ABSTRACT

The gear overlap ratio shows the characteristics of the spur gear and the helical gear and varies according to the torsional angle. The gear ratio, tooth width, and center distance, which are restricted in a space of performance and manufacturing and design in the gearbox, are fixed. A parametric study on modules, the number of teeth, and torsion angles was conducted to analyze the relationship between the overlap ratio and PPTE. Then, contact analysis was performed by correcting the tooth profile to improve the transmission error. Contact analysis was performed through correction of the tooth modification to improve transmission error, and the noise was analyzed according to the overlap ratio by applying a noise prediction equation.

-

KEYWORDS: Profile shift coefficient, Transmission error, Overlap ratio, Parametric study, Contact analysis, Gear

-

KEYWORDS: 전위계수, 전달오차, 중첩 물림율, 파라메트릭 스터디, 접촉해석, 기어

NOMENCLATURE

1. 서론

동력전달장치는 기계장비, 자동차, 항공 분야 등 모든 산업에 걸쳐 널리 사용되어 왔다. 동력전달장치 중에서도 두 개 이상의 서로 다른 톱니가 맞물려 회전하면서 동력을 전달하는데, 이 장치를 기어라고 한다. 일반 평기어에 비해 헬리컬 기어는 기어열에 대한 중첩 물림율(Overlap Ratio)이 높아 동력전달 측면이나 소음에 있어서 유리한 측면이 있다. 최근 친환경적인 문제가 대두되면서 동력전달계 산업에 있어서 전동식 시스템의 수요가 증가하고 있으며, 이에 따라 구동 소음이 전동식 동력전달장치의 품질을 결정하는 중요한 요소로 자리잡고 있다

[1-

6].

소음 및 진동 문제를 발생시키는 주요 원인으로 전달오차(Transmission Error, T.E.)가 있다. 설계적인 이론과 실제 제작에서 오는 오차로 인해 발생하는 요인으로 기어의 치형수정(Tooth Modification) 등으로 소음 및 진동 문제를 개선할 수 있다

[7,

8].

본 연구에서는 전동식 동력전달장치에 대해 헬리컬 기어열에 대한 중첩 물림율(Overlap Ratio)에 따른 파라메트릭 스터디(Parametric Study)를 통해 PPTE (Peak to Peak Transmission Error)의 변화를 분석하고, 비틀림 각에 따른 음압레벨(Sound Pressure Level)을 분석하였다. 이후 기어 치형수정(Tooth Modification)을 통해 Micro-Geometry를 설계 및 적용하여 전달 오차(T.E.)를 개선하였다.

적용한 모델에 대해 접촉해석(Contact Analysis)을 실시하여 하중을 받는 상태에 대해 기어의 물림율 및 접촉, 굽힘 응력을 평가 및 분석하였다.

2. 전동식 기어시스템의 설계 및 이론

2.1 전동식 기어시스템 설계

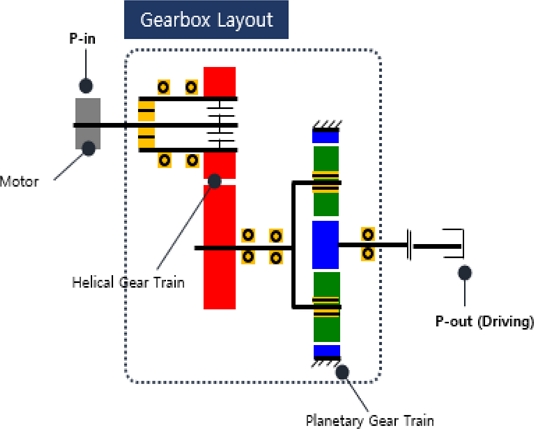

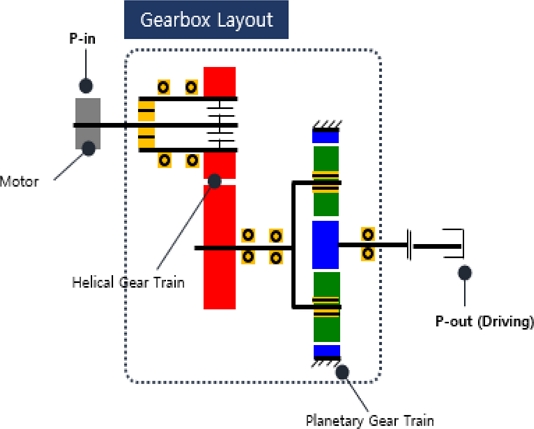

전동식 동력전달장치에 적용하는 기어시스템은

Fig. 1과 같다. Helical Gear Train 2단과 Planetary Gear Train 1단으로 구성하였다. 모터에서 들어오는 Input에 대해 고속 회전을 하는 1 Stage의 헬리컬기어 1 Stage가 주요 소음원이다. 1 Stage의 Gear Ratio는 1.75이고 Macro-Geometry 상의 주요 제원인 중심거리, 압력각, 이폭이 기어박스의 성능과 공간에 제약이 되기 때문에 고정하고 Module과 Helical Gear의 특성인 Helix Angle 변화에 따라 기어 이와 Profile Shift Coefficient를 조정하였다. Profile Shift Coefficient 및 Helix Angle을 결정하기 위하여 Specific Sliding이 최소가 되도록 하는 설계를 진행하였다.

Fig. 1Layout for gearbox structure

Helix Angle 변화에 대한 중첩 물림율(Overlap Ratio)의 분석을 위한 Gear Specification은

Table 1과 같다.

Table 1Gear specification of helical gear train

Table 1

|

Description |

Unit |

Gear |

Pinion |

|

Module |

Mm |

1.25/1.5/2.0 |

|

Pressure angle |

Deg. |

20 |

|

No. of teeth |

- |

56-65 |

32-37 |

|

Helix angle |

Deg. |

0-20 |

|

Face width |

Mm |

36 |

|

Profile shift coefficient |

- |

Applied (-) Profile shift |

|

Gear ratio |

|

1.75±3% |

2.2 기어 스터디 분석 이론

전동식 기어에 있어서 가장 중요한 핵심은 소음 및 진동이다. 소음 예측 식에 의해 소음분석이 가능하며

식(1)과 같다.

소음 및 진동은 전달오차(T.E.)가 주요 원인이며 기어 제조에 의한 오차 및 동하중에 의한 오차로 인해 기어의 물림에서 발생하는 피니언과 기어 사이의 속도차이로 정의된다. 따라서 전달 오차(T.E.) 단순히 최대값과 최소값의 절대크기보다는 실제 두 값의 차이가 물림상의 내부 가진을 일으킨다고 할 수 있으며,

식(2)와 같다.

기어 물림에 대한 접촉해석은 Gear Body Deformation, Bending, Hertzian Flattening을 고려하여 해석하였다. 또한, 하중에 따른 각각의 변형을 고려하기 위하여 Single Contact Stiffness를 스프링 방정식 F = dxC로 적용하였다.

Gear Micro-Geometry에서 기어의 물림과 하중에 따른 기어의 접촉면을 최적화하는 설계를 하기 위해 치형 수정(Tooth Modification)을 실시한다.

3. 기어의 파라메트릭 분석

3.1 모듈 및 중첩 물림율에 따른 PPTE 및 소음 분석

Parametric Study를 위한 조건으로 Input Speed로 1,800 rpm, Input Torque로 300 Nm을 적용하였다.

기어박스의 성능과 공간에 제약이 있는 Gear Ratio, Face Width, Center Distance를 고정하였다. Module은 일반적으로 많이 사용하는 1.25/1.5/2.0의 경우에서 비틀림 각을 0-30o 설정하여 Study를 진행하였다.

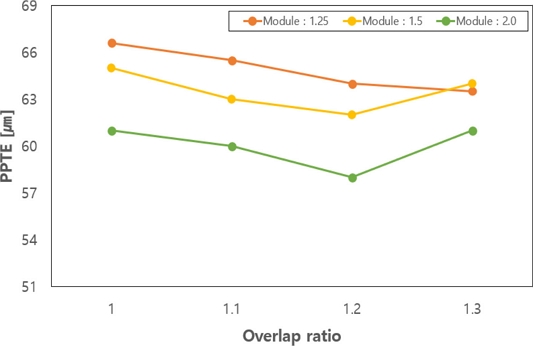

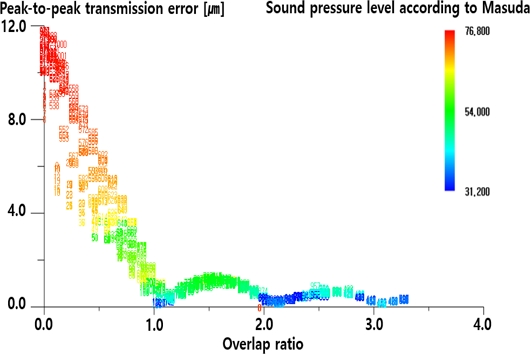

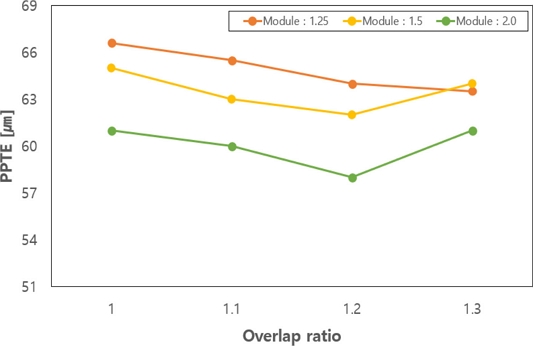

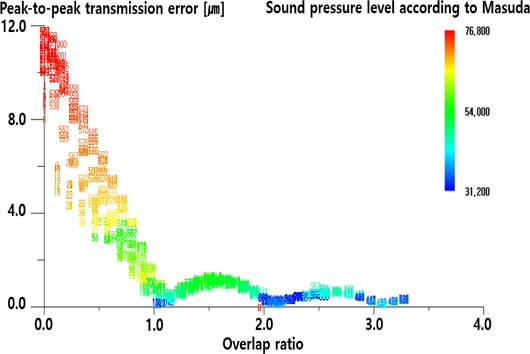

Parametric Study 결과, Module 및 Overlap Ratio에 따른 PPTE의 변화는

Fig. 2에서 확인할 수 있듯이 Overlap Ratio가 1.2의 구간에서 PPTE가 최저가 되고 이후 값이 증가할수록 PPTE 또한 증가하는 것을 확인할 수 있다. 각각의 Module에 대해서도 값의 차이만 있을 뿐 그래프의 경향은 동일한 것으로 확인하였다.

Fig. 2PPTE graphs for modules and overlap ratio

Module 2.0과 1.25에서 Overlap Ratio가 1.0으로 동일할 때 Module에 따른 최대값의 차이는 1.5 정도이다. Module 중에서 변화 폭이 가장 큰 1.5의 경우 최대값과 최소값의 차이가 약 2 정도 나는 것을 확인할 수 있다.

따라서 Module 값보다는 Overlap Ratio가 PPTE에 미치는 영향이 비교적 더 크다는 것을 알 수 있다.

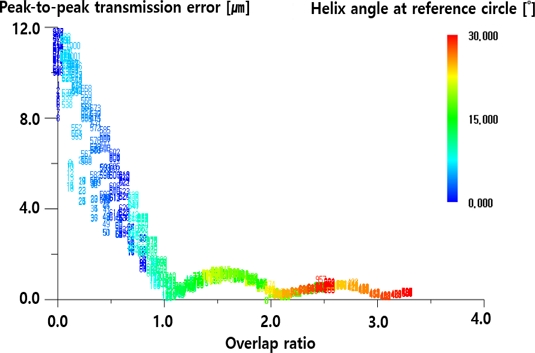

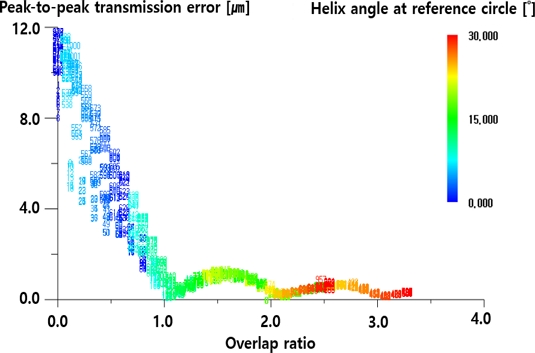

Fig. 3에서 Overlap Ratio가 1.0, 2.0, 3.0의 정수가 되는 값보다 1-5% 높은 값에서 각각 PPTE가 최저값이 되는 것을 확인할 수 있다. 비틀림 각이 0인 평기어의 경우 PPTE가 12 μm으로 가장 높고 Overlap Ratio가 1.1, 2.3, 3.3이 되는 구간에서 PPTE가 거의 0에 수렴하였다. 정수값이 아닌 특정 구간에서 반복적으로 PPTE가 0에 가깝게 수렴하는 부분에 대해 앞으로의 추가적인 연구를 통해 분석해볼 것이다.

Fig. 3PPTE analysis results for overlap ratio on parametric study

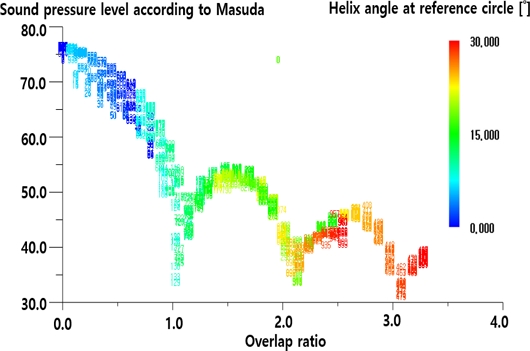

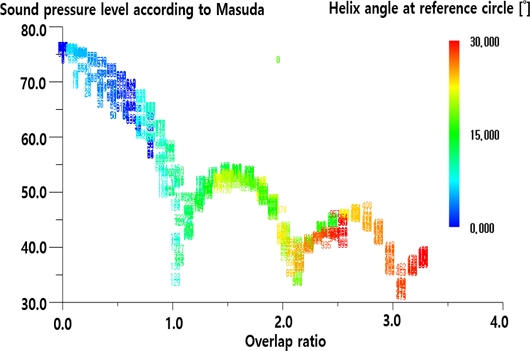

Fig. 4에서 Overlap Ratio에 따른 Sound Pressure Level을 분석하였다.

Fig. 3에서와 마찬가지로 Overlap Ratio가 정수값보다 1-3% 높은 부분에서 가장 낮게 음압 레벨이 형성되었다.

식(1)에 의해 Overlap Ratio 및 Helix Angle이 0으로 나타나는 평기어의 경우 예측 소음이 76.8 dB(A)이고, Overlap Ratio가 정수값에 근접할수록 예측 소음이 감소하는 하는 경향을 보였다.

Fig. 4dB analysis results for overlap ratio on parametric study

이에 따라

Fig. 5에서와 같이 Overlap Ratio에 따른 PPTE와 Sound Pressure Level의 관계를 분석하였다.

Figs. 3과

4에서와 같이 Overlap Ratio가 정수값에 근접할수록 PPTE와 Sound Pressure Level이 감소가 되는 경향을 보였고 특히 Overlap Ratio가 2.0 이상일 경우 PPTE와 Sound Pressure Level이 최소가 되는 값으로 수렴하는 경향을 보였다.

Fig. 5PPTE analysis results for overlap ratio on sound pressure

3.2 기어 치형 수정에 따른 PPTE 분석

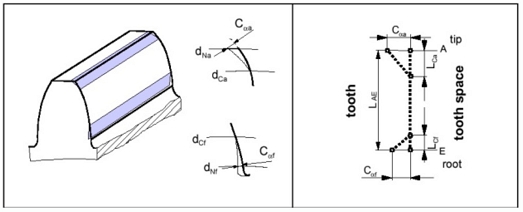

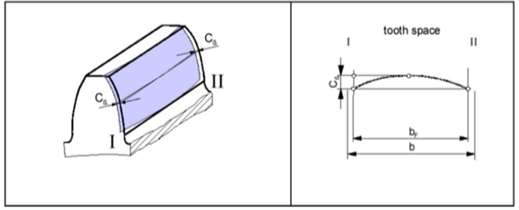

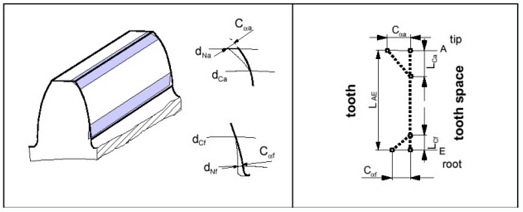

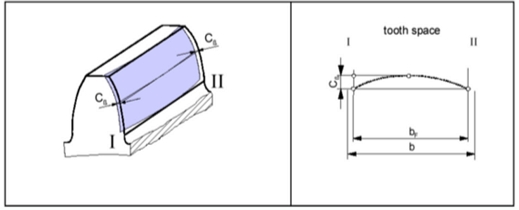

Gear의 물림과 하중에 따른 기어 접촉면을 최적화 하기 위해 치형수정을 실시하였다. 치형수정은

Figs. 6과

7에서와 같이 Profile 방향으로 수정하는 Profile Modification의 Tip Relief와 Profile Crowning의 방법으로 수정하였다. 기어 Sizing은 3-7 μm를 5단계로 나누어 Parametric Study를 실시하였다.

Fig. 6Definition of tip and root relief

Fig. 7Definition of profile crowning

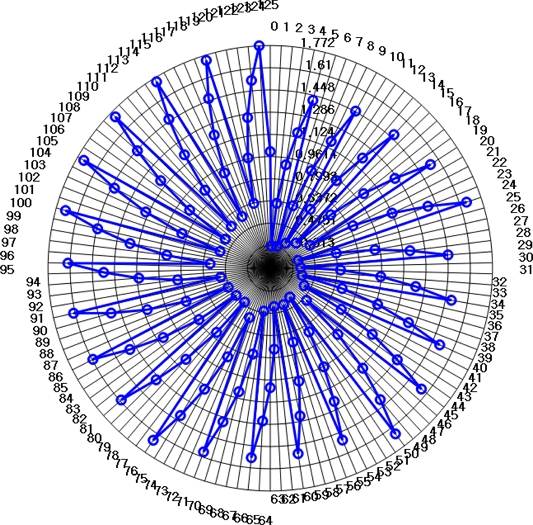

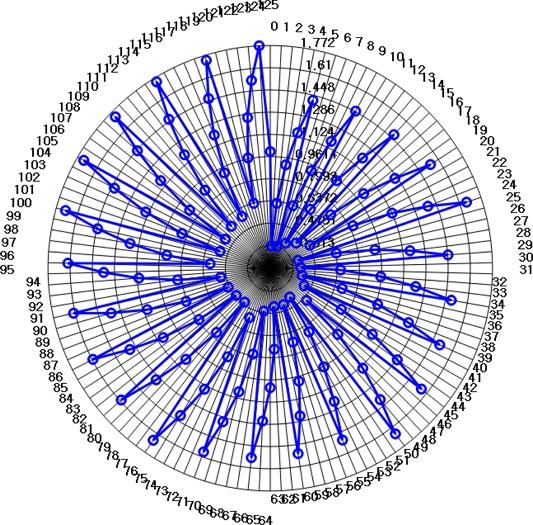

Modification Sizing의 결과는

Fig. 8과 같다. 그래프의 결과에 따라 3 μm이 PPTE가 최소가 되는 최적의 값으로 확인하고, 이에 따라 Pinion에서 Tip Relief에서 3 μm, Crowing에서 3 μm으로 수정하고 Gear에서는 Tip Relief에서 3 μm, Crowning에서 3 μm으로 수정하였다.

Fig. 8Modification sizing results on Parametric study

3.3 치형 수정을 적용한 기어의 접촉 해석 및 비교

치형수정결과에 따라 Micro-Geometry 수정을 적용한 모델과 수정 전의 모델에 대해서 Contacts Analysis를 진행하고, 비교 및 분석하였다.

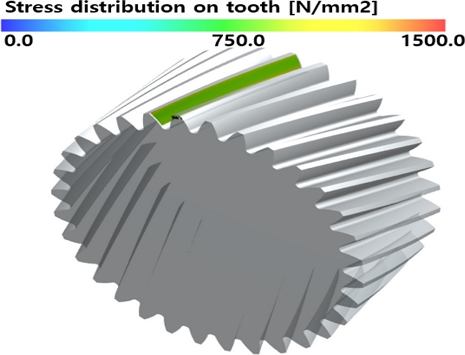

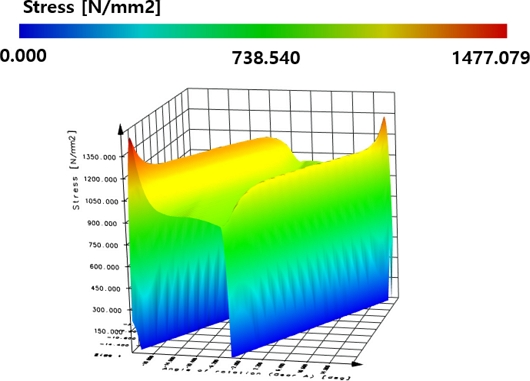

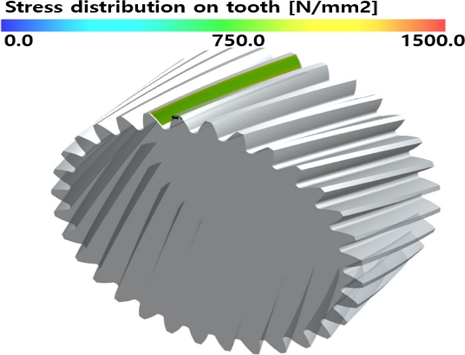

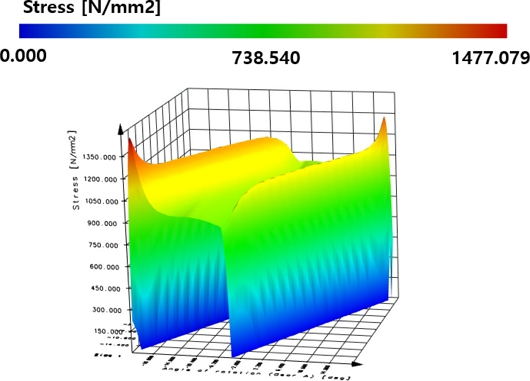

Table 2는 치형수정 이전 해석 결과로

Figs. 9와

10,

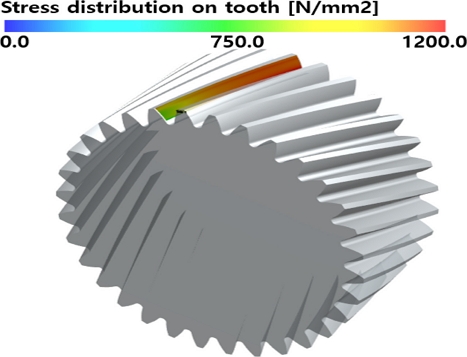

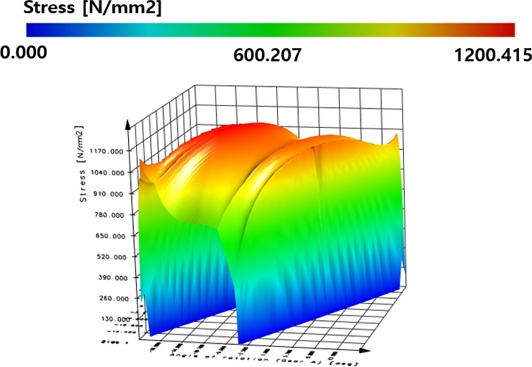

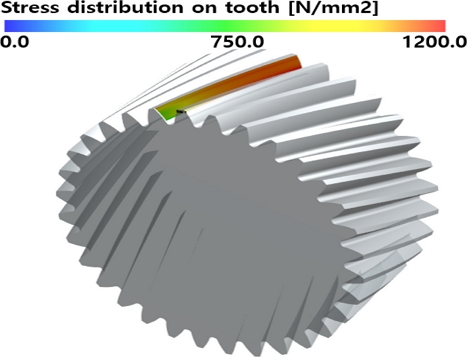

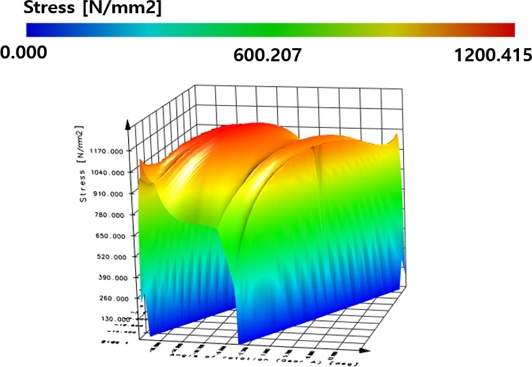

Table 3은 치형수정을 적용한 해석 결과로

Figs. 11과

12를 도식화하여 표로 나타낸 결과값이다. 각각의 그래프는 전달오차(T.E.)는 최대값과 최소값의 크기를 비교하는 것보다

식(2)에 의해서 치형 수정 전과 후의 최대값과 최소값의 크기의 차이라고 할 수 있는 절대값으로 비교하고 수정 전에서 0.2 μm, 수정 후에서 0.13 μm이다. 따라서 전달오차(T.E.)가 감소하였다는 것을 확인할 수 있다. Power Loss에서도 최대값과 최소값에서 전체적인 Loss가 줄어들었음을 확인할 수 있다.

Table 2Gear contact analysis on tooth modification (Before)

Table 2

|

Description |

Unit |

Value |

|

Transmission ERROR |

μm |

-18.54/-18.74 |

|

Power loss |

W |

558.0/531.0 |

|

Stress curve (Max.) |

N/mm2

|

1,477.08 |

|

Stress distribution on tooth |

N/mm2

|

1,500.0 |

Fig. 9Stress distribution on tooth modification before

Fig. 10Stress distribution on tooth modification after

Table 3Gear contact analysis on tooth modification (After)

Table 3

|

Description |

Unit |

Value |

|

Transmission error |

μm |

-15.90/-16.03 |

|

Power loss |

W |

520.0/504.0 |

|

Stress curve (Max.) |

N/mm2

|

1,200.42 |

|

Stress distribution on tooth |

N/mm2

|

1,200.0 |

Fig. 11Stress curve graphs on tooth modification before

Fig. 12Stress curve graphs on tooth modification after

Figs. 9,

10에서는 Pinion의 치의 표면에 작용하는 응력분포도를 나타낸다. 그림에서 확인할 수 있듯이 특정 부분의 응력집중현상은 나타나지 않으나 기어의 물림을 나타내는 LPSTC와 HPSTC 사이의 구간에 물림이 작용함으로서 나타나는 응력분포도가 형성되어 있지 않는 것을 확인하였다.

따라서 Profile 방향으로 수정값을 추가적으로 더하고, Crowning 방향으로 추가적으로 수정값을 가하여 적절한 Contact 지점에 응력분포가 형성될 수 있도록 추가적인 연구를 진행하여야 할 것이다.

Figs. 11과

12는 기어의 Stress Curve를 나타내는 그래프이다. 치면에는 응력 집중현상으로 인해 간혹 Pitting이 발생하여 파손이 일어나 제품의 수명에 문제가 생기는 경우가 생긴다. 이를 해결하기 위한 방안으로 치형수정을 통해 치면의 형태를 완만하게 하여 응력의 집중현상을 완화함으로서 개선할 수 있다.

4. 결론

본 연구는 전동식 기어시스템에 있어 가장 핵심적인 요인이라고 할 수 있는 소음에 대해서 KISSsoft의 Parametric Study를 활용하여 Overlap Ratio에 대해 PPTE와 예측소음에 대한 관계를 분석하고 연구하였다.

1. Overlap Ratio의 정수값의 오차범위 5% 이내에서 PPTE와 Sound Pressure Level이 최소가 되었다.

2. PPTE와 Sound Pressure Level 비례관계에 있으며 Overlap Ratio가 증가함에 따라 그 값이 줄어드는 방향으로 수렴하는 경향을 보였다.

3. Tooth Modification을 통해 전달오차(T.E.)가 감소하고 이에 따라 Power의 Loss도 줄어들었음을 확인하였고, 이와 같은 방법을 통해 경제적인 효과를 기대할 수 있으며 기어 시스템에서의 동력전달효율도 같이 증가하므로 산업 분야에서 긍정적인 효과를 기대할 수 있다.

4. 치형 수정을 통한 Stress Distributions이 감소하는 효과를 확인하였다. 따라서 소음 및 PPTE를 감소하는 설계 시 발생할 수 있는 Pitting 및 파손 현상을 감소시킬 수 있으므로, 산업에서 발생하는 기어 파손 문제를 개선시킬 수 있다.

ACKNOWLEDGMENTS

본 논문은 과학기술정보통신부 선도연구센터 기초연구사업(NRF-2019R1A5A 8083201)의 지원에 의해 연구되었으며 이에 감사드립니다.

REFERENCES

- 1.

Kim, N. Y., Kim, D. S., Park, S. B., Lyu, S. K., (2022), Effect of gear tooth wear on noise of single-stage meteor gear, Proceedings of the Korean Society for Precision Engineering 2022 Spring Conference, 401.

- 2.

Lee, Y. S., Park, Y. W., Kim, N. Y., Baek, S. H., Park, S. H., Lyu, S. K., (2022), A study on the design of the driving part and gear module for power train, Proceedings of the Korean Society for Precision Engineering 2022 Autumn Conference, 563.

- 3.

Kim, N. Y., Kim, D. S., Moon, S. M., Park, S. B., Lyu, S. K., (2022), A study on the contact analysis of single-stage planetary gears by center distance, Proceedings of the Korean Society of Manufacturing Process Engineers 2022 Spring Conference, 87.

- 4.

Kim, N. Y., Lee, K. H., Jeong, Y. S., Park. S. B., Lyu, S. K., (2022), Design of helical gear geometry considering noise and strength, Proceedings of the Korean Society of Manufacturing Process Engineers 2022 Spring Conference, 92.

- 5.

Lee, K. H., Jeong, Y. S., Kim, N. Y., (2021), A study on the gear profile shift coefficient design considering power loss and noise, Proceedings of the Korean Society of Manufacturing Process Engineers 2021 Autumn Conference, 176.

- 6.

Lee, K. H., Jeong, Y. S., Kim, N. Y., (2021), An analysis on effect of bending strength for gear dimension, Proceedings of the Korean Society of Manufacturing Process Engineers 2021 Spring Conference, 43.

- 7.

Cho, S.-J., Kim, J.-G., Park, J.-S., Kim, Y.-S., Lee, D., (2022), Development of the 80-kW test tractor for load measurement of agricultural operations, Journal of Drive and Control, 19(4), 46-53.

- 8.

Kim, J.-G., Cho, S.-J., Lee, D.-K., Oh, J.-Y., Shin, M. S., Park, Y.-J., (2021), Gear rating and contact pattern analysis for rotavator gearbox using actual working load, Journal of the Korean Society of Manufacturing Process Engineers, 20(6), 92-99.

10.14775/ksmpe.2021.20.06.092

Biography

- Nam Yong Kim

Ph.D. candidate in School of Mechanical & Aerospace Engineering, Gyeongsang National University. His research interest is gearbox optimal design.

- Jin-Uk Baek

Master’s degree candidate in School of Mechanical & Aerospace Engineering, Gyeongsang National University. His research interest is gearbox optimal design and gear system NVH analysis.

- Gi-Myung Gwak

Master’s degree candidate in School of Mechanical & Aerospace Engineering, Gyeongsang National University. His research interest is additive manufacturing including design, gear, gearbox, mechanical system design, hydrogen refueling nozzle.

- Sung Ki Lyu

Professor in the School of Mechanical Engineering of Gyeongsang National University. His research fields are mechanical parts design, gear, gearbox, mechanical system design, power transmission system, and so on.