ABSTRACT

In this study, we propose a deep learning-based method for large-area inspection aimed at the high-speed detection of micro hole diameters. Micro holes are detected and stored in large images using YOLOv8, an object detection model. A super-resolution technique utilizing ESRGAN, an adversarial neural network, is applied to images of small micro holes, enhancing them to high resolution before measuring their diameters through image processing. When comparing the diameters measured after 8x super-resolution with the results from existing inspection equipment, the average error rate is remarkably low at 0.504%. The time taken to measure an image of one micro hole is 0.470 seconds, which is ten times faster than previous inspection methods. These results can significantly contribute to high-speed measurement and quality improvement through deep learning.

-

KEYWORDS: Silicon cathode, Vision inspection, Object detection, Super resolution, Micro hole diameter

-

KEYWORDS: 실리콘 캐소드, 비전 검사, 객체 검출, 초해상화, 미세 구멍 직경

1. 서론

실리콘 캐소드(Si-Cathode)는 전극(Electrode)이라고도 하며, 반도체 제조공정 중 플라즈마 에칭(Plasma Etching) 공정에서 챔버 내에 가스를 흘리고 전압을 가해 플라즈마를 형성하는 과정에서 핵심적인 역할을 한다. 마이크로 드릴 공구로 실리콘 캐소드의 미세 구멍을 가공하는 과정에서 캐소드 내 결함이나 균열 등이 있을 경우, 충격에 의한 균열 전파가 이루어져 파티클이 발생하거나 부품의 수명을 단축하는 결과를 초래한다. 또한, 가공된 미세 구멍의 직경오차와 진원도가 균일하지 않을 경우, 식각 속도가 일정하지 않아 칩(Chip)의 부위별 모양이 달라지고, 특정 부위의 칩이 제대로 동작하지 않는 불량이 발생할 가능성이 높다. 따라서, 캐소드의 미세 구멍은 정밀하게 가공되어 균일도를 유지하기 위해 직경오차와 진원도를 엄격하게 관리해야한다[

1-

3]. 최근 반도체 집적도 향상에 따른 패턴 선폭 미세화와 웨이퍼의 대구경화로 인해, 챔버 내 식각 고밀도 및 고직진성 플라즈마 조성을 위한 고품질·고정밀의 실리콘 캐소드의 미세구멍 가공과 치수 검사가 요구된다. 반도체 건식 식각 장비(Dry-Etcher)에서 진공 분위기를 만드는 실리콘 캐소드는 수 천개의 미세 구멍을 전수 검사하여 품질을 확보해야 하지만, 양산 과정에서 완제품 생성 후 수천 번의 미세 구멍 검사는 생산 경쟁력 확보에 큰 어려움을 초래한다.

치수 검사는 제조 과정에서 결함과 설계 규격을 확인하기 위한 핵심적인 품질 관리 절차이다. 선행 연구에 따르면, 영상 기반의 머신 비전(Machine Vision)은 다양한 형상을 유연하게 검사하여 불량 및 치수 결함을 효과적으로 검출할 수 있는 이점이 있으며, 비용 절감, 검사 효율성, 정확도 측면에서도 우수해 널리 활용되고 있다[

4].

정밀 가공품의 미세한 결함을 검출하기 위해서는 고화질 및 고배율의 영상을 필요로 하는데, 검사 정밀도에 따라 고가의 조명과 산업용 카메라가 각각 요구되어 현장 적용이 어렵고 비경제적인 문제가 있다. 이로 인해 최근에는 현장 비용을 줄이기 위해 저해상도 카메라 장치를 활용하여 장치 검사를 수행하려는 연구들이 활발히 진행되고 있다[

5,

6]. 그러나, 저해상도 영상을 입력으로 활용하면 경제성은 확보할 수 있지만, 해상도의 한계로 좁은 영역만 검사할 수 있다는 단점이 있다.

최근 다양한 연구에서는 초해상화(Super-Resolution, SR) 기법을 적용하여 기존 영상 정보의 해상도를 증폭시키고 이를 활용하여 성능을 개선하였다. Yoo 등은 드론 사진의 해상도를 향상시키기 위해 딥러닝 기반의 초해상화 기술을 적용했으며, Enhanced Deep Residual Networks for Single Image Super-Resolution (EDSR)와 Super-Resolution GAN (SRGAN) 모델을 이용해 탐지 및 인식률을 향상시키기는 전처리로 활용하였다[

7]. Mun 등은 전기 설비의 디스플레이 정보를 영상으로 취득한 후, 초해상화 모델인 Enhanced SRGAN (ESRGAN)을 사용해 고해상화 영상으로 변환함으로써 광학 문자 인식 성능을 향상시켰다[

8].

기존 정밀 검사 연구는 장비를 추가하거나 교정하여 검사 정밀도를 분석하는 방식이었다. 그러나 고가의 장비는 현장에 큰 부담이 되며, 하드웨어에 따른 정밀 측정 수준은 측정 속도와 반비례하기 때문에 현장 적용에는 한계가 존재한다. 본 연구는 이러한 문제를 해결하기 위해 기존 검사 장비의 구조 변경 없이 객체 검출과 초해상화 인공지능 모델을 순차적으로 적용하여 대면적 정밀 검사가 가능한 프로세스를 제안하였다. 제안한 프로세스는 실제 가공된 캐소드 시편을 기존 검사 방법과 비교하여 유효성을 검증하였다.

2. 딥러닝 모델 기반 Si-Cathode의 미세 구멍 가공 치수 대면적 검사 방법

2.1 기존 치수 검사 방법

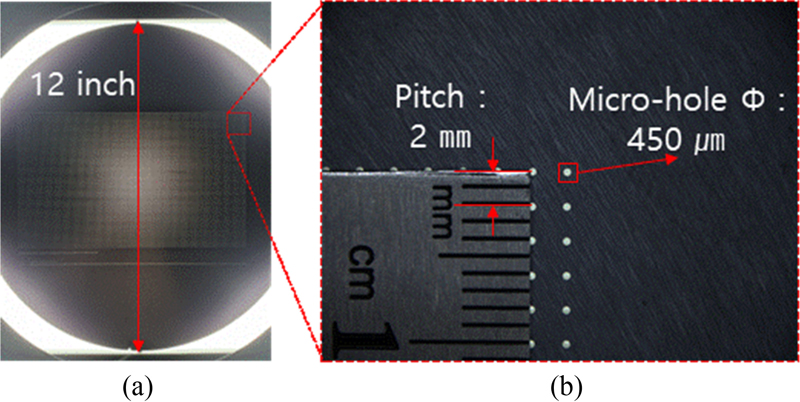

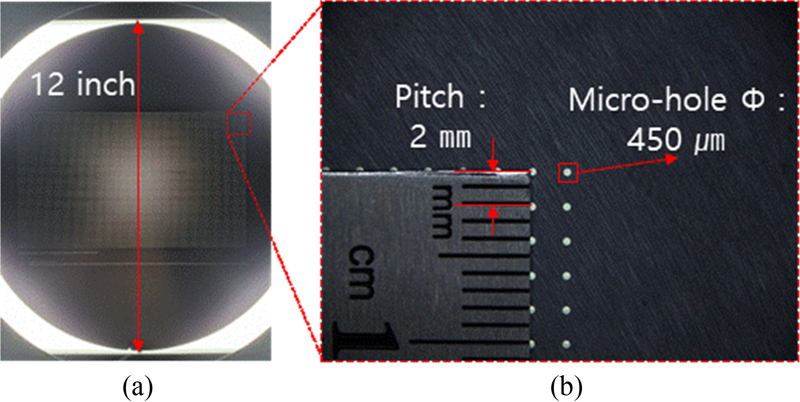

Fig. 1은 측정하고자 하는 실리콘 캐소드의 전면부(a)와 검출 대상인 미세 구멍(b)의 측정 사진을 나타낸다. 시편 크기는 12 inch (30.48 cm)이며, 미세 구멍의 직경 사양은 450 μm로, 시편 크기에 비해 매우 작다.

Fig. 1Si-Cathode specimen

본 연구에서는 알고리즘의 시험 검증을 위해 미세 구멍의 직경은 동일하게 하고 미세 구멍간 간격은 2 mm로 가공하여 시험용 시편을 제작하였다. 가공 시험 시편은 총 6,000개의 미세 구멍을 가지며, 가로 100줄, 세로 60줄의 직사각형 배열로 구성된다. 이 시편을 이용하여 본 연구에서 제안하는 프로세스를 기존 검사 방법으로 측정된 실측 값과 비교하였다.

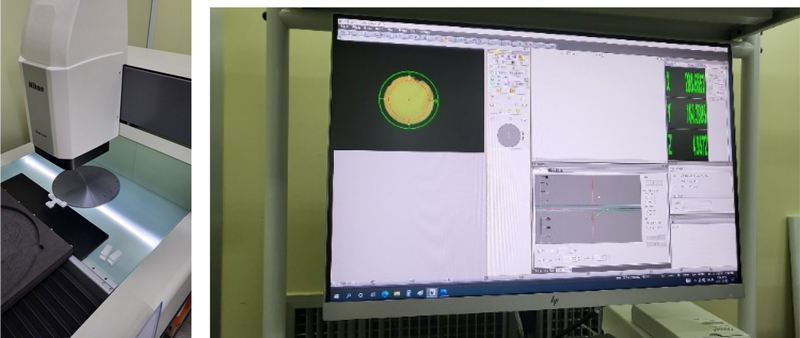

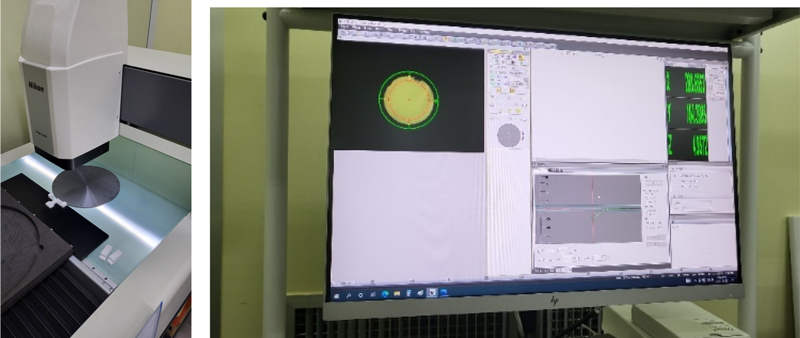

카메라 기반의 기존 측정 검사 방법은

Fig. 2에 나타나 있다. 사용한 장비는 Nikon 社의 VMA이며, 촬영되는 영상은 3.5x 배에서 Field of View (FOV)가 1.33 (w) × 1.0 mm (h)를 갖는다. 촬영된 영상은 640 × 480의 영상 크기와 2.15 μm/pixel의 픽셀 해상도(Pixel Resolution)로 얻어진다. 기존 검사 방법에서는 450 μm 크기의 홀을 확대한 후, 모션 컨트롤러를 이동하며 자동으로 측정한다. 이때, 렌즈 배율은 3.5x 배, 초점 거리는 15 cm로 조정한다. 한 개의 홀을 정밀 측정하는데 걸리는 시간은 모션 이동 및 검사를 포함하여 약 5초 소모되며, 6,000개를 모두 검사하는 데 약 8.33시간(30,000초)이 소모된다.

Fig. 2Method for measuring micro hole diameter using existing inspection equipment

기존 방법으로 측정된 미세 구멍의 영상을 분석 과정은

Fig. 2에 설명되어 있다. LED 광원을 하단 플레이트에 위치시키고, 촬영 시 빛을 수직 상단으로 투시하여 세척된 시편의 미세 구멍을 통과한 빛의 면적을 촬영한다. 이후 반사된 경계면을 영상 처리하여 직경을 얻어내는 방식이다. 미세 구멍의 영상은 가공면의 차이와 이물질 등을 전처리한 후 특성을 추출한다. 그러나, 한 번에 하나의 미세 구멍만 검사할 수 있어 이 과정을 반복하면 검사 시간이 크게 증가하는 단점이 있다. 이러한 문제를 해결하기 위해 FOV를 증가시켜 다수의 미세 구멍을 동시에 검사 할 수 있는 프로세스를 제안하였다.

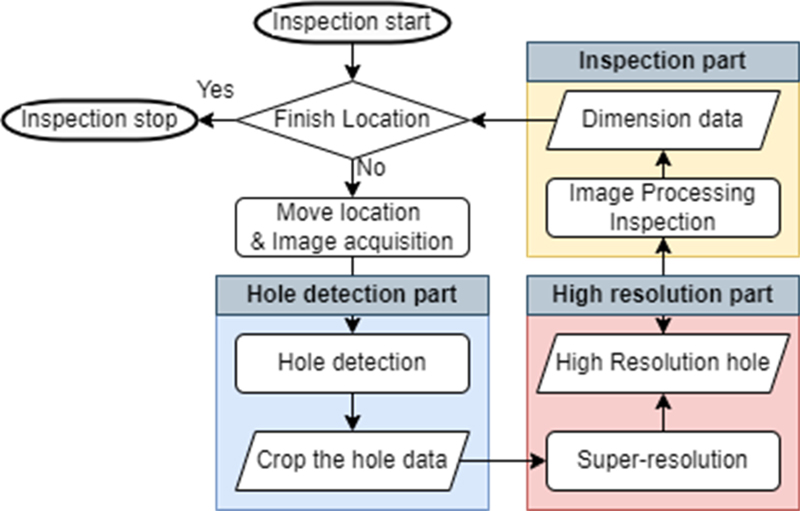

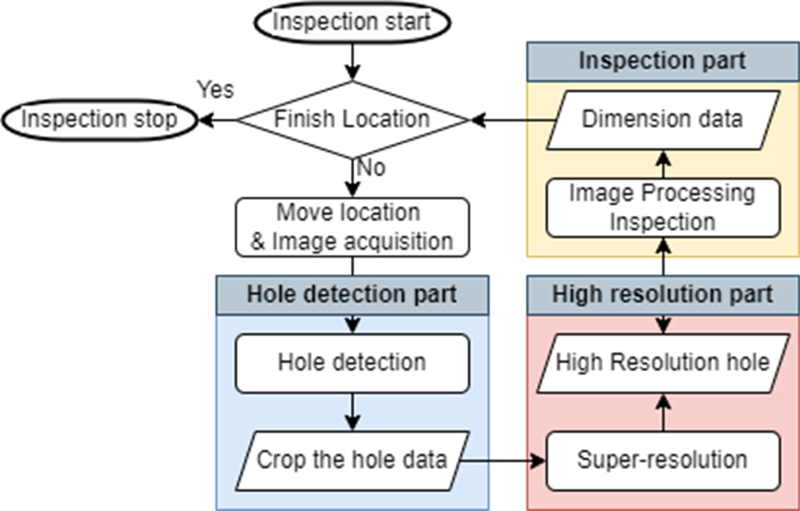

제안하는 프로세스는

Fig. 3과 같다. 프로세스 순서는 홀 검사, 초해상화, 검사 분석 부분으로 구분된다. 홀 검사 부분에서는 입력되는 비디오에서 영상 프레임을 획득한 후, YOLOv8 모델을 이용해 학습된 미세 구멍을 검출하고 영상을 추출한다. 이후, 추출된 개별 영상 데이터를 정밀 검사하기 위해 초해상화 부분에서 추출된 미세 구멍 영상의 해상도를 확대한다. 검사 분석 부분에서는 확대된 영상을 영상 처리하여 직경을 추출한다. 해당 프로세스를 통해 시험 시편에서는 최대 1.3 × 1.1 cm의 범위에서 35개의 미세 구멍 검사가 가능하다. 제안 검사 프로세스에서는 한 번에 35개의 홀을 동시에 검사할 수 있어, 산술적으로 기존 방법 대비 35배 빠른 검사 속도를 제공한다.

Fig. 3The proposed process of this study

2.2.1 직경 치수 검사를 위한 미세 구멍 영상 처리 프로그램 개발

기존 장비에 제안하는 프로세스를 이식하기 어렵기 때문에, 프로그램 개발을 통해 현장에서 기존 사용중인 현미경 측정 검사 방식을 동일한 영상처리 기법으로 모사하고 유사성을 검증하였다. 개발 환경은 NVIDIA GeForce RTX 3060 수준의 GPU를 사용하였으며, 프로그램은 Visual Studio Code에서 Python과 OpenCV 라이브러리를 활용하여 영상 처리를 구현하였다.

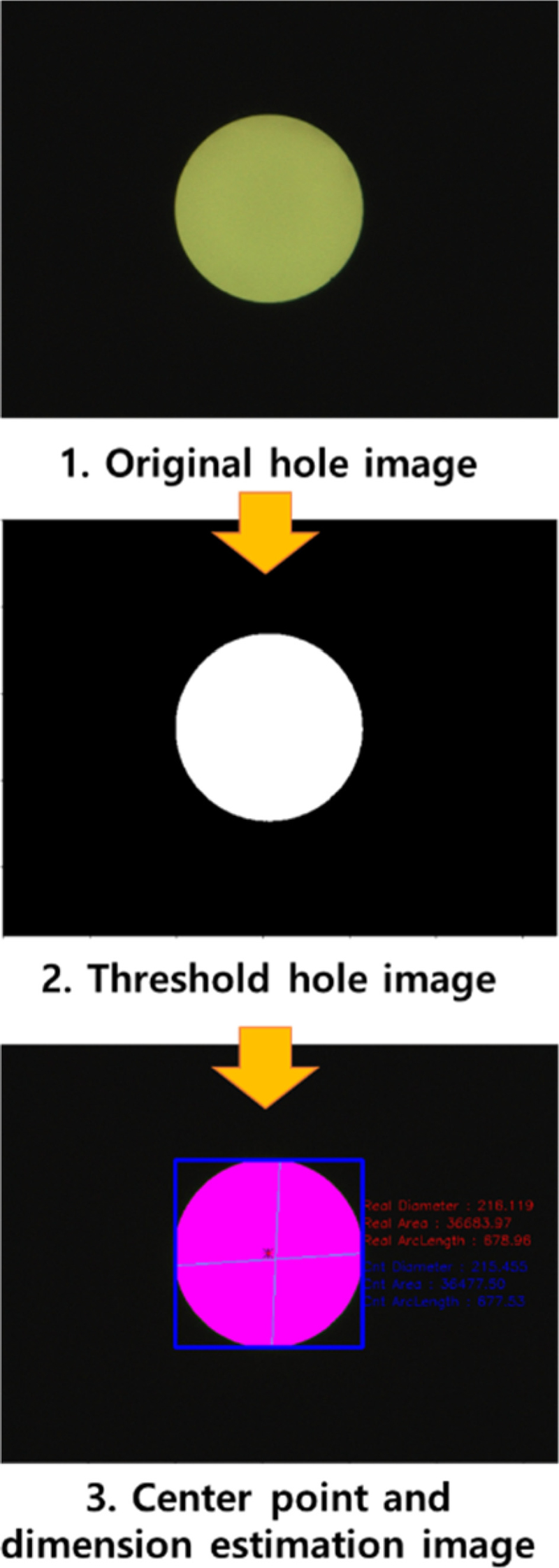

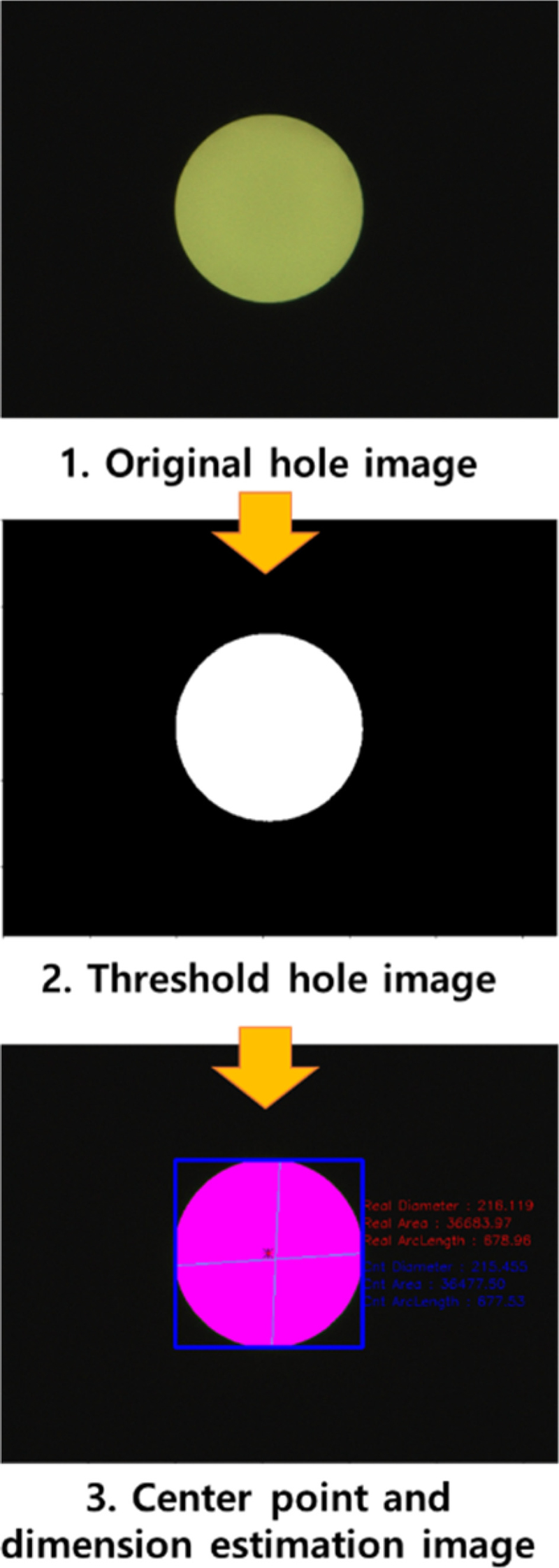

직경 치수 계산을 위한 이미지 전처리 순서는

Fig. 4와 같다. 먼저, 촬영된 미세 구멍 치수의 영상을 추출하고 원본 이미지를 읽어온다. 이후, 측정된 영상이 배경과 투과된 계면 간 색상 차이가 뚜렷한 점을 이용하여 영상의 그라디언트(Gradient)를 계산한다. 이를 기반으로 백색 투과면과 배경을 분리한 임계 영상(Threshold Image)을 생성한다. 마이크로 드릴로 가공된 미세 구멍은 원의 형태를 이루고 있어, 원의 중심과 직경을 계산하기 위해 임계 영상에서 배경과 픽셀의 기울기가 큰 경계선을 추출한다. 또한, 동일한 원리를 이용한 minEnclosingCircle 함수를 사용하여 해당 영역에 가장 최소로 접하는 원을 찾아 중심점과 직경을 계산한다. 그러나, 촬영된 미세 구멍의 영상은 세척 이후에도 검사 장비 주변의 눈에 보이지 않는 이물질이나 먼지로 인해 왜곡된 경우가 발생할 수 있다. 이때, 이전 단계에서 얻어진 중심점을 기준으로 경계선을 구성하는 양 끝 픽셀 간 가장 멀리 떨어진 치수를 실제 직경으로 추정하여 치수를 보정하였다.

Fig. 4Hole Image processing procedure

이때, 측정된 직경의 길이 단위는 영상의 픽셀 이므로, 계산된 직경의 길이를 장비의 픽셀 해상도 값인 2.54 μm/pixel로 곱하여 실제 치수로 환산하였다. 픽셀 해상도 값은 사양 값을 참고하고, 사전에 직경의 길이를 정확히 알고 있는 미세 구멍을 촬영하여 실제 길이를 측정된 픽셀 개수로 나누어 구할 수 있다.

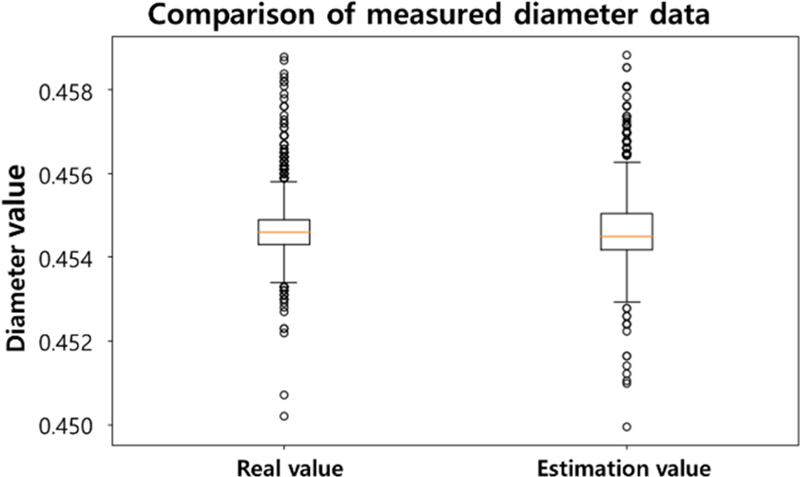

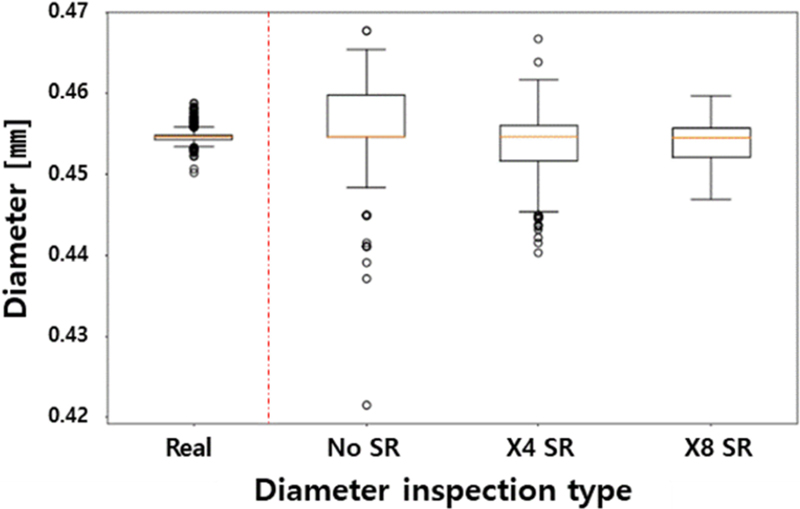

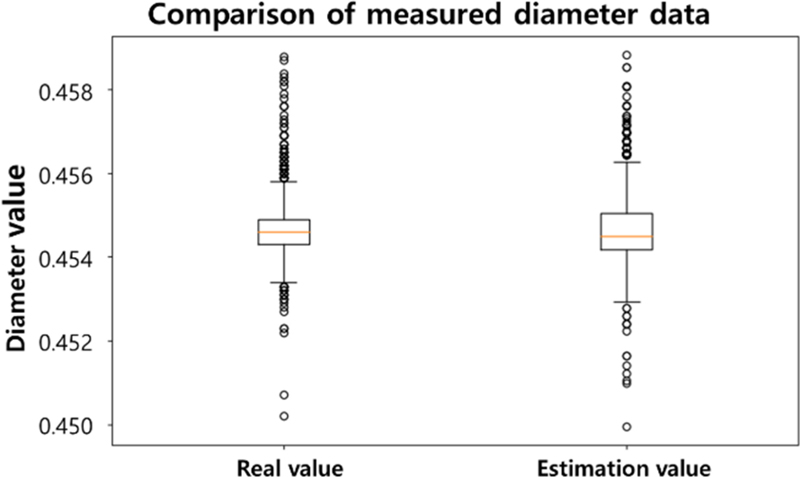

모사한 영상 처리 프로그램을 통해 추정된 직경 값을 실제 측정 값과 비교하여 영상 처리 기법의 활용도를 평가하였다. 평가 방법으로는 검사 장비로부터 얻은 640 × 480 해상도의 실측 영상을 기반으로 위의 영상 처리 기법을 적용한 후, 실측 값과 비교하였다. 그 결과, 각 미세 구멍 직경의 개별 절대오차 평균은 0.125 μm 수준이며, 오차율 평균은 0.151% 이다. 직경의 실측치와 추정치의 분포는

Fig. 5의 상자수염그림(Boxplot)으로 시각화하였다. 실제 가공 과정에서는 마이크로 드릴의 마모에 따라 가공 치수가 감소하게 된다. 이때, 가공된 전체 미세 구멍 6,000개의 치수에 대해, 실제 측정한 실측 직경(Real Diameter)과 영상 처리 기법으로 추정한 직경(Estimation Diameter)을

Table 1에 비교하여 제시하였다. 6,000개의 직경 치수에 대한 절대 오차를 비교하기 위해 실측 직경과 추정 직경의 평균 및 표준편차를 비교하였으며, 오차 수준이 1/10 μm 수준으로 나타나 영상 처리 기법을 품질 검사에 활용할 수 있을 것으로 판단하였다. 이때, 상대오차를 백분율로 나타낸 백분율 오차는 아래

수식(1)을 이용하여 계산하였다. 여기서

n은 입력한 이미지의 개수를 나타내고,

i번째 이미지에 대해서

Ei는 추정치,

Ri는 실측치로 정의된다.

Fig. 5Comparison of image processing results boxplot

Table 1Comparison of measured diameter

Table 1

|

Mean [mm] |

Standard dev. [mm] |

Mean error rate [%] |

|

Measured diameter |

454.5 |

0.508 |

- |

|

Estimated diameter |

454.4 |

0.634 |

0.151 |

2.2.2 대면적 영상 속 미세 구멍 검출 방법

본 연구에서는 영상 내 미세 구멍을 검출하기 위해 딥러닝 기반 객체 검출 방법을 도입하였다. YOLOv8은 실시간 객체 탐지를 위한 최신 YOLO(You Only Look Once) 모델로, 경량화와 성능 향상을 목표로 개발되었다[

9]. 이 모델은 입력 이미지를 그리드로 나누어 각 그리드 셀에서 객체의 존재 확률과 경계 상자의 위치를 직접 예측한다. YOLOv8은 ResNet과 같은 딥러닝 아키텍처를 백본 네트워크로 사용하여 특징을 추출하며, 다양한 컴퓨터 비전 작업에서 뛰어난 성능을 발휘한다

YOLOv8의 검출 프로세스는 다음과 같은 순서를 따른다. 먼저, 입력된 영상을 모델의 입력층으로 전달하고, 백본 네트워크에서 영상 내 다양한 특성을 추출한다. 이 정보를 객체 탐지 네트워크로 전달하여 다양한 크기의 그리드 셀로 이미지를 세분화하고, 각 셀에서 객체의 위치와 분류에 대한 정보를 예측한다. 예측된 정보는 개체의 좌표, 분류 값, 예측 확률 등의 정보를 포함하는 사각형의 박스로 시각화된다.

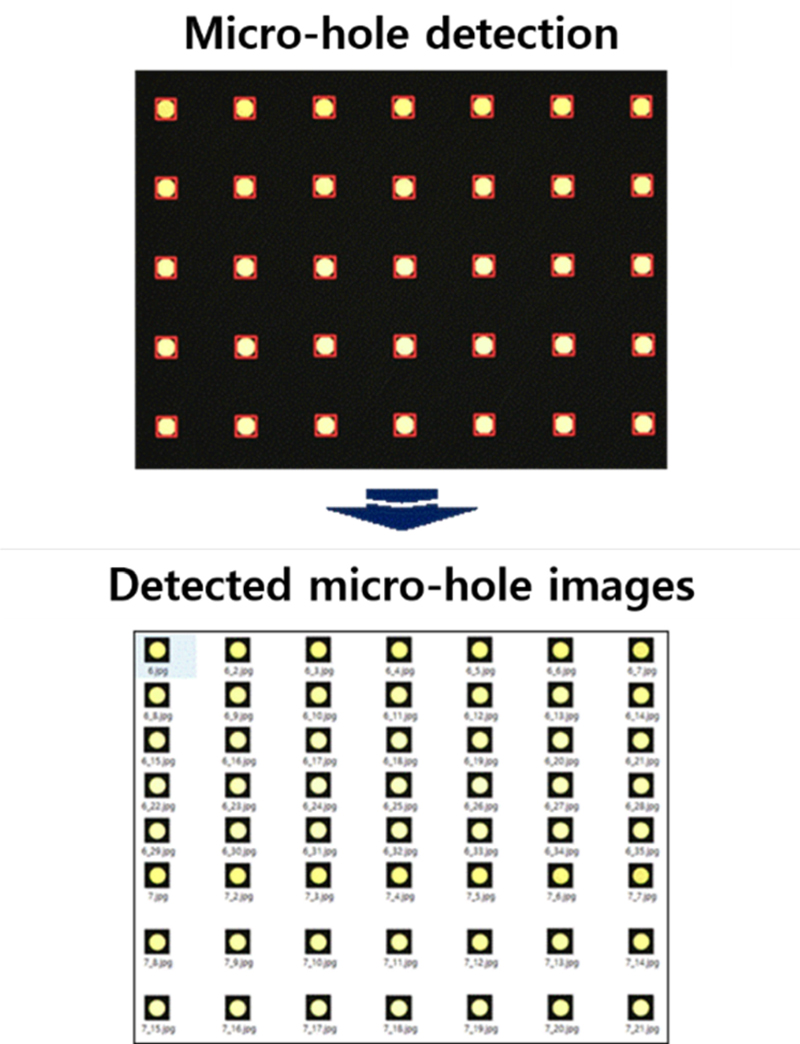

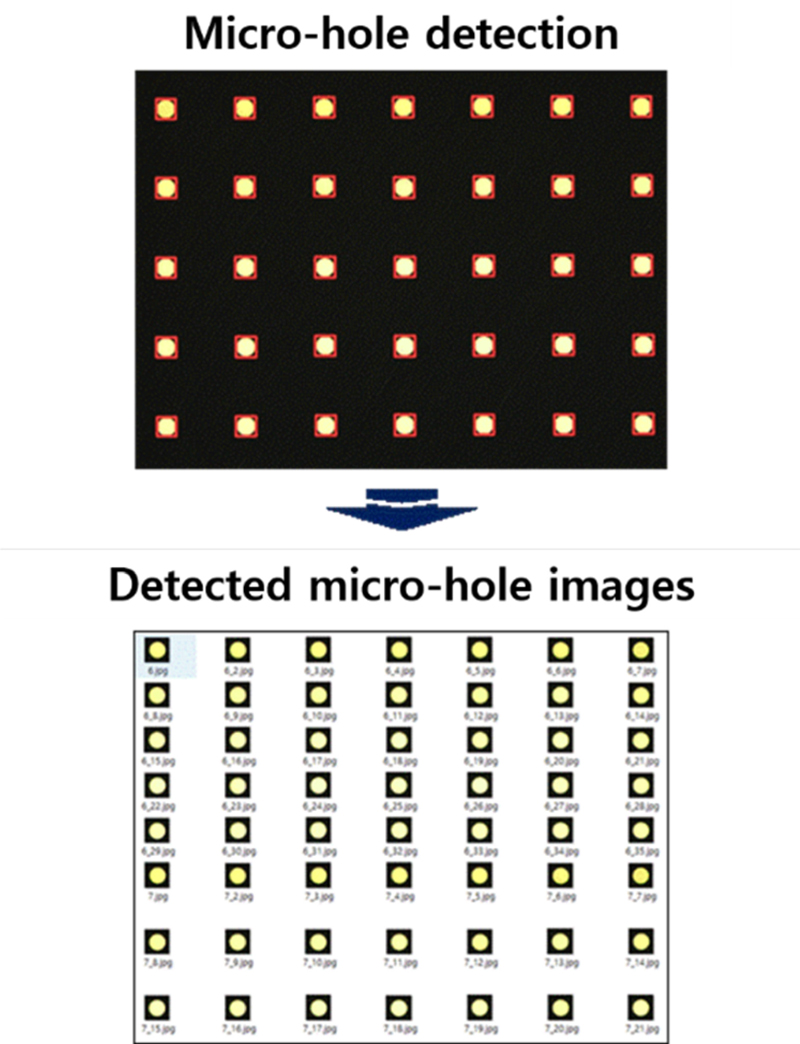

본 연구에서는 ImageNet 데이터로 사전 학습된 YOLOv8을 기본 네트워크로 활용하여, 시험 시편의 데이터를 직접 라벨링하고 전이 학습을 진행하였다. 시험 시편에서 촬용한 다수의 미세 구멍 영상을 바탕으로 작은 미세 구멍 영상들을 학습 데이터로 확보하였다. 이후, 전이 학습된 모델을 이용하여 미세 구멍의 객체 검출을 수행하였다. 아래

Fig. 6은 전이학습 모델을 통해 영상처리에 활용할 미세 구멍 영상들을 검출하는 과정을 보여준다.

Fig. 6Example of labeling data used for learning micro hole detection

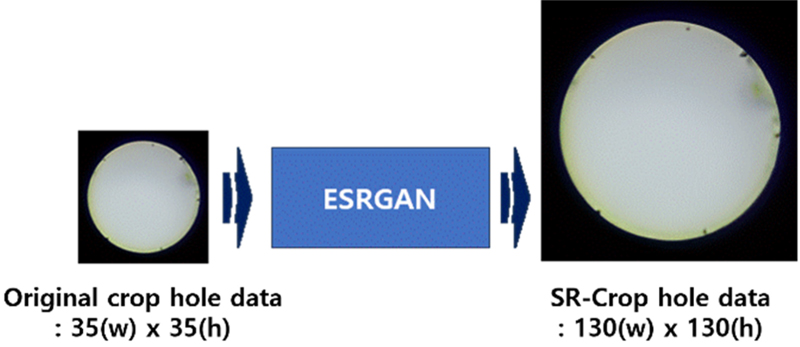

2.2.3 대면적화 검사를 위한 초해상화 방법

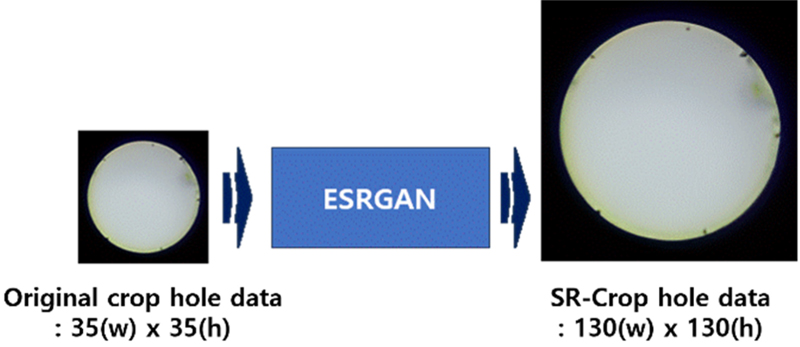

추출된 미세 구멍 영상의 크기는 35 × 35 픽셀 해상도를 갖는다. 이는 직경을 추정하는 영상 처리 알고리즘에 픽셀 해상도가 2.15 μm에 비해 매우 낮은 12.85 μm 수준이므로, 한 픽셀 당 약 6배의 정보 손실이 발생한다. 따라서, 기존의 검사 방법과 비교하기 위해서는 영상 자체의 해상도를 대폭 높일 필요가 있다.

본 연구에서는 초해상화 모델로 ESRGAN을 사용하였다[

10]. ESRGAN은 적대적 생성 신경망을 활용한 초해상화 기법인 SRGAN 구조를 기반으로 하며, ResNet의 잔차 학습과 DenseNet의 조밀한 연결 구조를 적용하여 네트워크 깊이를 더욱 깊게 하고 비선형성을 높여 풍부한 특징을 추출할 수 있도록 설계되었다. 이를 통해 데이터 학습을 통해 더 높은 특징 인식률을 얻을 수 있다. 본 연구에서는 ESRGAN의 풍부한 특징 추출 능력을 활용하여 대면적 영상에서 검출된 미세 구멍 영상의 픽셀 해상도를 높임으로써 구멍 직경 측정의 정밀도를 향상시키는 초해상화 기법을 적용하였다.

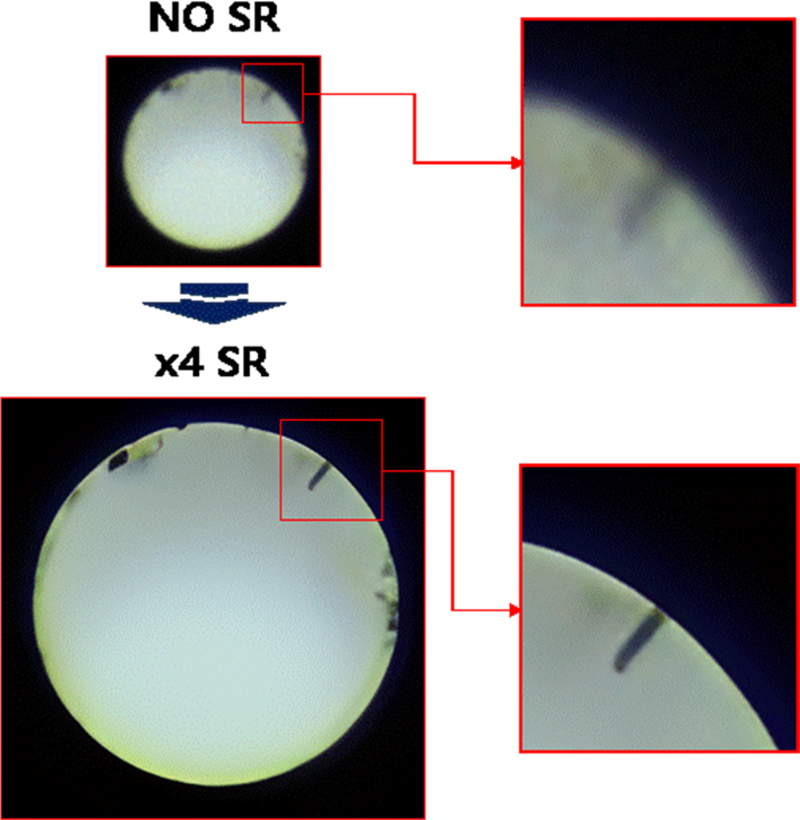

Fig. 7은 ESRGAN 모델을 미세 구멍 영상에 적용한 그림이다.

Fig. 7Micro hole data using super-resolution techniques

3. 실험 및 고찰

3.1 실험 데이터셋 준비

제안한 프로세스를 학습하고 평가하기 위해 본 논문에서 마이크로 드릴을 이용하여 직경 사양이 450 μm인 6,000개의 미세 구멍을 직접 가공하고 측정하였다. 이 시편을 검사 대상으로 하여, 본 연구에서 제안하는 대면적 검사 방법의 객체 검출 및 초해상화 결과에 따른 검사 성능 분석과 실행 시간을 기존 방식과 비교하였다. 또한, 실제 측정된 직경 치수와 객체 검출 후 초해상화 전후의 치수를 바탕으로

식(1)의 오차율을 계산하여 평가하였다.

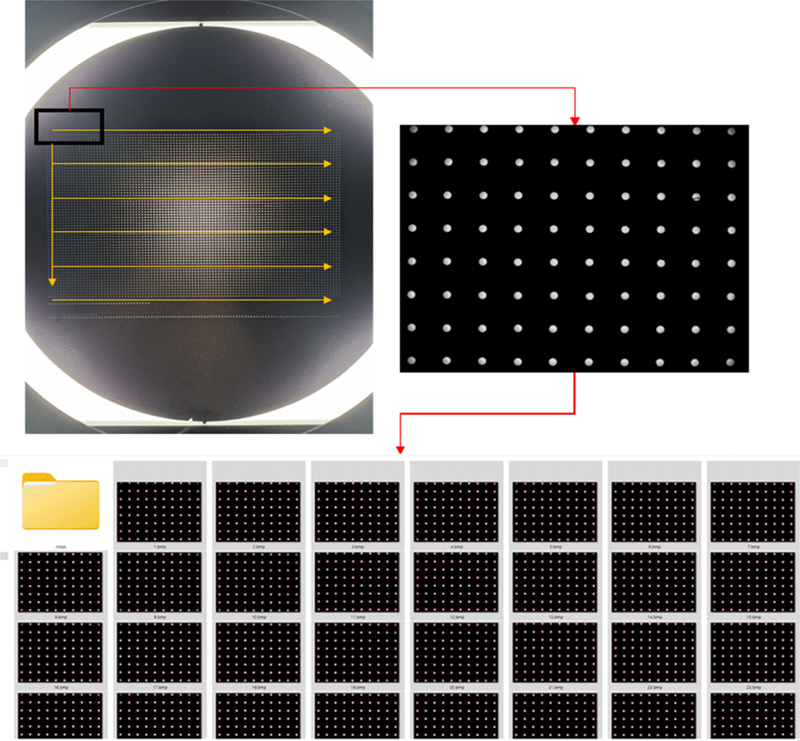

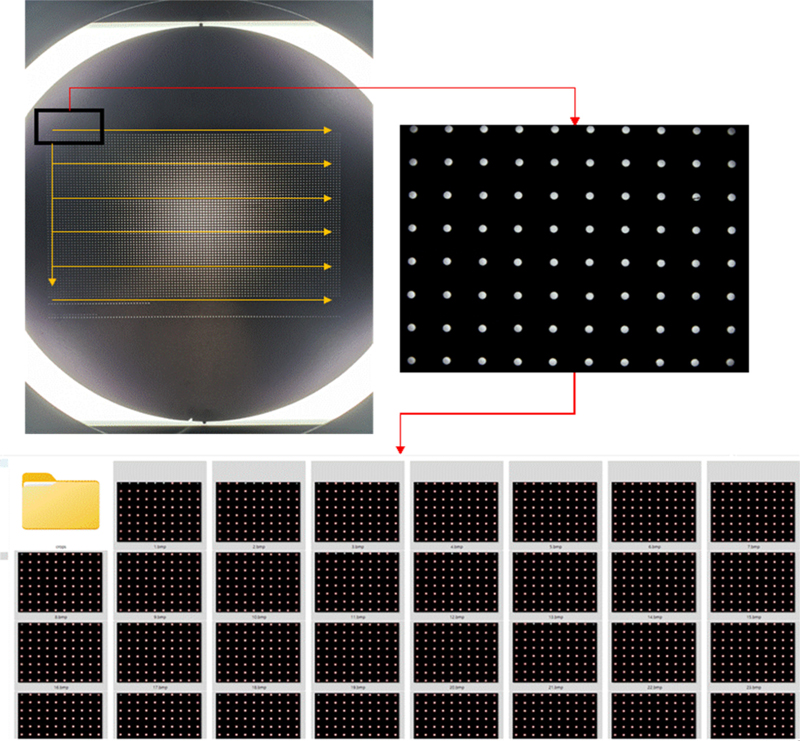

Fig. 8Large-area image-based object detection experiment

3.2 대면적 영상 기반 미세 구멍 영상 검출

기존 검사 장비에 제작한 시편을 위치시키고, 1x배율의 렌즈로 조정하여 최대 1.3 × 1.1 cm의 범위의 한 영상에서 가로 7개, 세로 5개의 총 35개의 미세 구멍이 촬영되도록 조정하였다. 이와 같은 방식으로 촬영된 대면적 촬영 영상은 총 200개이며, 한 영상당 35개의 미세 구멍이 촬영되어 시편 전체 6,000개의 미세 구멍을 분석하였다. 대면적 영상을 이용하여 객체 검출을 시도하고, 해당 미세 구멍 영상들을 모두 부분 추출하였다. 아래

Fig. 9와 같이 시편에 포함된 모든 미세 구멍은 중복 없이 6,000개가 모두 검출되어 치수 검사 결과에 활용될 수 있도록 하였다.

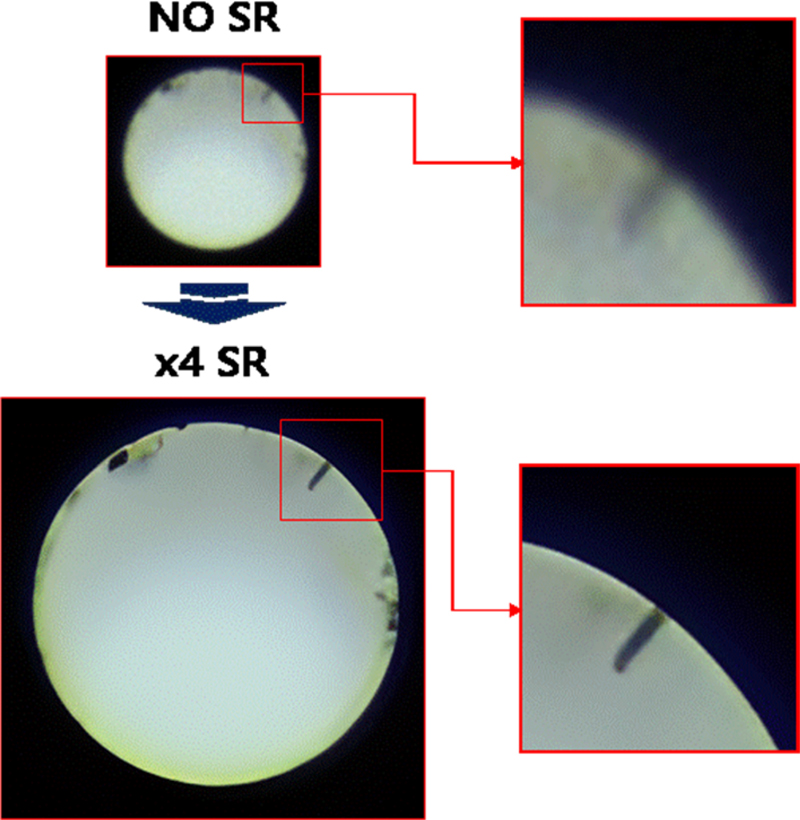

Fig. 9Comparison before and after super resolution

3.3 영상 초해상화 추출 성능 평가

대면적 검사를 수행하는데 앞서, 저해상도로 추출된 미세 구멍 영상의 픽셀 크기는 약 35(w) × 35(h) 해상도를 갖는다. 직경 사양이 450 μm임을 고려할 때, 1픽셀 당 약 12.85 μm에 해당한다. 기존 검사 방식에서는 216(w) × 216(h) 크기의 영상에서 1픽셀당 2.05 μm의 해상도로 직경을 추정하였다. 따라서 기존 검사 방식과 유사한 수준으로 비교하기 위해, 가로 x4(4배) 및 세로 x4(4배)의 초해상화를 통해 픽셀 해상도를 확보하는 것이 필요하다.

Fig. 9는 초해상화 전과 후를 동일한 크기로 비교한 결과이다. 초해상화 후 질감과 추정되는 크기를 더 선명하게 비교할 수 있다.

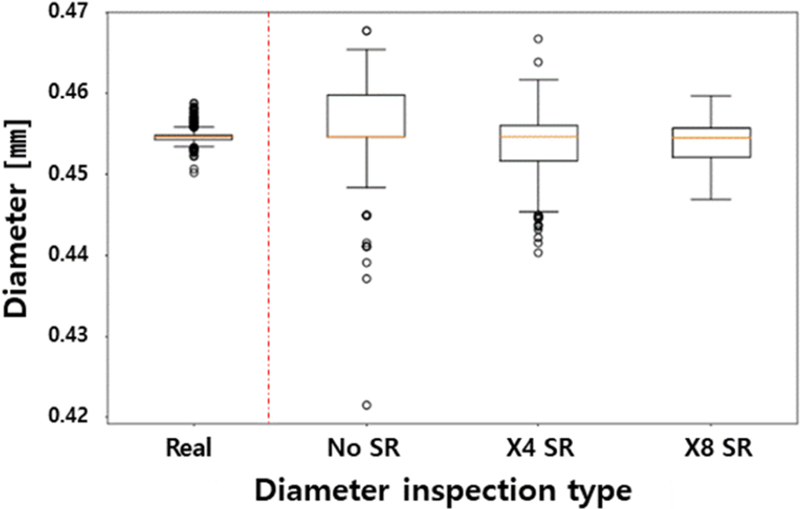

대면적 촬영 영상에서 초해상화를 진행하지 않은 미세 구멍의 영상의 픽셀 해상도는 12.85 μm/pixel이다. 이후, 초해상화 모델을 사용하여 4배, 8배 수준의 고해상도로 개선한 결과는 아래

Table 2와 같이 약 5.01, 2.50 μm/pixel 수준으로 감소하여 초해상화를 적용하지 않은 영상 대비 더욱 정밀한 정보를 표현할 수 있었다.

식(1)을 이용해 측정 오차율을 계산한 결과, 초해상화 배율이 증가함에 따라 오차율도 감소하는 것을 확인할 수 있었다. 1개의 미세 구멍을 초해상화한 후 직경 측정하는 데 걸리는 시간은 x4 초대상화의 경우 0.001 s, x8 초해상화의 경우 0.470 s가 소요되었다.

Fig. 10은 상자수염그림을 이용하여 좌측부터 실측 값, 초해상화 전, 후 (x4, x8) 값의 분포를 보여준다. 고해상화가 될수록 정보 추정의 정확도가 향상되었으며, 추정 오류의 산포가 감소함을 확인할 수 있다.

Table 2Comparison of super-resolution results

Table 2

|

No SR |

x4 |

x8 |

|

Pixel resolution |

12.85 |

5.01 |

2.5 |

|

Error [%] |

0.7072 |

0.544 |

0.5042 |

|

Time [s/image] |

0.001 |

0.32 |

0.47 |

Fig. 10Comparison before and after super resolution

4. 결론

본 논문에서는 미세 구멍 가공 치수를 고속으로 검사하기 위해 광각으로 대면적 영상을 획득하여 딥러닝 모델과 영상처리 기술을 적용한 프로세스를 제안하였다. 기존의 방식은 수천 개의 미세 구멍마다 영상을 획득하여 치수를 검사했으나, 제안된 방식은 넓은 영역을 한 번에 검사하며 객체 탐지와 초해상화 복원 딥러닝 기법을 주로 활용하였다. 결과적으로 직경 측정 오차율은 0.5042% 수준으로, 기존의 치수를 개당 0.470 s 이내로 측정할 수 있다. 이는 기존의 1개당 약 5 s가 소요되던 검사 시간에 비해 모션 컨트롤러의 이동 없이도 측정 효율이 10배 이상 향상되었음을 보여준다. 따라서 제안하는 방법을 활용하면 정밀 부품의 대면적화 측정을 통해 빠른 검사를 진행할 수 있다.

개발된 검사 프로세스는 기존 영상 장치의 사양을 변경하지않고, 속도와 정확도가 높은 딥러닝 모델을 학습하여 적용하였다. 제안된 프로세스를 실무에서 활용하기 위해서는 현장의 검사 시편을 이용한 치수 검사의 교정과 같은 정밀 고도화 기술 개발이 추가로 필요하다. 또한, 대면적 영상 프레임들을 이어 붙여 정합 하여 연산 처리하고, 검사 장치 이동을 독립적으로 구동하는 것도 실무에서 활용 가능한 방법이다. 향후, 현장 적용을 위해 컨트롤러와 연계한 자동 측정 기능을 추가하여 편의성을 개선하고, 검사 정확성을 높이기 위한 알고리즘 개발을 진행할 예정이다.

ACKNOWLEDGMENTS

본 논문은 중소벤처기업부에서 지원하는 2024년도 산학연플랫폼 협력기술개발 (R&D) 및 중소기업 기술혁신개발(Nos. 2420003527 and 2420000604)의 연구수행으로 인한 결과물임. 또한 2024년도 산업통상자원부(MOTIE) 및 한국산업단지공단의 연구비 지원으로 수행되었음(SG20240201). 연구에 도움을 주신 ㈜제이머티리얼즈에 감사드립니다.

REFERENCES

- 1.

Eum, J.-H., Chae, J.-M., Pee, J.-H., Lee, S.-M., Choi, K., Kim, S.-J., Hong, T.-S., Hwang, C.-H., Ahn, H.-J., (2010), Effect of defects on lifetime of silicon electrodes and rings in plasma etcher, Journal of the Korean Crystal Growth and Crystal Technology, 20(2), 101-105.

10.6111/JKCGCT.2010.20.2.101

- 2.

- 3.

Lee, E. Y., Choi, W. K., Yoo, J. H., (2017), Cutting condition optimization of micro hole for single crystal silicon, Journal of the Korean Society for Precision Engineering, 34(8), 551-555.

10.7736/KSPE.2017.34.8.551

- 4.

Mital, A., Govindaraju, M., Subramani, B., (1998), A comparison between manual and hybrid methods in parts inspection, Integrated Manufacturing Systems, 9(6), 344-349.

10.1108/09576069810238709

- 5.

Kang, M., Cheoi, K. J., Ko, P., (2023), Simultaneous multi-position and multi-part vision inspection with low-cost UVC cameras, Journal of Korea Multimedia Society, 26(9), 1097-1104.

10.9717/kmms.2023.26.9.1097

- 6.

Ko, K. W., Lee, J. Y., (2023), Development of a visual inspection system for wafer handling with collets, Journal of the Korean Society of Manufacturing Technology Engineers, 32(1), 29-36.

10.7735/ksmte.2023.32.1.29

- 7.

Yoo, S., Kim, P, Youn, J., (2023), Improving the spatial resolution of drone images using a deep learning-based super-resolution, Journal of the Korean Society of Surveying, Geodesy, Photogrammetry and Cartography, 41(6), 651-660.

10.7848/ksgpc.2023.41.6.651

- 8.

Song, H.-J., Mun, J.-H., Lee, K.-Y., Chae, D.-J., Lim, S.-T., (2022), A study on status information extraction of electrical installations through image super-resolution based on ESRGAN, The Transactions of The Korean Institute of Electrical Engineers, 71(10), 1497-1504.

10.5370/KIEE.2022.71.10.1497

- 9.

Kim, C. D., Baek, S. W., Chung, W. J., Lee, C. W., (2024), Defect detection in the forging process of wheel nut products through object detection, Journal of the Korean Society for Precision Engineering, 41(4), 279-286.

10.7736/JKSPE.023.147

- 10.

Wang, X., Yu, K., Wu, S., Gu, J., Liu, Y., Dong, C., Qiao, Y., Change Loy, C., (2018), ESRGAN: Enhanced super-resolution generative adversarial networks, Proceedings of the European Conference on Computer Vision (ECCV) Workshops.

10.1007/978-3-030-11021-5_5

Biography

- Jonghyeok Chae

Ph.D. candidate in the School of Mechanical Engineering, Pusan National University and Senior Researcher at KETI. His research interests include machine vision and PHM.

- Dongkyu Lee

Received Ph. D. degree from the School of Electronic and Electrical Engineering at Kyungpook National University in 2024. He has been working as a Senior Researcher at KETI since 2024. His research interests include energy-efficient edge devices with hardware acceleration.

- Seunghun Oh

Received a Ph. D. degree from the School of Nano Engineering, Pusan National University in 2011. He has been working as a Chief Researcher at KETI since 2011. His research interests include sensors, signal processing, and semiconductors.

- Yoojeong Noh

Professor in the School of Mechanical Engineering at Pusan national University. Her research interests include uncertainty quantification, surrogate modeling, and PHM.