ABSTRACT

The goal of this research is to develop intelligence data analytics system for quality enhancement of die-casting process. Targeting a die-casting factory in Korea, we first constructed an edge device-based infrastructure with wireless communication environment for data collection and a processing infrastructure to support the intelligence data analytics system. Using the real quality regarding data of the target factory, we developed two data analytics models for defect prediction and defect cause diagnosis using AdaBoostC2 algorithm. Accuracy of the developed data analytics model for defect prediction was verified as 86%. To use the developed data analytics model efficiently and produce a sequential process of data analytics model generation, execution, and update were conducted automatically. The edge device and integrated server-based dualized analysis system was proposed. The developed intelligence data analytics system was applied to the target factory, and the effectiveness was demonstrated.

-

KEYWORDS: Data analytics, Die-casting process, Dualized data analytics system, Edge device, Intelligence system, Smart factory

-

KEYWORDS: 데이터 분석, 다이캐스팅 공정, 이원화 데이터 분석 시스템, 엣지 디바이스, 지능화 시스템, 스마트 공장

1. 서론

국내 다이캐스팅 산업 대다수의 기업들은 영세한 기업의 비중이 높고, 공장의 ICT (Information and Communications Technologies) 기반 정보화 및 스마트화에 대한 인식 부족으로 인해 공장의 스마트화가 지진하게 이루어지고 있는 실정이다. 또한, 다이캐스팅 장비에서 제품을 성형할 때 투입되는 소재량의 불균형, 금형 온도 변화, 용탕 청정도 확인 미흡, 주조 압력 및 냉각 조건 변화 등의 주조 조건 관리의 어려움으로 인한 주조결함 발생, 현장 작업자들의 표준화된 작업조건 임의 변경으로 인한 공정 불량률 증가 및 공장 가동률 저하 등의 제조 현장의 문제들에도 불구하고 이를 위한 체계적인 방법론 및 시스템의 부재로 어려움을 겪고 있다. 특히, 주조 조건에 따라 발생하는 주조결함의 경우, 다이캐스팅 공정의 특성상 주조 공정 이후 가공, 사상 공정 등의 전 공정이 끝나야 결함 여부를 정확히 알 수 있기 때문에 생산성 향상과 제품 납기 준수를 위해 관리의 중요성이 크게 강조된다. 시장의 요구사항을 충족시키면서 현장에서 직면하고 있는 문제점을 체계적으로 해결하고, 산업의 경쟁력 확보를 위해서는 고성능 제품뿐 아니라 제품을 효율적으로 생산하기 위한 생산 현장의 스마트화 기술이 필요하다. 2017년 한국생산기술연구원

1에서 발간된 “뿌리공정 스마트화 전략 도출을 위한 연구” 최종보고서에 따르면, 스마트화의 핵심요소는 1) 공정기술 디지털화, 2) 데이터 활용, 3) 기업전용 전산망 및 서버 구축, 4) 설비의 컨트롤보드에 대한 접근, 5) 융합 인재 양성, 6) 스마트공장에 대한 긍정적 인식 및 도입 노력, 7) 기업 맞춤형 구축 총 일곱 가지로 정의된다. 본 연구에서는 국내 다이캐스팅 산업 내 1개 업체를 선정하여 7개 핵심 요소의 융합·적용함으로써 생산 공정의 스마트화를 실현하고자 한다. 본 연구의 최종 목표는 설비 인터페이스를 통해 수집된 데이터를 처리하고 분석하여 품질고도화를 위해 품질 관련 인자들의 분석을 지원하는 시스템으로 정의되는 ‘다이캐스팅 공정의 품질고도화를 위한 지능화 분석 시스템’의 개발로 주요 개발 내용은 다음과 같다. 첫째, 대상 공장을 대상으로 공정 지능화 기술을 지원하기 위한 엣지 디바이스 기반 무선통신 환경의 데이터 수집/처리 인프라를 구축한다. 둘째, 대상 공장의 주조 공정의 품질 관련 데이터들을 분석하는 불량 예측 모델과 불량 원인 진단 분석 모델을 개발한다. 셋째, 데이터 분석 모델의 학습 및 재학습, 실행의 과정을 효율적으로 연계하고 자동화할 수 있는 엣지-서버 연계 이원화 분석 시스템 구조를 설계하고 개발한다.

다이캐스팅 산업을 대상으로 한 품질 데이터 분석 및 시스템 적용과 관련된 선행 연구로는 Lee et al.

2이 진행한 연구가 있다. 해당 연구에서는 자동차 엔진 부품을 생산하는 주조 공장을 대상으로 주조 금형 온도 데이터를 활용하여 제품의 불량을 예측하는 랜덤포레스트 기법 기반의 데이터 분석 알고리즘을 개발하고, 개발한 알고리즘을 현장에 적용하였다. 또한 불량 예측 결과를 가시화하고 해당 결과를 활용하여 공장 운영을 지원할 수 있는 대시보드를 개발하였다. 다이캐스팅 이외의 제조 산업에서도 데이터 분석 기법을 활용하여 제품의 품질을 예측하거나 설비의 상태를 진단하고자 하는 연구는 꾸준히 진행되었다. Widodo and Yang

3은 Multi-Class Support Vector Machine 기법을 활용하여 설비 고장 데이터의 특성 값을 기반으로 한 설비 고장 진단 모델을 개발하였고, 개발한 모델이 베어링, 인덕션 모터, 컴프레서, 터빈 등 설비의 각 부품에 적용될 수 있다고 주장하였다. Yang et al.

4은 시계열 기반의 회귀 나무 분석 기법을 활용하여 설비의 잔존 수명을 예측하였는데, 설비의 고장 주기를 예측하여 사전에 작업자들에게 알람을 주는 시스템을 개발함으로써 공장의 설비 활용 효율을 극대화 시키고자 하였다. Chen et al.

5은 Adaptive Neuro-Fuzzy 기법과 High Order Particle Filtering 기법을 활용하여 설비의 상태를 예측하는 분석 모델을 개발하였다. 의사결정나무, Support Vector Macine, 랜덤포레스트 기법 등의 전통적인 머신 러닝 기법을 적용한 결과와 개발한 데이터 모델을 적용한 결과의 예측 정확도를 비교함으로써 개발한 데이터 분석 모델의 우수성을 입증하였다. Ali et al.

6은 와이블 분포 기반의 인공 신경망 기법을 활용하여 베어링의 잔존 수명을 예측하는 연구를 수행하였고, 베어링의 상태를 7개의 클래스로 구분하여 현재 베어링 상태 또한 함께 예측하는 데이터 분석 모델을 개발하였다. Hong et al.

7은 플랜트 공정 FD FAN 설비의 이상 상태 예측을 위해 센서 데이터를 분석하고 Nonlinear ARX 모델을 개발하였다. 또한 Kwak and Kim

8은 주조품의 피로 수명 예측을 위해 LEFM 기반 내부결함 모델링 기법을 사용하였고 Kim et al.

9은 딥러닝 기술을 활용하여 저항점 용접의 불량을 판별하는 모델을 개발하였다. Chen et al.

10은 Computerized Numerical Control (CNC) 가공설비 도구의 고장 상태를 진단하고 고장을 사전에 경고하기 위한 에너지 이상 나무 진단 기반의 가공설비 도구 진단 방법을 제시하였다. 또한 소비 전력, 전류, 온도, 진동 등의 데이터를 활용한 에너지 이상 진단 나무 알고리즘을 실제 현장에 적용해본 결과 설비 도구의 이상으로 인한 가공 불량이 50%가량 줄어든 것을 확인하였다. Li et al.

11은 설비의 고장을 진단하기 위해 사전에 고정적으로 정의된 유사도 행렬이 아닌 가변적으로 변화하는 기하 정보를 반영한 유사도 행렬을 고려한 Extreme Learning Machine Autoencoder (ELM-AE)를 개발하였다. Qian et al.

12은 회전기의 고장을 진단하기 위해 Adaptive Batch Normalization (AdaBN), Deep Neural Network (DNN), Stacked Autoencoder (SAE)를 활용한 세 단계의 Deep Transfer Learning 네트워크를 개발하였다. You et al.

13 또한 회전기의 고장을 진단하기 위한 Deep Feature Learning 방법을 제안하였는데 기존의 Convolutional Neural Network (CNN)을 발전시킨 Rectified Linear Units (ReLU)-CNN 기법을 개발하였다. Liu et al.

14은 전자기기의 고장 상태를 진단하기 위해 전자 기기의 진동 데이터의 형태를 활용한 Dislocate층, Convolutional층, Sub-Sampling층, 그리고 Fully Connected층으로 구성되어 있는 Dislocated Time Series CNN (DTS-CNN) 기법을 개발하였다. 이와 같은 선행 연구들은 주로 데이터 분석 모델의 학습에 초점이 맞추어져 있고, 데이터 분석 모델의 학습 및 재학습과 현장에서의 데이터 분석 모델 실행의 자동화된 시스템적 연계는 고려하고 있지 않다. 본 연구에서는 품질고도화를 위한 데이터 분석 모델의 학습과 재학습, 데이터 분석 모델의 실행을 효율적으로 연계하고 자동화하기 위한 엣지 디바이스와 통합 서버로 이원화된 시스템적 접근을 통해 데이터 분석 모델의 현장 적용 이슈를 고려한 지능화 분석 기술을 개발한다. 국내 다이캐스팅 산업군에 해당하는 기업의 공장을 대상 공정으로 선정하여 현장 실데이터를 기반으로 불량 예측 모델과 불량 원인 진단 모델 등의 품질 데이터 분석 모델을 개발하고, 지능화 분석 기술을 현장에 적용하여 분석 기술의 효과성을 실증한다.

본 논문의 구성은 다음과 같다. 2장에서는 지능화 분석 기술을 개발하기 위한 데이터 수집 및 처리 인프라 구축과 관련된 내용을 다루고, 3장에서 개발한 품질 데이터 분석 모델을 소개한다. 4장에서는 엣지 디바이스와 통합 서버로 이원화된 분석 시스템을 소개하고 5장에서 결론과 향후 연구 진행 내용에 대해 토의한다.

2. 데이터 수집 및 처리 인프라 구축

2장에서는 다이캐스팅 공정의 품질고도화를 위한 데이터 수집, 처리, 분석 기반 공정 지능화 기술 개발을 위한 엣지 디바이스 기반 무선 통신 네트워크 데이터 수집 및 처리 인프라 구축 관련 내용을 다룬다.

2.1 대상 공장 현황

본 연구의 대상이 되는 대상 공장은 주조 및 정밀가공을 기반으로 하는 제품군을 생산하는 공장으로서 주요 생산 제품은 정밀금형, HDD와 SDD 케이스와 같은 전자 부품, 하우징과 실린더 등의 자동차 부품이다. 대상 공장의 주요 공정은 금형에 용탕물을 받아 Shot을 찍어 제품을 생산하는 주조 공정, 주조 공정 이후 디케이팅된 제품에 붙어있는 불필요한 부분을 제거하는 사상 공정, 제품의 표면을 처리하는 쇼트 공정, 제품 형태를 정밀 가공하는 가공 공정, 제품의 양/불여부를 판단하는 최종 검사 총 다섯 가지이다. 대상 공장은 9기의 주조 설비와 12대의 Fanuc CNC 가공 설비와 23대의 Mitsubishi CNC 가공 설비를 운영하고 있는데, 대상 공장 내/외부의 환경 및 생산 계획 변경에 따라 주요 대상 설비의 배치가 매우 가변적이며, 신규 설비가 도입되는 경우도 잦은 편에 속한다. 대상 공장은 현재 주요 생산 현장의 데이터를 수집하여 모니터링하고, 주요 공정의 진행 현황을 관리할 수 있는 MES/POP(이하 NMS) 시스템을 기구축하여 운용하고 있다. NMS 시스템에서 관리되고 있는 주요 데이터는 주조 공정이 이루어질 때 발생하는 주조 조건 데이터, 보온로 온도, 냉각수 온도, 공장 온습도 등과 같은 센서 데이터, 생산 진행 현황, 품질 데이터 등이다. NMS 시스템은 대상 공장에서 주로 설비 종합현황 모니터링 용도로 활용되고 있으며, 제품의 불량 등과 같은 품질 관련 데이터를 분석하고, 분석 결과를 활용하는 고도화된 기능은 지원하고 있지 않다.

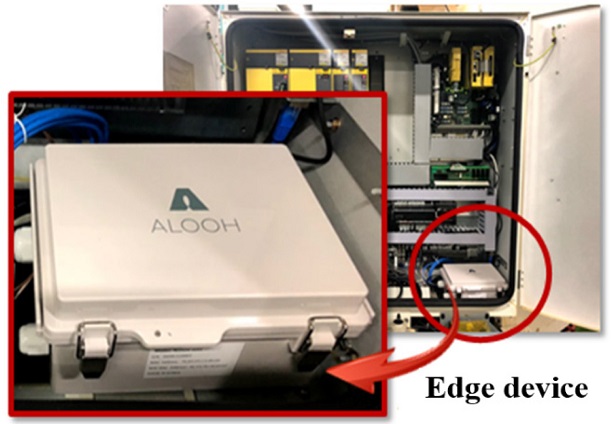

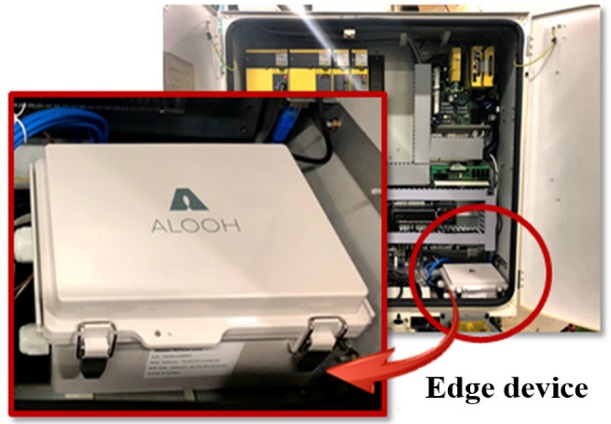

대상 공장을 대상으로 한 품질고도화를 위한 공정 지능화 기술 개발을 위해 필요한 데이터를 수집하는데 있어 큰 문제점은 설비 데이터 수집의 제한적 환경이었다. 대상 공장의 NMS 시스템을 통해 수집되고 있는 데이터는 주조 공정에 제한된 데이터와 수동으로 입력되는 품질 검사 결과 데이터로 제한적이었고, 가공 설비의 경우 사이클 타임, 생산 수량 등과 같은 기본적인 데이터 조차도 수집하고 있지 못했다. 또한 대상 공장의 특성상 가변적으로 운영되는 설비의 배치도 문제로 작용했는데 가변적인 설비의 배치 문제에 대응하기 위해 무선 네트워크 기반 데이터 전송 환경을 구축하였고, 다수의 가공 설비 데이터를 효과적으로 수집/처리하고 상황에 따라 이전 설치가 가능한 형태인 엣지 디바이스 기반의 데이터 수집 인프라를 구축함으로써 대상 공장의 문제점을 해결하고자 하였다. 실제 대상 공장에 구축된 엣지 디바이스는

Fig. 1과 같다.

Fig. 1Installed edge device

2.2 공정 지능화 지원 인프라 구축

2.1절에서 언급된 바와 같이 품질고도화를 위한 공정 지능화 기술 개발을 위해선 주요 공정의 데이터 추가 수집을 위한 H/W 인프라 구축이 선행되어야 하며, 무선 네트워크 인프라 구축, 데이터 수집 및 데이터 분석 모델의 실행을 위한 엣지 디바이스 설치, 수집된 데이터의 저장 및 관리를 위한 통합 서버의 설치 등이 수행되었다.

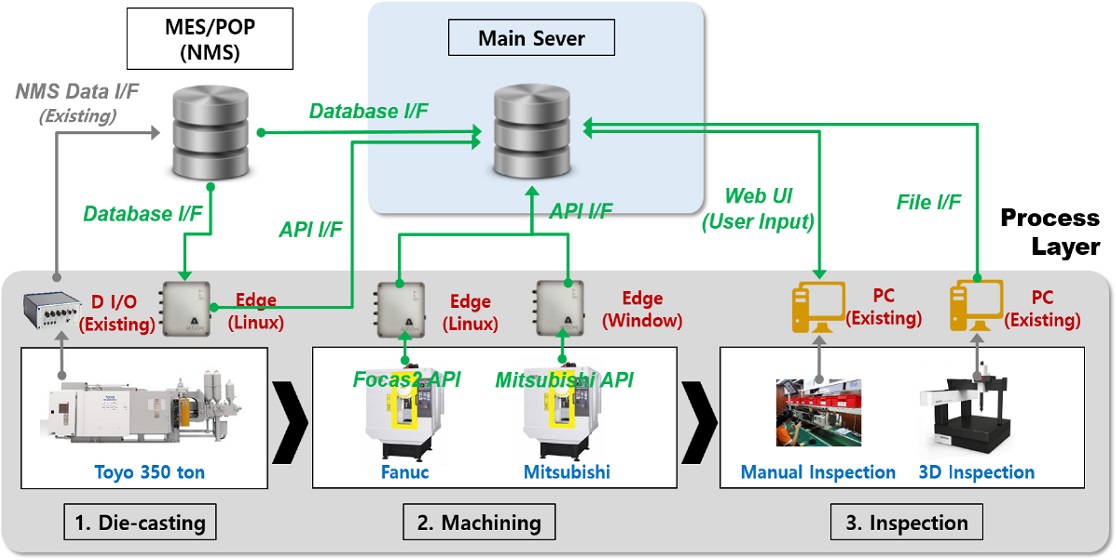

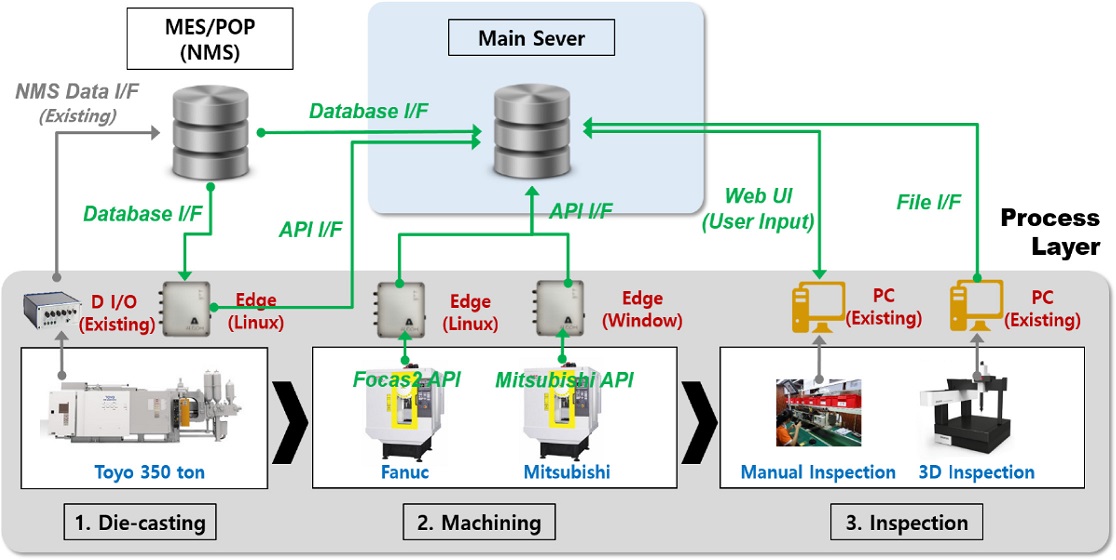

Fig. 2는 공정 지능화 지원 시스템의 인프라 구성도를 보여준다. 대상 공장의 주요 공정을 주조 공정, 가공 공정, 검사 공정 3단계로 요약했을 때 엣지 디바이스는 주조 공정과 가공 공정을 대상으로 설치되었으며, 주조 공정에서는 기구축된 NMS 시스템과의 데이터 인터페이스와 신규 설치한 엣지 디바이스가 혼용되어 사용된다. 주조 공정에서 발생하는 주조 파라미터와 같은 주조 조건 데이터는 기구축된 NMS 시스템을 통해 수집되고 있기 때문에 주조 설비에 설치된 엣지 디바이스는 수집된 데이터의 1차적인 처리와 데이터 분석 모델의 실행을 담당한다. 검사 공정에서 발생하는 데이터는 엣지 디바이스를 통해 수집되지 않고 기구축된 시스템을 통해 수집된다. 엣지 디바이스를 통해 수집되는 데이터는 NMS 시스템상의 데이터와 함께 신규로 설치된 통합 서버와 인터페이스되어 저장된다. 가공 설비에 설치된 엣지 디바이스에서는 설비 사이클 타임, 생산 수량, 머신 알람, 가공 NC 프로그램, 공구의 가공 횟수, 수명 대비 잔존 가공 횟수 등과 같은 공구 수명 주기 데이터가 수집된다.

Fig. 2Diagram of intelligence system supporting infrastructure

3. 품질 데이터 분석 모델 개발

본 연구에서는 주조 공정에 대한 품질 데이터 분석 모델을 개발하여 현장에 적용함으로써 대상 공장의 품질고도화를 이룩하고자 하였다. 본 연구에서 개발한 품질 데이터 분석 모델은 주조 조건 및 센서 데이터를 활용하여 제품의 불량을 예측하는 품질 예측 모델과 불량 예측 시 불량으로 예측한 원인을 진단해주는 불량 원인 진단 모델 등 두 가지이다. 품질 데이터 분석 모델 개발을 위해 사용한 데이터는 2019년 1월 1일부터 2019년 8월 7일까지 축적된 실제 현장 데이터로, 공정 변수 데이터, 센서 데이터, 생산 진행 현황 데이터, 불량 데이터 등을 사용하였다. 사용된 데이터는

Table 1에 정리되어 있다. 불량 예측 모델 개발 대상 제품은 해당 기간 불량률이 가장 높은 BPC TOP 제품으로 선정하였으며, 총 23개의 불량 유형을 고려하였다.

Table 1 Data for data analysis model generation

Table 1

|

Category |

Collected data |

Processing

variable

parameter |

Shot No, Physical strength, Biscket thickness, Injection velocity, High speed velocity, Cylinder pressure, Cycle time, Pressure increase time, Casting pressure, Spray time |

|

Sensor |

Factory temperature, Factory humidity, Heating furnace temperature, Coolant temperature, Air pressure |

|

Production |

Lot No, Product No, Product name, Product code, Production start time, Production end time, Production quantity |

|

Defect |

Process, Product No, Product name, Machine code, Worker, Defect code, Defect quantity |

3.1 품질 예측 모델 개발

본 연구에서 개발하는 품질 예측 모델의 목표는 제품이 주조될 때의 주조 공정 변수 데이터와 센서 데이터 등을 활용하여 주조 과정에서 발생하는 불량을 예측하는 것이다. 주조 공정에서 발생하는 불량은 주조 직후에도 일부 가능하나 대부분 가공 공정 이후 최종 검사를 거쳐야 가시적으로 알 수 있다. 주조 공정이 끝나고 최종 검사까지 평균적으로 3-5일이 소요되는 대상 공장의 특성상 주조 불량품의 뒤늦은 발견은 제품 출하 일정의 지연, 생산 계획의 변경 등과 같은 문제를 야기한다. 따라서 최종 검사까지 가기 전 주조 공정에서의 공정 변수 등을 활용하여 해당 생산 제품의 불량 여부를 예측하고 관리함으로써 공장의 생산성 향상을 도모하고, 공장 운영 효율 및 생산 품질의 고도화를 꾀할 수 있다.

품질 예측 모델을 개발하기 위해 NMS 시스템의 데이터베이스 테이블에 개별적으로 저장되어 있는 원본 데이터들을 대상으로 데이터 필터링, 통합, 이상치 제거 등의 전처리 과정을 통해 데이터 분석 모델 개발을 위해 필요한 입력 데이터 형식에 맞는 데이터셋을 생성하였다. 데이터 전처리는 불량 데이터의 전처리와 공정 변수 데이터 전처리 두 가지로 구현되었고 원본 데이터의 종류는 공정 변수, 불량, 생산 진행 현황, 센서 데이터 네 가지 데이터 파일로 구성된다. 불량 데이터 전처리 부분에서는 최종 검사 시 입력되는 불량 데이터의 정보와 생산 진행 현황에서 확인 가능한 제품의 Lot 정보를 매칭하고 데이터 분석에 사용되지 않는 불필요한 칼럼 및 열을 제거한다. 공정 변수 데이터 전처리 과정에서는 제품의 주조 시간과 공정 변수, 센서 데이터를 매칭하여 데이터 분석 모델의 개발을 가능하게 한다.

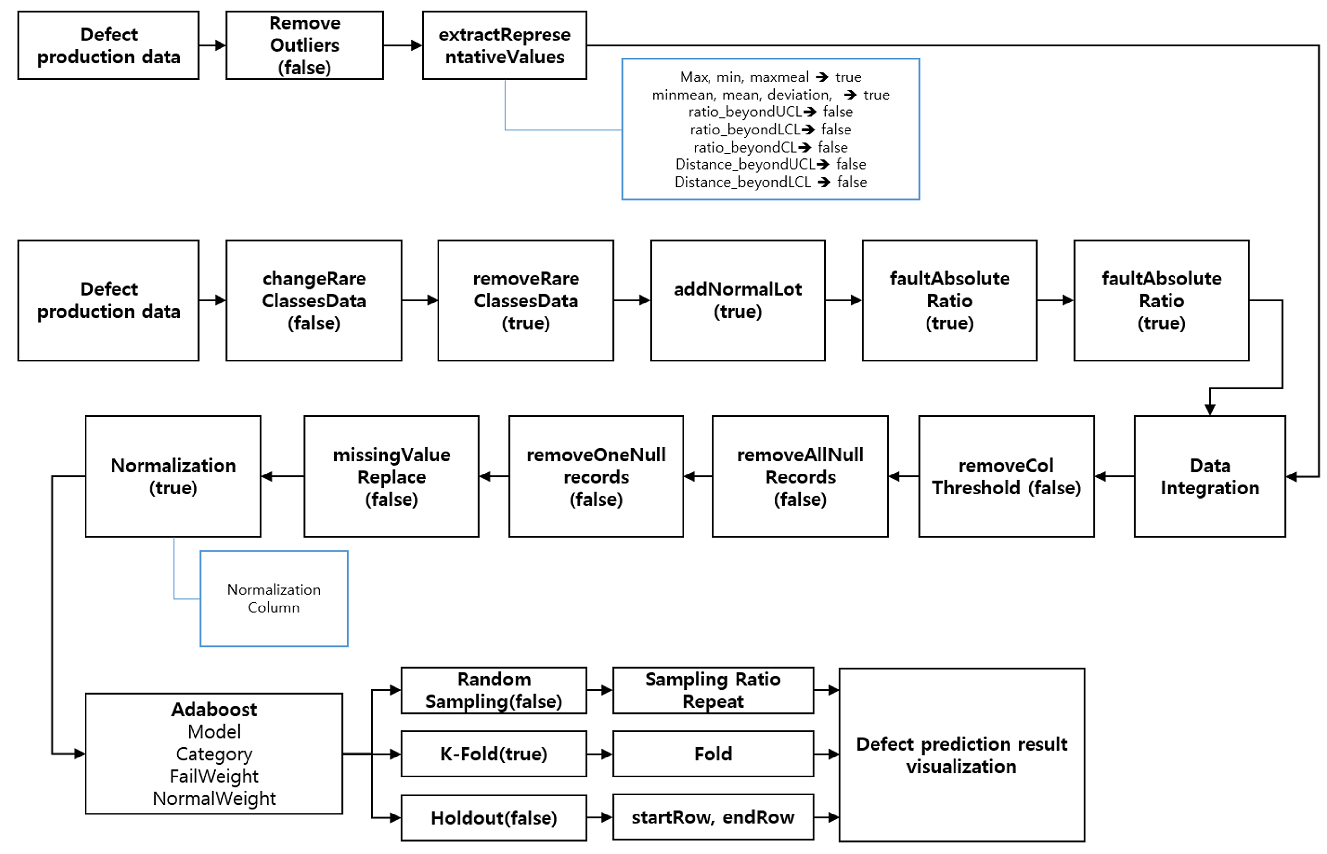

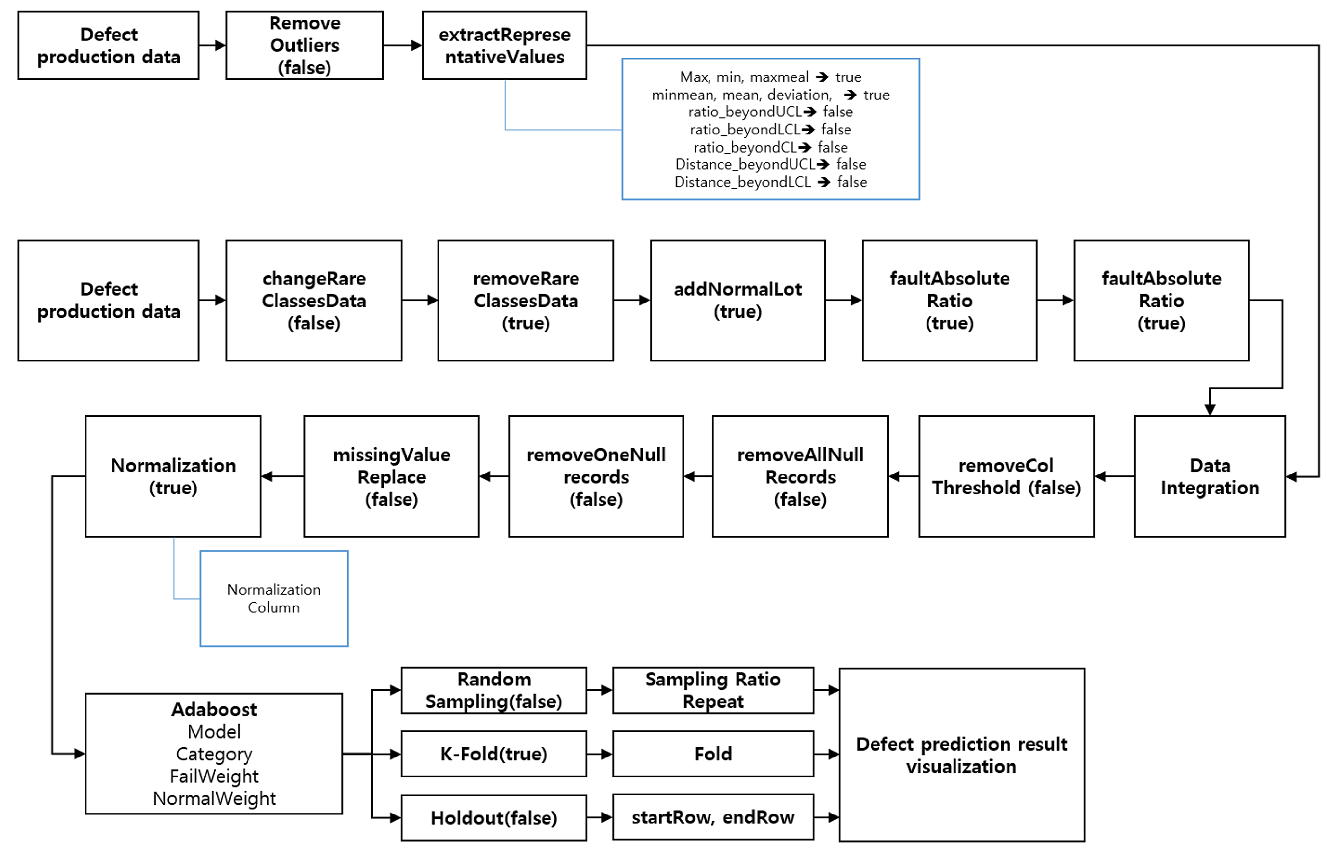

본 연구에서 개발한 품질 예측 모델은 C4.5 분류기 및 AdaBoostC2 알고리즘을 활용하여 개발하였다. 불량 예측 분석 모델 개발 프로세스는

Fig. 3과 같다. 제품이 주조되는 사이클 타임 동안 발생하는 센서 데이터와 공정 변수 등의 공정 정보는 이상치 데이터를 제거 한 후 대푯값(Max, Min, Maxmean, Minmean 등)을 추출하여 인풋 값으로 사용하였고 불량이 적은 유형은 희소 클래스 대체 및 삭제 과정을 통해 예측에서 제외하였다. 전처리가 완료된 공정 정보와 불량 정보 파일을 제품 주조 시간을 기준으로 데이터 병합 후 정규화 과정을 수행하였고 C4.5 분류기와 AdaBoostC2 알고리즘의 실행을 위해 모델수, 카테고리, 불량가중치, 정상가중치 등 네 가지 변수를 설정한 후 예측 모델을 학습하였다. 예측 모델의 정확도를 향상시키기 위해 총 10회에 거쳐 실험 조건을 변경하며 예측 모델을 학습하였는데 각 실험 조건은

Table 2에 요약되어 나타난다. T01의 경우 데이터 모델 학습 시간을 높이기 위해 Model Count와 Category Count 변수를 낮게 설정하여 학습을 수행하였고, 학습에 사용되는 불량데이터와 양품데이터의 수량이 비슷하기 때문에 Fail, Normal Weight는 모두 1로 설정하였다. T02와 T03의 경우 Model Count를 각각 5와 10으로 조정 후 학습을 수행하였고 T04에서 T10은 T01에서 T03의 변수 값을 기준으로 하여 예측 정확도를 높이기 위해 희소 클래스 변수, 희소 레코드, Model Count, Category Count, Normal Weight 변수를 실험적으로 변경해가며 학습을 진행하여 예측 모델의 정확도를 향상시켰다. 각 실험 조건별 분석 결과는

Table 3으로 요약된다. 실험 결과 T09와 T10조건으로 학습을 진행할 경우 미성형, 소착, 코어핀 소착, 밀핀, 수축, 이형제 얼룩, 크랙 7개의 불량 유형에 대하여 약 86%의 예측 정확도를 보이는 것을 확인하였다.

Fig. 3Defect prediction model generation process

Table 2Data model parameter

Table 2

Data

set |

Rare class

substitution |

Rare class

elimination |

Model

Count |

Category

Count |

|

T01 |

0.05 |

0.05 |

3 |

2 |

|

T02 |

0.05 |

0.05 |

5 |

2 |

|

T03 |

0.05 |

0.05 |

10 |

2 |

|

T04 |

0.05 |

0.05 |

20 |

2 |

|

T05 |

0.05 |

0.05 |

10 |

5 |

|

T06 |

0.05 |

0.05 |

3 |

2 |

|

T07 |

0.01 |

0.01 |

3 |

2 |

|

T08 |

0.01 |

0.01 |

10 |

2 |

|

T09 |

0.01 |

0.01 |

10 |

5 |

|

T10 |

0.01 |

0.01 |

20 |

2 |

Table 3Prediction accuracy for each parameter

Table 3

|

Data set |

Accuracy |

Error |

|

T01 |

0.65 |

0.35 |

|

T02 |

0.64 |

0.36 |

|

T03 |

0.67 |

0.33 |

|

T04 |

0.63 |

0.34 |

|

T05 |

0.62 |

0.38 |

|

T06 |

0.61 |

0.39 |

|

T07 |

0.81 |

0.19 |

|

T08 |

0.84 |

0.16 |

|

T09 |

0.86 |

0.14 |

|

T10 |

0.86 |

0.14 |

3.2 불량 원인 진단 분석 모델 개발

주조 공정의 특성상 한 가지 불량 유형 발생 시 동일한 유형의 불량이 연속하여 발생하는 상황이 발생하기 때문에 공정 변수 등의 조절을 통해 동일한 유형의 불량이 연속적으로 발생하지 않도록 하는 것이 중요하다. 따라서 품질 예측 모델을 활용하여 제품의 불량이 예측될 경우 공정 변수 등의 효과적인 조절을 지원하기 위하여 불량의 원인이 되는 공정 변수와 관련된 규칙을 추출하여 불량 원인을 진단해주는 분석 모델을 개발하였다. 1차적으로 불량 예측 분석 모델을 실행한 후 생성된 AdaBoostC2 알고리즘 의사결정나무 집합을 활용하여 불량이 발생하는 의사결정나무의 조건(규칙)을 기반으로 한 조합 행렬을 생성하고, 최종적으로 여러 조건들을 병합함으로써 해당 불량이 발생하는 공정 변수 관련 규칙을 생성하도록 분석 모델을 개발하였다.

4. 서버-엣지 이원화 분석 시스템 개발

본 연구에서는 앞서 개발한 두 가지 품질 분석 모델의 학습 및 재학습, 대상 공장 설비에서의 실시간 데이터 분석 모델 실행 프로세스의 자동화를 위한 서버-엣지 연계 이원화 분석 환경을 구축하고 개발하였다. 본 장에서는 개발한 서버-엣지 이원화 분석 시스템에 대하여 다룬다.

4.1 서버-엣지 이원화 분석 시스템 구조

실제 현장에서 실시간 데이터를 기반으로 데이터 분석 모델을 학습하고 실행할 때 고려해야 하는 이슈들이 몇 가지 있다.

첫 번째 이슈는 학습을 위한 데이터 양에 따른 과부하 문제이다. 설비에서 발생하는 모든 원데이터들을 모두 그대로 데이터 학습을 위한 서버에 저장할 경우 방대한 양으로 인해 데이터 저장 및 분석 모델 학습을 위한 시스템상에서 과부하가 발생할 수 있다. 본 연구에서는 각 설비의 데이터 수집을 엣지 디바이스를 활용하여 수행하고 있기 때문에 분석에 필요한 데이터를 분석용 서버에 전달하는 주기를 조절하고, 이상치 및 결측치 처리 등과 같은 전처리 과정을 엣지 디바이스에서 수행함으로써 서버의 데이터 처리 부하를 낮추었다.

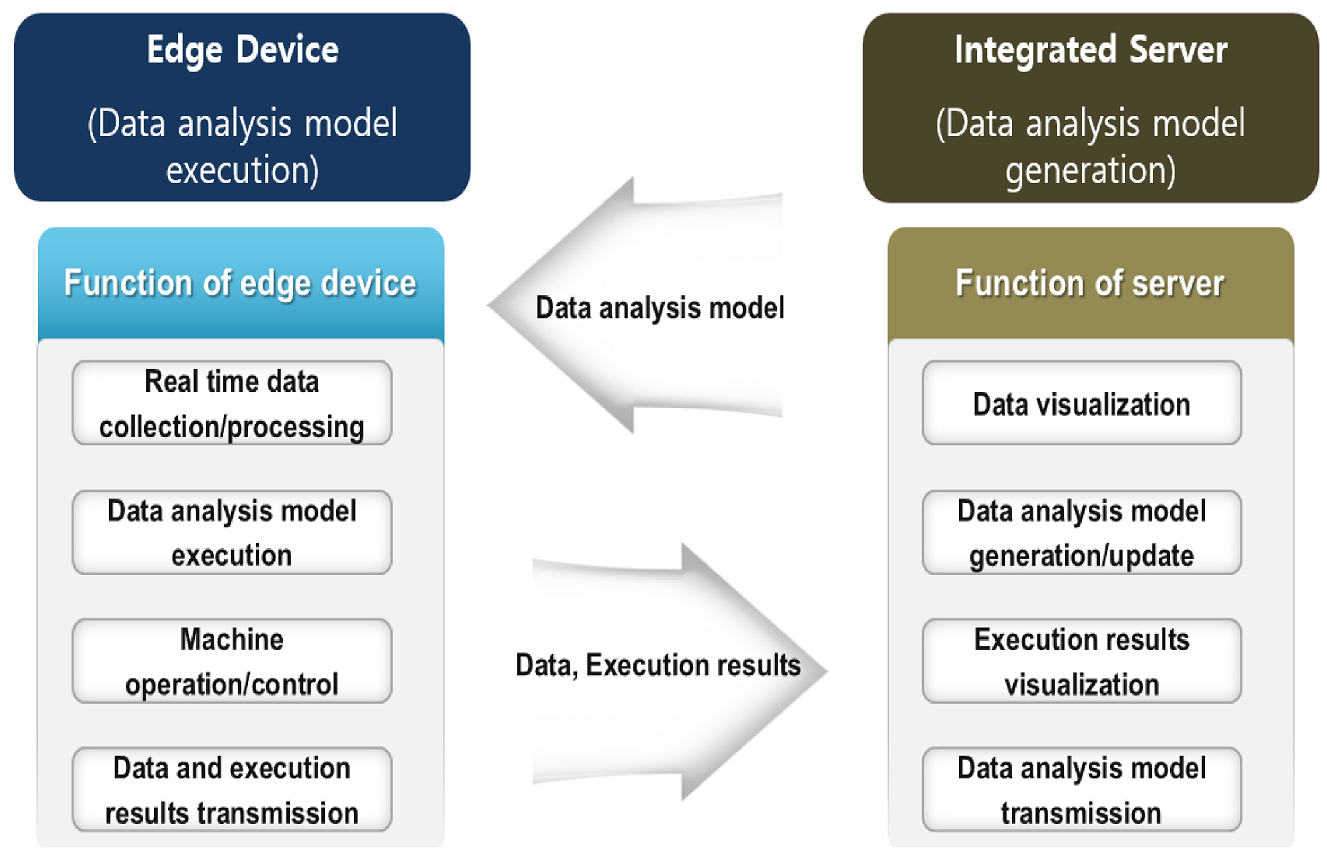

두 번째 이슈는 데이터 분석 모델의 학습과 실행의 자동화 문제이다. 기존 연구들을 살펴보면 데이터 분석 모델을 학습하고, 학습 결과를 실제 현장에 적용하고, 주기적으로 데이터 분석 모델을 재학습하는 일련의 과정들이 독립적으로 수행되고 시스템적으로 적용될 때 수동으로 수행됨을 알 수 있다. 본 연구에서는 데이터 분석 모델의 학습 및 재학습, 실행 과정을 연속적으로 고려하고 자동화하기 위해 엣지 디바이스와 통합 서버의 이원화된 구조 기반의 분석 시스템을 개발하였다. 데이터 분석 모델의 학습 및 재학습은 통합 서버에서 수행되고, 학습된 데이터 분석 모델의 실제 실행은 각 설비에 부착된 엣지 디바이스에서 수행되도록 시스템을 설계함으로써 데이터 분석 및 분석 모델 실행의 효율을 높였다. 데이터 분석 모델의 학습과 실행이 이원화된 구조에서 자동화되기 위해선 추가적으로 학습된 데이터 분석 모델 정보를 전달할 수 있는 파싱 기능이 필요하다. 본 연구에서는 데이터 분석 모델의 XML 기반 표준 언어인 Predictive Model Markup Language (PMML)를 활용하여 통합 서버와 엣지 디바이스 간 학습된 데이터 분석 모델이 전달될 수 있는 시스템을 개발하였다.

세 번째 이슈는 데이터 분석 모델 실행 시 실시간성과 관련된 이슈이다. 설비에서 수집되는 실시간 데이터를 기반으로 데이터 분석 모델을 데이터가 저장되는 통합 서버에서 데이터 분석 모델을 실행한다면 데이터 통신 문제와 미들웨어에서의 데이터 전송 지연 문제로 인해 실시간성이 떨어지게 된다. 따라서 본 연구에서는 데이터 분석 및 분석 결과 활용의 실시간성을 보다 강조하기 위해 설비 데이터의 수집이 이루어지는 엣지 디바이스에서 데이터 분석 모델을 실행하도록 시스템을 개발하였다.

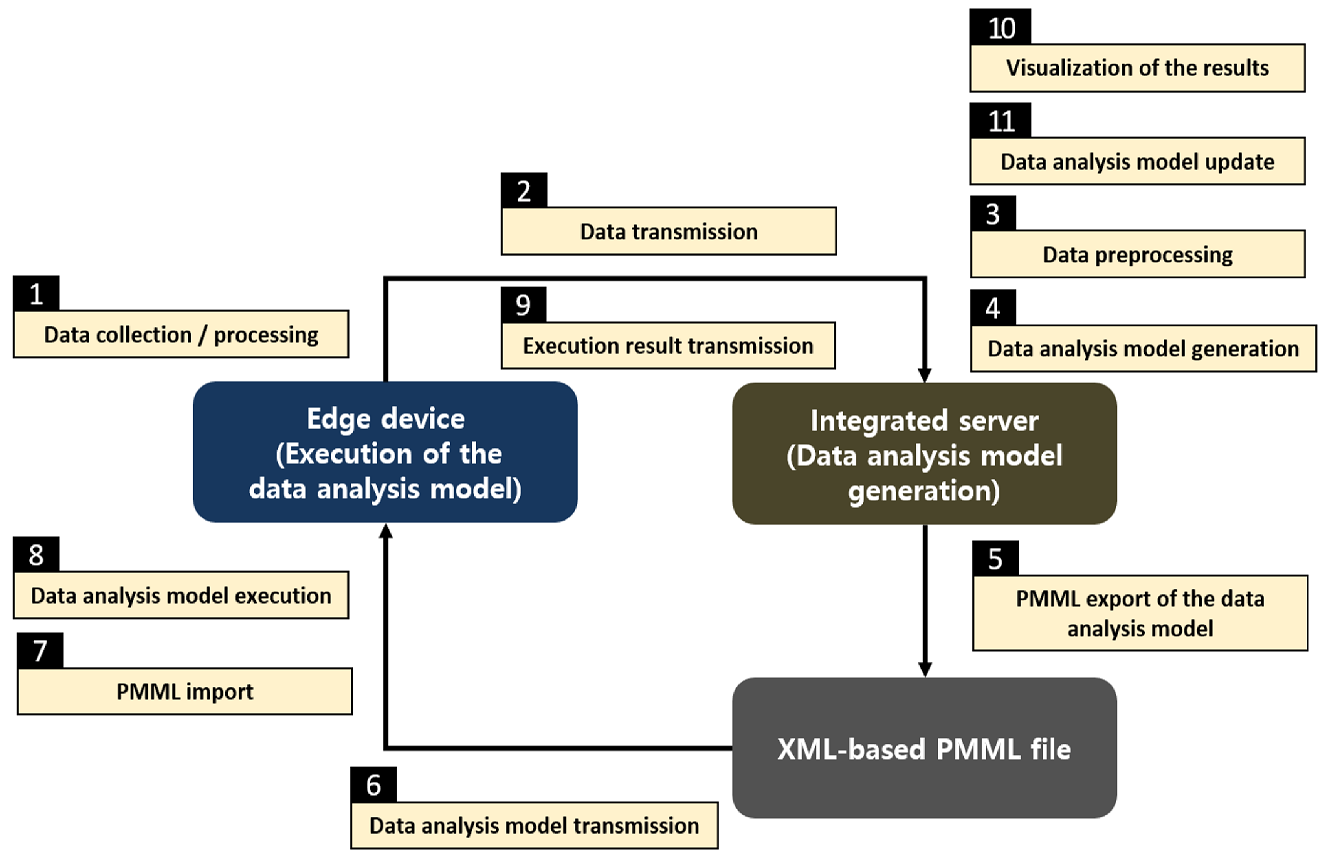

앞서 언급된 세 가지 이슈 사항을 고려한 서버-엣지 연계 이원화 분석 시스템 구조는

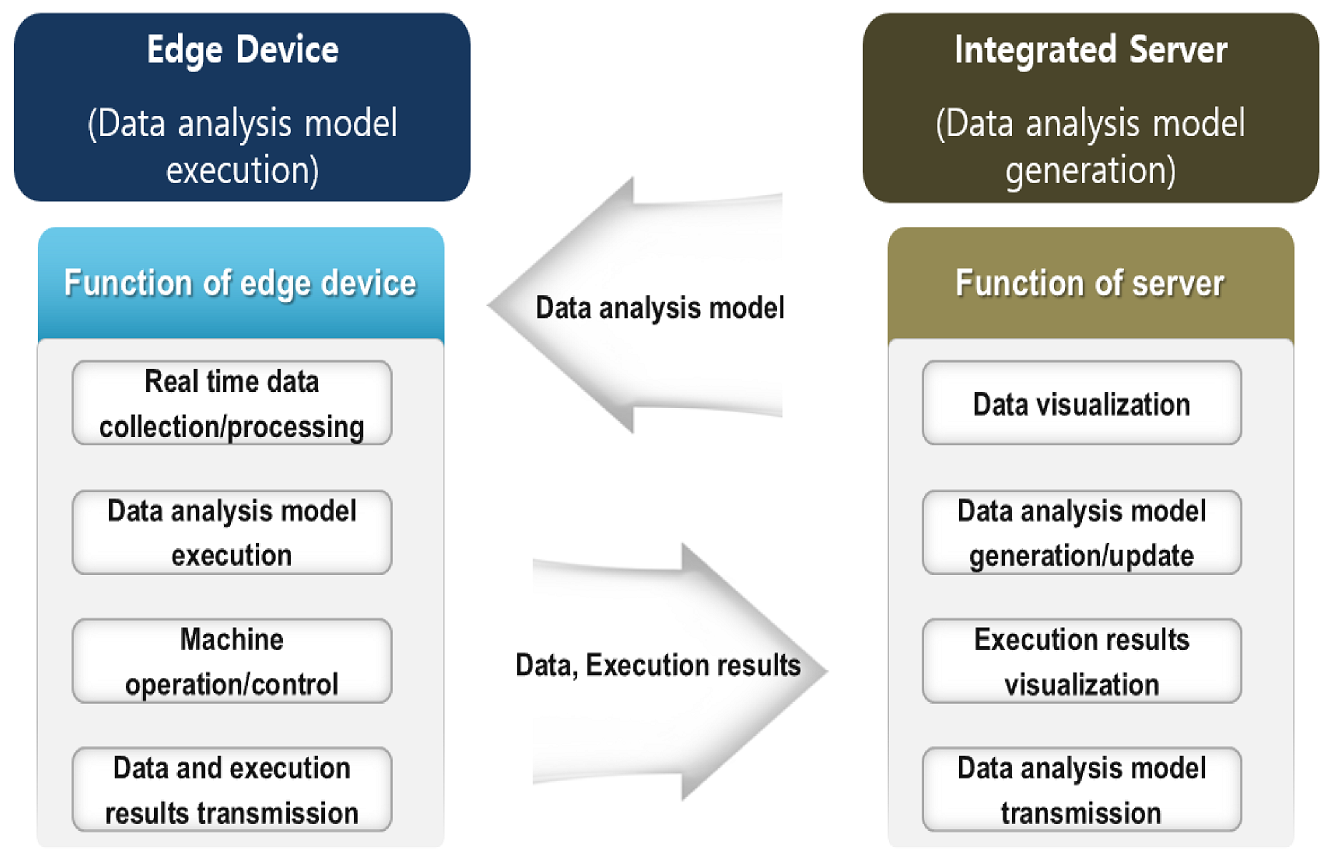

Fig. 4에 나타난다. 엣지 디바이스에서는 실시간 데이터를 수집 및 처리, 데이터의 통합 서버 전송, 데이터 분석 모델의 수신 및 실행, 데이터 분석 결과의 서버 전송 등과 같은 기능을 담당하고, 통합 서버에서는 실시간 수집 데이터의 가시화, 데이터 분석 모델의 학습 및 재학습, 데이터 분석 결과의 가시화 등의 기능을 담당한다. 또한 엣지 디바이스에서 실행 가능한 데이터 분석 모델을 파싱하는 기능은 PMML 기반 구조를 활용하여 설계되었다.

Fig. 4Server-edge dualized analysis system

4.2 이원화 분석 시스템 활용 시나리오

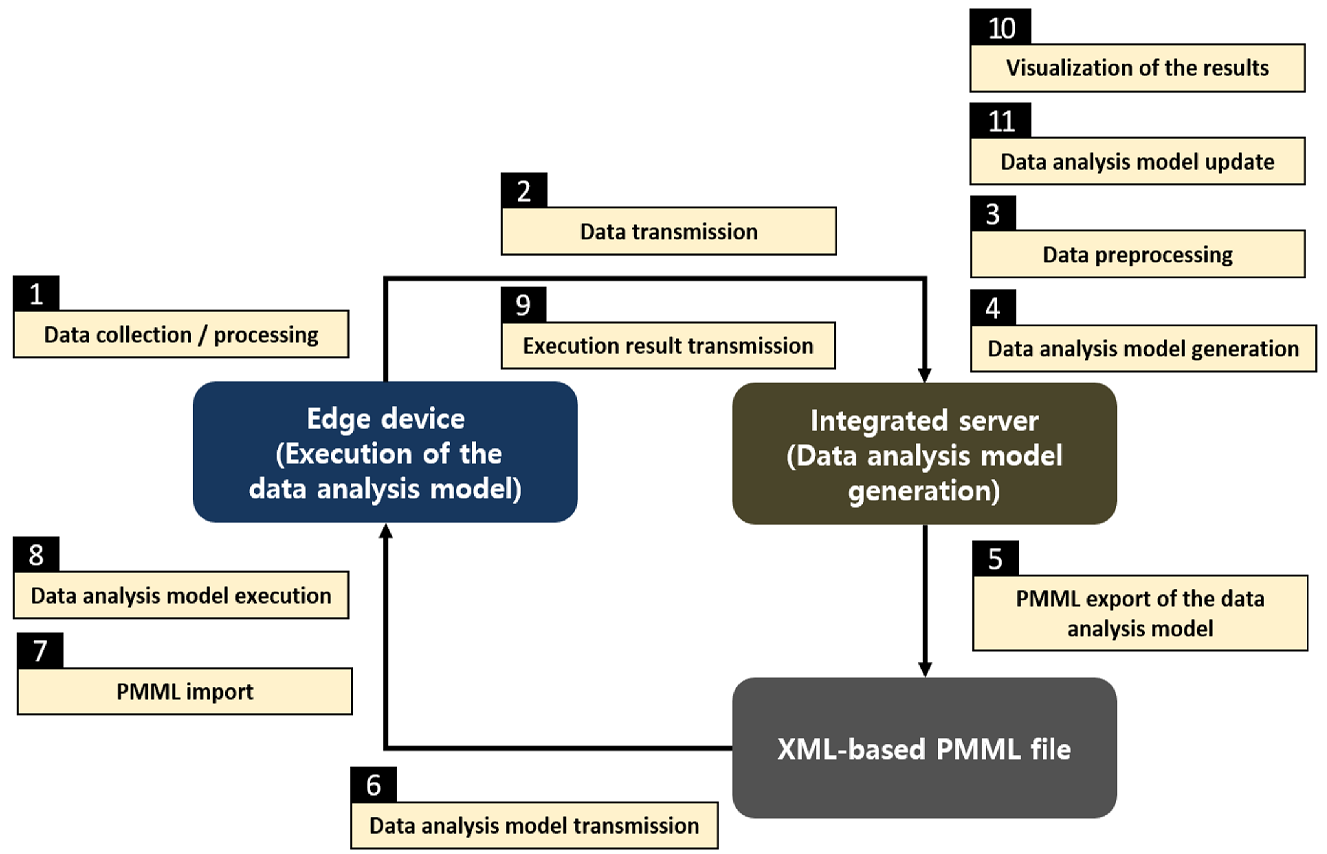

현장에 적용되는 이원화 분석 시스템의 실제 활용 시나리오는

Fig. 5와 같다. 엣지 디바이스에서 수집된 데이터는 이상치 제거 및 결측치 처리 등과 같은 1차 전처리 수행 후 통합 서버로 전송된다. 통합 서버에서는 데이터 분석 모델의 학습을 위한 데이터 전처리 이후 데이터 분석 모델을 학습하고 학습된 모델을 엣지 디바이스로 전송하기 위한 PMML 기반의 형태로 추출한 뒤 엣지 디바이스로 전송한다. 엣지 디바이스는 전송받은 PMML 기반 분석 모델을 실행 가능한 구조로 읽어들이고 분석 모델을 실행한다. 본 연구에서 개발한 데이터 분석 모델은 불량 예측 모델과 불량 원인 진단 모델이므로, 엣지 디바이스에서 실시간 수집 데이터를 활용하여 각 제품의 양/불 여부를 판단하고 불량으로 예측된 제품에 대해서 불량 원인을 진단한다. 분석 모델의 실행 결과는 다시 엣지 디바이스에서 통합 서버로 전송되며 분석 결과가 가시화된다. 사전에 설정된 데이터 분석 모델 업데이트 주기가 만족되거나 데이터 분석 모델의 정확도가 일정 수치 이하로 낮아진다면 통합 서버에서 데이터 분석 모델의 재학습이 자동으로 이루어지고, 재학습된 데이터 분석 모델과 기학습된 데이터 분석 모델의 정확도 비교 후 보다 좋은 성능의 분석 모델을 엣지 디바이스로 전송하여 실행한다.

Fig. 5Flow of dualized data analysis system utilization

5. 결론

본 연구에서는 다이캐스팅 산업의 대상 공장을 대상으로 품질고도화를 위한 데이터 수집, 처리, 분석 기반의 공정 지능화 기술을 개발하였다. 대상 공장의 주요 문제 상황을 도출하고, 해당 문제 상황을 해결하기 위해 주요 공정 및 설비 데이터의 수집, 처리, 분석을 통해 공정 지능화를 지원하는 엣지 디바이스 기반 무선 네트워크 인프라를 구축하였다. 또한 주조 공정을 대상으로 품질을 고도화하기 위해 공정 변수, 불량, 생산 진행 현황 및 센서 데이터 등을 기반으로 불량 예측 및 불량 원인 진단 분석을 수행하기 위한 데이터 분석 모델을 개발하였다. 불량 예측 모델의 경우 C4.5 분류기 및 AdaBoostC2 알고리즘을 기반으로 한 앙상블 모형을 적용하여 개발하였고, 예측률 86%를 달성하였다. 불량 예측 분석 과정에서 사용된 AdaBoostC2 알고리즘의 의사결정나무 집합을 활용하여 공정 변수에서 불량에 관한 규칙을 추출함으로써 불량 예측 시 해당 불량에 대한 원인을 진단해주는 분석 모델을 개발하여 대상 공장의 효과적 운영을 지원하였다. 개발된 공정 지능화 기술은 실제 현장에 적용될 때 엣지 디바이스와 통합 서버로 이원화된 구조의 시스템으로 구현이 되었다. 데이터 분석 모델의 학습 및 재학습은 통합 서버에서 수행되고 실시간 데이터 기반 분석 모델 실행은 엣지 디바이스에서 실행되는 이원화 데이터 분석 구조는 데이터 분석 모델 학습, 실행, 재학습 과정의 효율적 연계를 가능하게 한다. 또한 PMML 기반의 통합 서버와 엣지 디바이스 간 데이터 분석 모델 파싱 기능을 개발함으로써 데이터 분석 모델의 학습 및 재학습과 실행 과정의 자동화가 가능하게 하였다.

현재 주조 공정에 대한 데이터 분석 모델은 개발된 상황이나, 가공 설비의 이상 상태 진단 분석, 고장 징후 분석 등 가공 공정에 대한 데이터 분석 모델은 개발이 되지 않은 상황이다. 따라서 향후 가공 공정에 대한 데이터 분석 모델을 개발하여 시스템에 추가 적용할 계획이며, 또한 실시간 수집 데이터 및 주요 데이터 분석 결과의 가시화 기능을 개발, 적용함으로써 대상 공장의 운영을 지원할 예정이다.

ACKNOWLEDGMENTS

This material is based upon work supported by the Ministry of Trade, Industry & Energy (MOTIE, Korea) under Industrial Technology Innovation Program (No. 20003661).

REFERENCES

- 1.

Chae, C. W., “Research for Smartification Strategy of Root Processes,” Korea Institute of Industrial Technology, 2017.

- 2.

Lee, J., Noh, S. D., Kim, H. J., and Kang, Y. S., “Implementation of Cyber-Physical Production Systems for Quality Prediction and Operation Control in Metal Casting,” Sensors, Vol. 18, No. 5, p. 1428, 2018.

10.3390/s18051428

- 3.

Widodo, A. and Yang, B. S., “Support Vector Machine in Machine Condition Monitoring and Fault Diagnosis,” Mechanical Systems and Signal Processing, Vol. 21, No. 6, pp. 2560-2574, 2007.

10.1016/j.ymssp.2006.12.007

- 4.

Yang, B. S., Oh, M. S., and Tan, A. C. C., “Machine Condition Prognosis based on Regression Trees and One-Step-Ahead Prediction,” Mechanical Systems and Signal Processing, Vol. 22, No. 5, pp. 1179-1193, 2008.

10.1016/j.ymssp.2007.11.012

- 5.

Chen, C., Zhang, B., Vachtsevanos, G., and Orchard, M., “Machine Condition Prediction based on Adaptive Neuro-Fuzzy and High-Order Particle Filtering,” IEEE Transactions on Industrial Electronics, Vol. 58, No. 9, pp. 4353-4364, 2010.

10.1109/TIE.2010.2098369

- 6.

Ali, J. B., Chebel-Morello, B., Saidi, L., Malinowski, S., and Fnaiech, F., “Accurate Bearing Remaining Useful Life Prediction based on Weibull Distribution and Artificial Neural Network,” Mechanical Systems and Signal Processing, Vol. 56, No. 57, pp. 150-172, 2015.

10.1016/j.ymssp.2014.10.014

- 7.

Hong, K. T., Heo, J. Y., Whang, S. Y., and Lee, J. H., “Analysis of Sensor Data for Detecting the Abnormal State of FD Fan,” Korean Journal of Computational Design and Engineering, Vol. 23, No. 2, pp. 137-143, 2018.

10.7315/CDE.2018.137

- 8.

Kwak, S. Y. and Kim, H. G., “Strain-Life and LEFM Method for Fatigue Life Prediction,” Proc. of the Society for Computational Design and Engineering Conference, pp. 435-444, 2012.

- 9.

Kim, J. H., Ko, M. H., and Ku, N. K., “A Study on Resistance Spot Selding Failure Detection Using Deep Learning Technology,” Korean Journal of Computational Design and Engineering, Vol. 24, No. 2, pp. 161-168, 2019.

10.7315/CDE.2019.161

- 10.

Chen, X., Song, Z., Li, H., Gong, Q., and Li, Y., “Research on Fault Early Warning and the Diagnosis of Machine Tools based on Energy Fault Tree Analysis,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, Vol. 233, No. 11, pp. 2147-2159, 2019.

10.1177/0954405418816848

- 11.

Li, Y., Zeng, Y., Liu, T., Jia, X., and Huang, G. B., “Simultaneously Learning Affinity Matrix and Data Representations for Machine Fault Diagnosis,” Neural Networks, Vol. 122, pp. 395-406, 2020.

10.1016/j.neunet.2019.11.007

- 12.

Qian, W., Li, S., Wang, J., Xin, Y., and Ma, H., “A New Deep Transfer Learning Network for Fault Diagnosis of Rotating Machine under Variable Working Conditions,” Proc. of the Prognostics and System Health Management Conference, pp. 1010-1016, 2018.

10.1109/PHM-Chongqing.2018.00180

- 13.

Liu, R., Meng, G., Yang, B., Sun, C., and Chen, X., “Dislocated Time Series Convolutional Neural Architecture: An Intelligent Fault Diagnosis Approach for Electric Machine,” IEEE Transactions on Industrial Informatics, Vol. 13, No. 3, pp. 1310-1320, 2016.

10.1109/TII.2016.2645238

- 14.

You, W., Shen, C., Wang, D., Chen, L., and Jiang, X., “An Intelligent Deep Feature Learning Method with Improved Activation Functions for Machine Fault Diagnosis,” IEEE Access, Vol. 8, 2019.

10.1109/ACCESS.2019.2962734

Biography

- Jun Kim

Researcher in the IT Converged Process R&D Group, Korea Institute of Industrial Technology. His research interest are optimization and data analytics.

- Hyoung Seok Kang

Post doctor in the IT Converged Process R&D Group, Korea Institute of Industrial Technology. His research interest is digital twin model generation.

- Ju Yeon Lee

Senior researcher in the IT Converged Process R&D Group, Korea Institute of Industrial Technology. Her research interest is cyber model generation and data analytics.