ABSTRACT

CNN is one of the deep learning technologies useful for image-based pattern recognition and classification. For machining processes, this technique can be used to predict machining parameters and surface roughness. In electrical discharge machining (EDM), the machined surface is covered with many craters, the shape of which depends on the workpiece material and pulse parameters. In this study, CNN was applied to predict EDM parameters including capacitor, workpiece material, and surface roughness. After machining three metals (brass, stainless steel, and cemented carbide) with different discharge energies, images of machined surfaces were collected using a scanning electron microscope (SEM) and a digital microscope. Surface roughness of each surface was then measured. The CNN model was used to predict machining parameters and surface roughness.

-

KEYWORDS: Micro EDM, Micro machining, Deep learning, Convolutional neural network, Grad CAM

-

KEYWORDS: 미세 방전 가공, 미세 가공, 딥러닝, 합성곱신경망, 그래드캠

1. 서론

CNN (Convolutional Neural Network)은 딥러닝 알고리즘 중 하나로서, 이미지와 관련된 네트워크에 특화 되어있어 이미지 분류, 객체 감지, 얼굴 인식 등 주로 이미지 내 패턴인식에 활용되고있다[

1,

2]. 또한 가공 공정에서 표면 이미지를 활용하여 가공조건 모니터링 및 분석, 표면 거칠기 예측, 표면 결함 검출 등에 CNN을 비롯한 인공신경망(Artificial Neural Network, ANN) 알고리즘이 활용되고 있다[

3]. Giusti 등은 금형에 많이 사용되는 5가지 금형강 샘플의 표면 거칠기를 CNN을 통해 훈련시키고 예측하도록 하였다. 또한 머신러닝을 활용하여 가공표면의 이미지에 결함이 있을 경우 결함 부분을 표시함으로써 결함탐지모델을 제시하였다[

4]. Saeedi 등은 이미지 회귀모델 학습을 통해 가공표면의 거칠기를 예측하였다. 또한 ROI (Region of Interest) 추출 방법을 사용하여 가공 표면의 결함을 식별하는 모델을 제시하였다[

5]. Rifai 등은 CNN을 이용하여 선삭 가공과 밀링 가공의 가공표면 거칠기를 예측하였으며 Abhilash 등은 금속 적층 가공으로 제작된 부품의 표면 품질을 CNN을 이용하여 분류하였다 [

3,

6].

방전가공은 선삭이나 밀링 가공과는 달리 공구 전극과 가공물 사이에 방전을 일으키고 그때 발생하는 열에너지로 재료를 제거하는 비접촉식 가공이다[

7]. 높은 열이 발생하는 순간 재료의 용융과 절연액의 기화가 일어나 가공 표면에 방전흔(Crater)이 남게 된다[

8,

9]. 이때 방전흔의 크기와 형상은 재료의 열적물성치와 방전에너지에 따라 달라지며, 방전흔이 중첩되면서 가공 표면을 형성한다[

10,

11]. 방전흔의 크기와 형상은 결과적으로 가공 표면의 표면 거칠기를 결정하게 된다.

본 논문에서는 각기 다른 방전 가공 조건을 이용하여 황동, 스테인리스강, 초경합금의 3가지의 금속을 가공한 후 CNN 모델을 사용하여 가공면의 이미지만으로 가공물 재료, 방전가공조건, 표면 거칠기를 예측하고자 하였다. CNN 모델 학습을 위해 주사전자현미경(GeminiSEM 300, Zeiss Co.)과 디지털 현미경(DSX1000, Olympus Co.)으로 가공 표면 이미지를 수집하였으며 이미지 촬영 방법에 따른 예측 정확도를 비교하였다. 또한 Grad-CAM기법을 통해 방전흔 형상의 어느 부분이 예측 정확도에 영향을 미치는지 분석하였다.

2. 실험 장치와 방법

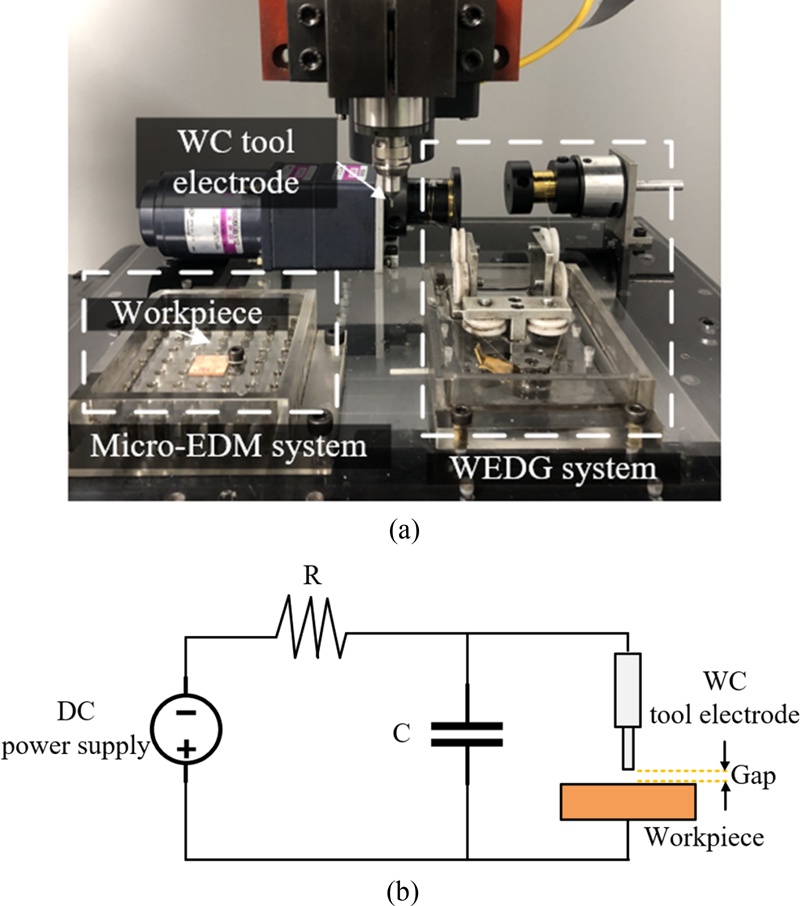

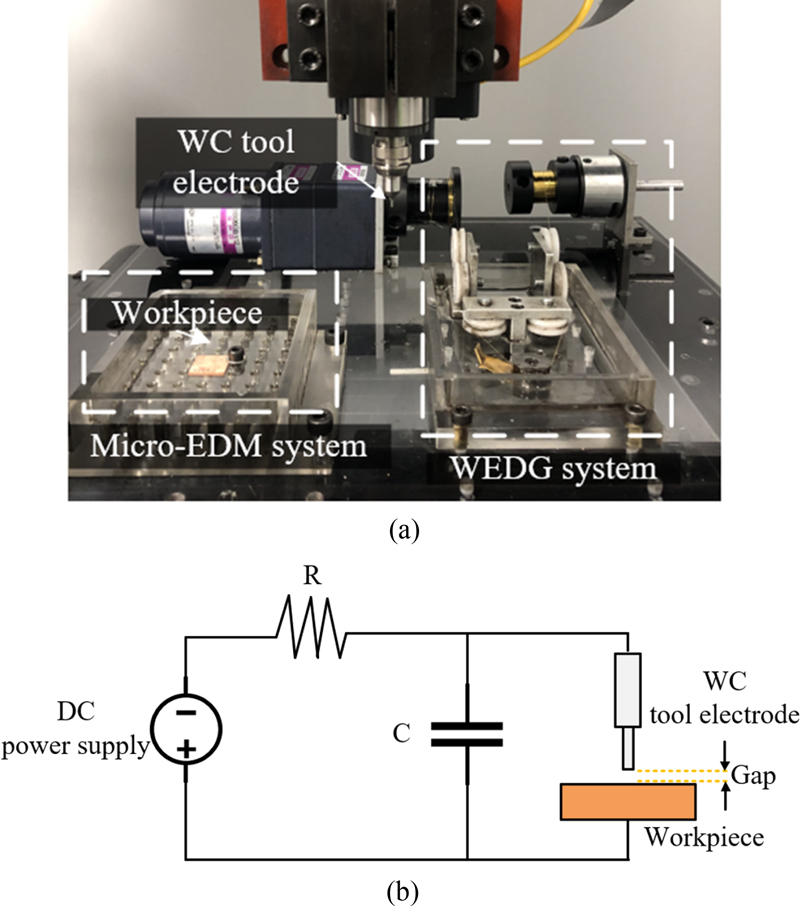

Fig. 1(a)는 본 실험에서 사용한 방전가공을 위한 시스템이다. 공구 전극 제작을 위한 와이어 방전 연삭(Wire Electro Discharge Grinding, WEDG) 장치와 방전 가공을 위한 수조가 장착되어있으며, 수직 이송기구에 스핀들이 장착되어 있다. 수조에는 두께 1 mm의 황동, 스테인리스강, 초경합금 판재를 고정하였다. 방전 회로는

Fig. 1(b)와 같이 RC 회로를 사용하였다. 공구 전극의 재료로서 초경합금을 사용하였으며, 100 V의 인가 전압과 20,000 pF 축전용량(Capacitance)을 사용하여 WEDG방법으로 지름 1 mm의 환봉을 지름 0.7mm으로 가공하였다[

12,

13].

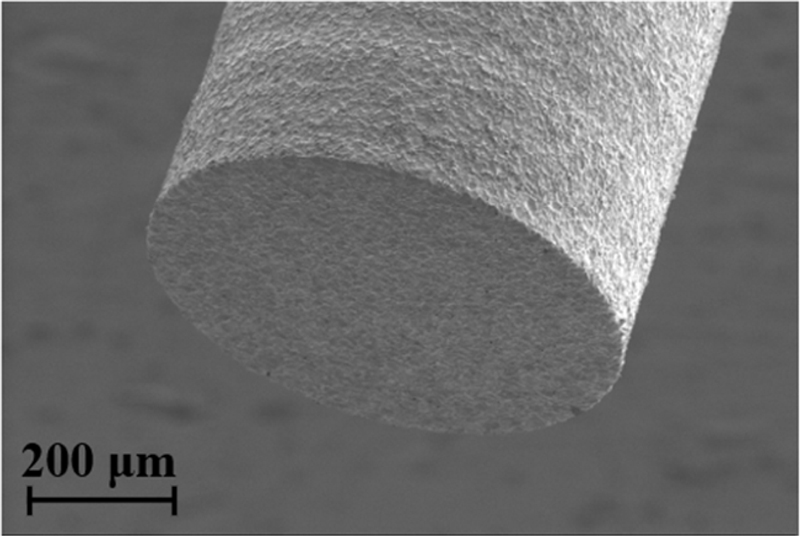

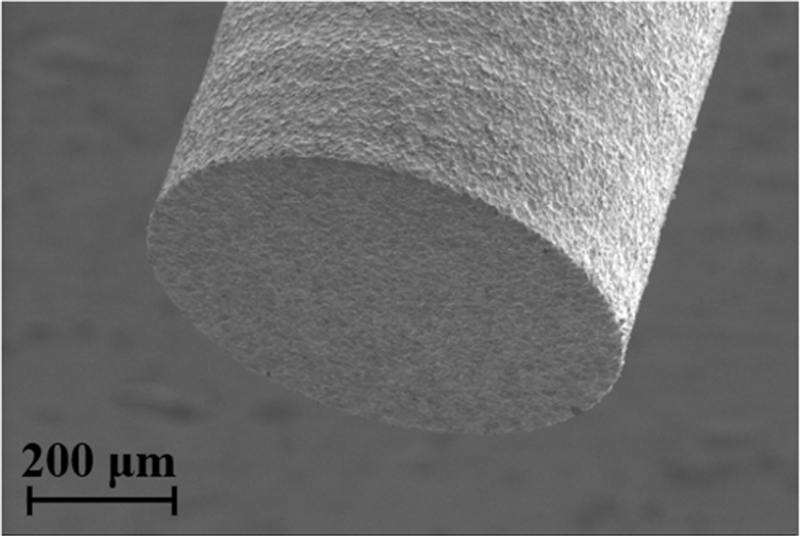

Fig. 2는 제작한 미세 공구전극의 전자현미경 사진이다.

Fig. 1 (a) Micro EDM system and (b) EDM circuit

Fig. 2 SEM image of a micro tool electrode

가공물 재료와 방전에너지에 따른 방전 표면을 제작하기 위해 초경합금 공구전극을 이용해 방전 가공을 수행하였다. 가공물의 재료로는 황동(Brass), 스테인리스강(Stainless Steel), 초경합금(WC-Co)을 사용하였으며 동일한 인가 전압 100 V에서 축전용량은 20, 200, 2,000 nF 총 3가지를 사용하였다. 이때 가공물에 나타나는 단발 방전흔과 중첩 방전흔의 형상과 크기를 관찰하고 이미지 데이터를 수집하였다. 방전흔의 이미지 측정과 수집을 위해 주사전자현미경과 디지털 현미경을 사용하였으며 방전흔의 3차원 형상 및 표면조도는 공초점 현미경(OLS-5000, Olympus Co.)으로 측정하였다.

3. 실험 결과

3.1 축전용량과 재료에 따른 단발 방전흔

방전에너지는 방전흔의 크기에 영향을 미치는 주요 원인 중 하나이다[

9]. RC회로를 방전 회로로 사용하는 경우, 방전에너지는 축전용량과 인가 전압으로 결정된다. 이때 방전에너지는

식(1)과 같이 표현할 수 있다[

14,

15].

위의 식에서 E는 전체 방전에너지, C는 축전용량, V는 전압을 의미한다. 단일방전에너지는 인가 전압과 축전용량의 크기가 증가함에 따라 에너지가 커지기 때문에 방전흔의 크기가 커진다. 본 실험에서는 가공물 재료와 축전용량에 따른 단발 방전흔의 크기를 관찰하였다.

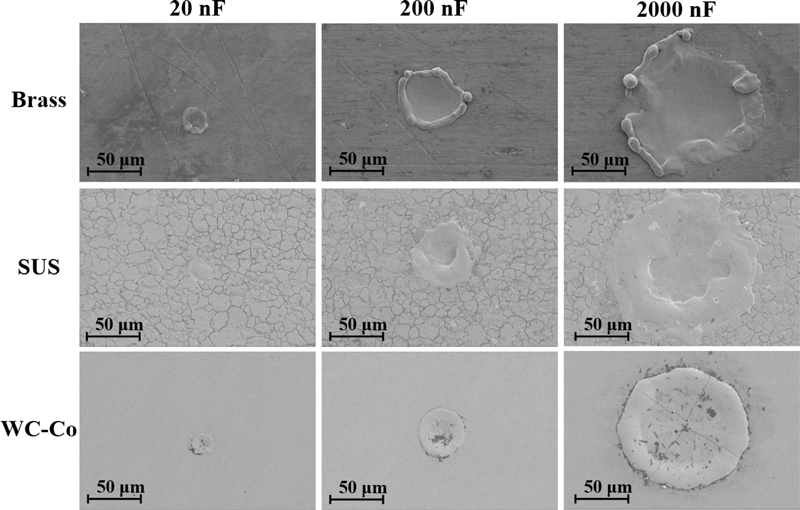

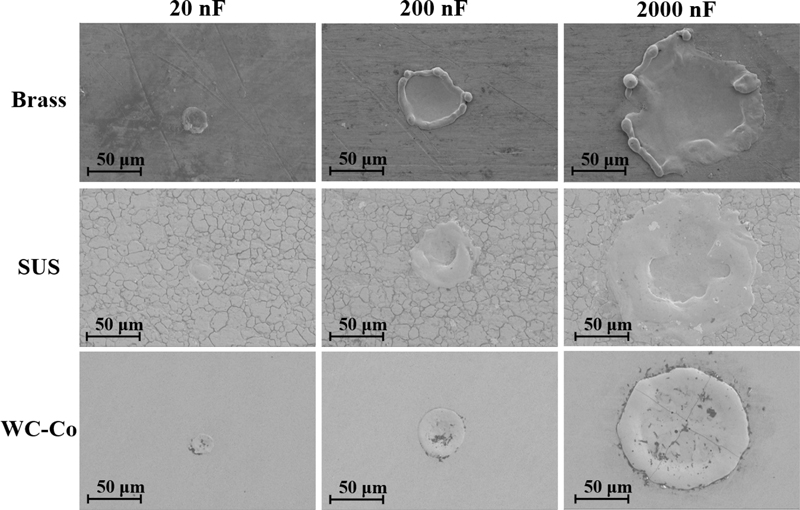

Fig. 3은 황동, 스테인리스강, 초경합금의 단발 방전흔의 전자현미경 사진이며, 축전용량이 20, 200, 2,000 nF순으로 증가함에 따라 방전흔의 크기가 커지는 것을 확인하였다. 이는 축전용량이 증가함에 따라 펄스에너지가 커지고 플라즈마 반경이 증가하기 때문이다[

16].

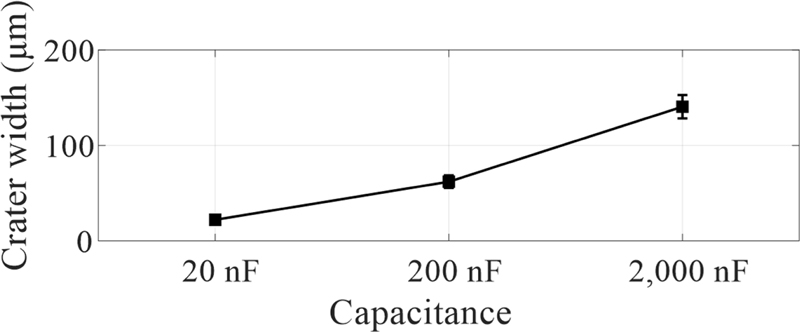

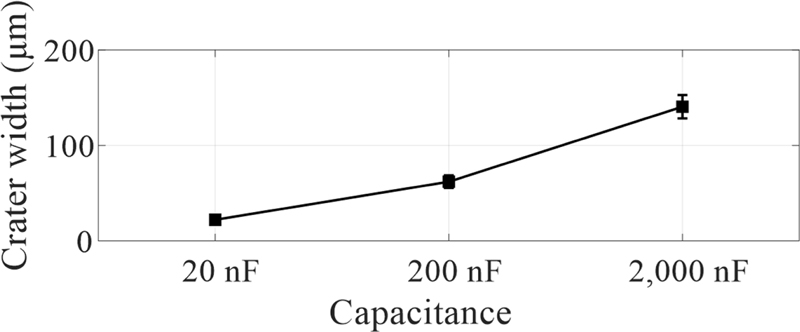

Fig. 4는 황동의 단발 방전흔의 폭을 측정한 결과이다.

Fig. 3SEM image of single discharge craters

Fig. 4Single crater width according to capacitance (workpiece: brass, voltage: 100 V)

3.2 가공물 재료에 따른 중첩 방전흔 형상

실제 방전 가공된 제품의 가공표면은 단발 방전흔이 중첩되어져 있으므로 중첩 방전흔의 형상을 관찰할 필요가 있다. 중첩 방전흔은 단일 방전흔과 다르게 기존에 형성되어 있는 방전흔 위에 연속적으로 방전이 발생하면서 생성되어 표면이 불균일하게 형성된다. 방전흔의 모양은 재료의 용융과 재응고층에 의해 결정되며, 재료의 녹는점, 열전도도, 비열, 열확산도 등에 의해 영향을 받는다[

17].

본 실험에서는 가공물 재료에 따른 중첩 방전흔의 형상을 관찰하였다.

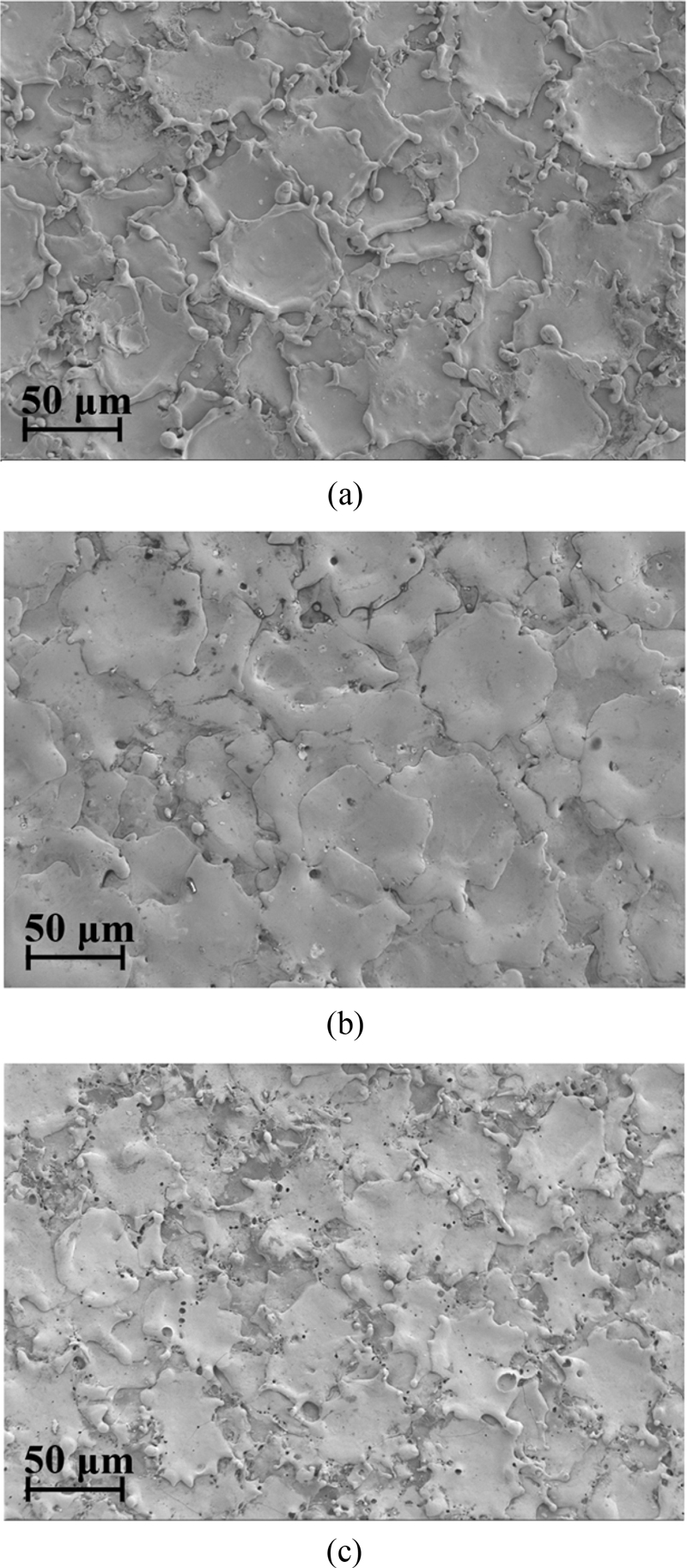

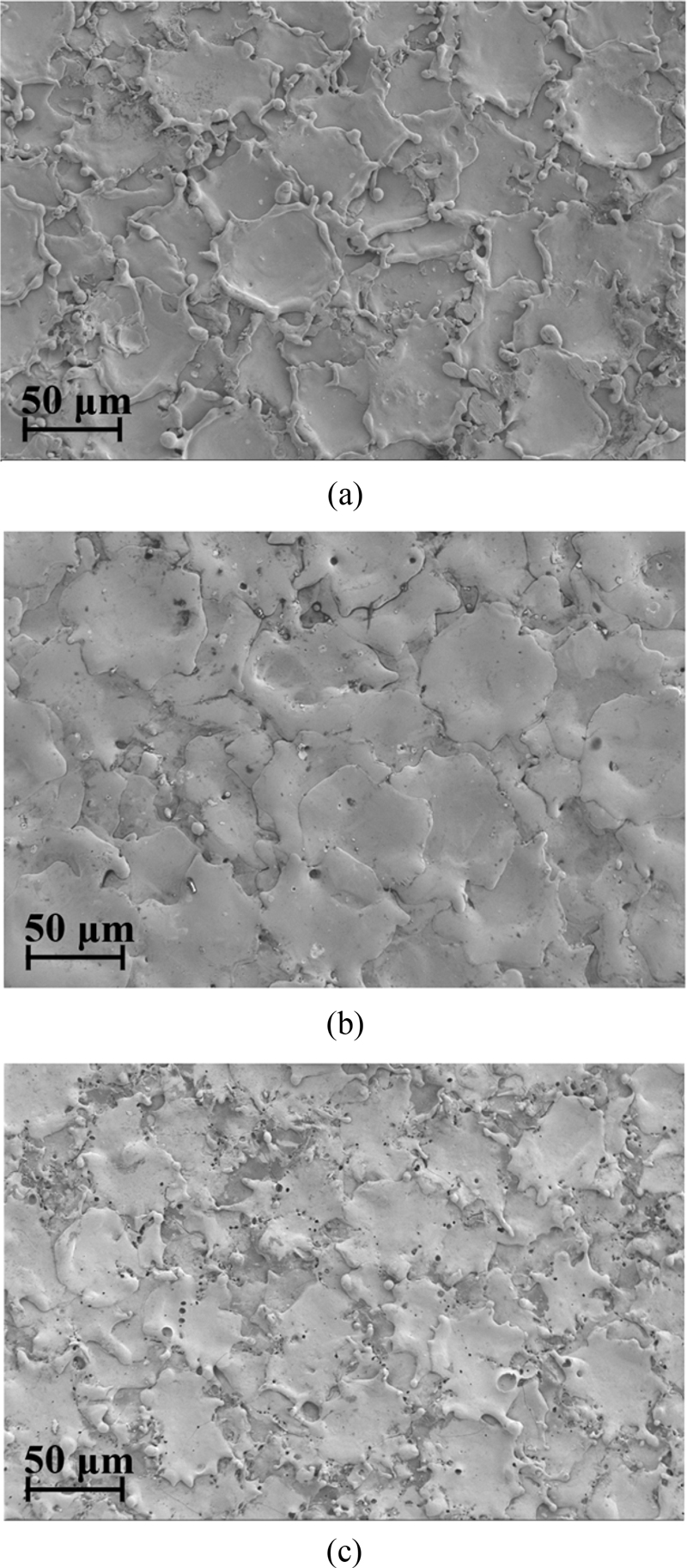

Fig. 5는 가공물 재료에 따른 중첩 방전흔의 전자현미경 사진이다. 사진에서 볼 수 있는 것처럼 각 재료별로 방전흔의 모양이 각기 다른 것을 확인할 수 있으며, 황동과 초경합금은 스테인리스강에 비해 방전흔 가장자리 부분이 돌출된 것을 볼 수 있다. 방전가공 시 재료는 고온의 열로 용융되고 절연액의 폭발로 인해 방전이 시작된 지점을 중심으로 주변으로 흘러 나가게 된다. 방전 직후 용융된 재료가 냉각되면서 재응고층(Recast Layer)을 형성하며 재료의 열전도율과 열확산율(Thermal Diffusivity)이 높을수록 재응고층이 더 두껍고 많이 형성된다[

18-

22]. 각 재료의 열특성을 나타낸

Table 1에서 볼 수 있듯이, 스테인리스강은 황동과 초경합금에 비해 낮은 열전도율과 열확산율을 가지고 있어 방전흔 주변에 재응고층이 거의 형성되지않은 반면 황동과 초경합금은 방전흔 주변에 재응고층이 두껍고 많이 형성되었음을 알 수 있다. 또한 녹는점이 높고 밀도가 높을수록 재료제거율이 낮아지고 방전흔의 크기가 작게 형성되기 때문에 초경합금의 방전흔이 가장 작은 것을 알 수 있다[

23]. 초경합금은 황동과 스테인리스강에 비하여 가공 표면에 균열과 기공 등이 많이 나타났다. 이는 초경 합금에 포함된 코발트가 영향을 미쳤기 때문이다. 코발트의 녹는 점은 텅스텐 카바이드의 녹는 점에 비해 낮기 때문에 방전 가공 시 고온의 열에 의해 코발트가 증발되면서 가공 표면에 핀홀과 벌집모양 등의 균열이 표면에 형성된다[

24].

Fig. 5Overlapping discharge crater SEM images (a) brass, (b) stainless steel, and (c) WC-Co

Table 1Properties of workpiece materials

Table 1

|

Material |

Brass |

Stainless steel |

WC-Co |

|

Thermal conductivity [W/m·K] |

99 |

16.8 |

110 |

|

Specific heat [J/kg × K] |

920 |

490 |

280 |

|

Melting temperature [K] |

1,228 |

1,700 |

3,140 |

|

Latent heat of melting [kJ/kg] |

168 |

285 |

330 |

|

Density [kg/m³] |

8,700 |

8,000 |

15,800 |

|

Thermal diffusivity [mm²/s] |

12.4 |

4.28 |

24.9 |

3.3 축전용량과 재료에 따른 표면거칠기

축전용량과 재료에 따른 방전 표면의 표면거칠기를 공초점 현미경을 사용하여 측정하였다.

Table 2는 가공물 재료와 축전용량에 따른 표면거칠기(Average Roughness, Ra) 값을 나타낸다.

Table 2Surface roughness of EDMed surface

Table 2

|

Material |

Capacitance [nF] |

Ra [μm] |

|

Brass |

20 |

1.5 |

|

200 |

2.7 |

|

2,000 |

4.3 |

|

Stainless steel |

20 |

1.1 |

|

200 |

2.1 |

|

2,000 |

3.2 |

|

WC-Co |

20 |

1.7 |

|

200 |

2.3 |

|

2,000 |

3.3 |

4. 이미지 분류 CNN 모델 제안

4.1 이미지 데이터 셋

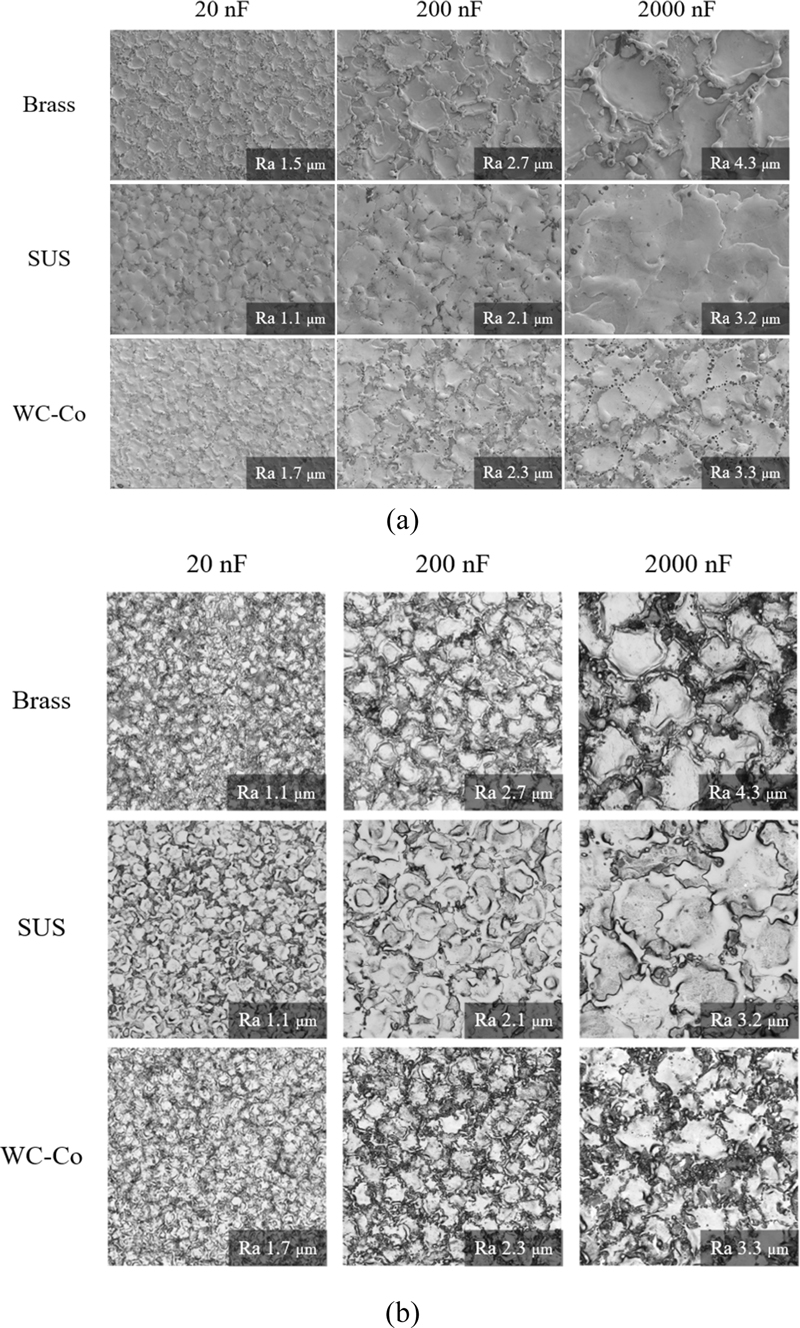

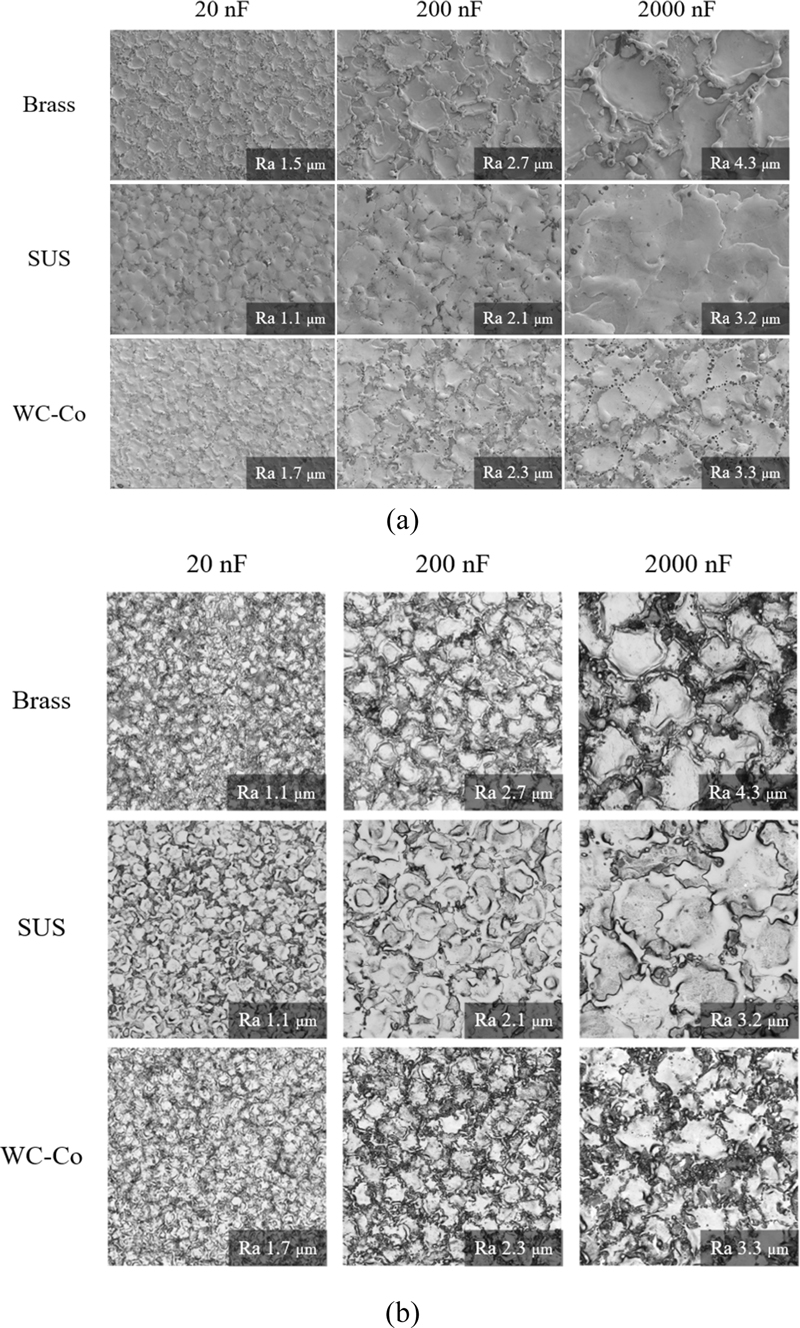

방전흔 이미지의 데이터는 가공물의 종류와 가공 조건에 따라 다르게 나타난 방전흔을 디지털 광학 현미경과 주사전자현미경으로 촬영하여

Fig. 6과 같이 이미지를 수집하였다. 또한 각 현미경 별로 가공 조건에 따른 방전흔 이미지를 2장씩 수집하여 18장으로 이미지 데이터셋을 구성하였다.

Fig. 6Dataset images (a) SEM image and (b) digital image

4.2 데이터 증강

모델학습시 이미지 데이터에 방전흔 외에 불필요한 데이터가 포함되지 않도록 데이터 전처리를 진행하였다. 또한 데이터의 개수가 많지 않으므로 데이터 부족에 의한 과적합을 방지하고자 데이터 증강(Data Augmentation)을 사용하였다. 데이터 증강기법으로는 이미지 분할 기법을 사용하였으며 디지털 이미지와 SEM 이미지 데이터에 대해 각각 적용하였다. 이미지 분할은 가로, 세로 축으로 64픽셀씩 이동시키면서 하나의 이미지를 여러 장으로 분할하는 방식으로 진행하였다. 또한 분할 이미지 데이터의 크기는 CNN 모델의 입력 이미지 데이터 크기와 동일한 픽셀 크기를 가지도록 하였다. 이를 바탕으로 디지털 이미지와 SEM 이미지에 대해 각각 900장의 이미지 데이터를 확보하였다. SEM 이미지 데이터는 1차원의 Grayscale 형태 그대로 사용하였으며 디지털 이미지 데이터는 3차원의 RGB 형태 이므로 Grayscale 형태로 변환하여 사용하였다. 라벨링은 가공물의 종류, 축전용량 조건, 표면 거칠기에 따라 가공 조건 클래스를 정의하였다. 또한 모델 학습과 평가를 위해 전처리한 분할 이미지 데이터의 80%는 훈련 데이터로, 20%는 검증 데이터로 나누어 진행하였다.

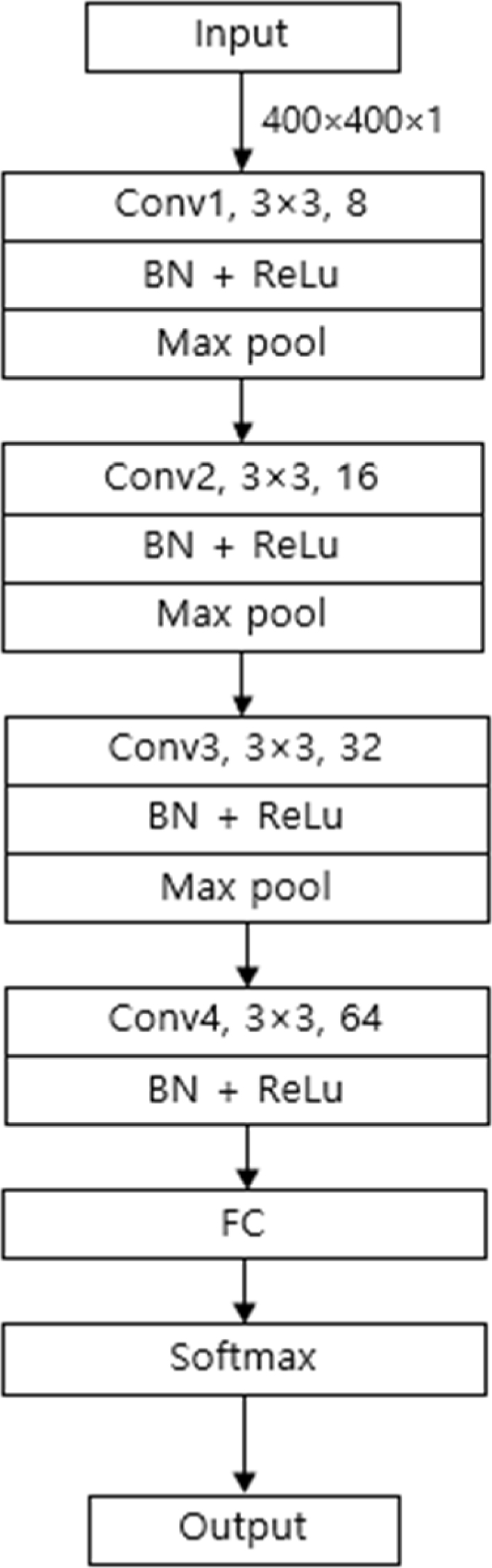

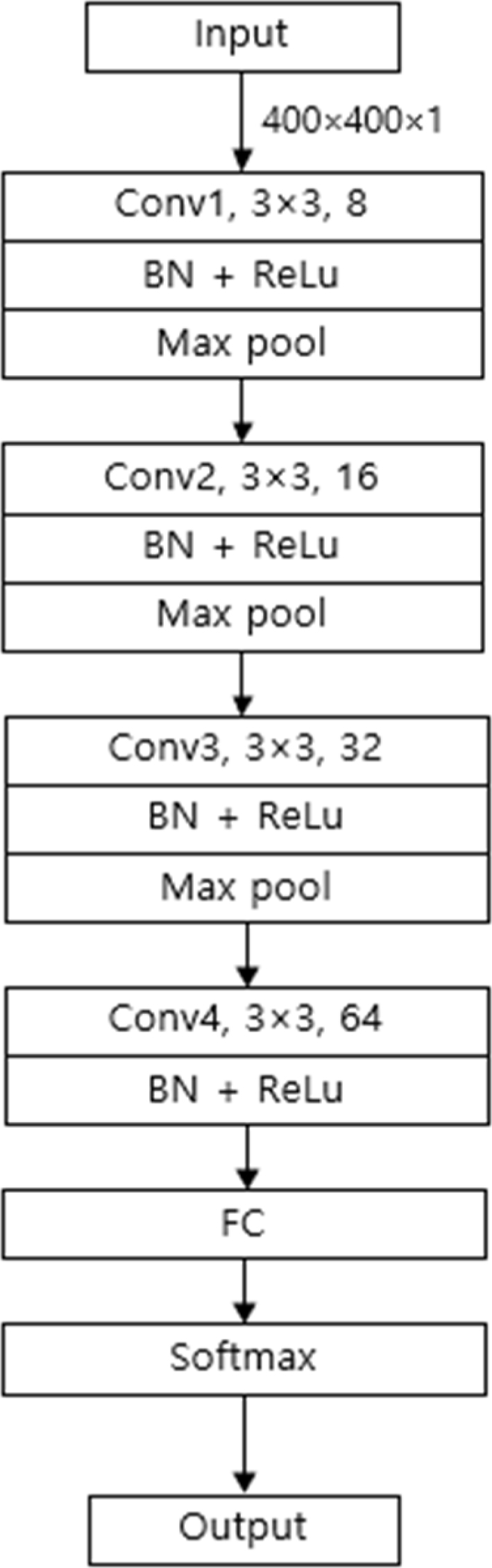

4.3 CNN 모델

Fig. 7은 본 연구에서 사용하기 위해 설계한 CNN 모델 구조를 나타낸다. CNN 모델은 4개의 Convolution Layer와 1개의 Fully-connected Layer로 구성하였다. Convolution Layer에는 ‘Same’ Padding과 활성화 함수 ReLu를 적용하였다. 또한 과적합방지와 심층신경망 학습을 가속시킬 수 있는 Batch Normalization을 Convolution Layer와 ReLu 함수 사이에 사용하였다. Pooling Layer에서는 Max Pooling Layer를 사용하여 최댓값으로 데이터 크기를 줄였다. 이후 Dropout Layer를 적용하여 랜덤으로 은닉층에 있는 노드를 삭제해 훈련시켜 과적합을 방지하였다[

25]. 또한 Fully-connected Layer와 Softmax 함수를 사용한 Output Layer를 사용해 최종 클래스와 확률값을 출력하였다.

Fig. 7CNN architecture

4.4 모델 성능 평가

디지털 이미지와 SEM 이미지 모두 900장의 이미지 중 720장의 이미지를 학습 데이터로 사용하여 모델 학습을 진행하였다. 나머지 180장의 이미지는 검증데이터로 사용해 모델 검증을 진행하였다. 이때 학습 Epoch는 30으로 설정하였다. 또한 모델 학습에서는 모델의 손실률을 줄이고자 Adam을 Optimizer로 사용하였다.

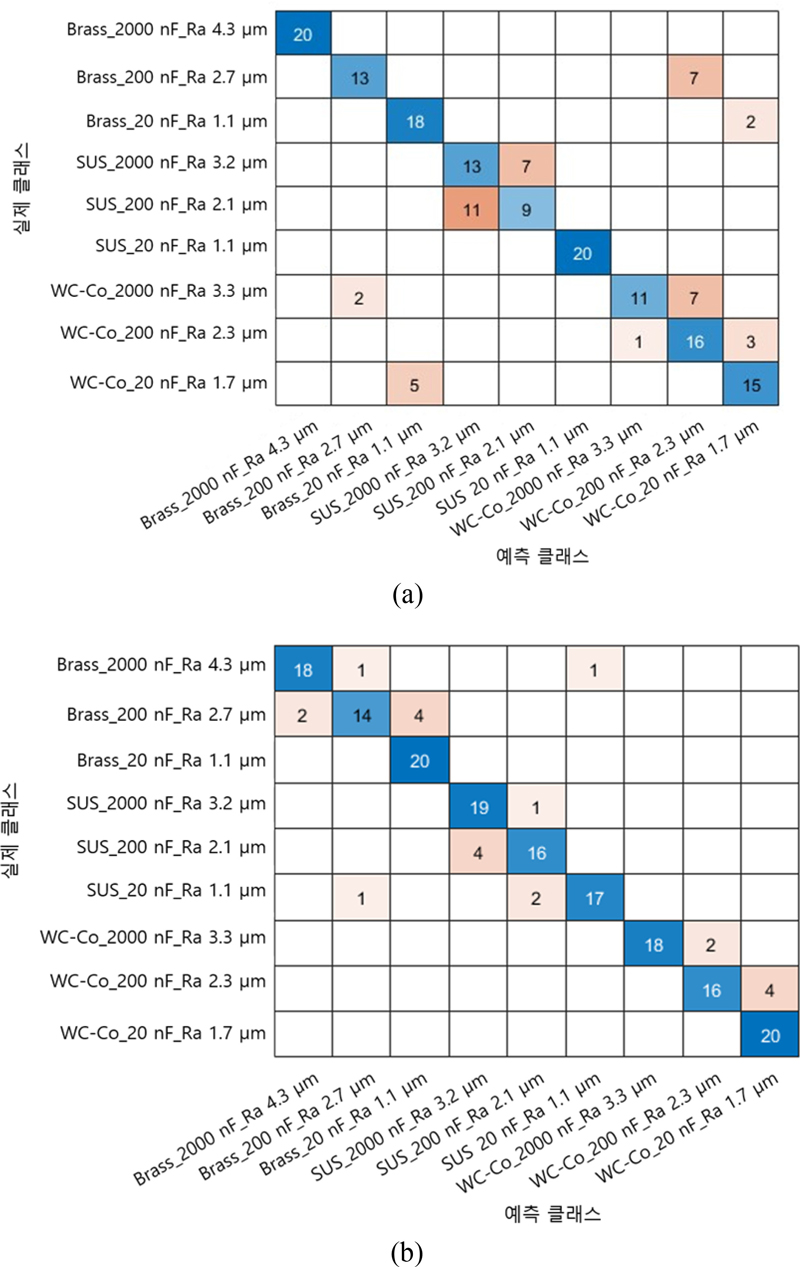

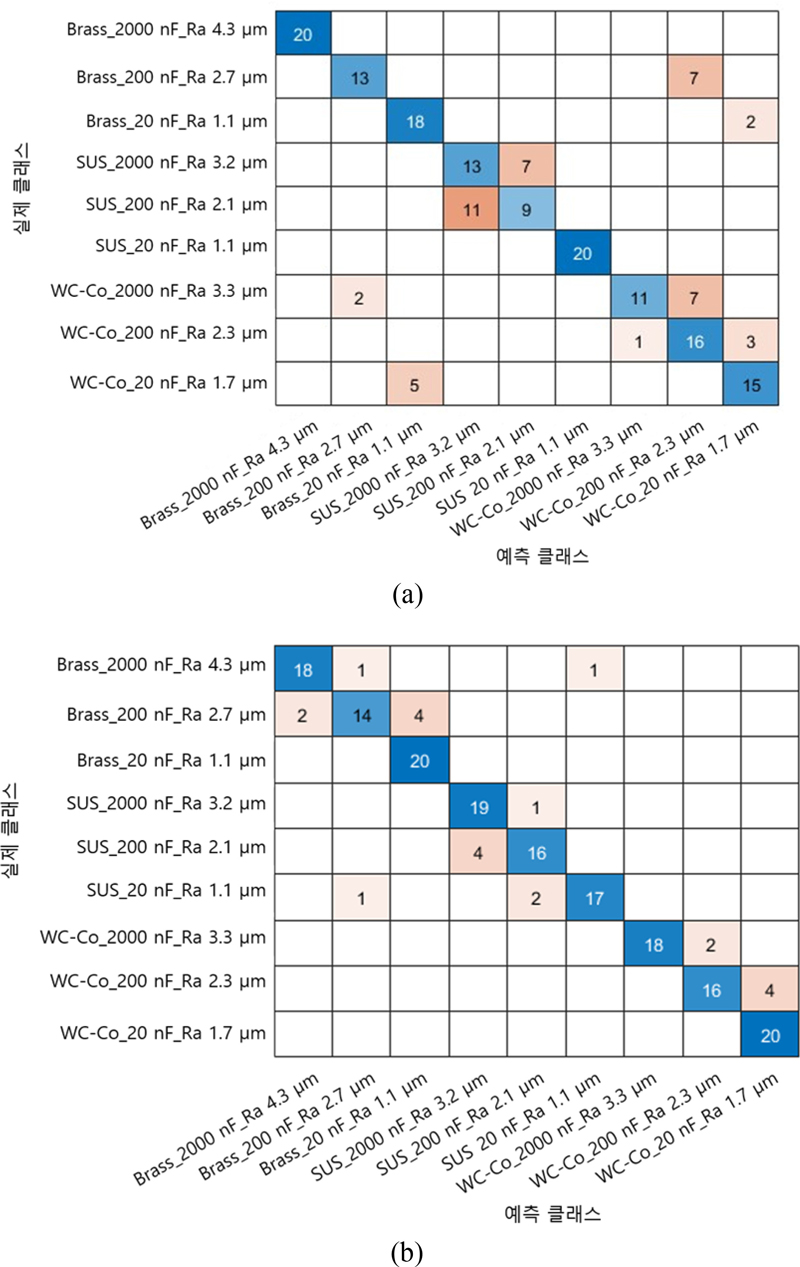

Fig. 8은 CNN 모델을 검증데이터에 적용하였을 때 분류 결과를 Confusion Matrix로 나타낸 그림이다. 혼동 행렬 표에서 대각선은 올바르게 분류한 이미지 개수를 나타낸다.

Fig. 8(a)와 같이 디지털 이미지 데이터를 사용할 경우에는 180장의 검증이미지 데이터 중 오분류된 이미지가 45장으로 검증데이터에 대해서 75%의 정확도를 얻었다. 반면 SEM 이미지 데이터를 사용할 경우에는

Fig. 8(b)와 같이 총 180장의 검증 이미지 데이터 중 오분류된 이미지가 22장으로 검증데이터에 대해서 87%의 정확도를 얻었다. 디지털 이미지와 SEM 이미지에 동일한 CNN 알고리즘을 사용하였으나 SEM 이미지를 사용할 때 정확도가 더 높았음을 확인하였다.

Fig. 8Confusion matrix of CNN model (a) digital image and (b) SEM image

4.5 Grad-CAM 시각화

Grad-CAM은 CNN 모델이 입력데이터에 대한 판단의 근거를 시각적으로 보여주는 기법이다[

26]. Gradient 신호로 Grad-CAM 스코어를 계산함으로써 CNN 모델의 의사결정에 많은 영향을 미치는 입력 이미지의 특정 부분을 확인할 수 있다. Grad-CAM 스코어는 CNN 모델 구조에서 마지막 Convolution Layer의 Feature Map인 A

K와 Softmax 함수를 적용하기 전 각 클래스에 대한 예측값인 y

c값에 대한 스코어 기울기를 계산하여 나타낸다. 스코어 기울기는

식(2)과 같이 정의한다. 이후 각 Feature Map마다 스코어 기울기를 계산한 후 전체 픽셀 수 Z에 대해 Global Average Pooling을 적용하여 평균 가중치

wkc를 계산한다. 평균 가중치는

식(3)와 같이 정의한다. 이후 전체 Feature Map의 가중치를 합산하고 ReLU 함수를 적용하여 음수값을 제거함으로써 최종 Grad-CAM 스코어를 계산한다. 최종 Grad-CAM 스코어는

식(4)와 같이 정의한다[

26].

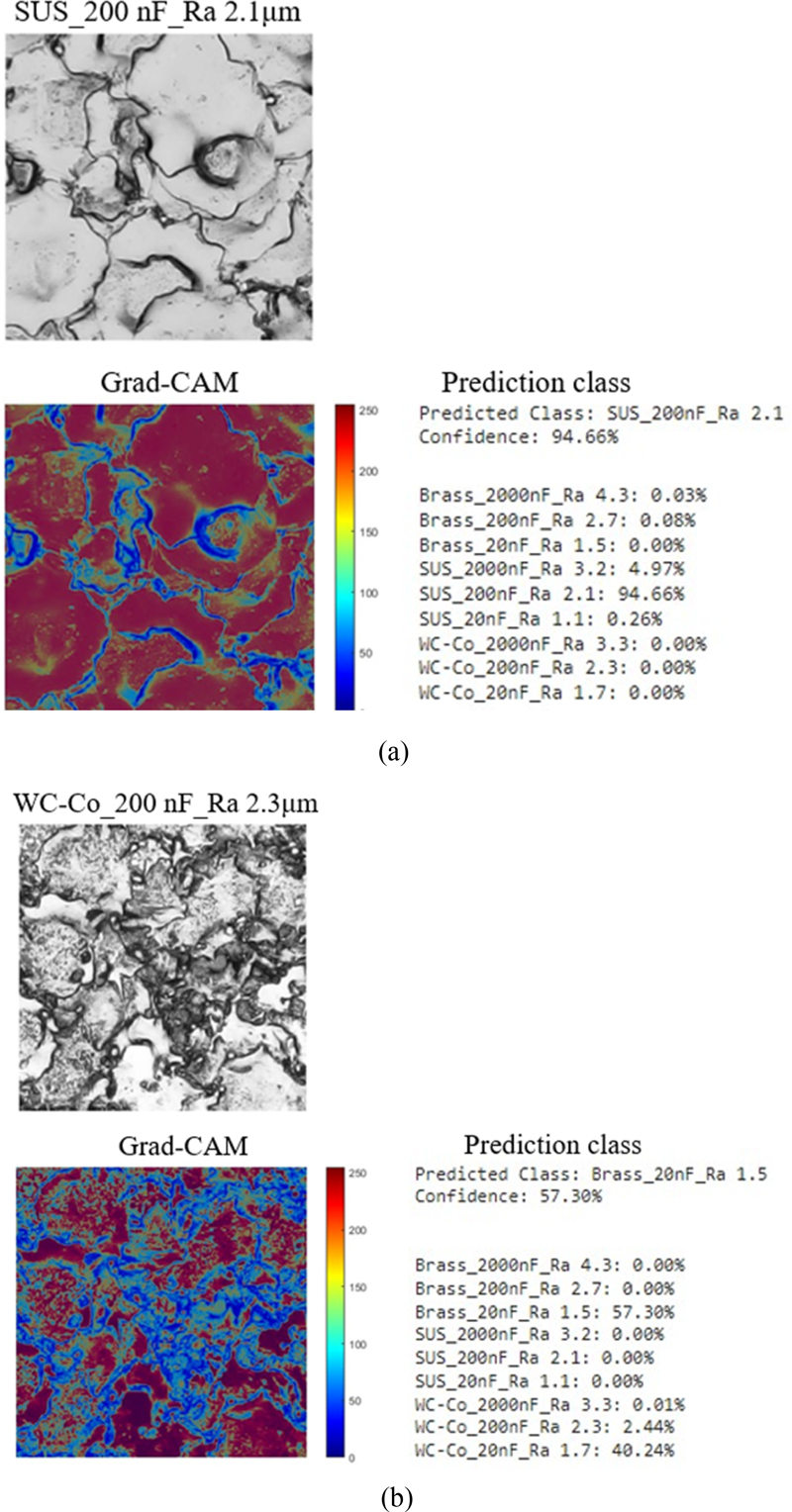

입력데이터인 디지털 이미지와 SEM 이미지에 대해CNN 모델의 클래스 분류 결정에 영향을 미친 영역을 확인하기 위해 Grad-CAM을 적용하였다.

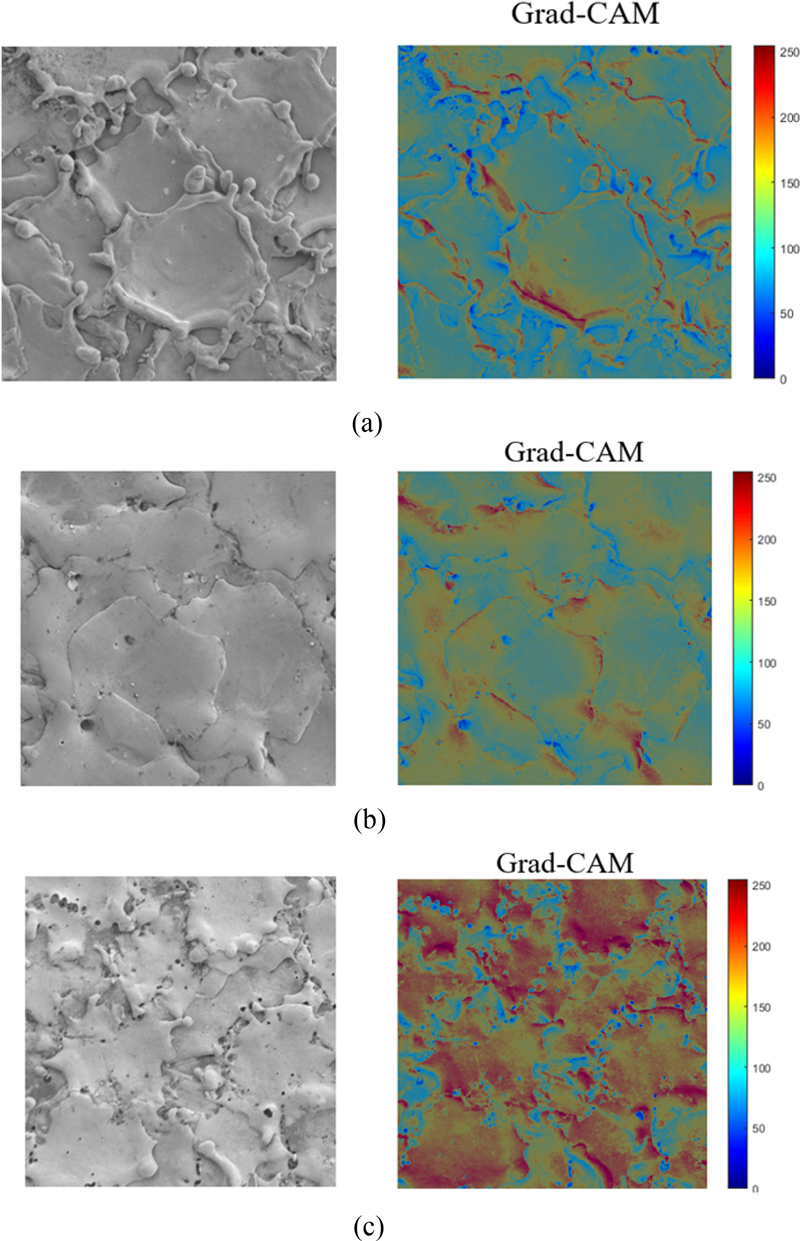

Figs. 9와

10은 각각 디지털 현미경과 전자현미경으로 촬영한 방전 가공면의 Grad-CAM을 Heatmap으로 시각화한 결과이다. Heatmap에서 CNN 모델의 의사결정에 많은 영향을 미치는 영역일수록 픽셀값과 Grad-CAM 스코어 값이 높아 붉은 색을 띈다.

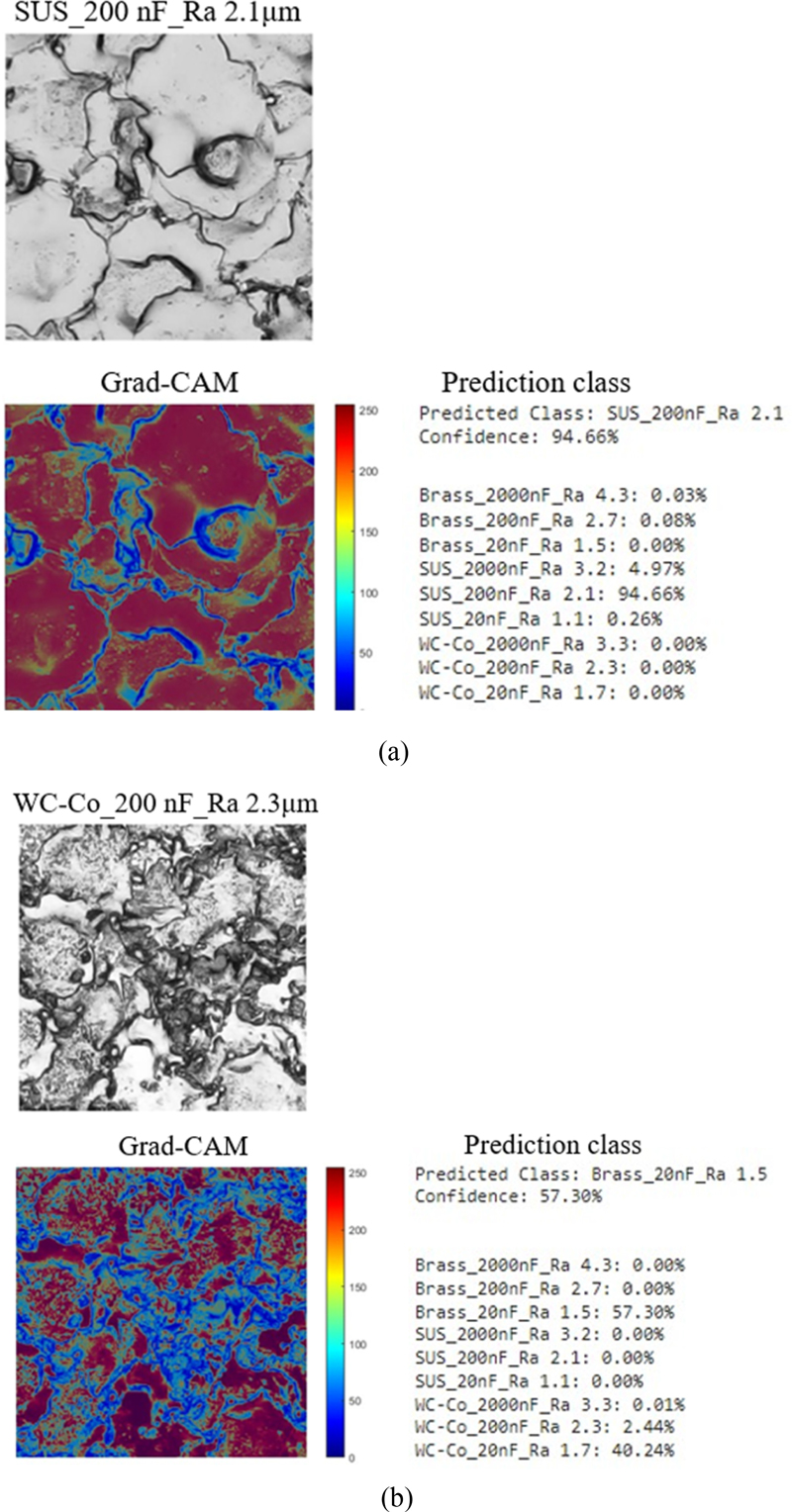

Fig. 9Grad cam and prediction class of (a) correct predictions and (b) inaccurate predictions

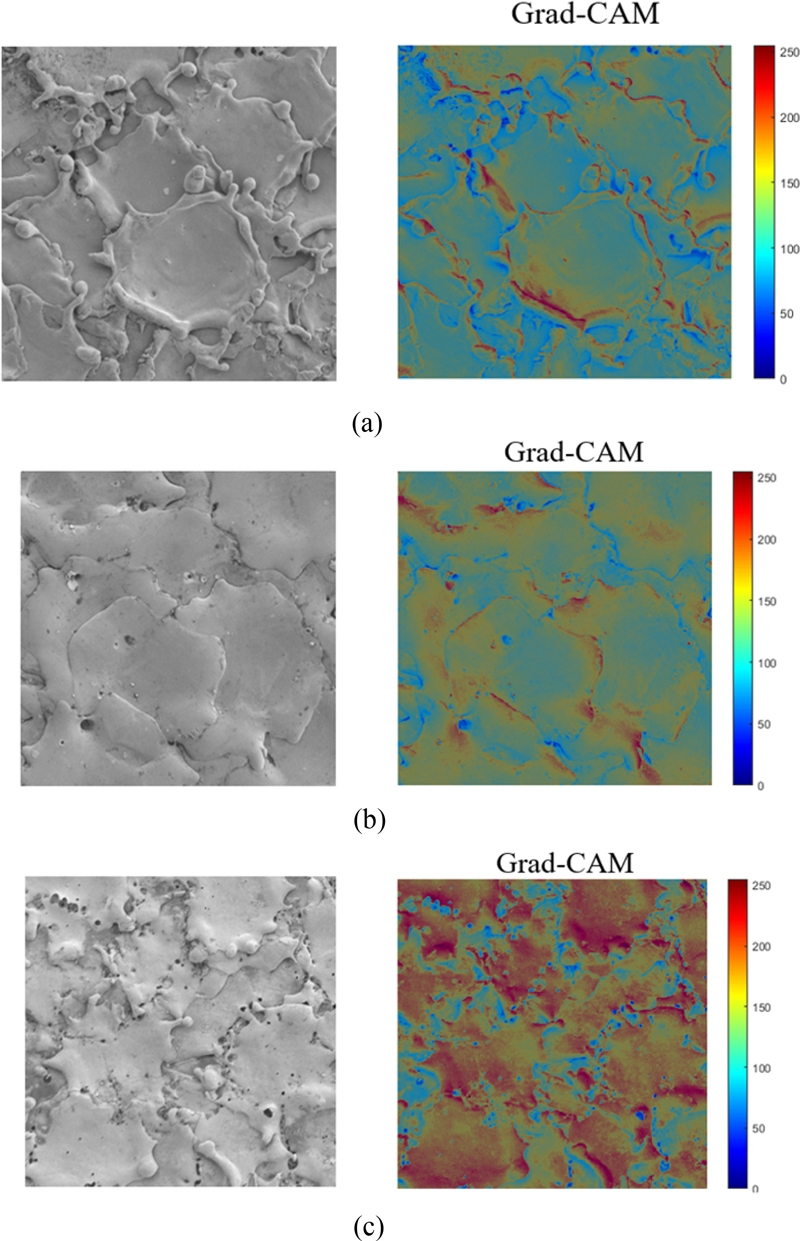

Fig. 10Grad cam visualization of input data according to (a) brass, (b) stainless steel, and (c) WC-Co

디지털 이미지를 사용하였을 때

Fig. 9(a)와 같이 CNN이 올바르게 예측할 경우 이미지 내 방전흔 형상을 띄는 부분이 가장 붉게 나타났으며 방전흔의 경계 부분은 푸른색으로 나타났다. 이는 CNN 모델이 클래스 분류 시 방전흔의 중심부분을 기준으로 방전흔 모양과 형태가 분류 결정 의사에 많은 영향을 미쳤음을 확인하였다. 반면

Fig. 9(b)와 같이 예측 결과가 다를 경우 방전흔이 아닌 부분도 붉은색으로 나타났다. 이에 CNN 모델이 방전흔의 모양과 형태를 제대로 인식하지 못하였으며 방전흔이 아닌 표면 결함과 불순물 등이 클래스 분류에 영향을 미쳤음을 확인하였다.

전자현미경 이미지를 사용하였을 때 CNN이 올바르게 예측한 경우

Fig. 10과 같이 가공 재료에 따라 Grad-CAM을 적용하였을 때의 Heatmap을 확인하였다. 황동과 스테인리스강의 Heatmap은 방전흔 가장자리의 재응고가 붉은 색을 띰에 따라 재응고층이 CNN 모델의 분류 결정에 많은 영향을 미친다는 점을 확인하였다. 초경합금의 경우 황동과 스테인리스강에 비해 방전흔의 중심 부분이 CNN의 분류 결정에 영향을 미쳤음을 Grad-CAM으로 확인하였다. 그러나 방전흔의 가장자리 부분의 재응고층이 중심부보다 더 진한 붉은색으로 표시됨에 따라 결론적으로는 재응고층이 분류 결정에 가장 큰 영향을 미친다고 판단되었다. 이를 바탕으로 방전흔의 중심부보다 방전흔 사이의 경계면이나 방전흔의 가장자리가 CNN 모델의 분류 결정의사에 영향을 미친다는 것을 확인하였다.

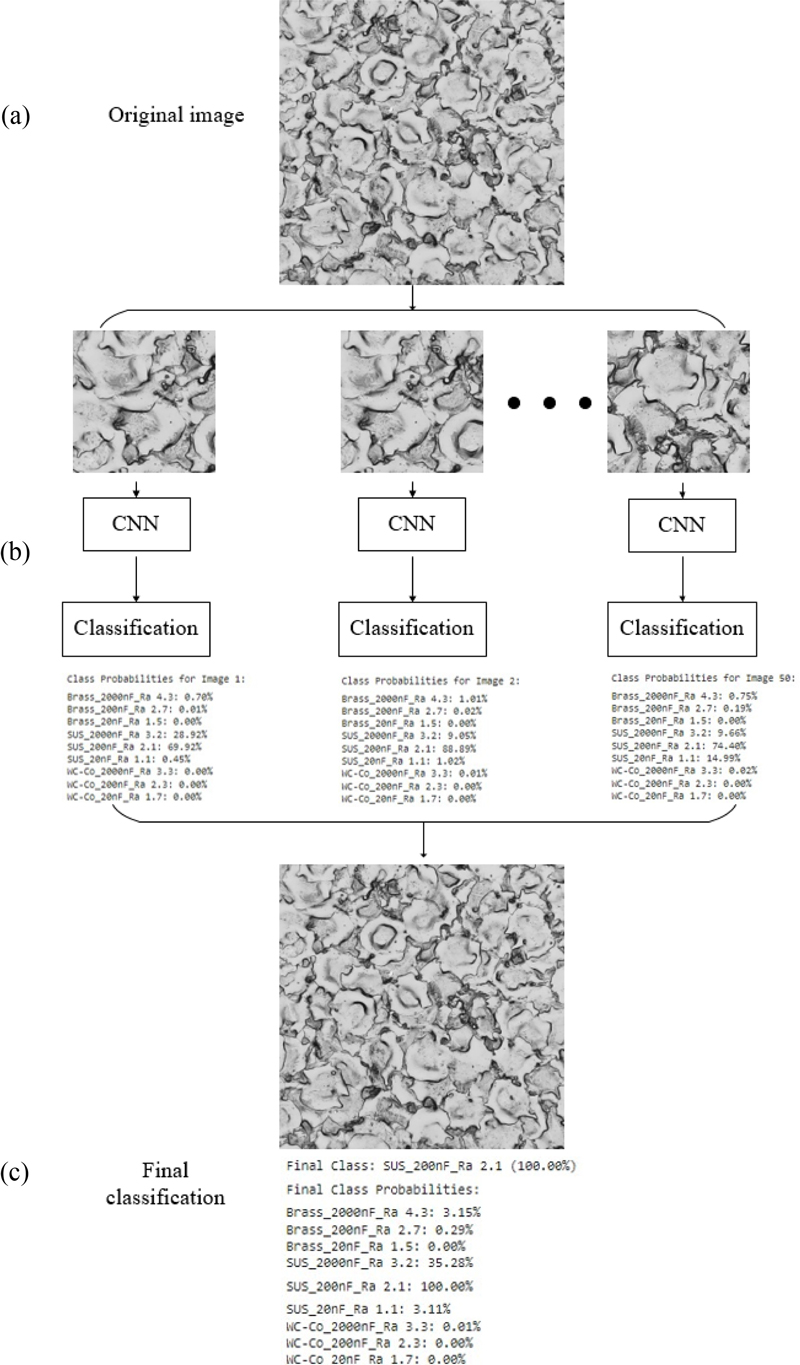

5. 이미지 분할을 이용한 예측 향상 모델 제안

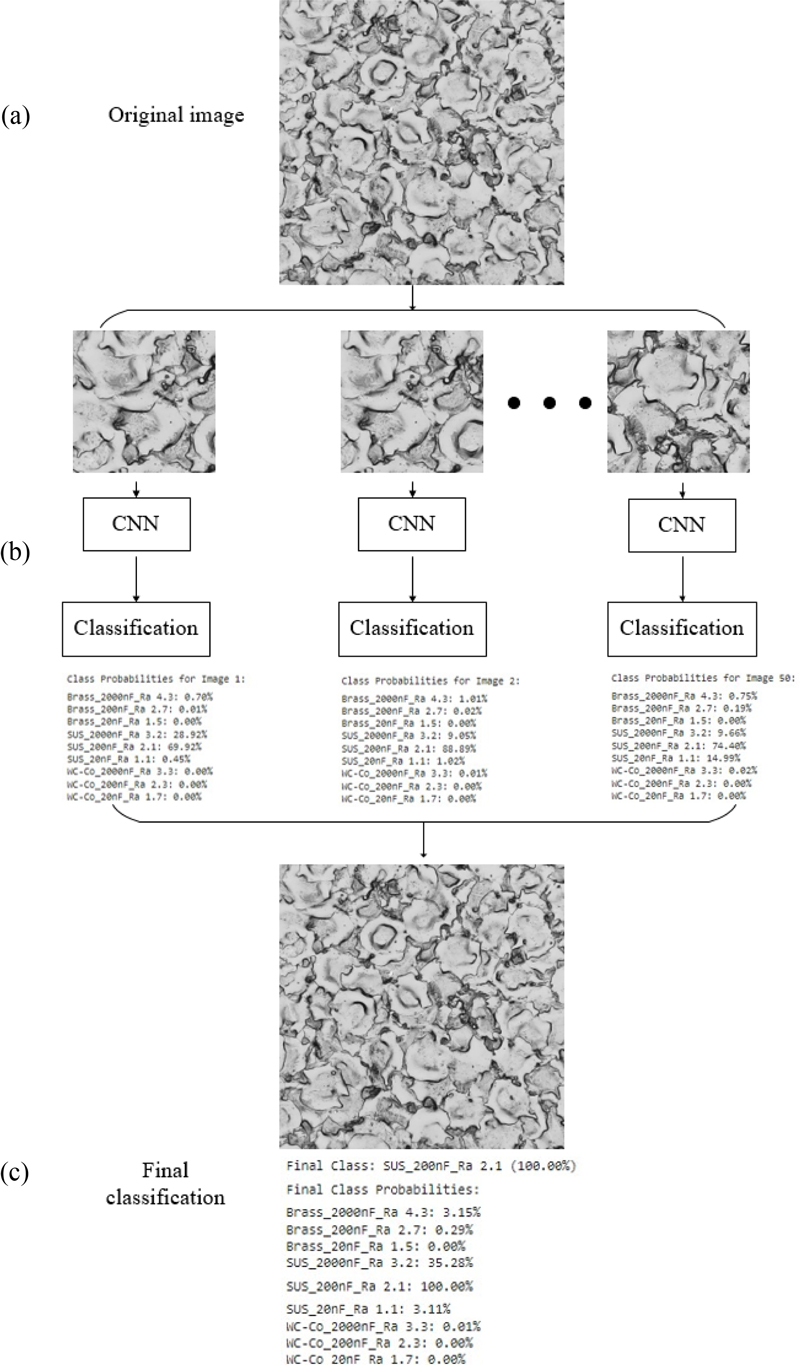

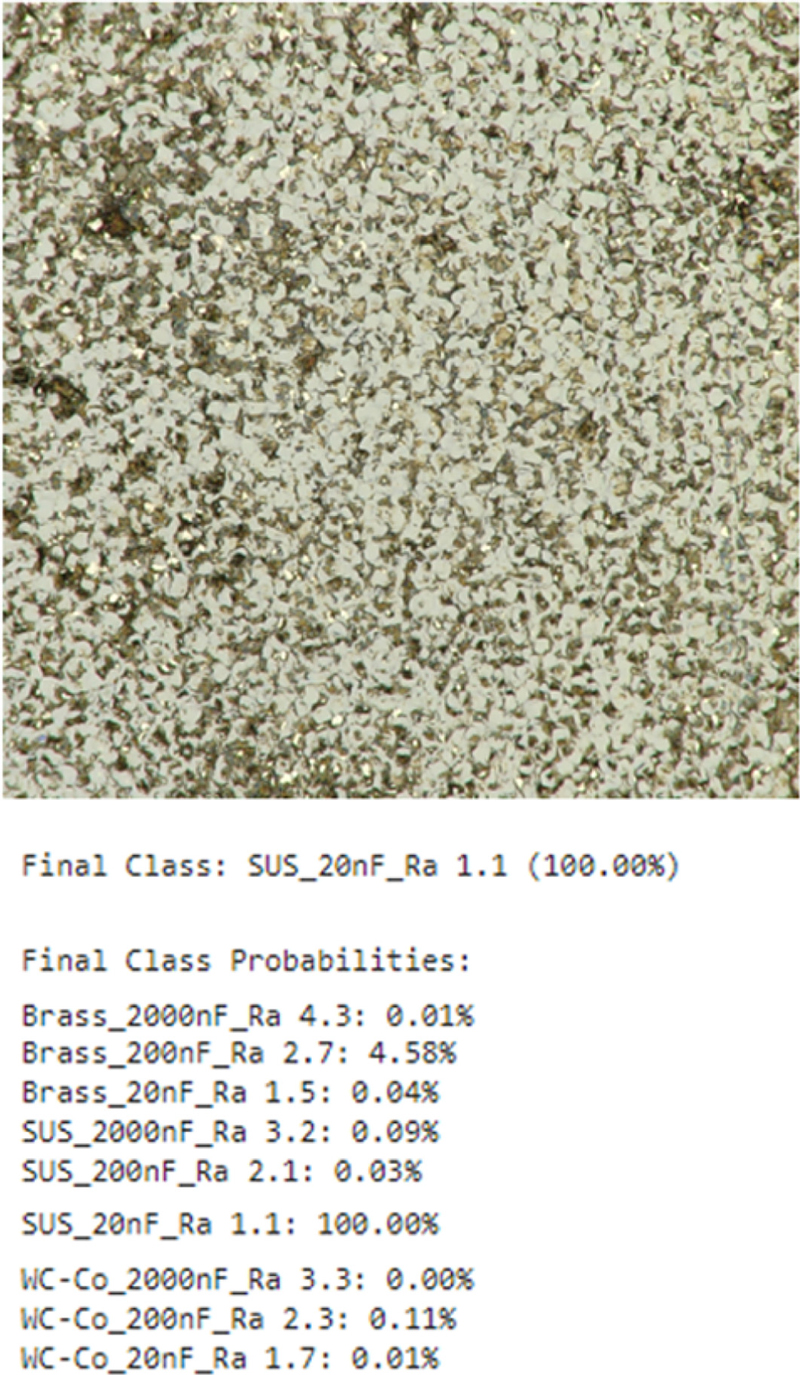

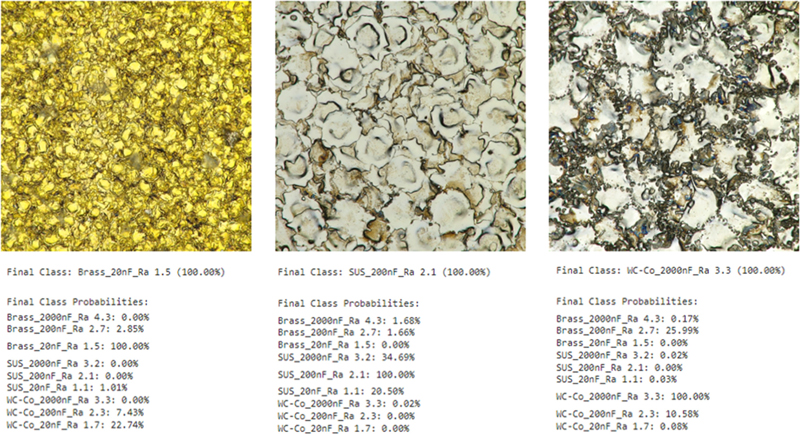

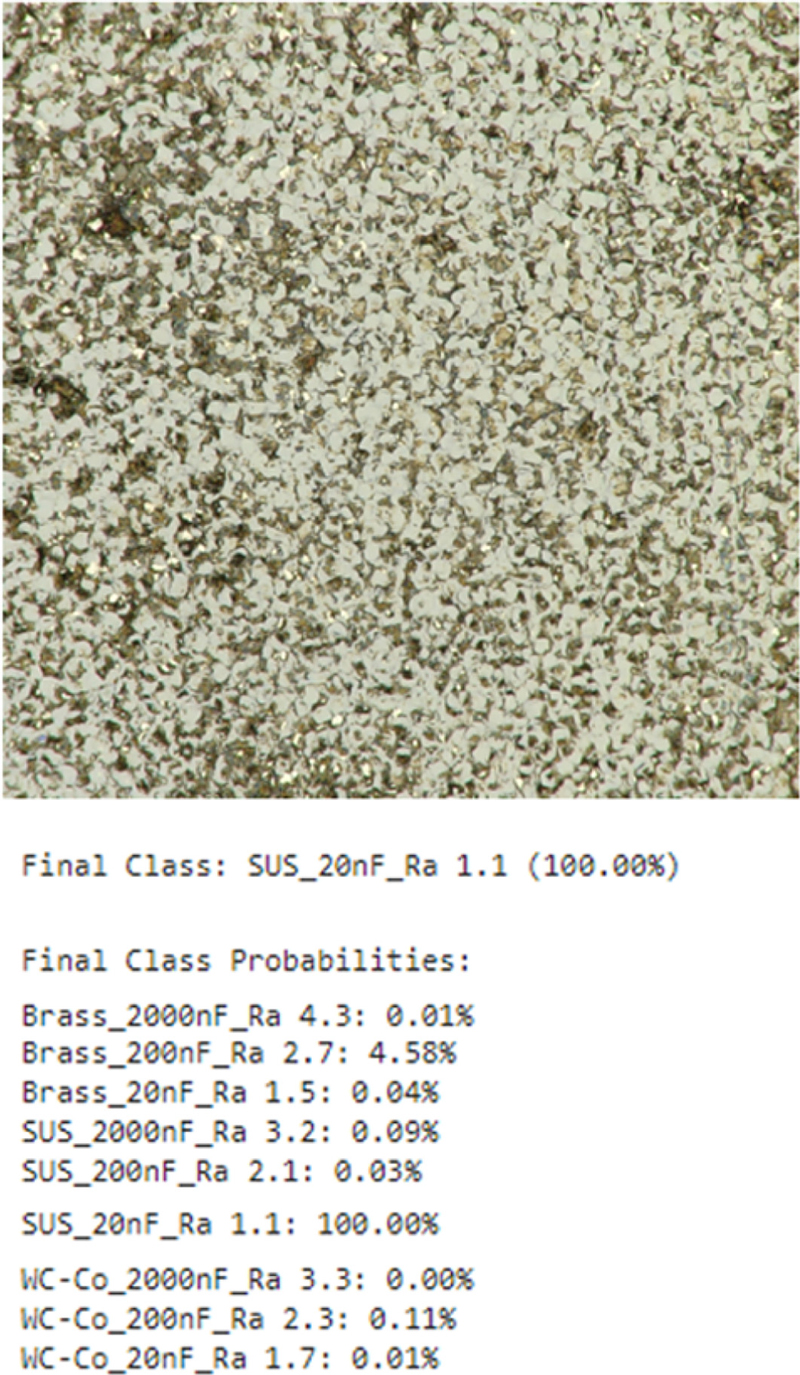

가공 현장에서 방전 가공면의 분류와 표면 거칠기를 예측하고자 할 때, 주사전자 현미경보다 디지털 현미경을 사용하는 것이 용이하지만 디지털 이미지의 경우 이미지 분류 예측 정확도가 낮다는 한계가 있다. 이에 본 논문에서는 기존의 CNN 모델 구조를 변경하지 않고

Fig. 11과 같이 이미지 분할과 병합 기법을 사용해 디지털 이미지 기반 표면 거칠기 예측 정확도를 향상시켰다. 방전 가공면에는 일부 불균일한 방전흔이나, 경계에서의 재응고층 등의 결함이 존재하고 이러한 형상이 CNN 모델의 예측 정확도를 떨어뜨리게 된다. 하지만 디지털 현미경으로 방전 가공 표면을 촬영할 때 측정 영역을 조절하면

Fig. 11(a)와 같이 충분히 많은 방전흔이 포함된 이미지를 얻을 수 있다. 전체 이미지에서 가공 조건별 방전흔의 형태와 특징이 잘 드러나도록 방전흔 크기 정도의 이미지로 분할한 뒤

Fig. 11(b)와 같이 분할한 이미지들을 기존 CNN 모델을 사용하여 각 이미지마다 해당되는 가공물 재료, 가공 조건, 표면 거칠기와 클래스별 예측률이 출력되도록 하였다. 이후

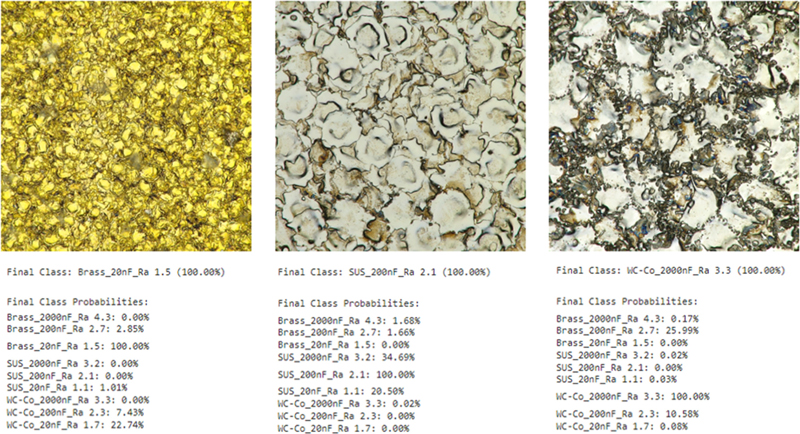

Fig. 11(c)와 같이 분할 이미지에 대해 출력된 예측률을 합산하고 그중 가장 높은 값을 가진 클래스가 출력되도록 하였다. 디지털 이미지를 사용한 기존 CNN 모델의 예측 정확도는 75%를 보인 반면에, 이 방식을 통해 거의 100%에 가까운 예측 정확도를 얻을 수 있었다. 또한

Fig. 12와 같이 모델 훈련에 사용되지 않은 가공 표면에 대해서도 100%의 예측 정확도를 얻었다. 이는 분할한 일부 이미지에서 불균일한 방전흔, 불순물 등이 존재하여 분류 예측 결과가 부정확하더라도 결과적으로 분할 이미지의 클래스 예측률을 모두 합산해 최종 클래스 예측이 이뤄지기 때문에 가공표면 결함이 예측 정확도에 미치는 영향을 크게 줄이는 것을 확인하였다.

Fig. 11 Model structure to enhance prediction accuracy

Fig. 12 Prediction results for images that were not used for model training

6. 결론

본 연구에서는 방전흔 이미지를 기반으로 가공물 재료, 가공 조건, 표면 거칠기를 예측하기 위한 CNN 모델을 설계하고 예측 정확도 향상을 위한 딥러닝 구조를 제안하였다. 방전흔 이미지는 주사전자 현미경과 디지털 현미경 두 가지 방법으로 수집하였다. 동일한 CNN 모델 알고리즘을 사용할 때 검증데이터의 정확도는 주사전자현미경의 이미지가 디지털 현미경의 이미지보다 높게 나타났으며 Grad-CAM 시각화를 통해 방전흔의 가장자리 또는 방전흔 주변의 재응고층이 CNN 모델의 클래스 분류 결과와 예측 정확도에 영향을 미친다는 것을 확인하였다. 디지털 현미경 이미지의 예측 정확도를 높이는 방법으로 CNN 모델 구조를 수정하지 않고 이미지 분할 및 예측률 합산 기법을 제안하였다. 이를 통해 정확도가 낮은 디지털 이미지의 CNN 모델 예측 정확도를 향상시켰다. 본 연구에서는 축전 용량 20, 200, 2,000 nF의 일부 가공 조건에 대해서만 CNN 모델을 훈련시켰으므로 다른 가공 조건에 대한 예측에 한계가 있다. 그 예로,

Fig. 13과 같이 2 nF으로 가공된 방전흔은 20 nF으로 예측이 된다. 하지만 훈련된 가공 조건 중, 방전흔 크기가 가장 작은 조건인 20 nF으로 예측되는 것으로 보아 다양한 가공 조건의 이미지를 추가하여 훈련시키면 예측 정확도를 향상시킬 수 있을 것으로 판단된다.

Fig. 13 Prediction results for EDM surface machined with 2 nF

ACKNOWLEDGMENTS

이 성과는 정부(과학기술정보통신부)의 재원으로 한국연구재단의 지원을 받아 수행된 연구임(No. 2022R1F1A1067961).

REFERENCES

- 1.

Janiesch, C., Zschech, P., Heinrich, K., (2021), Machine learning and deep learning, Electronic Markets, 31(3), 685-695.

10.1007/s12525-021-00475-2

- 2.

Sharma, N., Jain, V., Mishra, A., (2018), An analysis of convolutional neural networks for image classification, Procedia Computer Science, 132, 377-384.

10.1016/j.procs.2018.05.198

- 3.

Rifai, A. P., Aoyama, H., Tho, N. H., Md Dawal, S. Z., Masruroh, N. A., (2020), Evaluation of turned and milled surfaces roughness using convolutional neural network, Measurement, 161, 107860.

10.1016/j.measurement.2020.107860

- 4.

Giusti, A., Dotta, M., Maradia, U., Boccadoro, M., Gambardella, L. M., Nasciuti, A., (2020), Image-based measurement of material roughness using machine learning techniques, Procedia CIRP, 95, 377-382.

10.1016/j.procir.2020.02.292

- 5.

Saeedi, J., Dotta, M., Galli, A., Nasciuti, A., Maradia, U., Boccadoro, M., Gambardella, L. M., Giusti, A., (2021), Measurement and inspection of electrical discharge machined steel surfaces using deep neural networks, Machine Vision and Applications, 32, 1-15.

10.1007/s00138-020-01142-w

- 6.

Abhilash, P. M., Ahmed, A., (2023), Convolutional neural network-based classification for improving the surface quality of metal additive manufactured components, The International Journal of Advanced Manufacturing Technology, 126(9), 3873-3885.

10.1007/s00170-023-11388-z

- 7.

Lee, J. H., Yang, C. Y., Kim, B. H., (2024), Machining characteristics of micro edm of silicon carbide, Journal of the Korean Society for Precision Engineering, 41(2), 131-137.

10.7736/JKSPE.023.137

- 8.

Moon, I. Y., Kim, B. H., (2013), Micro machining of titanium alloy using polycrystalline diamond tools, Journal of the Korean Society of Precision Engineering, 30(3), 284-291.

10.7736/KSPE.2013.30.3.284

- 9.

Lee, U. S., Yang, C. Y., Lee, J. H., Kim, B. H., (2021), Micro drilling of single crystal sic using polycrystalline diamond tool, Journal of the Korean Society for Precision Engineering, 38(7), 471-478.

10.7736/JKSPE.021.013

- 10.

Lee, P. A., Lee, U. S., Sim, D. B., Kim, B. H., (2023), Microfluidic chip fabrication of fused silica using microgrinding, Micromachines, 14(1), 96.

10.3390/mi14010096

- 11.

Na, Y., Lee, U. S., Kim, B. H., (2021), Experimental study on micro-grinding of ceramics for micro-structuring, Applied Sciences, 11(17), 8119.

10.3390/app11178119

- 12.

Lee, P. A., Kim, B. H., (2022), A study of microdrilling of fused silica using edmed PCD tools, Applied Sciences, 12(21), 11166.

10.3390/app122111166

- 13.

Kim, M. K., Yang, C. Y., Sim, D. B., Lee, J. H., Kim, B. H., (2024), Study on micro grooving of tungsten carbide using disk tool, Journal of the Korean Society for Precision Engineering, 41(2), 123-129.

10.7736/JKSPE.023.138

- 14.

Chu, X., Feng, W., Wang, C., Hong, Y., (2017), Analysis of mechanism based on two types of pulse generators in micro-edm using single pulse discharge, The International Journal of Advanced Manufacturing Technology, 89, 3217-3230.

10.1007/s00170-016-9287-8

- 15.

Wong, Y. S., Rahman, M., Lim, H. S., Han, H., Ravi, N., (2003), Investigation of micro-EDM material removal characteristics using single rc-pulse discharges, Journal of Materials Processing Technology, 140(1-3), 303-307.

10.1016/S0924-0136(03)00771-4

- 16.

Shao, B., Rajurkar, K. P., (2015), Modelling of the crater formation in micro-EDM, Procedia CIRP, 33, 376-381.

10.1016/j.procir.2015.06.085

- 17.

Feng, X., Wong, Y. S., Hong, G. S., (2016), Characterization and geometric modeling of single and overlapping craters in micro- EDM, Machining Science and Technology, 20(1), 79-98.

10.1080/10910344.2015.1085317

- 18.

Nadda, R., Nirala, C. K., (2019), Effect of single spark micro- EDM on crater size of different alloys, IOP Conference Series: Materials Science and Engineering, 012032.

10.1088/1757-899X/561/1/012032

- 19.

Kar, S., Patowari, P. K., (2019), Experimental investigation of machinability and surface characteristics in microelectrical discharge milling of titanium, stainless steel and copper, Arabian Journal for Science and Engineering, 44(9), 7843-7858.

10.1007/s13369-019-03918-3

- 20.

Feng, W., Chu, X., Hong, Y., Wang, K., Zhang, L., (2018), Studies on micro-EDM surface performance using a comprehensive method, The International Journal of Advanced Manufacturing Technology, 96, 1875-1889.

10.1007/s00170-018-1711-9

- 21.

Kumar, A., Kumar, V., Kumar, J., (2016), Surface crack density and recast layer thickness analysis in wedm process through response surface methodology, Machining Science and Technology, 20(2), 201-230.

10.1080/10910344.2016.1165835

- 22.

Mahardika, M., Tsujimoto, T., Mitsui, K., (2008), A new approach on the determination of ease of machining by EDM processes, International Journal of Machine Tools and Manufacture, 48(7-8), 746-760.

10.1016/j.ijmachtools.2007.12.012

- 23.

Paswan, K., Sharma, S., Li, C., Mohammed, K. A., Kumar, A., Abbas, M., Tag-Eldin, E. M., (2023), Unravelling the analysis of electrical discharge machining process parameters, microstructural morphology, surface integrity, recast layer formation, and material properties: A comparative study of aluminum, brass, and inconel 617 materials, Journal of Materials Research and Technology, 27, 7713-7729.

10.1016/j.jmrt.2023.11.186

- 24.

Pandey, P. C., Jilani, S. T., (1987), Electrical machining characteristics of cemented carbides, Wear, 116(1), 77-88.

10.1016/0043-1648(87)90269-9

- 25.

Alzubaidi, L., Zhang, J., Humaidi, A. J., Al-Dujaili, A., Duan, Y., Al-Shamma, O., Santamaría, J., Fadhel, M. A., Al-Amidie, M., Farhan, L., (2021), Review of deep learning: Concepts, cnn architectures, challenges, applications, future directions, Journal of Big Data, 8, 1-74.

10.1186/s40537-021-00444-8

- 26.

Selvaraju, R. R., Cogswell, M., Das, A., Vedantam, R., Parikh, D., Batra, D., (2017), Grad-cam: Visual explanations from deep networks via gradient-based localization, Proceedings of the IEEE International Conference on Computer Vision, 618-626.

10.1109/ICCV.2017.74

Biography

- Ji Hyo Lee

M.S. student in the Department of Mechanical Engineering, Graduate School Soongsil University. Her research interest is micro machining.

- Jae Yeon Kim

M.S. student in the Department of Mechanical Engineering, Graduate School Soongsil University, His research interest is micro machining.

- Dae Bo Sim

M.S. student in the Department of Mechanical Engineering, Graduate School Soongsil University, His research interest is micro machining.

- Bo Hyun Kim

Professor in the School of Mechanical engineering, Soongsil University. His research topics are micro mechanical and non-conventional machining processes.