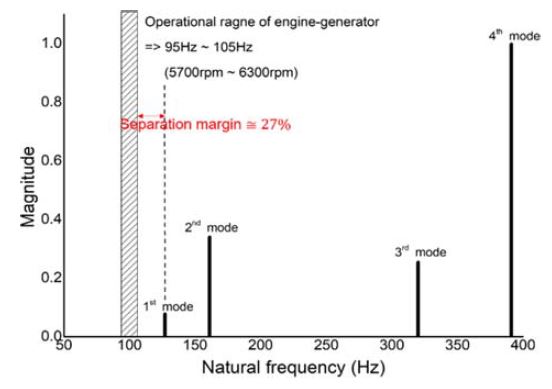

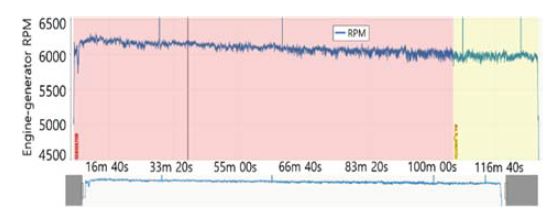

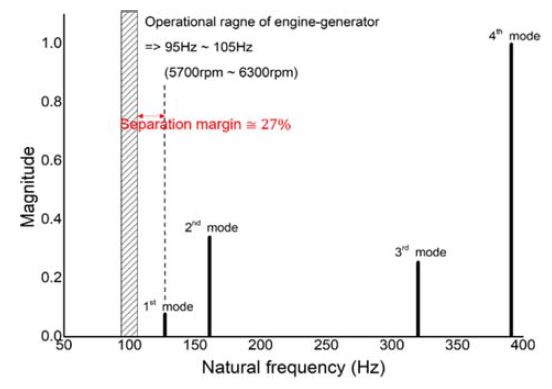

실험적 고유진동수와 엔진-발전기 운용주파수 사이의 분리여유(Separation Margin) 검토를 통해 공진 현상의 발생 가능성을 예측하기 위해 개선된 지지구조물이 적용된 하이브리드 드론을 약 2시간 정도 호버링(Hovering)하는 동안의 운용 RPM 데이터를

Fig. 20에서와 같이 획득하였다. 이를 통해, 측정 노이즈로 인한 영향을 제외하면 엔진-발전기는 약 5,700-6,300 RPM의 운용 환경을 갖는 것을 알 수 있었으며, 주파수 대역으로 변환하면 약 95-105 Hz 범위임을 의미한다. 이와 더불어,

Fig. 21에서와 같이 엔진-발전기 운용주파수와 가장 근접한 진동 모드는 1차 모드임을 알 수 있다. 1차 모드의 상대적 변위 크기가 매우 작고, 운용주파수와 1차 모드 사이에는 약 27%의 분리여유가 확보됨에 따라 엔진-발전기 지지구조물 개선 모델의 공진 발생 가능성은 충분히 낮다고 판단된다[

10]. 또한 하이브리드 드론용 엔진-발전기 지지구조물은 운용 시 엔진 결합으로 인해 구속조건이 늘어남에 따라 강성이 증가한다. 그러므로 엔진-발전기 지지구조물 개선 모델의 고유진동수는 증가하게 되며, 운용주파수로부터의 분리 여유 또한 더욱 증가될 것으로 예상된다. 모드해석 결과를 살펴보면, 1-4차 모드 형상 모두 지지구조물의 기둥 부분에서 변형이 발생하는 것으로 예측되었으나, 엔진이 지지구조물 기둥부에 8개의 위치에서 고정되기 때문에 진동에 의한 상대적 변형의 크기가 다소 작을 것으로 판단된다.

Fig. 20Engine-generator operational data during hovering tests

Fig. 21Separation margin of 1st mode and operational range

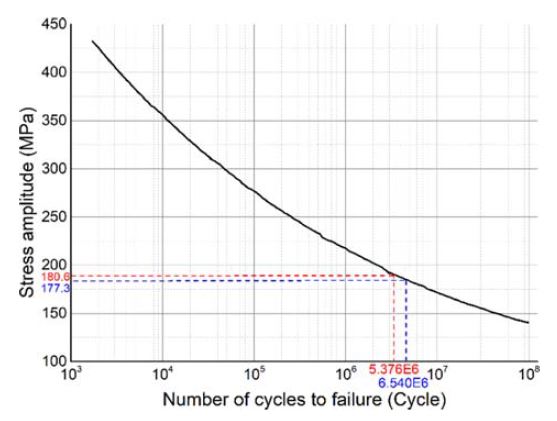

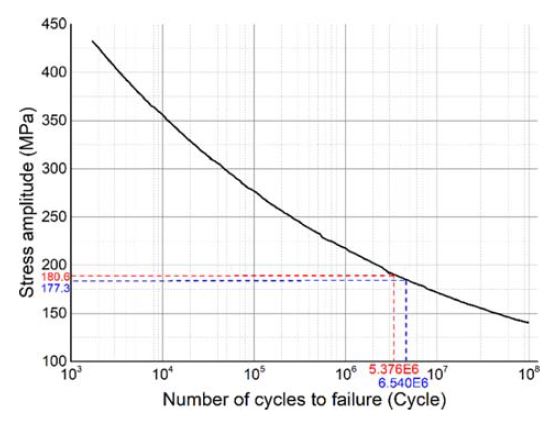

AA6061-T6 소재가 적용된 엔진-발전기 지지구조물 초기 모델(

Fig. 5)의 구조시험 결과, 약 5,376,000 사이클과 약 6,540,000 사이클에서 구조물 파손이 발생하였기 때문에 이들 파손 사이클을 기준으로 단순히 AA7075-T6 소재가 적용되었을 경우에 대한 응력 진폭을 검토해 보았다. 이를 위해 AA7075-T6 소재의 피로 선도를

Fig. 22에 나타내었다[

11]. 지지구조물 초기 설계 모델(

Fig. 5)에 대해 AA6061-T6 소재 적용 시 파손이 발생하는 약 5,376,000 사이클과 약 6,540,000 사이클을 기준으로, 해당 사이클들을 AA7075-T6 소재의 피로 선도에 적용해 보면 응력 진폭은 약 180.6 및 177.3MPa로 확인되었다. 즉, 초기 모델에 있어서 지지구조물용 소재를 AA7075-T6로 변경할 경우 보다 개선된 약 2.79의 안전계수를 확보할 수 있음을 알 수 있다. 그러나, 하이브리드 드론의 부피 최소화 및 효율적 공간 활용을 위한 지지구조물의 형상 및 소재 개선이 병행되었기 때문에 이러한 단순 비교는 다소 한계가 존재할 수 있으나, 엔진-발전기 지지구조물 형상 개선 및 소재 변경을 통해 검토된 결과들을 종합해보면 유의미한 개선 효과를 기대할 수 있음을 확인하였다.

Fig. 22S-N curve of AA7075-T6 [11] (Adapted from Ref. 11 on the basis of OA)

5. 결론

본 연구에서는 하이브리드 드론용 엔진-발전기 지지구조물의 구조시험 과정에서 발생한 파손의 원인을 파악하기 위해 유한요소법 기반의 구조해석을 수행하였다. 초기 설계 모델에 대한 정적 구조해석을 통해 약 2.17의 안전계수를 확인하였고, 알루미늄합금 소재인 AA6061-T6 피로 선도의 사이클 비교 수행을 통해 파손 원인을 피로파괴로 추정하였다. 이러한 피로파괴 문제를 해결하고, 하이브리드 드론용 엔진-발전기 지지구조물의 구조건정성을 개선함과 동시에 내부 공간 활용 극대화를 위한 목적으로 지지구조물의 형상을 수정하였으며, 이와 더불어 지지구조물용 소재를 AA7075-T6로 변경하였다. 개선된 지지구조물의 형상 및 소재가 적용된 유한요소해석 모델을 이용하여 정적구조해석과 모드해석 및 진동실험을 수행하여, 엔진-발전기 지지구조물 개선 모델의 구조건전성을 재검토하였다. 본 연구를 통해 도출된 결과를 요약하면 다음과 같다.

1) 하이브리드 드론용 엔진-발전기 지지구조물의 초기 설계모델에 대한 시제품 구조시험을 2가지의 분당 평균 회전수(RPM) 조건에서 수행하였으며, 파손 발생 시점에서 엔진 크랭크축의 분당 회전수에 따른 하중 인가 사이클(약 5,376,000, 약 6,540,000 사이클)을 조사하였다.

2) 지지구조물 초기 설계 모델에 대한 정적 구조해석 결과를 살펴보면, 최대 유효응력은 약 110.9 MPa로 예측되었으며, AA6061-T6의 파손 발생 사이클에서 응력 진폭이 102.7 MPa이다. 이에 따라, 초기 설계 모델에 대한 파손 원인은 반복적인 하중 인가에 따른 피로파괴가 원인인 것으로 예측되었다.

3) 지지구조물의 피로파괴를 방지하기 위한 개선 모델에 대해서 구조해석을 재수행하였으며, 최대 유효응력은 약 134.5 MPa로 나타났고, 이에 따른 안전계수는 약 3.74로 평가되었다. 이는 초기 모델의 안전계수 대비 72.35% 증가함에 따라 정적 구조건전성이 개선됨을 알 수 있다.

4) 공진 현상 발생 가능성을 파악하기 위해 고유진동수 측정실험과 모드해석을 수행하여 고유진동수를 확인하였고, 지지구조물 개선 모델의 고유진동수와 운용주파수 사이의 분리 여유가 약 27%로 조사되었다. 이를 통해 공진 발생 가능성은 낮은 것으로 나타났다.

5) 지지구조물 초기 모델의 소재를 AA7075-T6로 변경 시, 파손이 발생했던 사이클에서 안전계수는 약 2.79를 확보할 수 있음을 알 수 있으나, 지지구조물의 형상 개선 및 소재 변경을 통해 유의미한 구조건전성 개선 효과를 기대할 수 있다.

ACKNOWLEDGMENTS

본 논문은 부산대학교 기본연구지원사업(2년)에 의하여 연구되었음.

REFERENCES

- 1.

Park, J.-H., Lyu, H.-G., Lee, H.-T., (2019), Power system optimization for electric hybrid unmanned drone, Journal of the Korean Society for Aeronautical & Space Sciences, 47(4), 300-308.

10.5139/JKSAS.2019.47.4.300

- 2.

Kim, K. B., (2020), Overview of development and design characteristics of hybrid power system for drone, Current Industrial and Technological Trends in Aerospace, 18(1), 51-64.

- 3.

Gang, B. G., Kim, K.-B., (2020), The design of a hybrid engine system based on a reciprocal engine for unmanned aerial vehicles, Journal of Aerospace System Engineering, 14(5), 42-48.

- 4.

Lee, M.-H., Park, I.-K., Kim, S.-J., Ahn, S.-M., (2011), Estimation of fatigue integrity for small aircraft engine mount strut, Journal of the Korean Society for Aviation and Aeronautics, 19(4), 58-66.

- 5.

Kim, S.-J., Lee, S.-G., Kim, T.-U., (2017), Structural safety factor for small unmanned aircraft, Journal of the Korean Society for Aviation and Aeronautics, 25(2), 12-17.

- 6.

- 7.

Yahr, G. T., (1997), Fatigue design curves for 6061-T6 aluminum, Journal of Pressure Vessel Technology, 119(2), 211-215.

10.1115/1.2842286

- 8.

Kim, S.-R., Kim, W.-D., (2020), Research of vibration analysis and resonance avoidance design of composite quadcopter, Composites Research, 33(3), 133-139.

- 9.

- 10.

Kim, M., Kim, J., Byun, Y., Kim, J., Kang, B., (2016), Study on analysis of vibration characteristics and modal test for a quad-rotor drone, Journal of the Korean Society for Precision Engineering, 33(9), 707-714.

10.7736/KSPE.2016.33.9.707

- 11.

Biography

- Ki Beom Kim

M.S. candidate in the Department of Aerospace Engineering, Pusan National University. His research interests include CAE application for structural integrity evaluation of drone.

- Jae Nam Kim

Ph.D. candidate in the Department of Aerospace Engineering, Pusan National University. His research interests include design and development for system integration of drone and UAM.

- Hyun Seock Lee

Project Manager in the R&D Center, Korean Air. His research interests include system design and system integration of UAV, UAM and UATM.

- Hyun Cheol Kim

Director General in the Office of Policy Research and Planning, Korea Institute for Advancement of Technology. His research interest includes industrial technology policy.

- Tae-Wan Ku

Professor in the ERC/ITAF and the Department of Green Transportation System Design, Pusan National University. His research interests include structural integrity evaluation, metal forming and process design.

- Beom-Soo Kang

Professor in the Department of Aerospace Engineering, Pusan National University. His research interests include FEM, material processing, system integration of UAM and AI.